Patents

Literature

44 results about "Gaseous ozone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone is a natural gas composed of three atoms of oxygen. Its chemical symbol is O3. It is blue in color and has a strong odor. Normal oxygen (O2), which we breathe, has two oxygen atoms and is colorless and odorless.

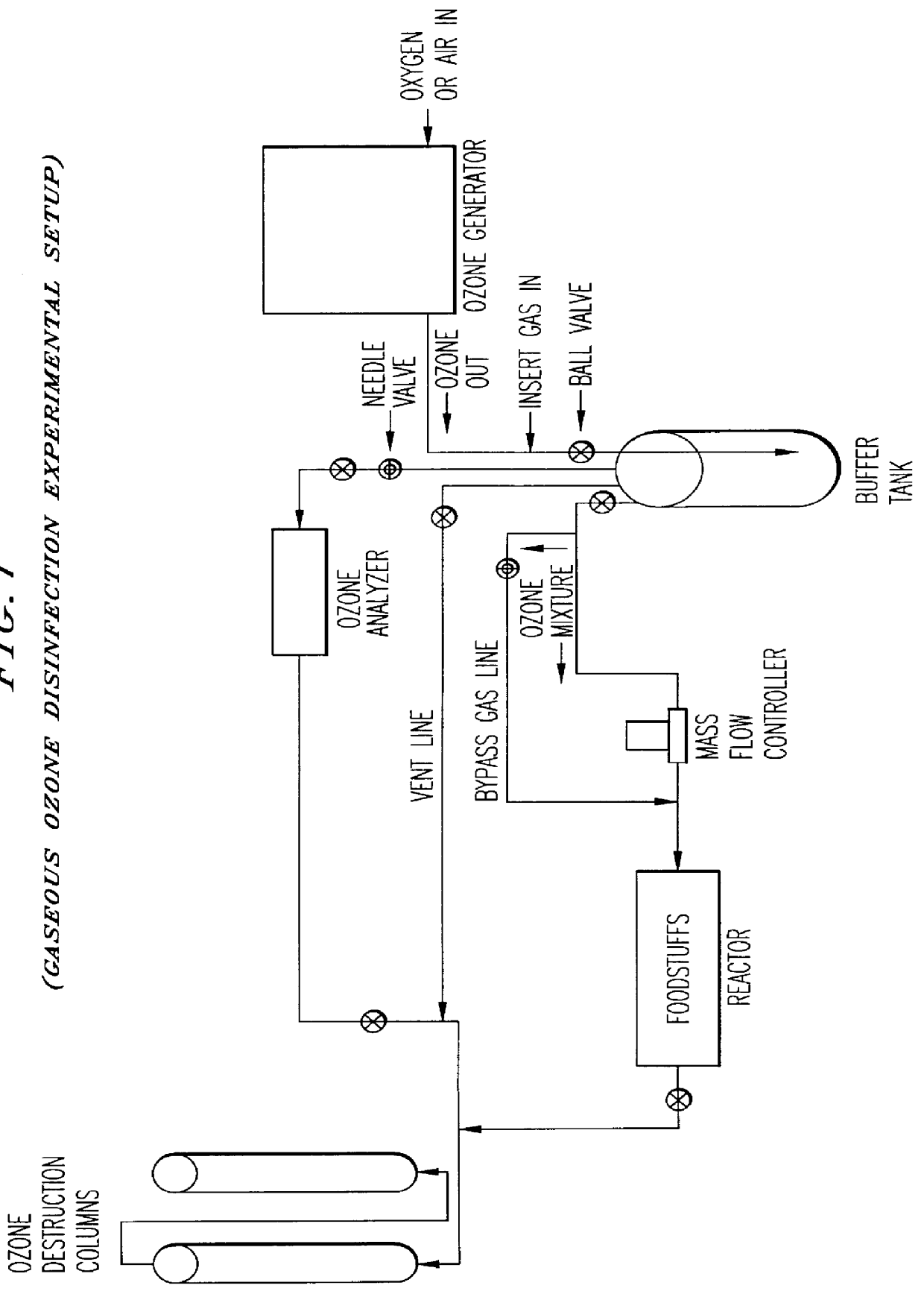

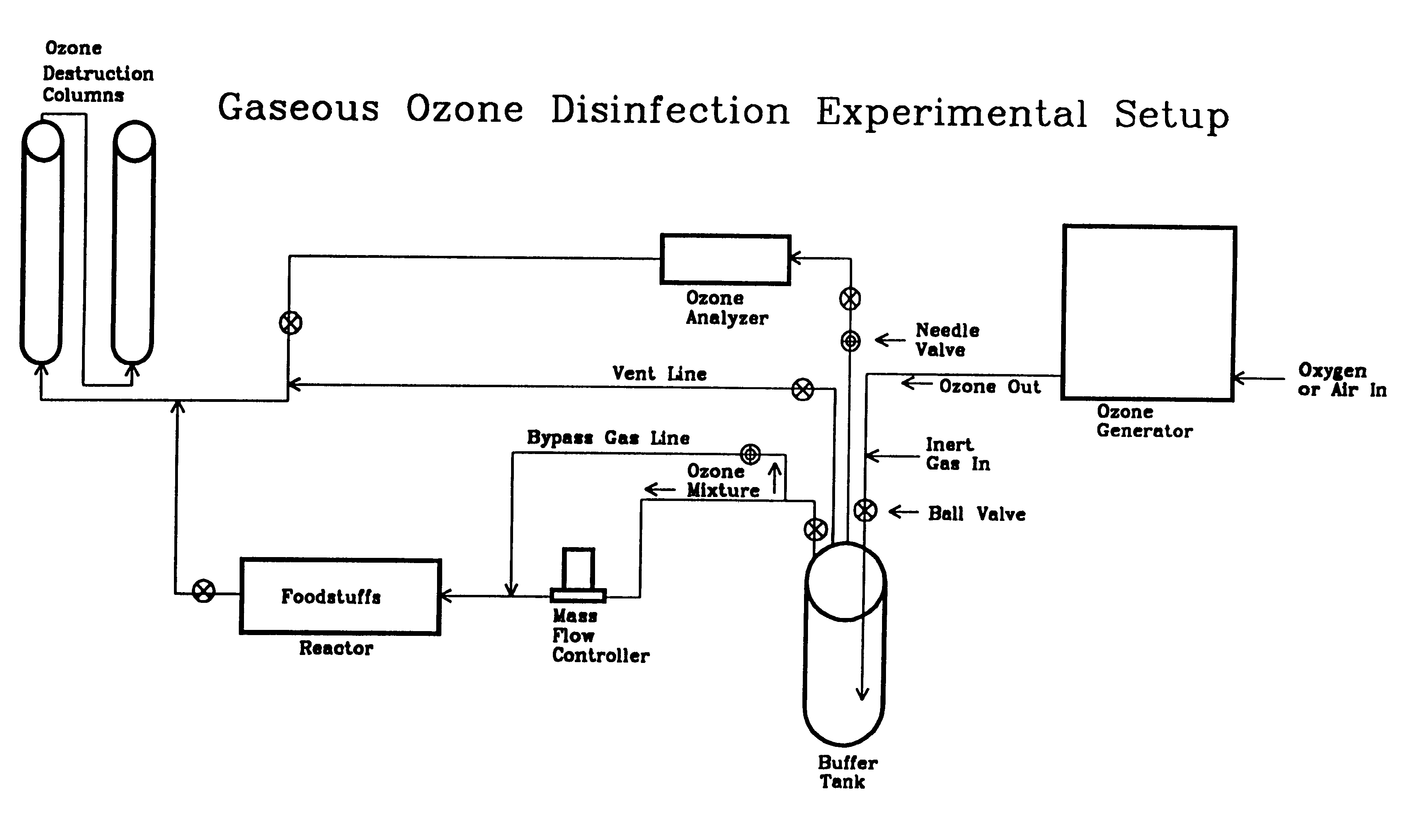

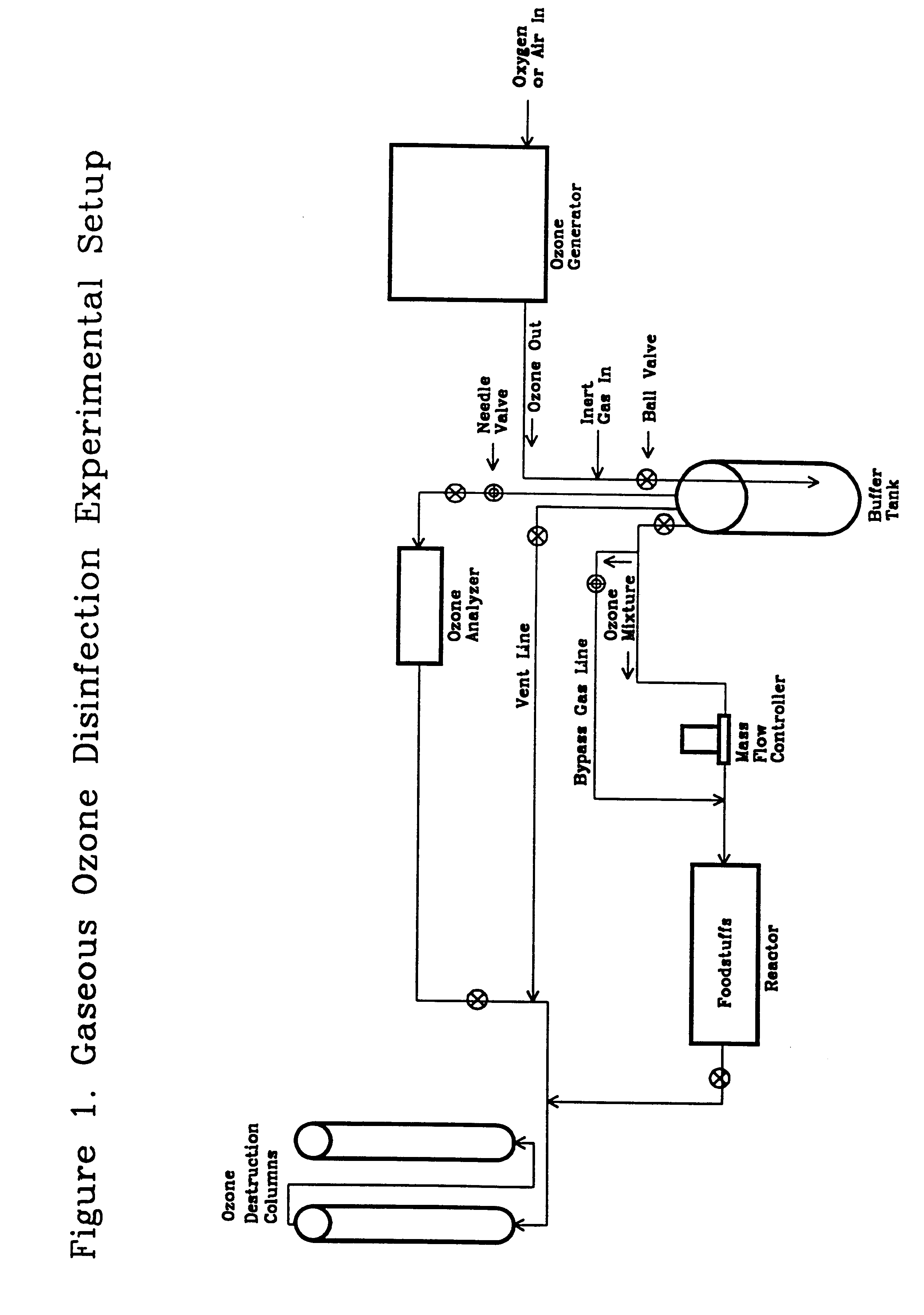

Method of disinfecting a foodstuff using gaseous ozone

The present invention provides a method of disinfecting a foodstuff using a gaseous mixture containing ozone in an amount and for a time sufficient to effect disinfection.

