Balancing lead smelting process for comprehensive resource utilization and device thereof

A balancing and lead smelting technology, applied in the direction of photography process, photography auxiliary process, process efficiency improvement, etc., can solve the problem of no substantial progress in recycling, and achieve the reduction of material amount, complete oxidation reaction, and reduction of coke consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution provided by the present invention will be explained in detail below in conjunction with the examples, but it is not intended to limit the protection scope of the claims of the present invention.

[0025] In the following examples, the lead raw material that adopts is lead concentrate, and its main component by total mass percentage is as follows:

[0026] Pb: 55%; S: 18%; SiO 2 : 6%; Fe: 11%; CaO: 3.5%; Bi: 0.62%; Zn: 1.7%; Cu: 1.6%;

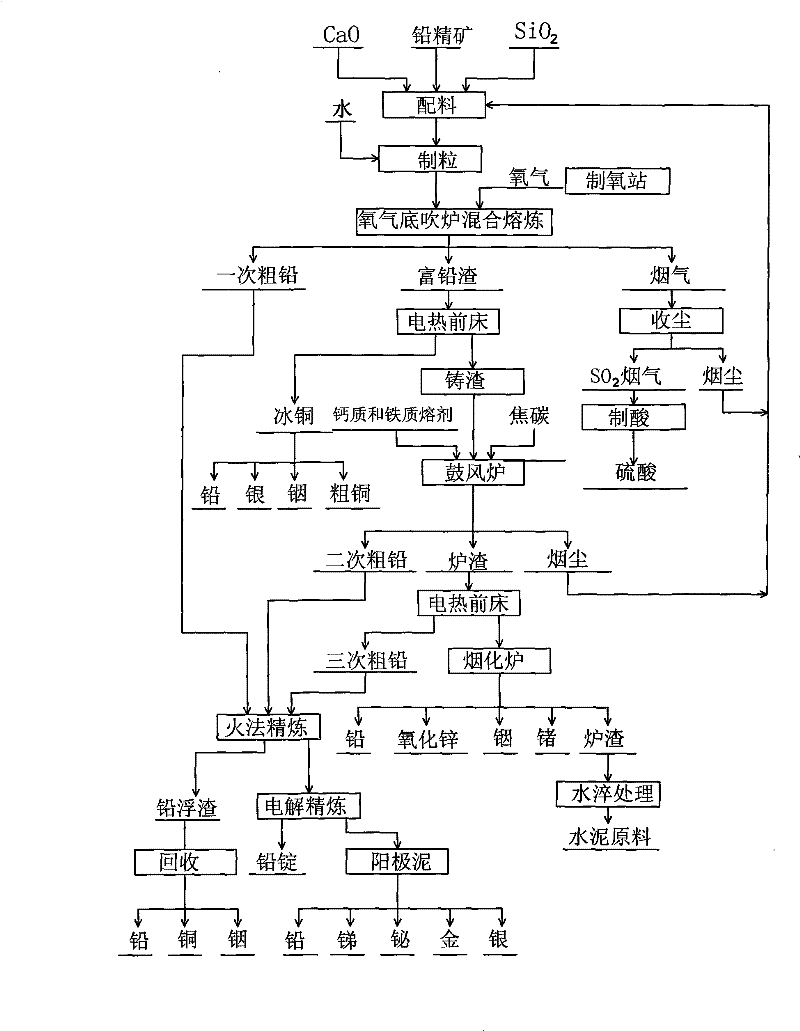

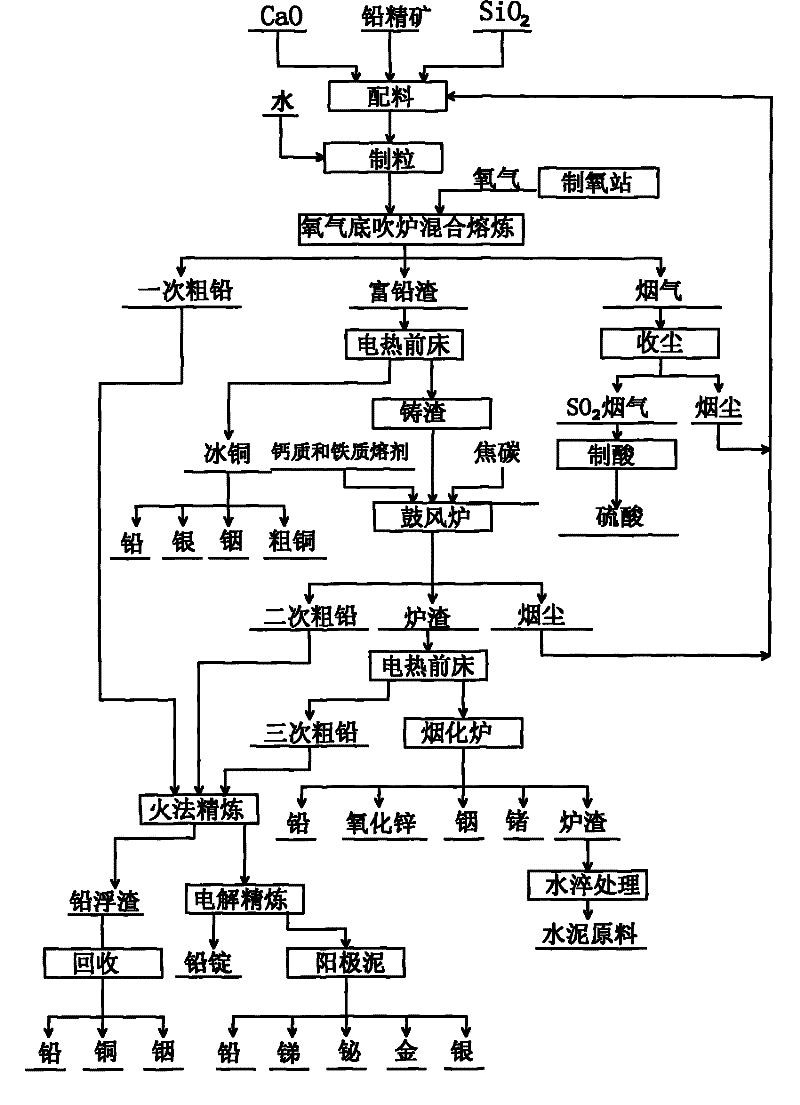

[0027] as attached figure 1 As shown, the lead concentrate and CaO, SiO 2 After the ingredients are granulated, they are smelted in an oxygen bottom-blown furnace, and the temperature of the molten pool in the oxygen bottom-blown furnace is 1260°C to 1350°C. There are 3 oxygen injection inlets at the bottom of the smelting furnace, including O 2 98% (total volume percentage) of industrial oxygen is sprayed into the furnace through an oxygen lance, and the oxygen lance is protected by nitrogen and demineralized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com