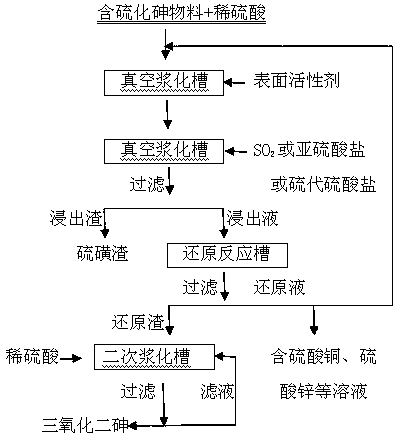

Treatment process for arsenic sulfide containing material

A treatment process, arsenic sulfide technology, applied in the field of metallurgy, can solve the problems of high equipment material requirements, incomplete reaction, poor reduction effect, etc., achieve high resource utilization rate, avoid large-scale pollution, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A treatment process for arsenic sulfide-containing materials, the process flow is: 1) Add 4t of arsenic sulfide filter cake (50% water content) into a 10m³ vacuum reaction tank, add 8m³ dilute sulfuric acid with a concentration of 8% to 20%, Add surfactant A, start the stirring paddle, feed steam into the heating coil to heat up the slurry, raise the temperature to 80-100°C and slurry for 2-4 hours, and pump it into the oxidation reaction kettle through a hose pump; 2) Into the oxidation reaction kettle Introduce compressed air of 1.2MPa to react with the slurry in the oxidation reactor, control the reaction temperature at 90-180°C, the reaction pressure at 1.0MPa, the stirring speed of the oxidation reactor at 600rpm, and the reaction residence time of 2h; 3) After the oxidation reaction, the liquid is pumped into Oxidize the cooling tank, and then send it to the filter for filtration. The main component of the leached slag is sulfur, which can be returned to the smelti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com