Owner:AIR LIQUIDE AMERICA INC

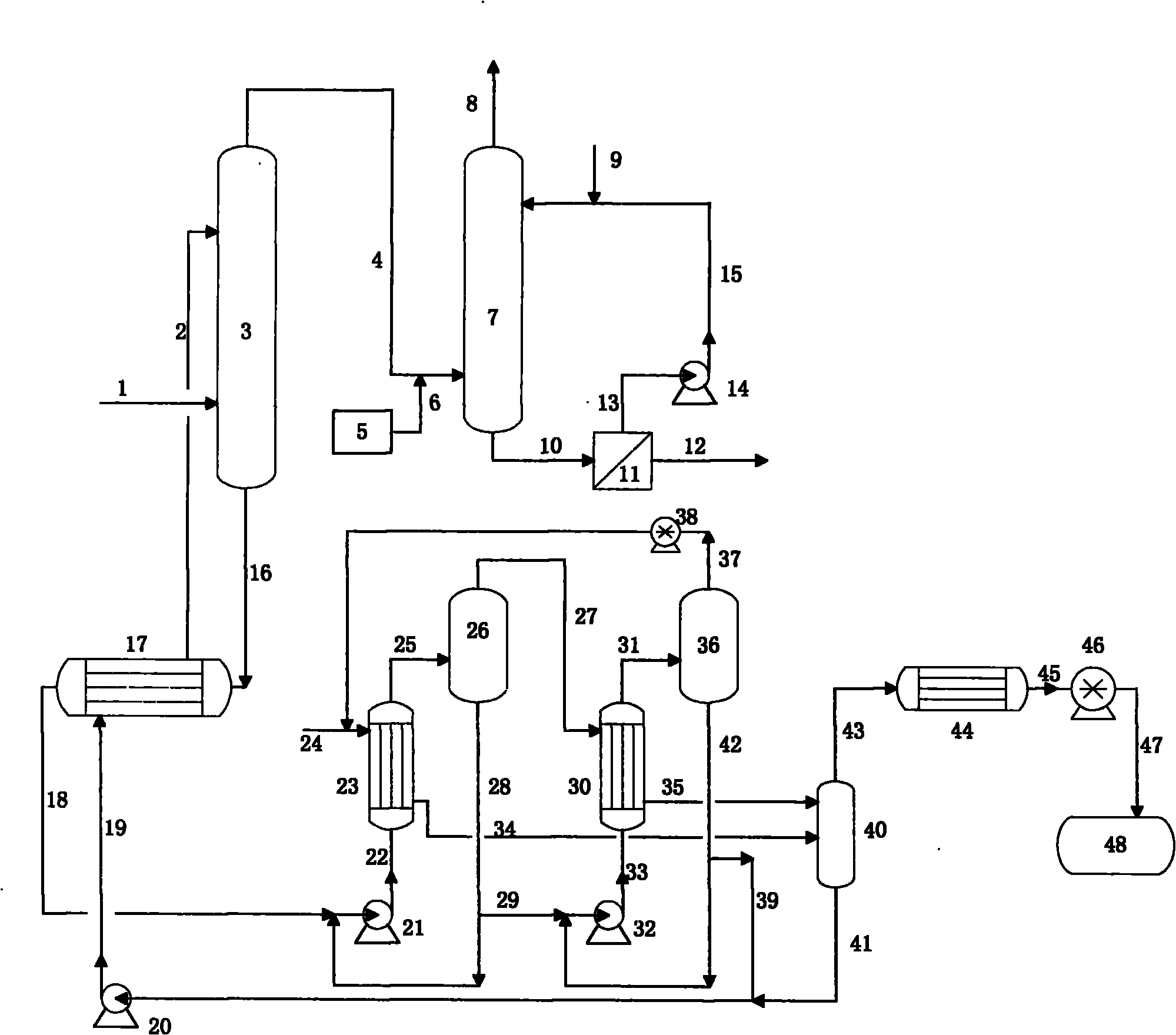

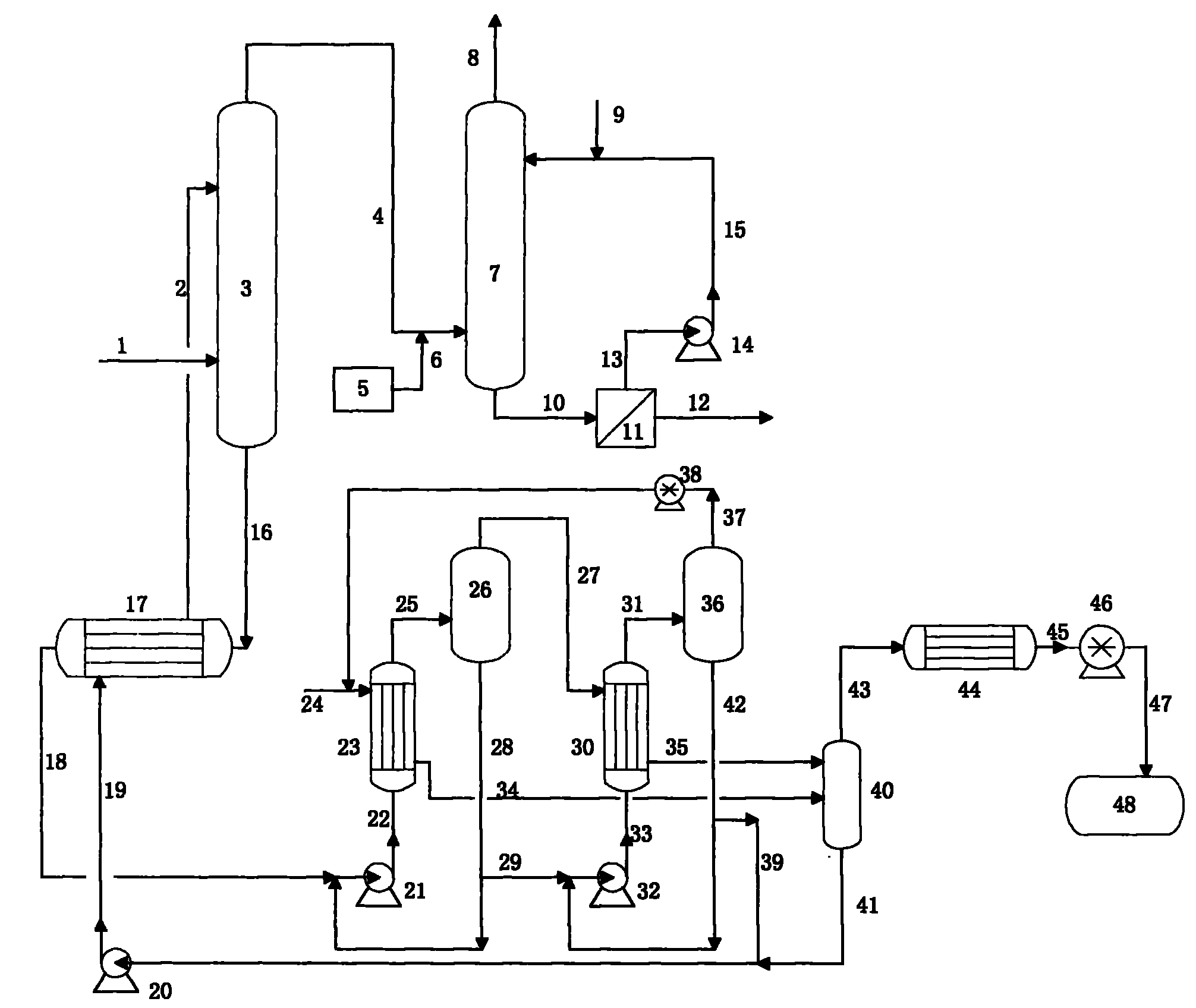

Recycled flue gas desulfurization and denitration method

The invention relates to a recycled flue gas desulfurization and denitration method, which sequentially comprises the following steps of: introducing flue gas of SO2 and NOx into a desulfurizing tower, and absorbing the SO2 with a desulfurizing agent (barren liquor) in the desulfurizing tower; desorbing the desulfurizing agent (rich liquor) which absorbs the SO2 through a multi-effect evaporator,releasing the SO2 gas, and concentrating the SO2 gas into liquid SO2 through condensation drying; making the desulfurized flue gas enter a denitration tower, injecting gaseous ozone from an ozone generator, oxidizing the NO in the flue gas, absorbing the oxidized NO by using a denitrifier to form nitrate; crystallizing and separating out the nitrate in the solution after the nitrate reaches certain concentration, and filtering and drying to obtain the nitrate product. The method turns the wastes into wealth, and the SO2 and NOx in the flue gas are recycled by higher-additional value liquid SO2 and nitrate products, so that the recycling and value maximization in the desulfurization and denitration process is realized. Due to the adoption of the technical scheme, the high desulfurization and denitration rate can be achieved, the desulfurization rate is over 96 percent, the denitration rate is more than 90 percent, and the purity of the nitrate product is over 96 percent. The method hasthe advantages of simple desulfurization and denitration process, low investment, and low operation cost for desulfurization and denitration, and solves the problems that the conventional desulfurization and denitration process has high cost, generates a side product of a mixture of sulfuric acid (sulfate) and nitric acid (nitrate), and has low additional value.

Owner:EAST CHINA UNIV OF SCI & TECH

Method of disinfecting a foodstuff using gaseous ozone

The present invention provides a method of disinfecting a foodstuff using a gaseous mixture containing ozone in an amount and for a time sufficient to effect disinfection.

