PPS (polyphenylene sulfide) resin composite material for corrosion-resistant end surface sealing strips and preparation method thereof

A PPS resin and end face sealing technology, which is applied in the field of composite materials, can solve the problems of decreased elongation at break, poor bending resistance, and high brittleness, and achieve the effects of reduced creep, good toughness, and reduced friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

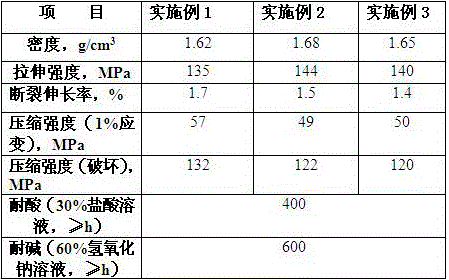

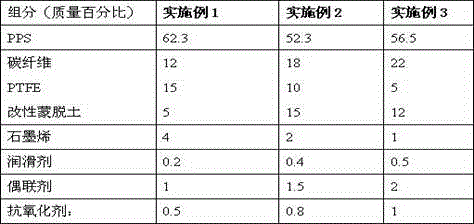

Embodiment 1-3

[0027] The preparation method of the corrosion-resistant end face sealing strip for the scroll compressor of the air conditioner comprises the steps of:

[0028] (1) Add 10 parts of sodium montmorillonite, 2 parts of sodium hydroxide, and 5 parts of vinylbenzyl dimethyl octadecyl ammonium chloride into water, heat up to 50°C and stir, then centrifuge to obtain the precipitate, and the precipitate After washing to neutrality, drying is obtained to obtain modified montmorillonite;

[0029] (2) After the carbon fiber is soaked in acetone, it is washed, dried, added to the acid solution to heat up and stirred, then suction filtered, washed until neutral, and the acidified carbon fiber is obtained;

[0030] (3) Weigh the raw material according to the amount, dry it at 150°C for 2~6h, add it into the high-speed mixer, stir it at high speed for 2~3min, and then take it out;

[0031] (4) The mixed raw materials are fed into the vertical screw extruder, the barrel temperature is 300~4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com