Oxidized corn starch adhesive and preparation method thereof

A technology for oxidizing corn starch and corn starch, which is applied in the field of starch adhesives and applied fine chemicals. It can solve the problems of slow drying speed, poor water loss rate of starch glue, thickening of starch adhesive, etc., and achieve fast drying speed and high initial viscosity. Large, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of oxidized cornstarch adhesive of the embodiment of the present invention specifically comprises the following steps:

[0036] 1) Prepare the raw materials according to the above ratio, the water is deionized water, prepare two parts, one for dissolving cornstarch, and the other for dissolving other raw materials.

[0037] 2) Add cornstarch into the reactor, add water and stir continuously until a uniform milky white suspension is formed, add catalyst, heat and stir for 20-40min to carry out pre-gelatinization.

[0038] 3) After pregelatinization, add H 2 o 2 Add NaOH dropwise under constant stirring to adjust the pH=8-10, heat and stir for 1-2 hours for oxidation.

[0039] 4) After oxidation, add the remaining NaOH and stir for 25-40 minutes for gelatinization.

[0040] 5) After gelatinization, add a cross-linking agent and stir for 20-40 minutes to carry out cross-linking.

[0041] 6) After cross-linking, add polyacrylamide and stir f...

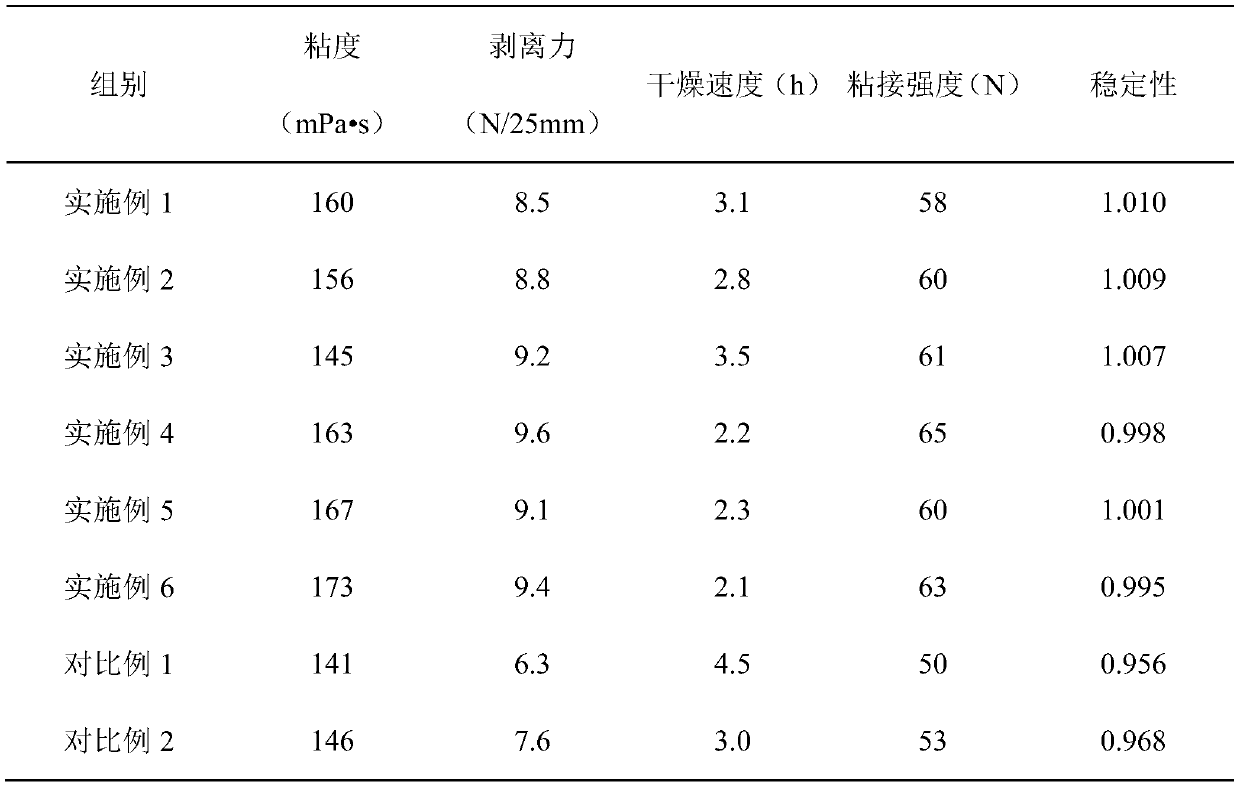

Embodiment 1

[0049] A kind of preparation method of oxidized cornstarch paste adhesive of the embodiment of the present invention, concrete steps are as follows:

[0050] The raw material composition and weight / number ratio of the adhesive are: 15 parts of cornstarch, 1.25 parts of NaOH, H 2 o 2 2.5 parts, 75 parts of water, 0.03 parts of ferrous sulfate catalyst, 0.05 parts of surfactant, 0.05 parts of polyacrylamide, 0.15 parts of borax crosslinking agent, 0.25 parts of urea thinner, 0.03 parts of tributyl phosphate defoamer, catalyst 0.35 part of dry agent, 0.1 part of preservative.

[0051] Prepare raw materials according to the ratio, divide 75 parts of water into 50 parts for dissolving cornstarch, and 25 parts of water for dissolving NaOH.

[0052] Add 15 parts of cornstarch into the reactor, then add 50 parts of water and stir until a uniform milky white suspension is formed, then add 0.03 parts of ferrous sulfate catalyst, raise the temperature to 40°C and continue stirring for ...

Embodiment 2

[0054] A kind of preparation method of oxidized cornstarch paste adhesive of the embodiment of the present invention, concrete steps are as follows:

[0055] The raw material composition and weight / number ratio of adhesive are: 15 parts of cornstarch, 1.25 parts of NaOH, H 2 o 2 2.5 parts, 75 parts of water, 0.03 parts of ferrous sulfate catalyst, 0.05 parts of surfactant, 0.05 parts of polyacrylamide, 0.15 parts of sodium trimetaphosphate crosslinking agent, 0.25 parts of urea thinner, 0.03 parts of tributyl phosphate defoamer parts, 0.35 parts of sodium bentonite drier, and 0.1 parts of acrylic preservative.

[0056] Prepare raw materials according to the ratio, divide 75 parts of water into 50 parts for dissolving cornstarch, and 25 parts of water for dissolving NaOH.

[0057] Add 15 parts of cornstarch into the reactor, then add 50 parts of water and stir until a uniform milky white suspension is formed, then add 0.03 parts of ferrous sulfate catalyst, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com