Owner:AIR LIQUIDE AMERICA INC

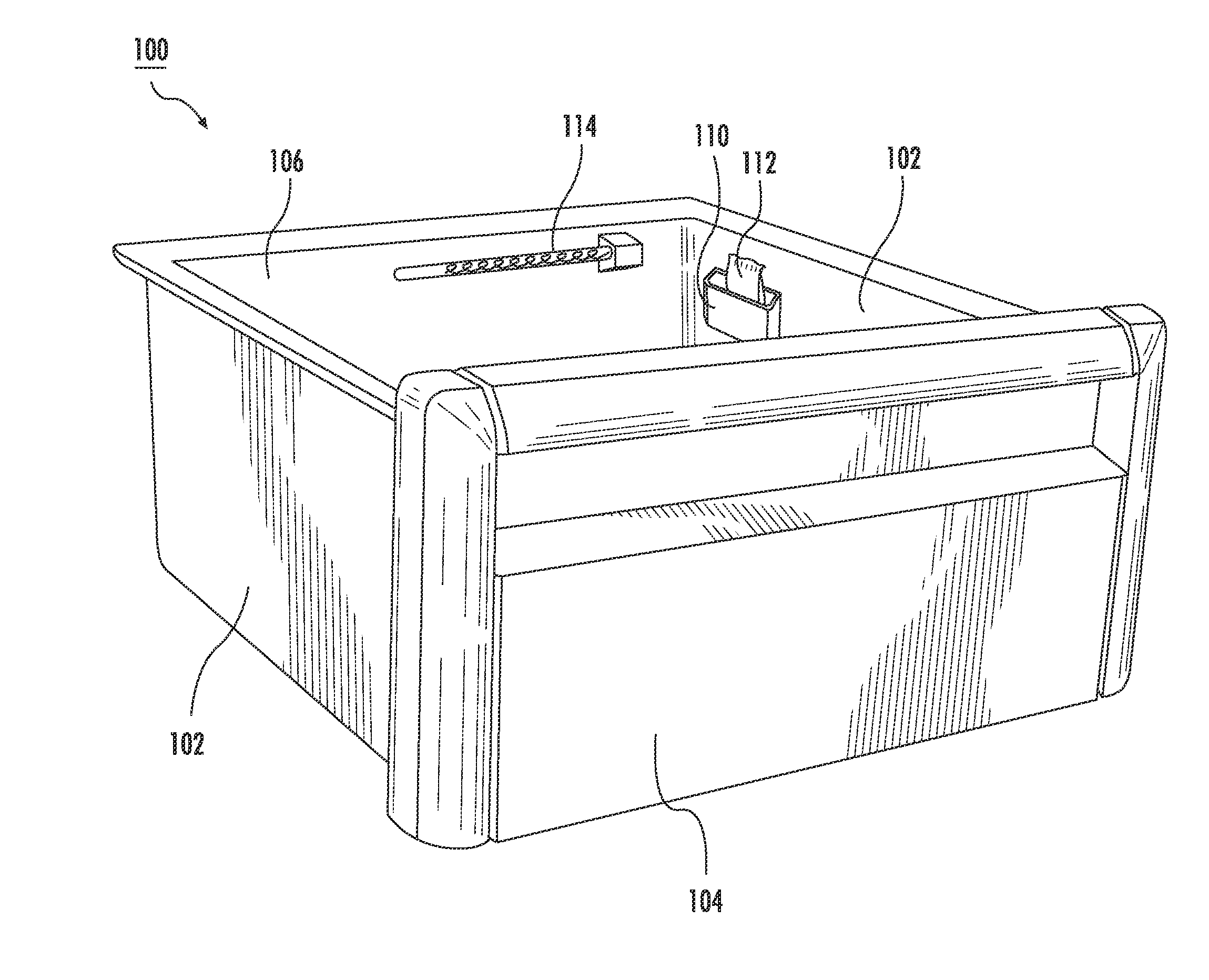

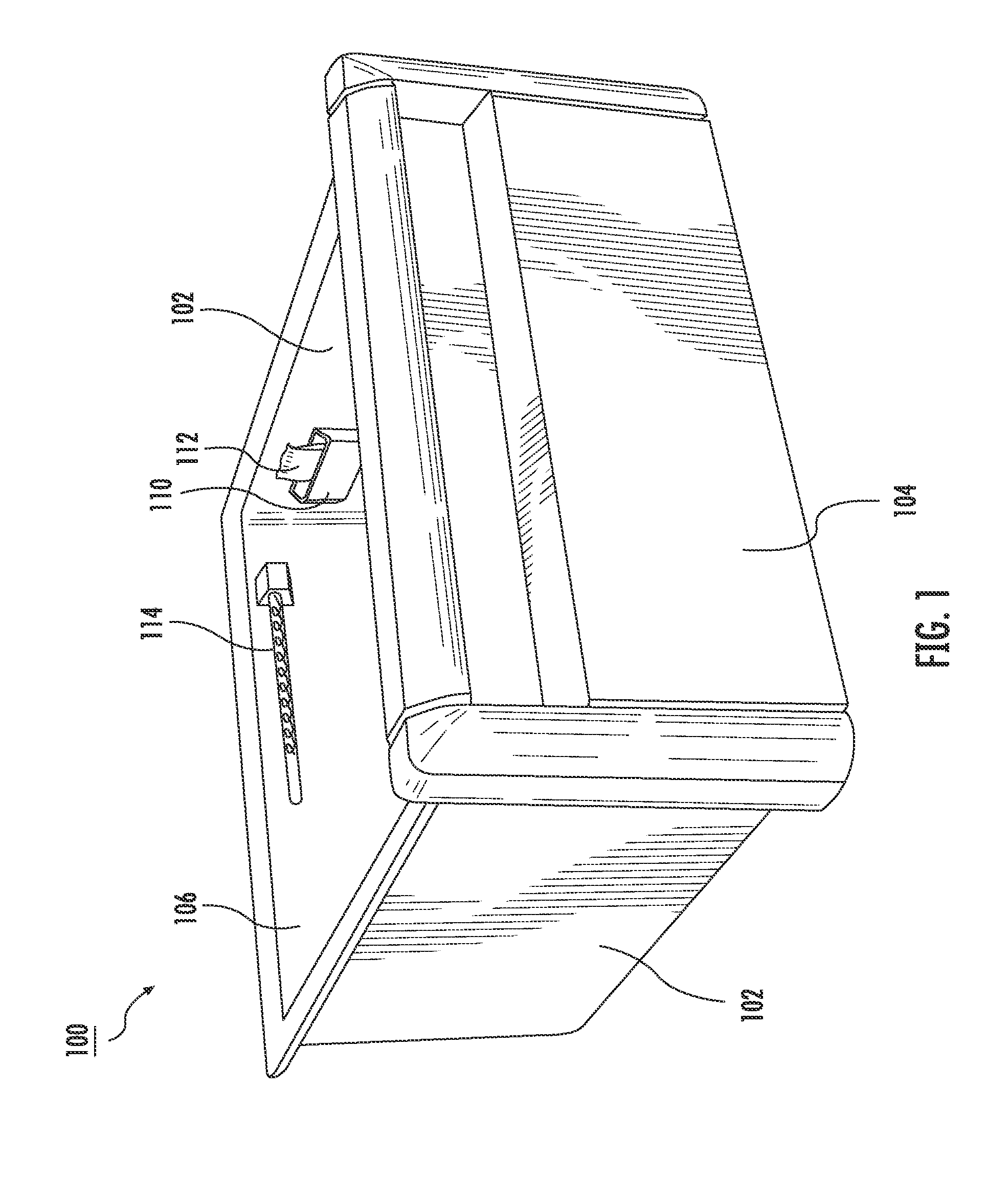

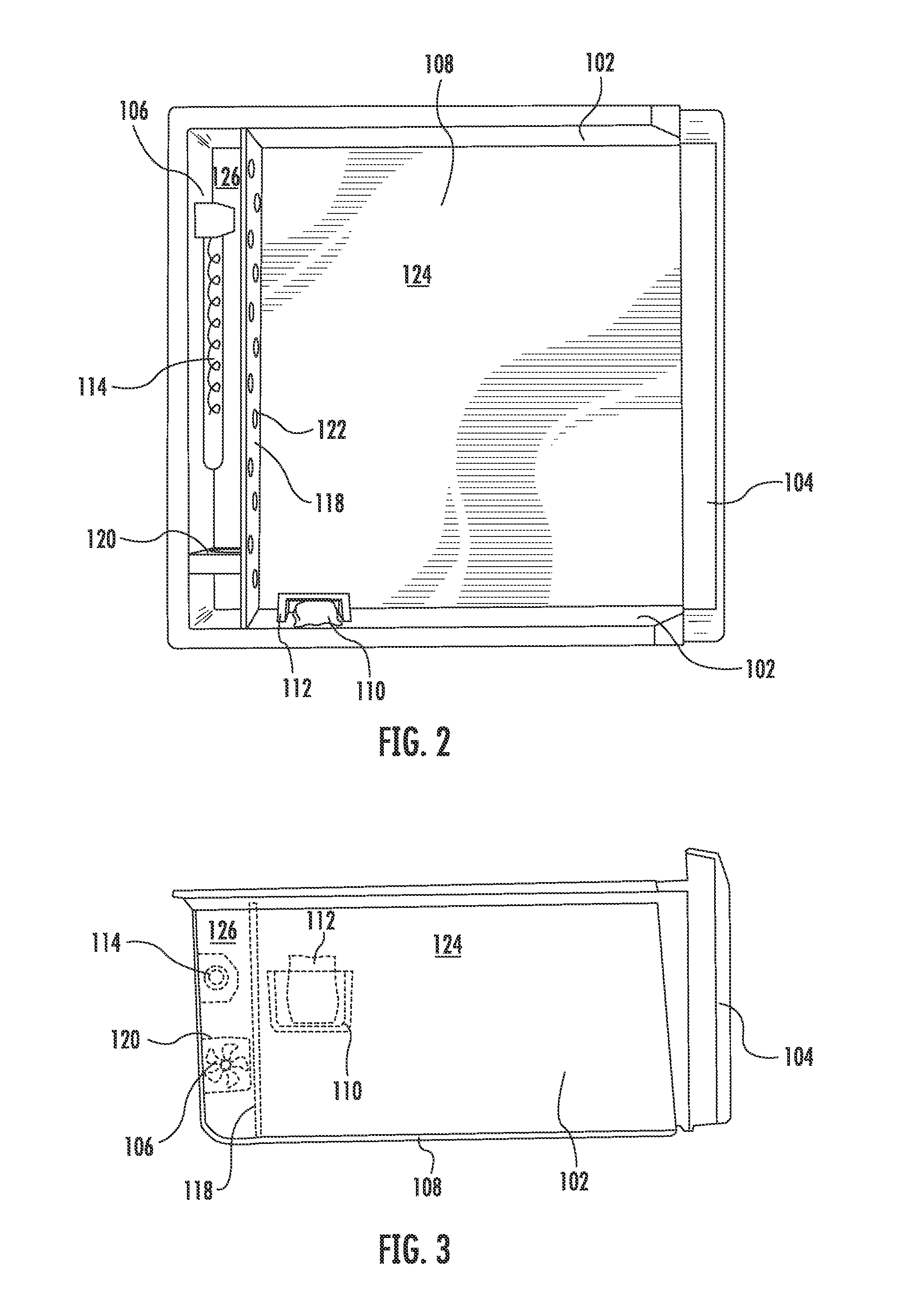

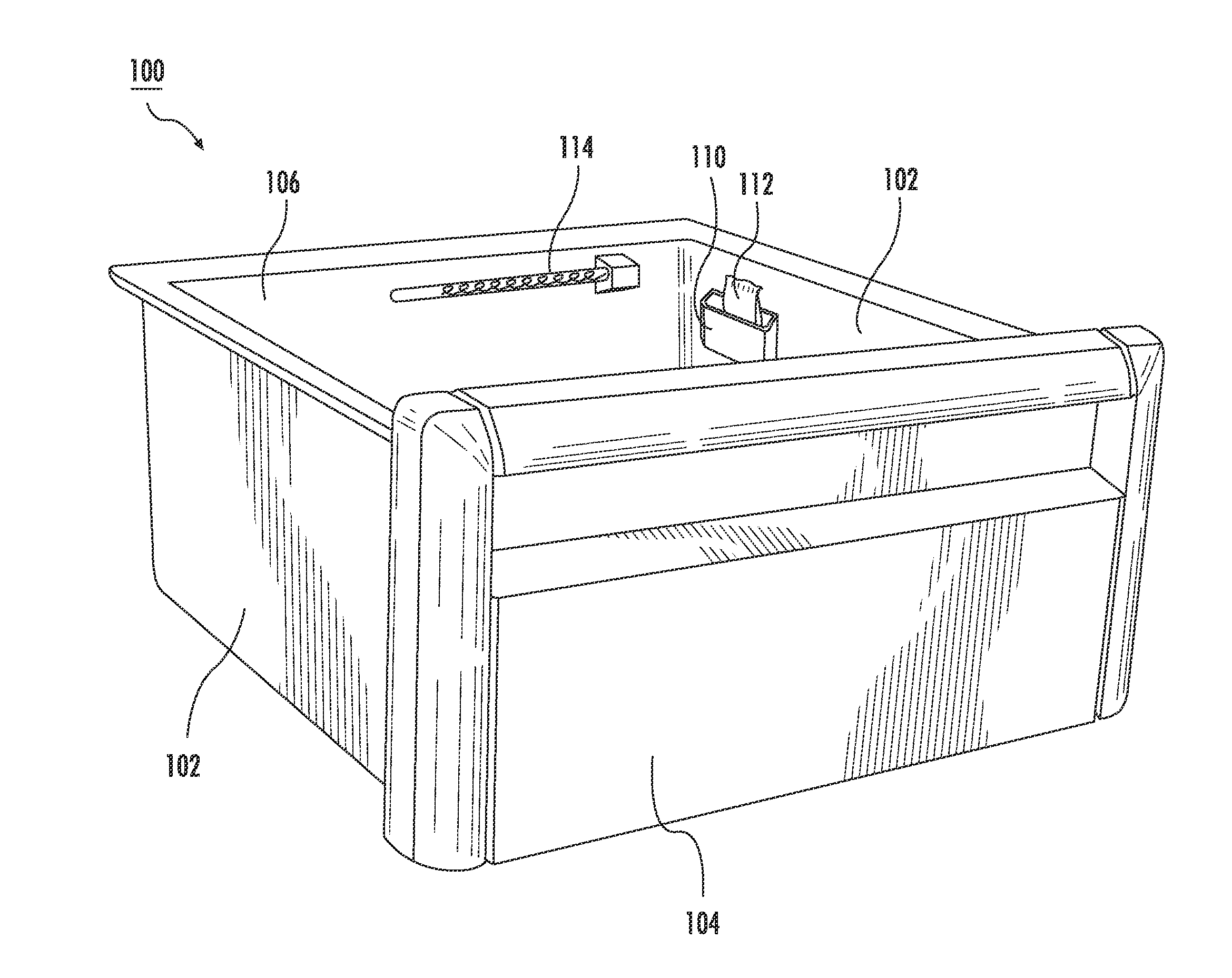

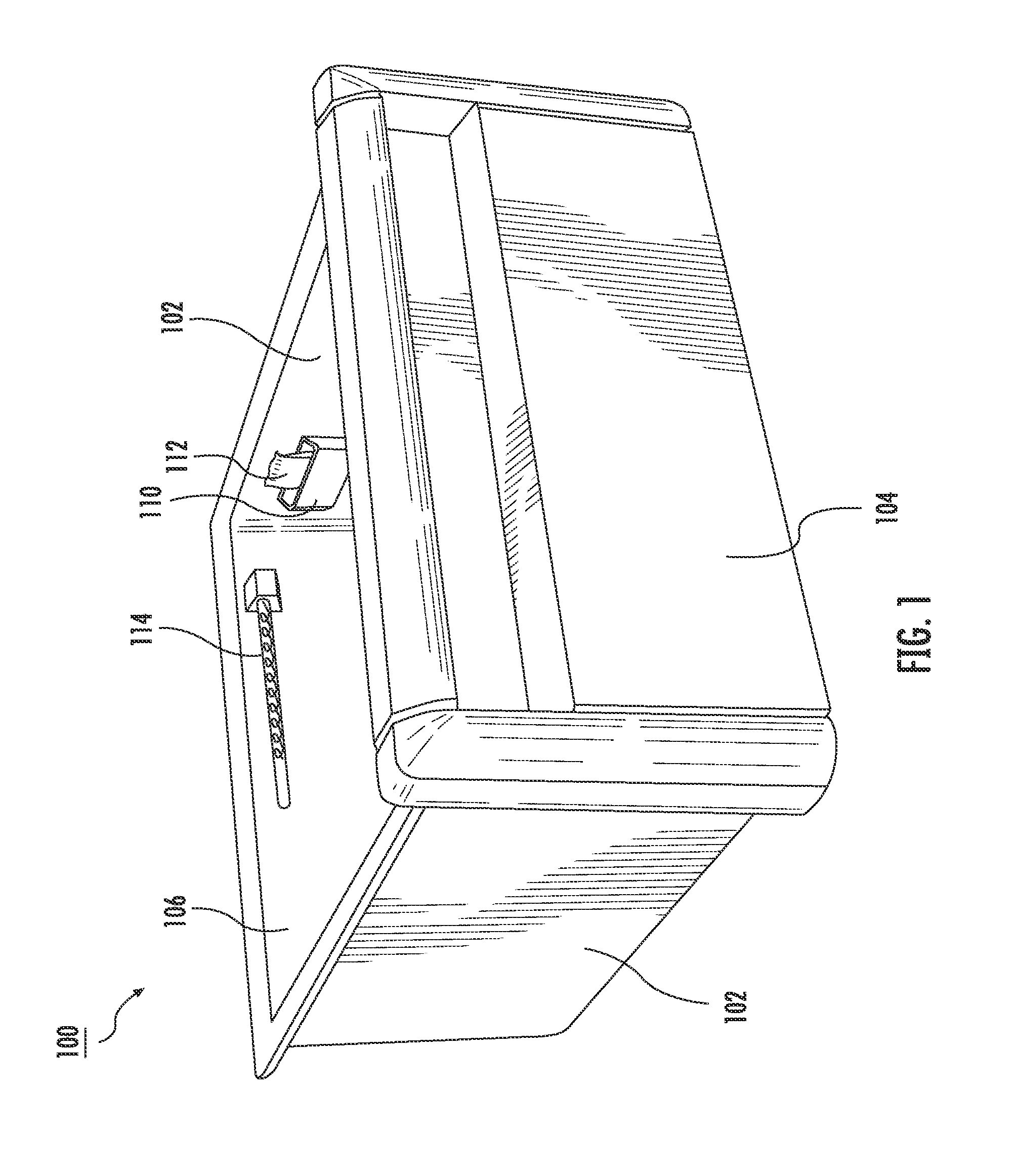

