Insulating operating rod having trimming function

An insulating operating rod and functional technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of easily damaged overhead transmission lines, staff safety threats, etc., and achieve the effect of reducing the number of emergency repairs, shortening the time of emergency repairs, and avoiding work delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

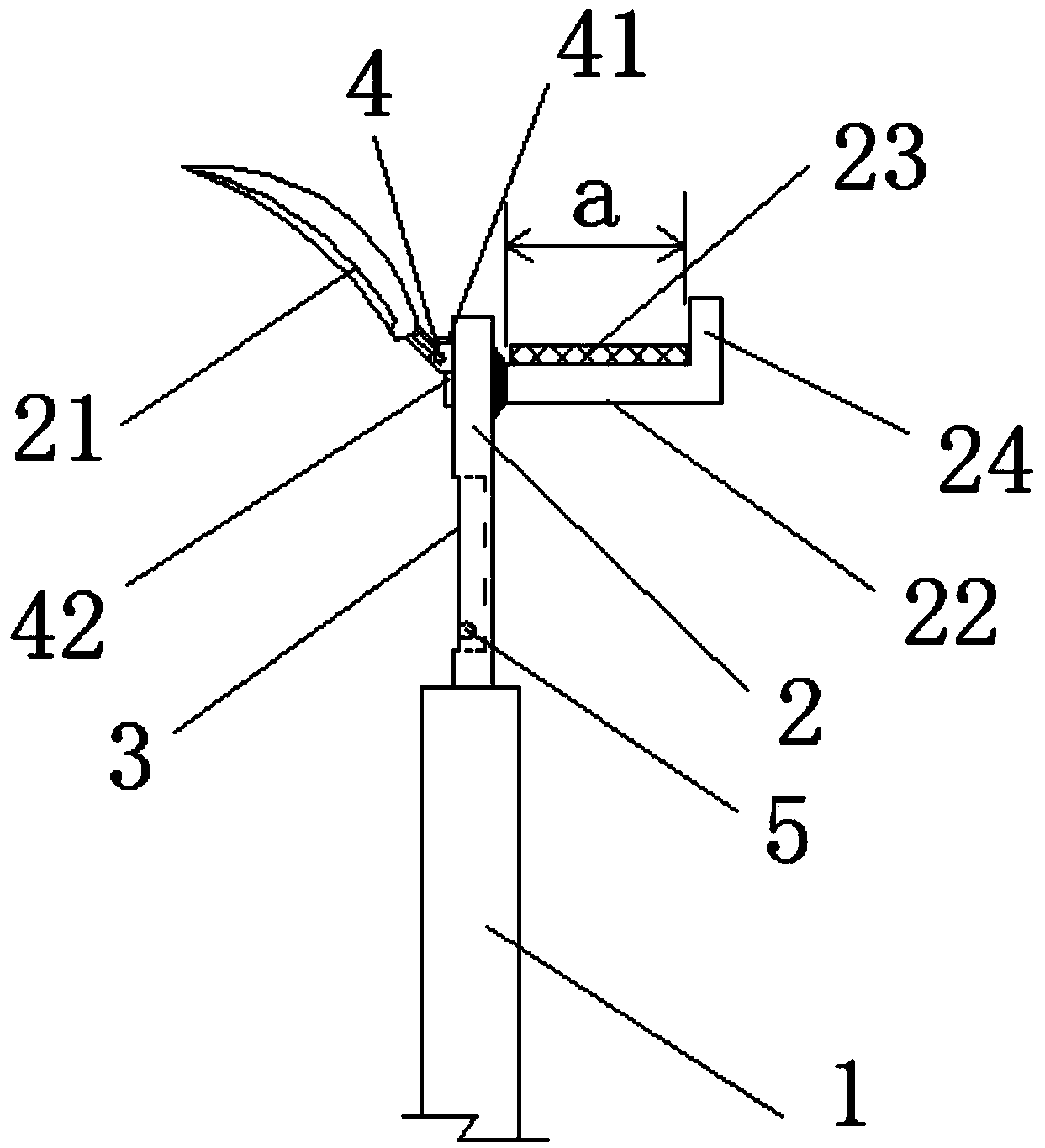

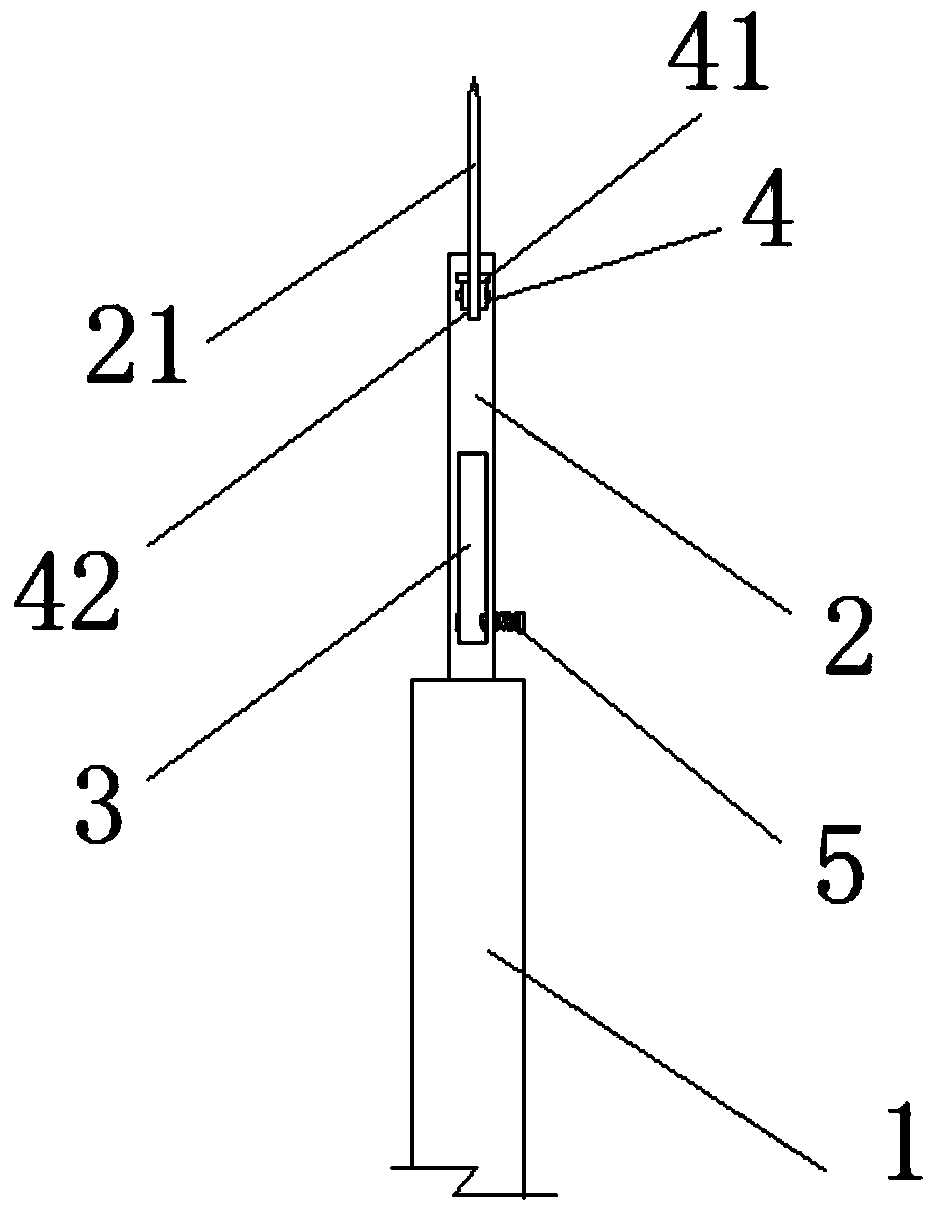

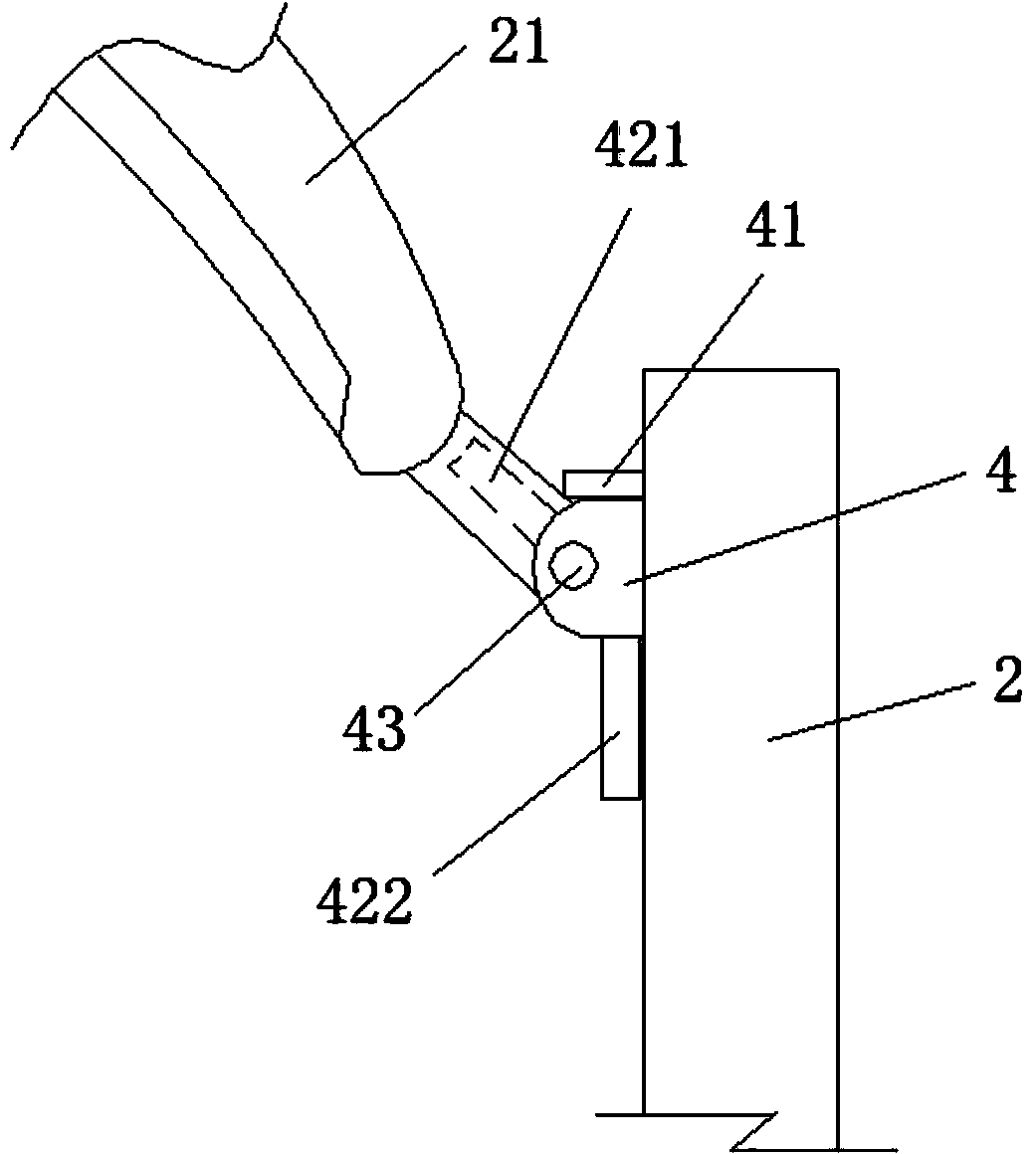

[0024] Such as figure 1 , 2 As shown, an embodiment 1 of an insulating operating rod with pruning function of the present invention includes an insulating operating rod 1 , an operating head 2 is connected to the front end of the insulating operating rod 1 , and the gap between the insulating operating rod 1 and the operating head 2 is Connected by bolts, the operating head 2 is provided with a half-moon-shaped hook knife 21 and a hook part 22. The half-moon-shaped hook knife 21 can be used to remove hanging branches, and the insulating operating rod can be used to carry out live pruning of branches to ensure operation and maintenance. Staff safety. The hook part 22 is a solid galvanized steel bar, and the end of the hook part 22 is fully welded to the operating head 2. The hook head ends of the operating rod in the prior art are basically straight. It is easy to fall off from the insulating operating rod. The operating head 2 of the present invention, because the hook part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com