High temperature resisting ultralong chain viscoelastic surfactant, preparation method and application thereof

A surfactant and viscoelastic technology, applied in the preparation of carboxylic acid amide, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of difficult acidification in deep rock formations, large differences in vertical permeability of reservoirs, and fast acid-rock reaction speed and other problems, to achieve the effects of good chemical structure stability, excellent acid thickening performance, and good viscosity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

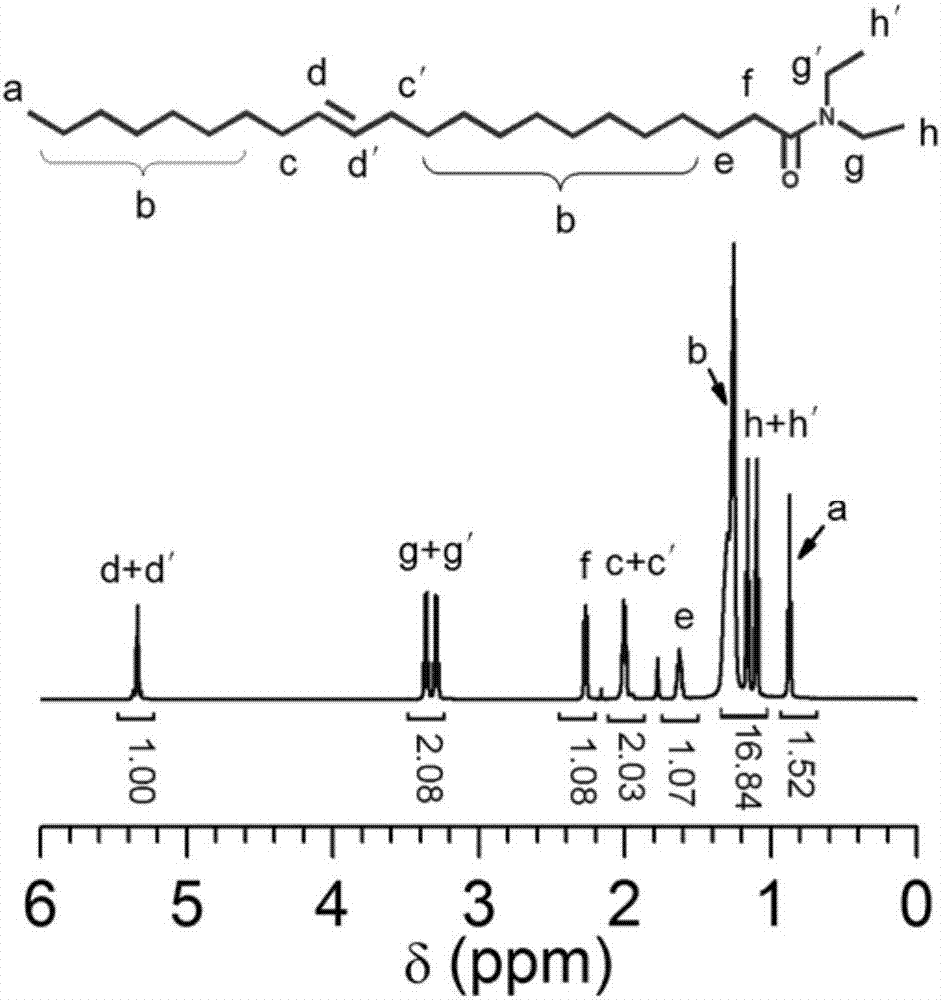

[0044] (1) Weigh 16.92g (0.05mol) cis-docos-13-enoic acid (commonly known as "erucic acid") and dissolve it in dichloromethane, add 4.02g (0.055mol) diethylamine, 19.1g ( 0.1mol) EDC·HCl, after the dissolution is complete, add 1.22g (0.01mol) DMAP, and react at room temperature for 24h. After the reaction is over, dilute the reaction solution with 250mL of dichloromethane, then use 0.1% HCl solution, saturated NaHCO 3 solution and saturated NaCl solution were washed three times, the organic phase was collected, and anhydrous MgSO 4 Dry for 2 hours, filter, remove the solvent by rotary evaporation of the filtrate, and dry in vacuo to obtain N,N-diethyl-N-n-docosylamide. For its structural characterization, see 1 H NMR spectrum ( figure 1 ), the chemical shifts of each proton peak in the compound have been assigned in the spectrum, and the ratio of the integral area of each proton resonance peak is in good agreement with the theoretical value, indicating that the compound ha...

