Preparation method of viscoelastic surfactant for development of low-permeability oil reservoir

A surfactant and reservoir development technology, applied in the field of viscoelastic surfactant preparation, can solve the problems of poor temperature resistance, high concentration of surfactant and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

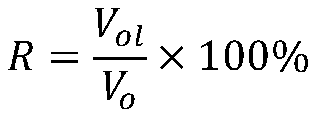

Image

Examples

preparation example Construction

[0011] (1) Preparation of amidation product

[0012] Add organic acid, 1-methylpiperazine, and sodium fluoride into a four-neck glass bottle equipped with a stirrer, a nitrogen pipe, a drying pipe and a thermometer, raise the temperature and stir until all the raw materials are dissolved. Control the reaction temperature at 120-190°C, react for 3-48 hours, and distill off the volatile components under reduced pressure at 180°C to obtain the product; the mass ratio of organic acid to 1-methylpiperazine is 1:(0.2-1.5) , the mass ratio of 1-methylpiperazine to sodium fluoride is 1:(0.003~0.02);

[0013] (2) Preparation of amphoteric surfactant

[0014] In a four-neck glass bottle equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel, add the amidation product, raise the temperature and stir until all the raw materials are dissolved. Gradually raise the temperature, control the reaction temperature at 60-130°C, and react for 0.5-10 hours to obtain the...

specific Embodiment approach

[0028] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0029] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0030] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

Embodiment 1

[0032] (1) Preparation of amidation product

[0033] Add 100g of octadecanoic acid, 50g of 1-methylpiperazine, and 0.4g of sodium fluoride into a four-neck glass bottle equipped with a stirrer, a nitrogen pipe, a drying pipe and a thermometer, heat up and stir until all the raw materials are dissolved, and then pass After nitrogen gas for 20 minutes, control the reaction temperature at 170°C, react for 12 hours, and distill the volatile components under reduced pressure at 180°C to obtain the amidation product;

[0034] (2) Preparation of amphoteric surfactant

[0035] In a four-necked glass bottle equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel, add 100 g of the amidation product, heat up and stir until all the raw materials are dissolved, and after nitrogen gas is introduced for 20 minutes, add 50 g of propanesulfonic acid successively under stirring After the lactone is completed, the temperature is raised gradually, the reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com