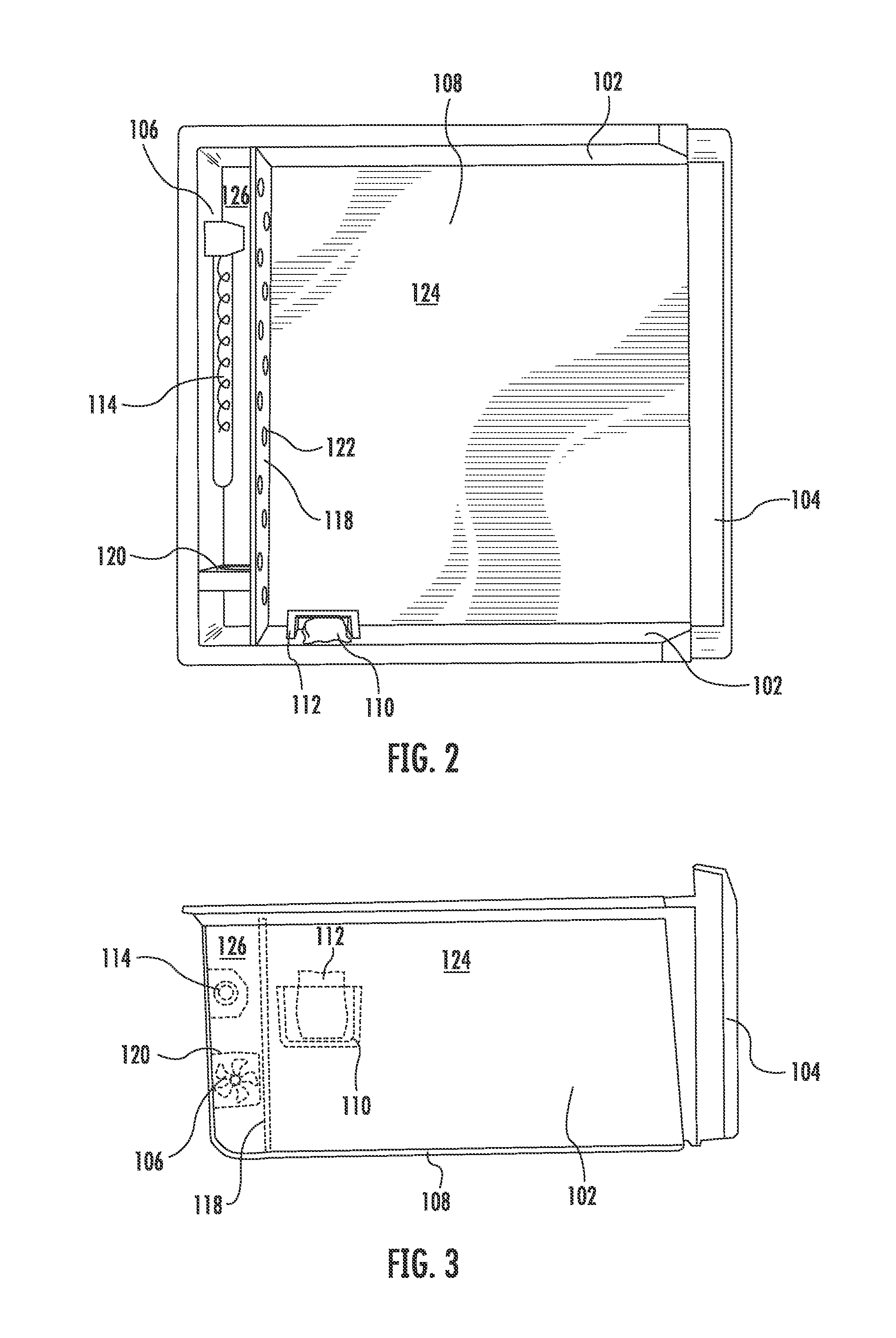

Refrigerator Crisper Ozonation System and Related Method

InactiveUS20130059047A1Delaying postharvest produce deteriorationSufficient sizeMechanical apparatusFruit and vegetables preservationOzone generatorEnvironmental engineering