Embodiment 2

[0050] The difference between this implementation and Example 1 is that in step (4), the amount of HCl solution is such that N-(cis-docos-9-enyl)-N,N-diethyl tertiary amine salt The mass concentration of acid salt in viscous acid solution is 3.5%.

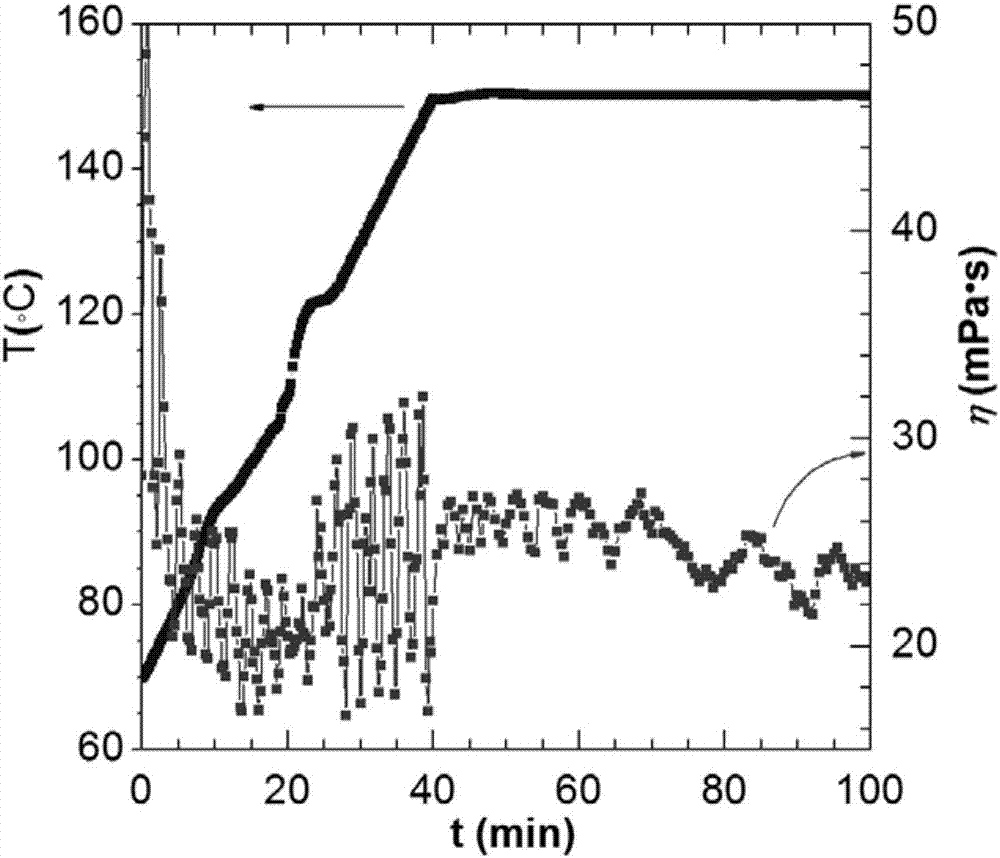

[0051] At a shear rate of 100s -1 The relationship between the viscosity of viscous acid solution obtained by measuring the change with temperature and time is as follows, the results are shown in Figure 4 . From Figure 4 It can be seen that when the temperature is stable at 150°C, the viscosity of the solution is relatively stable and greater than 20mPa·s, indicating that the viscoelastic ultra-long-chain surfactant obtained in this example has good temperature resistance as a thickener.

