Transmission line unmanned aerial vehicle and electric lifting device combined live working method

An electric lifting device and live working technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of electrician's physical exertion, relatively large working conditions, and the inability to carry out live work, so as to meet the requirement of lower physical fitness and age of workers. The effect of less and less use of tools and utensils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

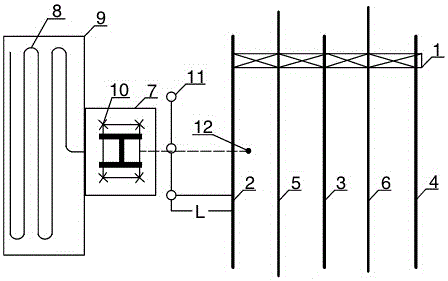

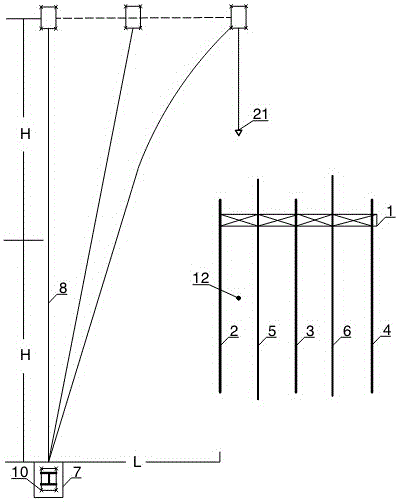

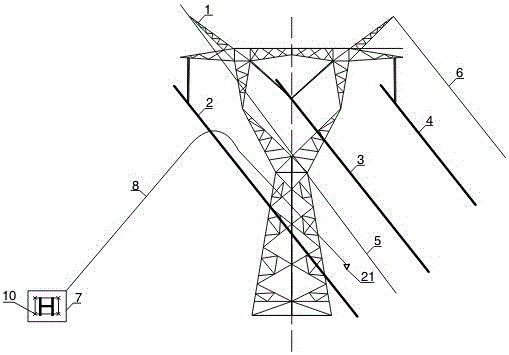

[0053] Embodiment 1; this embodiment is when the left-phase wire side-phase operation is performed, the transmission line UAV and the electric lifting device combined live working method (those skilled in the art can understand that when the right-phase wire 4-side phase operation needs to be carried out , can be realized with reference to this embodiment), the steps are as follows:

[0054] 1. Set up the drone and Φ4 insulating rope

[0055] Such as figure 1 and figure 2 Shown: the distance from the vertical projection of the side-phase conductor to the stainless steel shroud is L, where L is 10m, three stainless steel shrouds 11 are used to set a 10m observation line, and the UAV parking apron 7 is set close to the 10m observation line, close to the no The man-machine landing pad 7 is provided with a moisture-proof insulating canvas 9. Φ4 insulating ropes 8 are arranged in an S shape on the moisture-proof insulating canvas 9, and one end of the Φ4 insulating ropes 8 is c...

Embodiment 2

[0075] Embodiment 2: This embodiment is a combined live working method of a transmission line UAV and an electric lifting device when it is necessary to achieve the operation of the middle-phase conductor.

[0076] 1. The UAV and Φ4 insulating rope are set, the same as in Embodiment 1.

[0077] 2. Check the unmanned aerial vehicle, same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com