A crisper drawer for postponing postharvest produce deterioration having a drawer housing that substantially defines the size and shape of the crisper drawer and fits within a residential refrigerator. A chamber within the drawer housing is cooled by the refrigerator. An ozone generator provides gaseous ozone to the chamber, and an ethylene scrubber reduces levels of ethylene in the chamber. An ozone level control with the ozone generator controls ozone levels.

Owner:ARRIGO VINCENT M

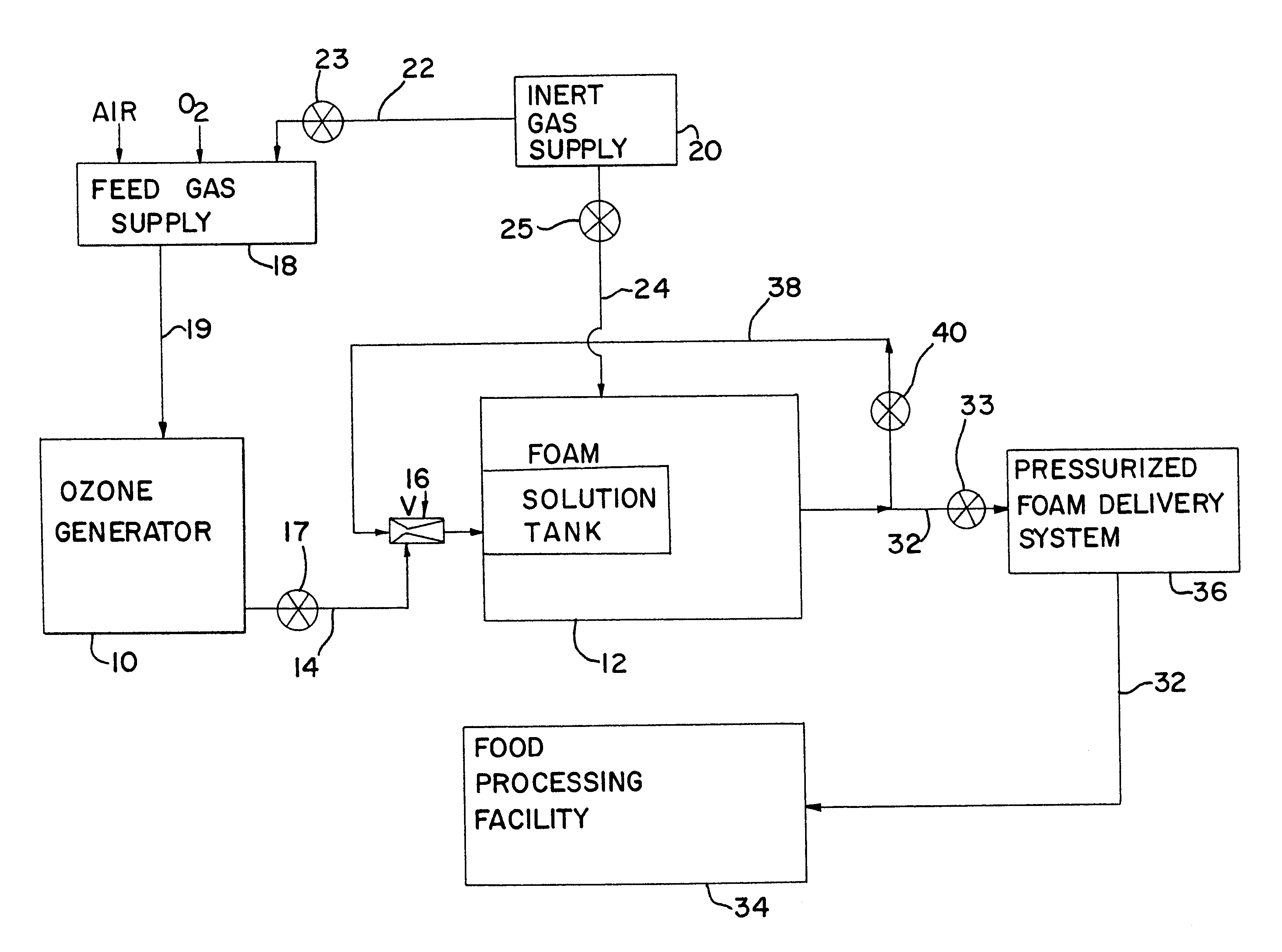

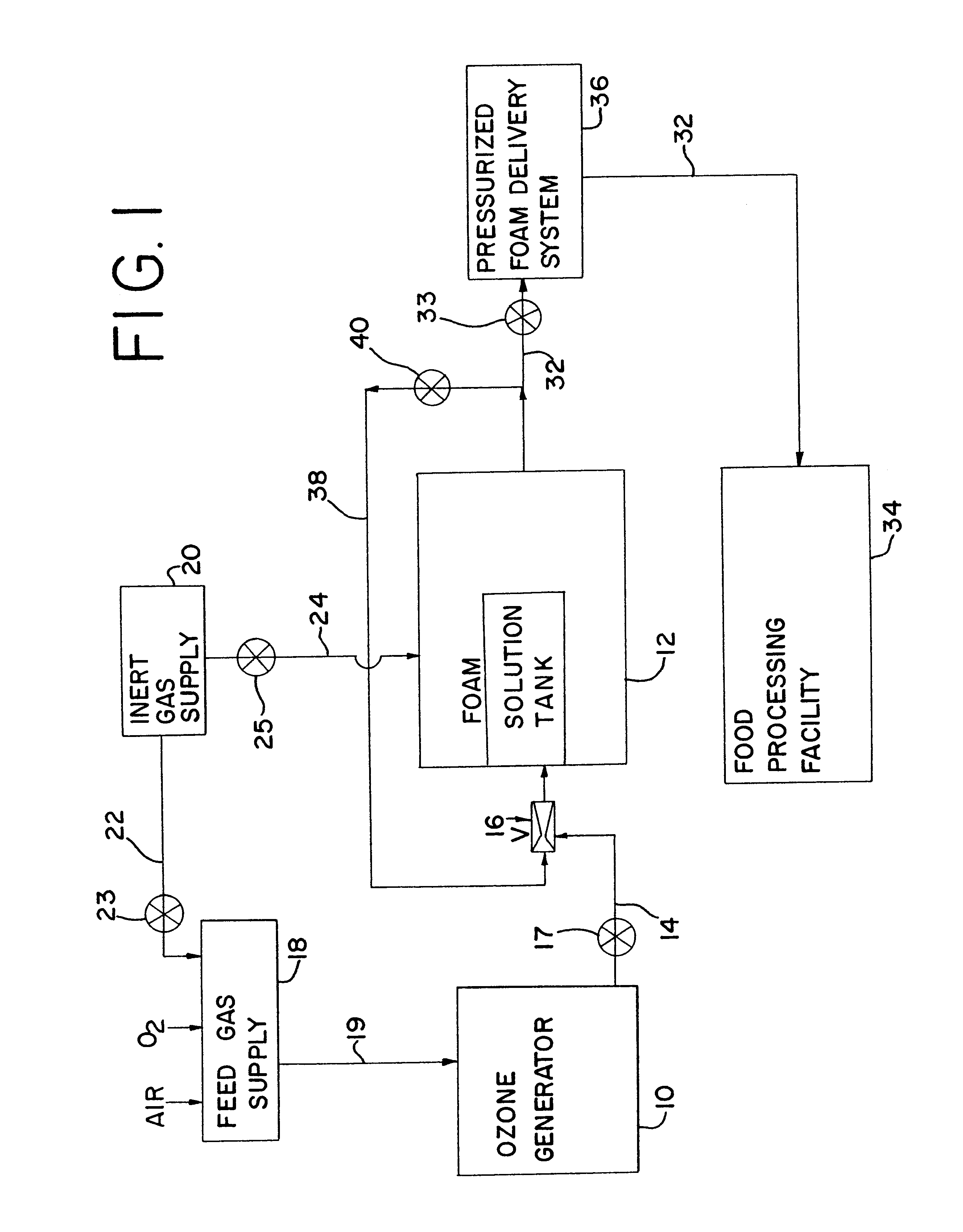

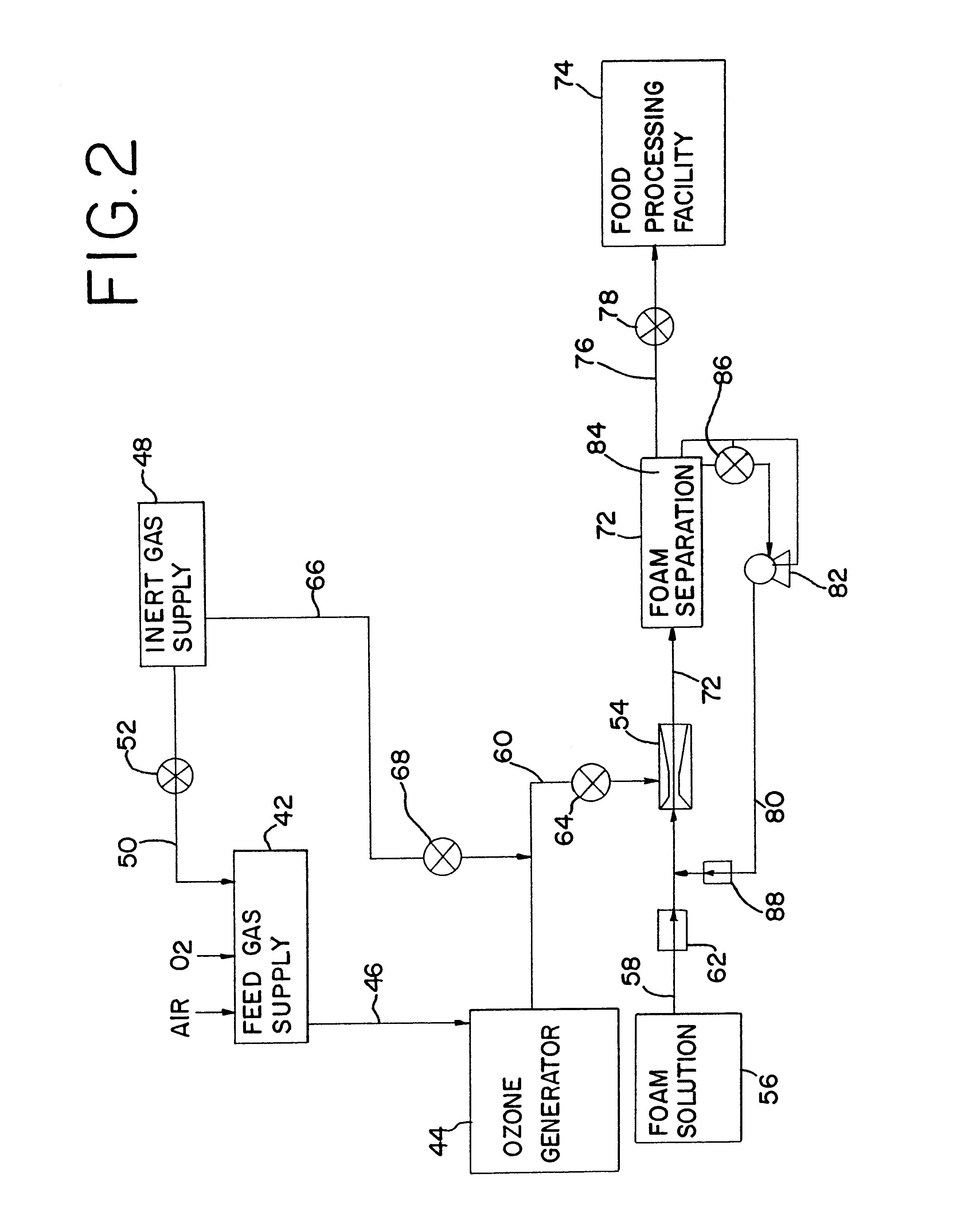

Ozonated foam medium and production system and method for sanitizing a food processing environment

InactiveUS6669902B1Improve efficiencyEffective limitInorganic/elemental detergent compounding agentsBiocideFood contactNitrogen gas

A method for sanitizing a food processing environment includes preparing an ozonated foam sanitizing medium and applying the sanitizing medium to either objects in the food processing environment, such as food processing equipment, food contact surfaces, interior surfaces of the food processing facility, or the ambient environment within the food processing facility, or both the objects within the food processing facility and the ambient environment of the food processing facility. An ozonated foam sanitizing medium includes a foaming agent dissolved in an aqueous solution and an ozone concentration of at least about 0.1 ppm and is prepared by either injecting gaseous ozone or introducing an aqueous ozone solution into an aqueous solution containing a foaming agent. In a system for generating the ozonated foam medium, the gaseous ozone can be injected with a feed gas, such as oxygen, air, an inert gas, and mixtures thereof. Additionally, an inert gas, such as nitrogen, carbon dioxide, argon, krypton, xenon, neon, and mixtures thereof can be injected separately into the aqueous foam solution. Once prepared, the ozonated foam is applied to a surface within the food-processing environment to a thickness of about 0.25 inches to about 7 inches or more, and allowed to stand for a predetermined period of time. The ozonated foam is then washed away with an aqueous solution.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Method and apparatus for surface treatment using inorganic acid and ozone

InactiveUS20120138097A1Increase dissolved ozone concentrationHigh ozone concentrationLighting and heating apparatusSemiconductor/solid-state device manufacturingTreatment useGaseous ozone

Improved removal of ion-implanted photoresist in a single wafer front-end wet processing station is achieved by dissolving gaseous ozone into relatively cool inorganic acid, dispensing the acid ozone mixture onto a wafer, and rapidly heating the surface of the wafer to a temperature at least 30° C. higher than the temperature of the acid ozone mixture.

