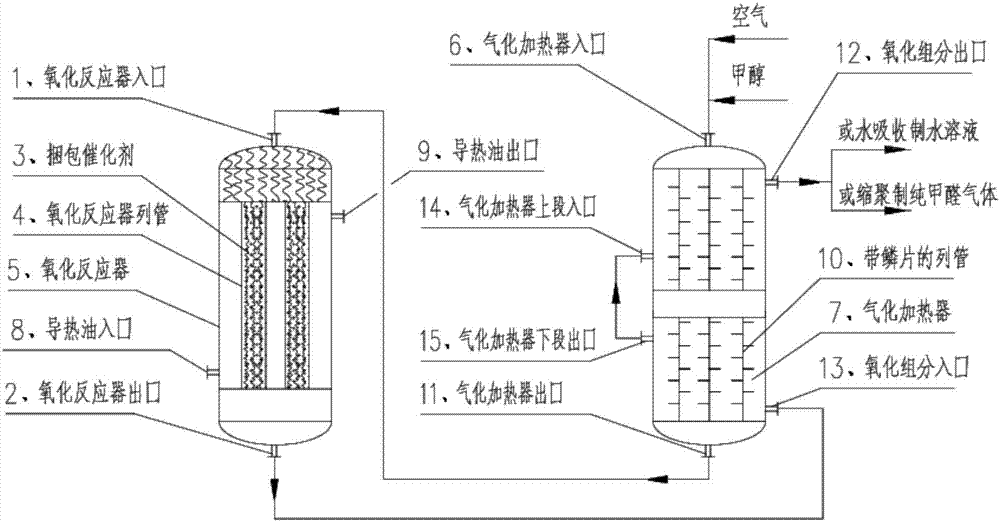

Methanol oxidation reaction device and method

A methanol oxidation and oxidation reactor technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of short tubes, small diameters, and extensive oxidation reactors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

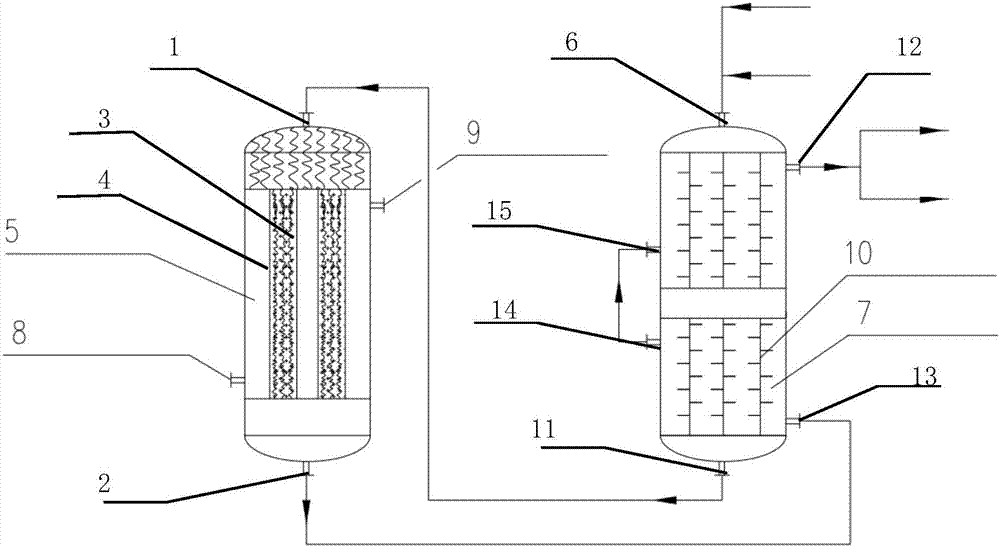

Method used

Image

Examples

Embodiment 1

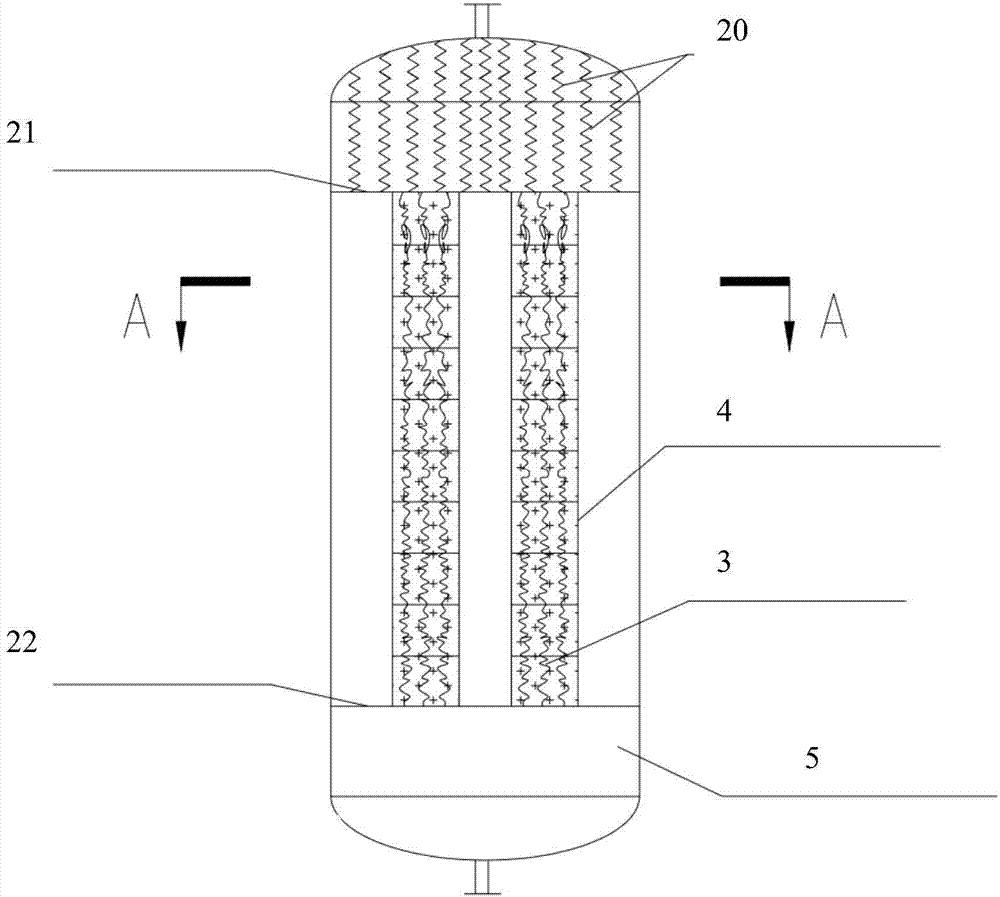

[0073] In the embodiment of the present invention, in order to save costs, the tubes in the oxidation reactor are single tubes, and the specifications of the tubes are 50 mm in inner diameter and 3000 mm in height, and the bundled catalysts are filled and sealed; each tube is equipped with 10 bundles Catalyst packs, the stagger angle of two adjacent packs of catalysts is 15 degrees;

[0074] The mass percent of the active ingredient of bundled catalyst is: M O o 3 74%, Fe 2 o 3 25%, Al 2 o 3 1.0%;

[0075] The mass of the active ingredient in the packaged catalyst of the first layer (ie the uppermost layer) is 10 g, and the mass of the active component in the packaged catalyst of the second layer is 12 g, ie K=0.2.

[0076] A method for methanol oxidation, comprising the steps of:

[0077](1) Feed pretreatment: first turn on the heat transfer oil pump, and the heat transfer oil enters the shell side of the oxidation reactor from the heat transfer oil inlet; then turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com