Wet oxidation desulfurization method and device

A technology of wet oxidation and desulfurization equipment, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of increasing the load of water treatment facilities and achieve the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

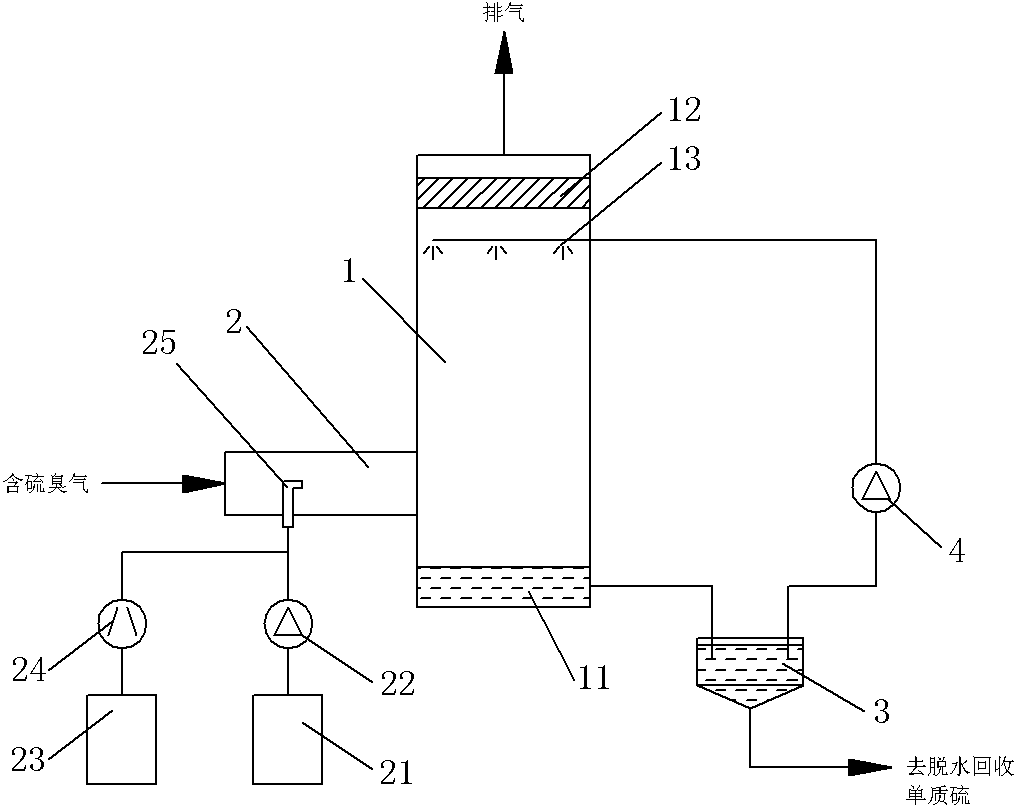

[0021] A specific embodiment of the wet oxidation desulfurization method of the present invention comprises the following steps:

[0022] (1) Pressurize the ozone gas through the compressor, and pressurize the hydrogen peroxide solution through the booster pump;

[0023] (2) Mix the pressurized ozone gas and hydrogen peroxide and atomize it through the injector;

[0024] (3) Spray the hydrogen sulfide-containing odor into the mixing tube, and at the same time spray the atomized ozone gas and hydrogen peroxide into the mixing tube to mix with the hydrogen sulfide-containing odor;

[0025] (4) Pass the mixed hydrogen sulfide-containing odor, ozone gas and hydrogen peroxide into the spray tower through the mixing pipe for spraying.

[0026] (5) Wash off the oxidation products in the mixing tube and the products that are further absorbed and oxidized in the spray tower, pass the washing liquid into the sedimentation tank, and drain the sedimentation tank regularly to obtain eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com