Manufacturing method of durable composite antibacterial textile

A composite antibacterial and manufacturing method technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problem of high cost, and achieve the effect of strong durability and significant antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

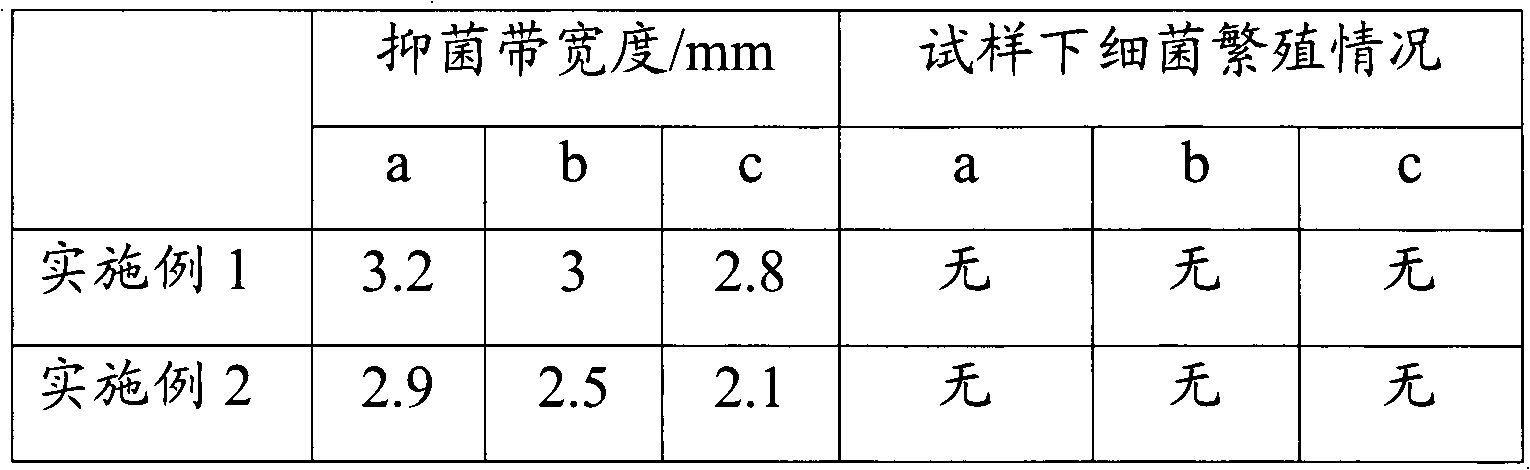

Examples

Embodiment 1

[0025] Preparation of composite antibacterial finishing agent:

[0026] Mix 5 grams of alkyl ethylene urea, 3-(trimethoxysilyl) propyl dimethyl octadecyl ammonium chloride and 8 grams of sorbic acid, then slowly add zinc oxide 65 with an average particle diameter of 500 nanometers gram and 3 grams of aluminum zirconate coupling agent, complete feeding within 2 hours, continue to mix for 50 minutes. Then add water to prepare an impregnating solution with a mass solid content of 40%.

[0027] Finishing of antibacterial fabrics:

[0028] Soak the fabric in the dipping solution containing the composite antibacterial finishing agent at 85°C for 20 minutes; then keep the fabric at a constant temperature of 120°C for 1 hour.

Embodiment 2

[0030] Preparation of composite antibacterial finishing agent:

[0031] 3 grams of trifluoromethyl diphenylurea, 3-(trimethoxysilyl) propyl dimethyl octadecyl ammonium chloride and 11 grams of sorbic acid are mixed, and then slowly add 1200 nanometers of average particle diameter at the same time 50 grams of zinc oxide and 5 grams of aluminum zirconate coupling agent were fed within 1.5 hours, and the mixing was continued for 30 minutes. Then add water to prepare an impregnation solution with a mass solid content of 50%.

[0032] Finishing of antibacterial fabrics:

[0033] The fabric is immersed in the dipping solution containing the composite antibacterial finishing agent at 90°C for 5 minutes; then the fabric is kept at a constant temperature of 115°C for 1.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com