Sludge treatment reactor

A sludge treatment and reactor technology, applied in the direction of oxidation treatment of sludge, can solve the problems of air pollution, large energy consumption, groundwater resource pollution, etc., and achieve the effect of complete oxidation reaction and efficient sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

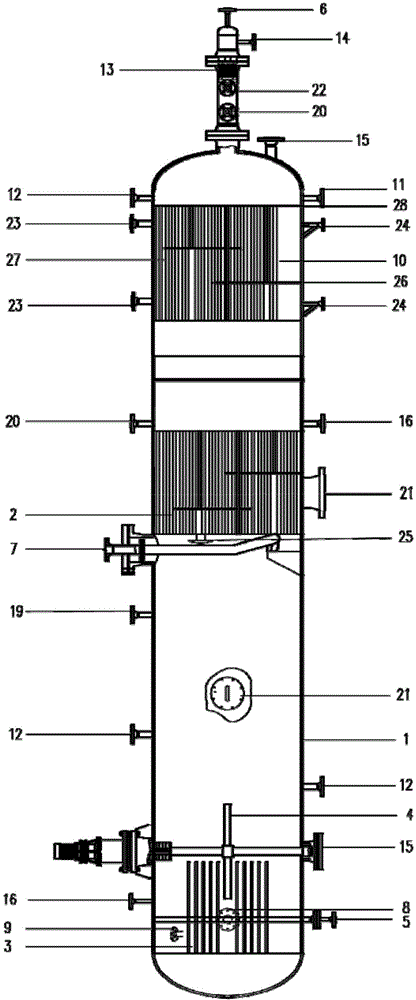

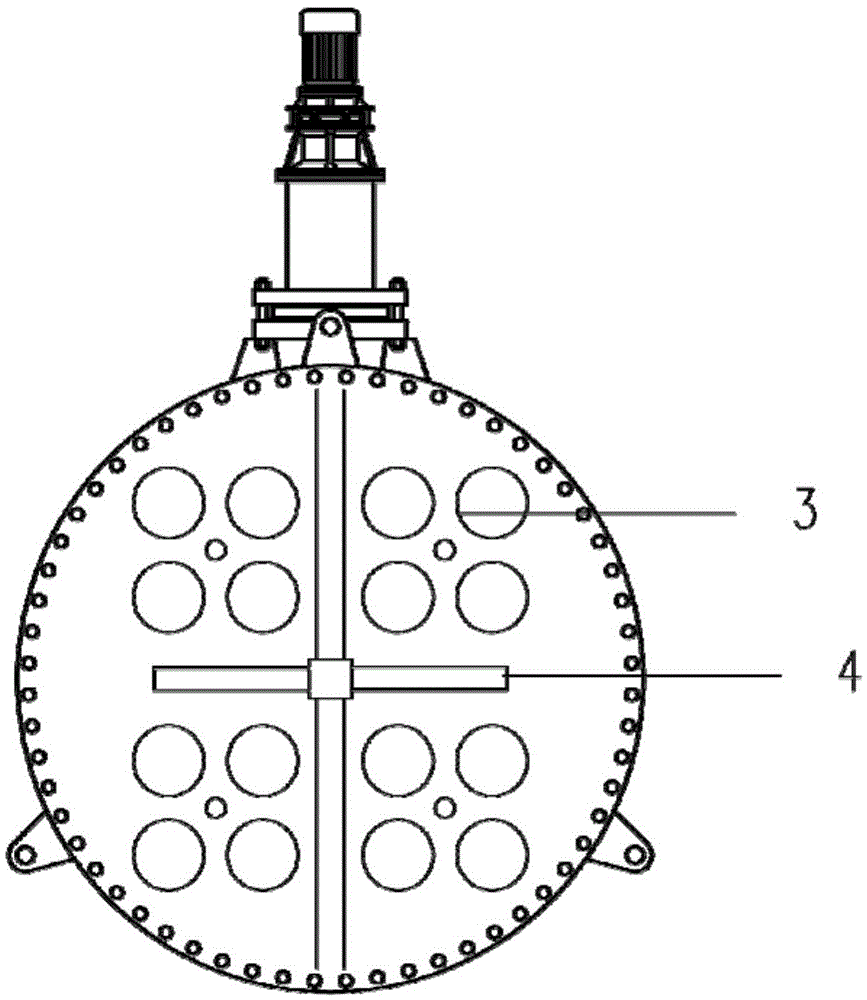

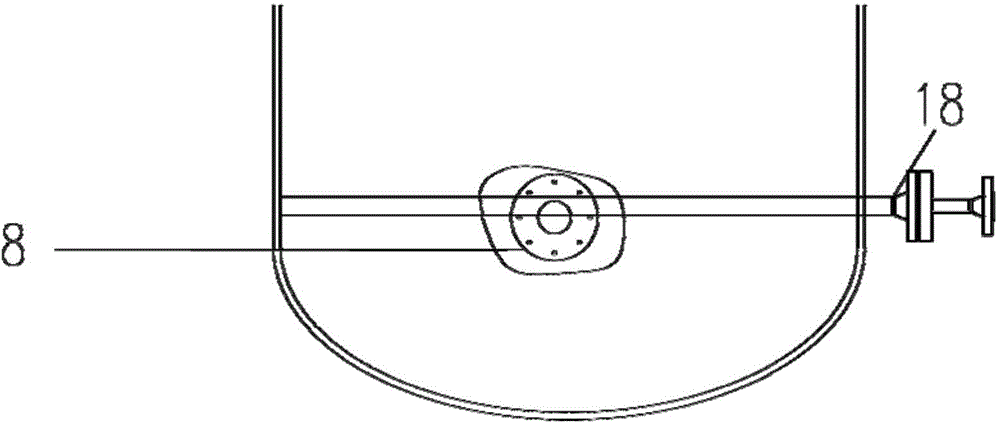

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0025] The invention provides a sludge treatment reactor, see figure 1 , the reactor includes a vertically arranged kettle body 1 and an insulation layer coated on the outside of the kettle body 1 , the arranging of the insulation layer can effectively prevent heat exchange between the outside world and the kettle body 1 , and maintain the kettle body 1 The constant temperature inside plays a crucial role. The material of the kettle body 1 is an explosive composite metal plate, the inner layer of the explosive composite metal plate is 316 stainless steel, and the outer layer is carbon steel to ensure sufficient strength so that the kettle body 1 can work under high temperature and high pressure.

[0026] A heat exchanger 10 for preheating air is provided on the inner upper part of the kettle body 1 , and the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com