Owner:LAM RES AG

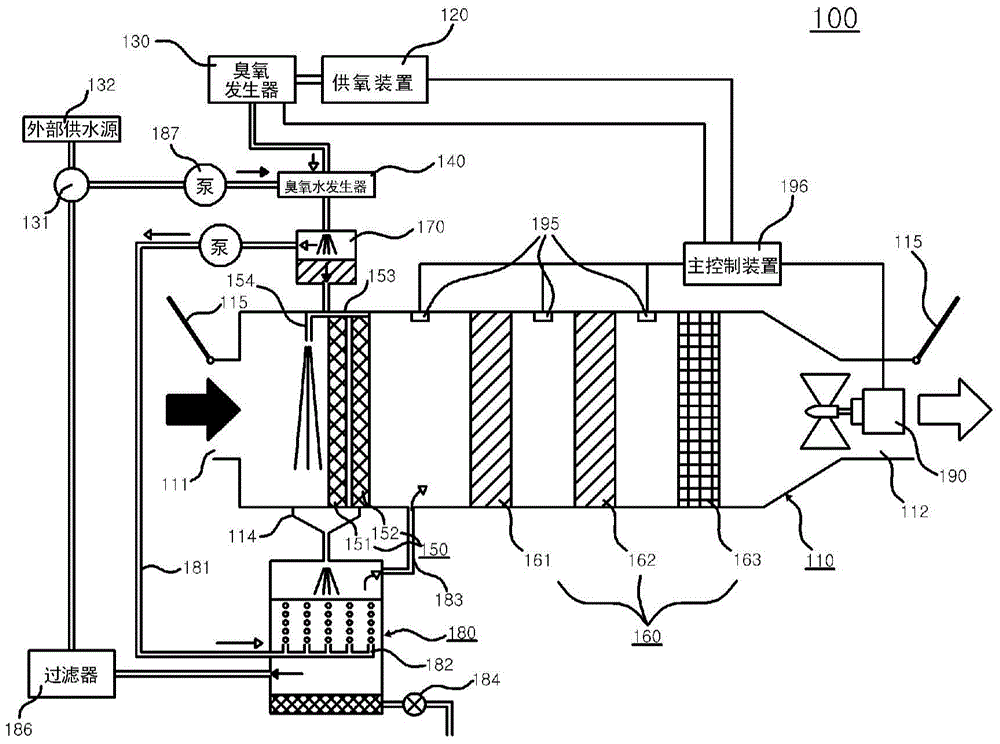

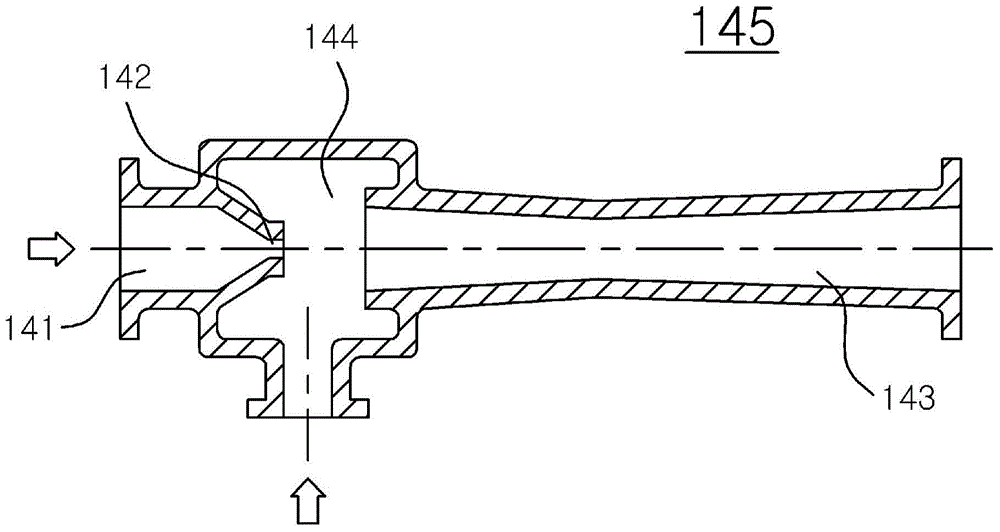

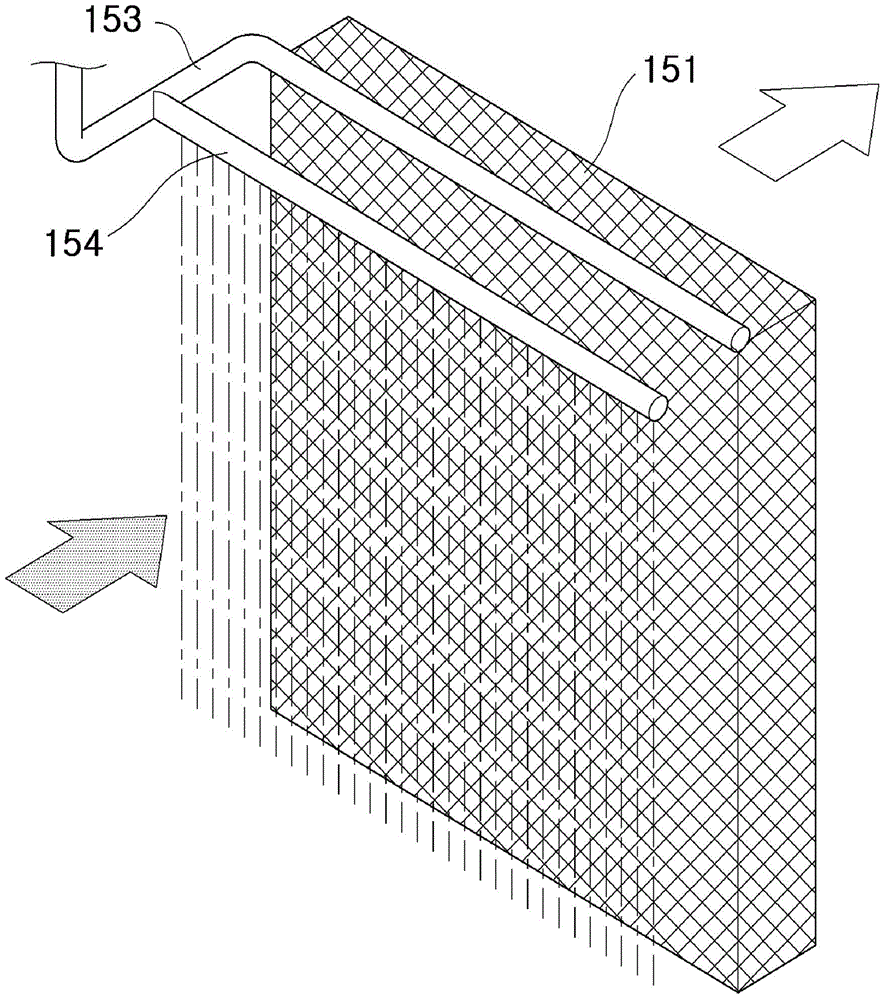

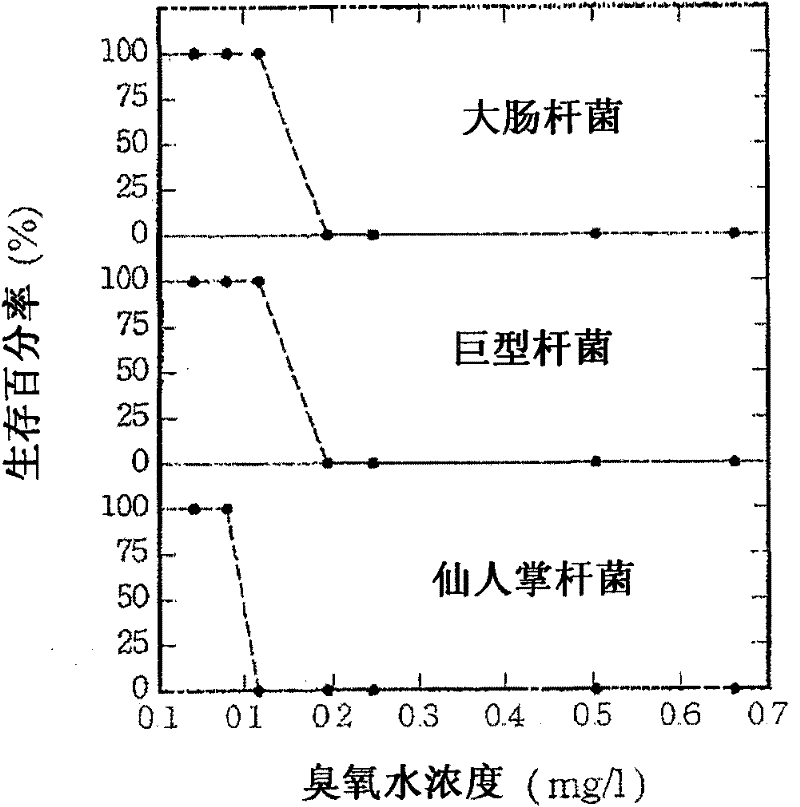

Air purifier using ozone water generator

InactiveCN104023825AImprove performanceImprove purification efficiencyGas treatmentDispersed particle separationHigh concentrationAir purifiers

The present invention relates to an air purifier using an ozone water generator. According to an odor remover which purifies air containing a pollutant having a malodorous component, high-concentration oxygen is supplied in order to generate ozone, and the gaseous ozone is mixed with working water in order to generate aqueous ozone water, and then the non-dissolved gaseous ozone is separated using a gas-liquid separation device such that the ozone water is used to purify the air through a metal filter unit and the gaseous ozone is used to purify the ozone water containing the pollutant flowing down through the metal filter.

Owner:JIN WOO IND

Method of descenting hunter's clothing

A method for removing the human scent and any other scent that is not advantageous to the environment you are in from clothing and equipment used by sportsmen by the use of gaseous ozone or hydroxyl and hydroperoxide ions. The gas is applied directly or indirectly to the clothing, equipment and body while the hunter is in the field and / or prior to or after the hunt. The method can also be used by fishermen to eliminate fish odor. The method of delivering a gas in compressed / generated form from a container.

Owner:PARAH