Embodiment 3

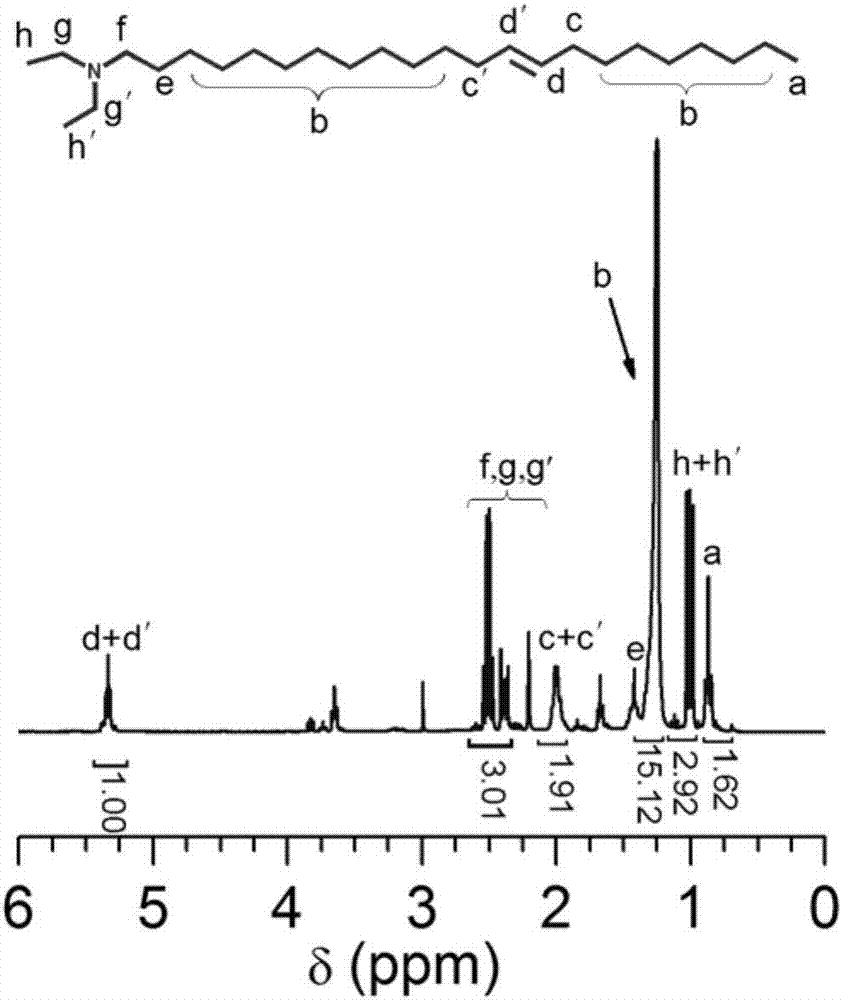

[0053] (1) Weigh 17.03g (0.05mol) of behenic acid (commonly known as "arachidic acid") and dissolve it in dichloromethane, then add 4.75g (0.065mol) of diethylamine and 21.01g (0.11mol) of EDC. After HCl is completely dissolved, add 1.83g (0.015mol) DMAP, and react at room temperature for 30h. After the reaction, dilute the reaction solution with 250mL dichloromethane, and then use 0.2% HCl solution, saturated NaHCO 3 solution and saturated NaCl solution were washed three times, the organic phase was collected, and anhydrous MgSO 4 Dry, filter, remove the solvent by rotary evaporation of the filtrate, and dry in vacuo to obtain N,N-diethyl-N-n-docosylamide, whose structure is characterized in 1 H NMR spectrum ( Figure 5 ), the chemical shifts of each proton peak in the compound have been assigned in the spectrum, and the ratio of the integral area of each proton resonance peak is in good agreement with the theoretical value, indicating that the compound has been successfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com