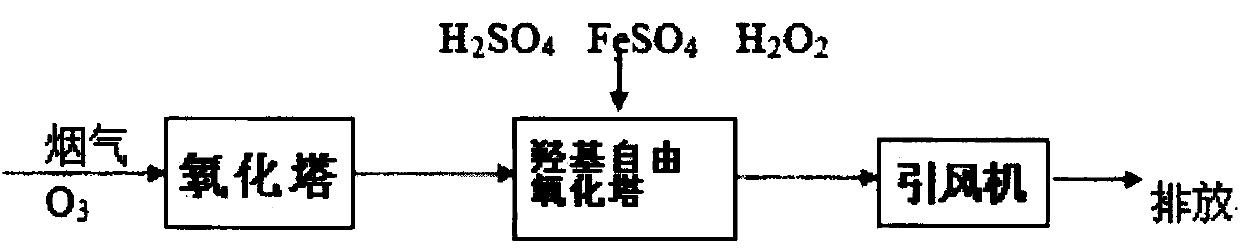

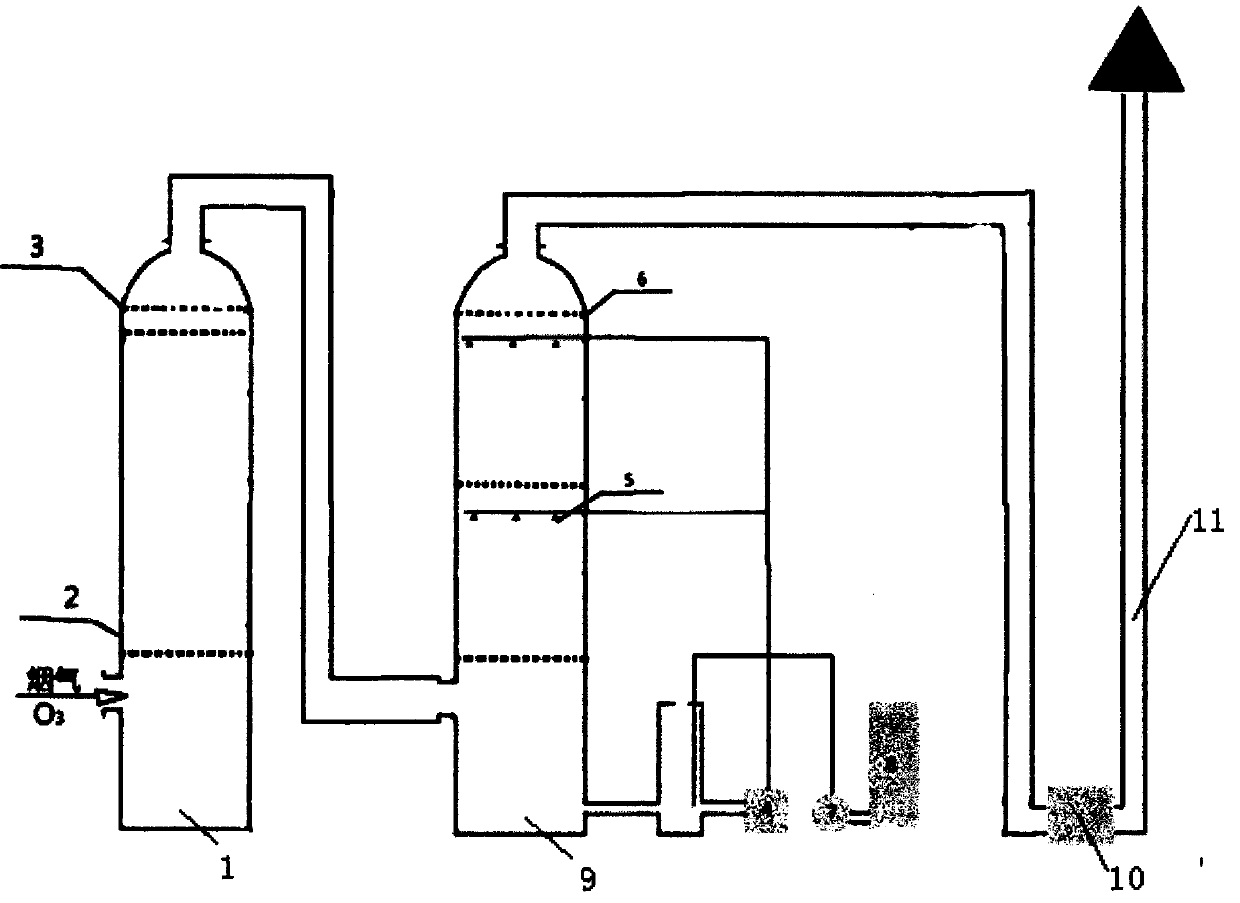

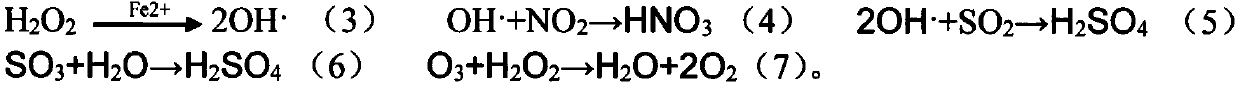

Ozone-hydroxy free radical dry-wet combined desulphurization and denitration technology

ActiveCN104587809AAvoid pollutionAvoid corrosionDispersed particle separationAir quality improvementAtmospheric airReaction temperature

The invention belongs to the technical field of treatment on sulphur oxides and nitrogen oxides in flue gas and discloses an ozone-hydroxy free radical dry-wet combined desulphurization and denitration technology. The desulphurization and denitration technology comprises the following steps of carrying out dry or wet dedusting on flue gas to be treated so that a temperature is less than 80 DEG C and dust content of the flue gas of each cubic meter is less than 120mg, feeding gaseous ozone into the flue gas to be treated, feeding the flue treated by gaseous ozone into a H2SO4 solution with a catalyst FeSO4, and carrying out H2O2 cycle spraying along a direction opposite to a flue gas feeding direction. The produced OH.(hydroxy free radical) can remove NO2 and SO2 in flue gas, a SO2 removal rate is 98% or more and a denitration rate is 90% or more. Excess ozone is reduced into O2 by H2O2 so that ozone-caused atmosphere environment pollution is prevented. An oxidation reaction temperature is controlled to 80 DEG C or more so that equipment is effectively controlled and air channel corrosion problems are solved. A dry ozone oxidation method is used so that equipment corrosion is prevented.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

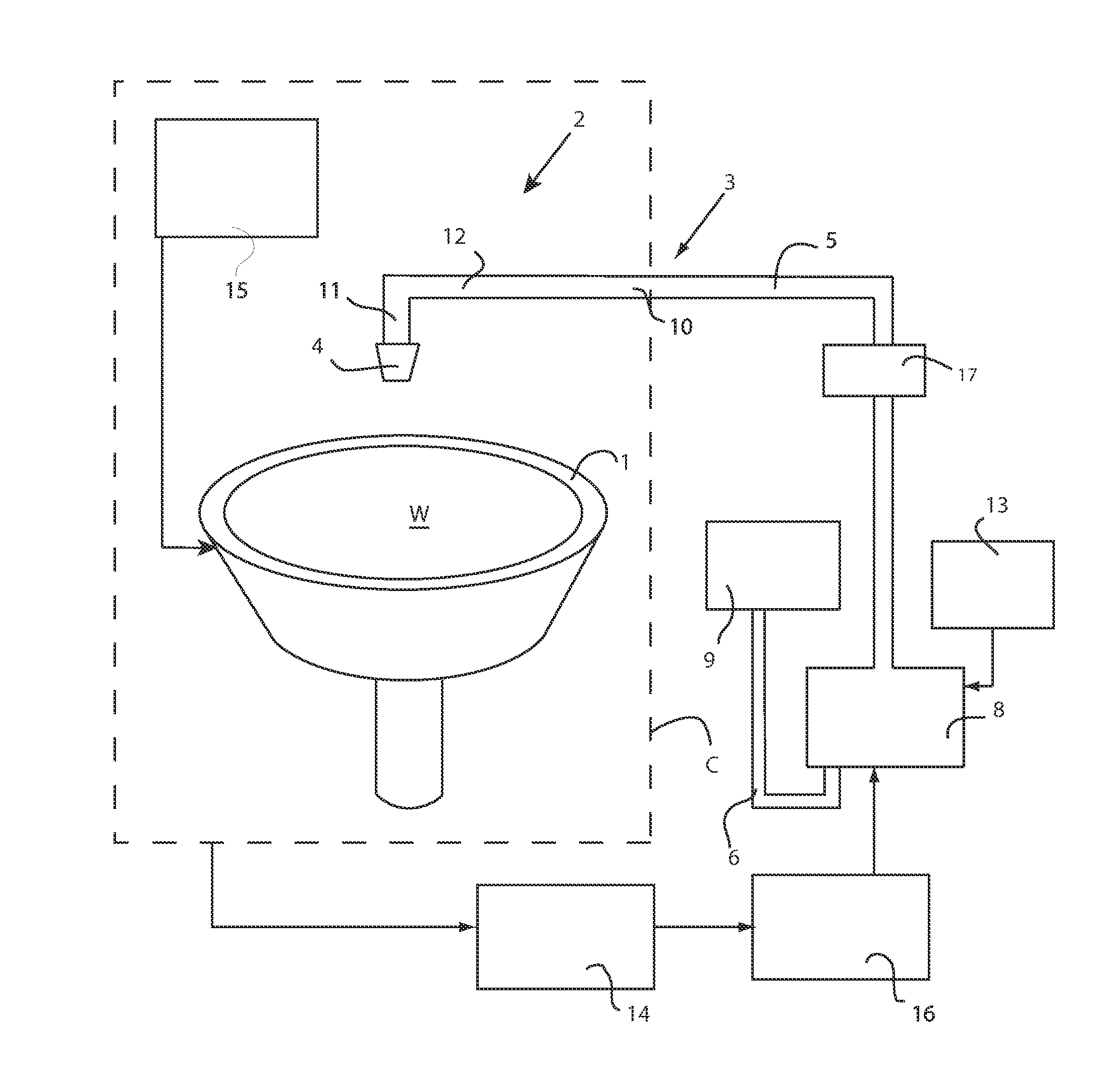

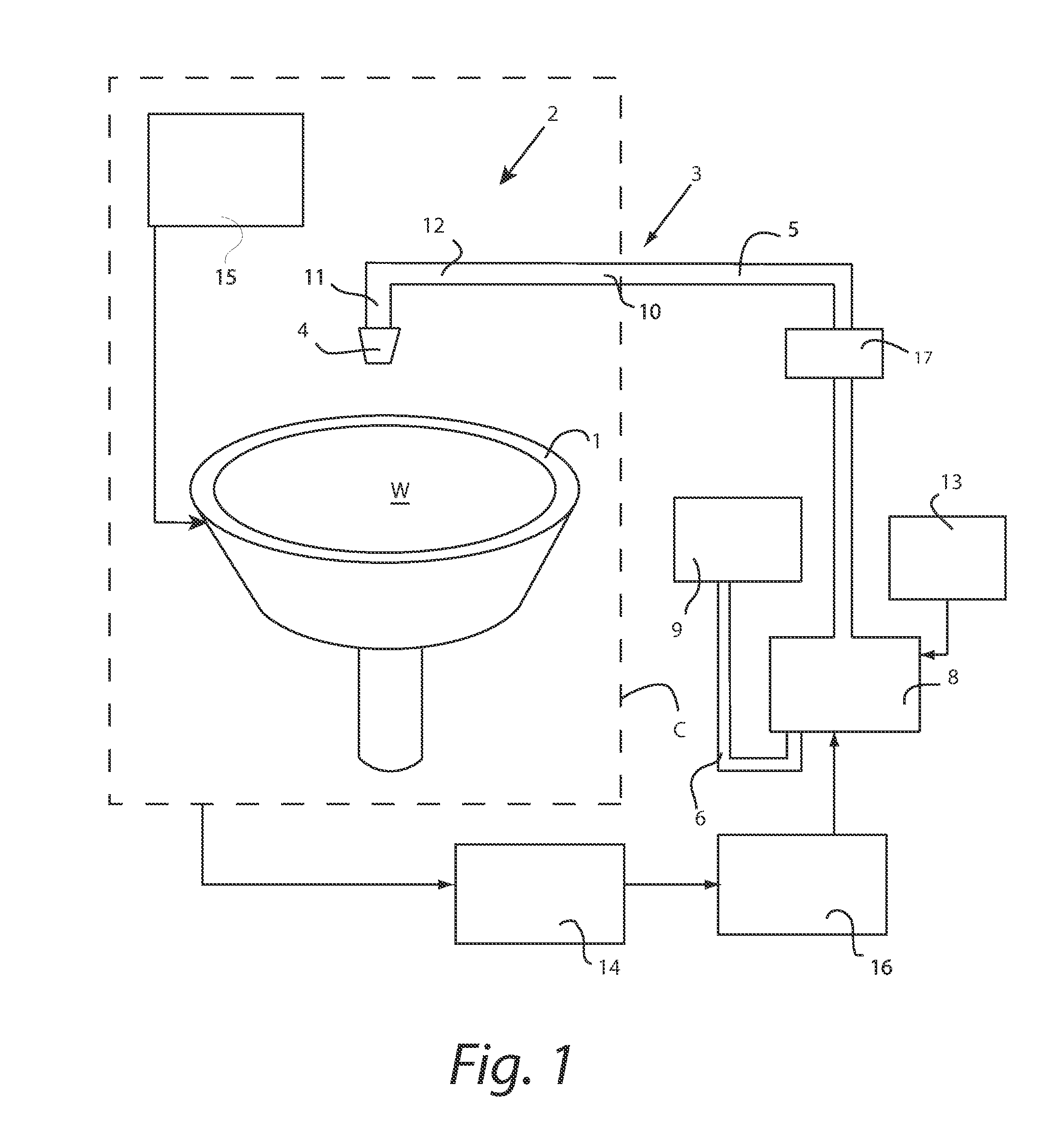

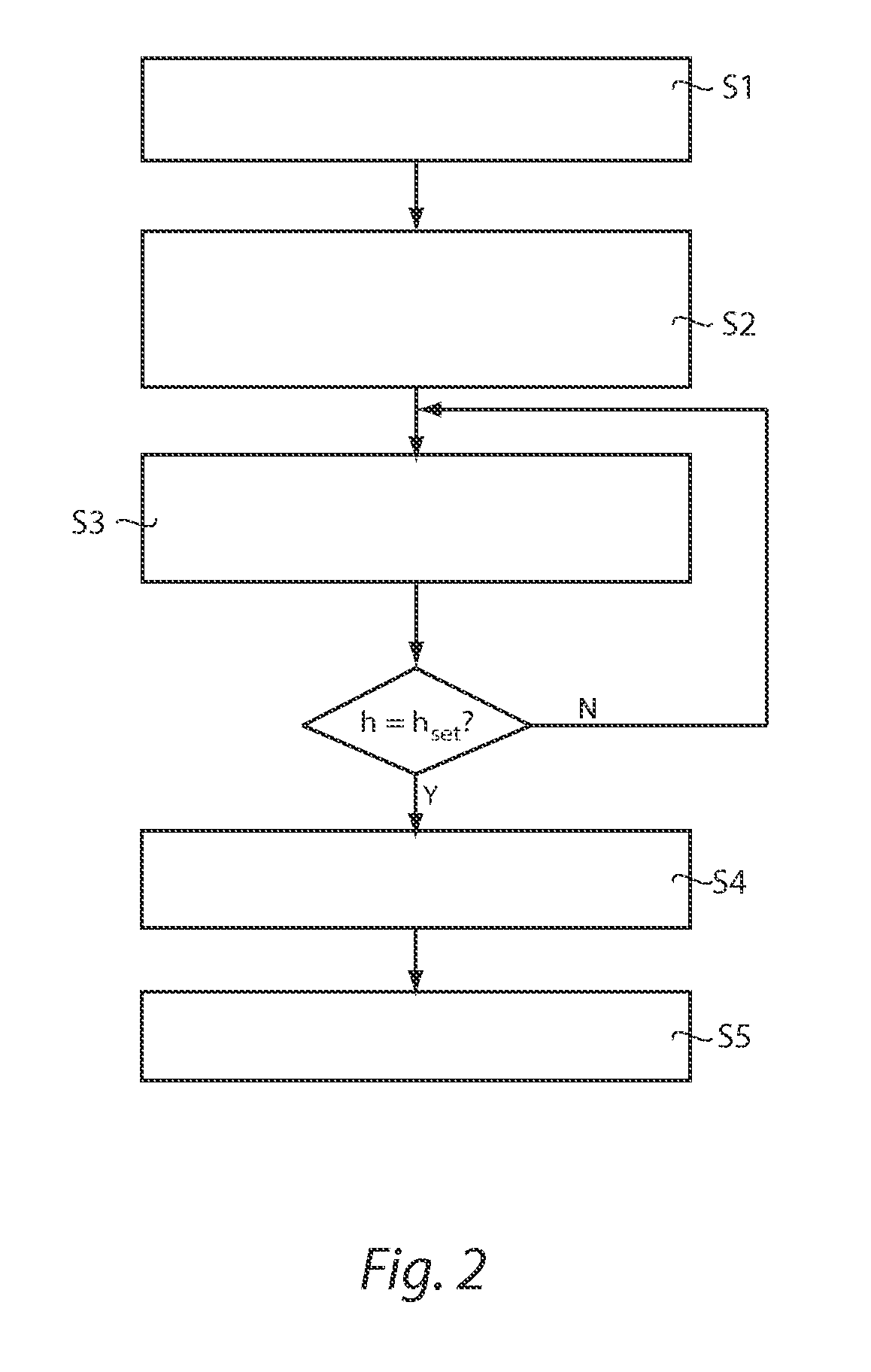

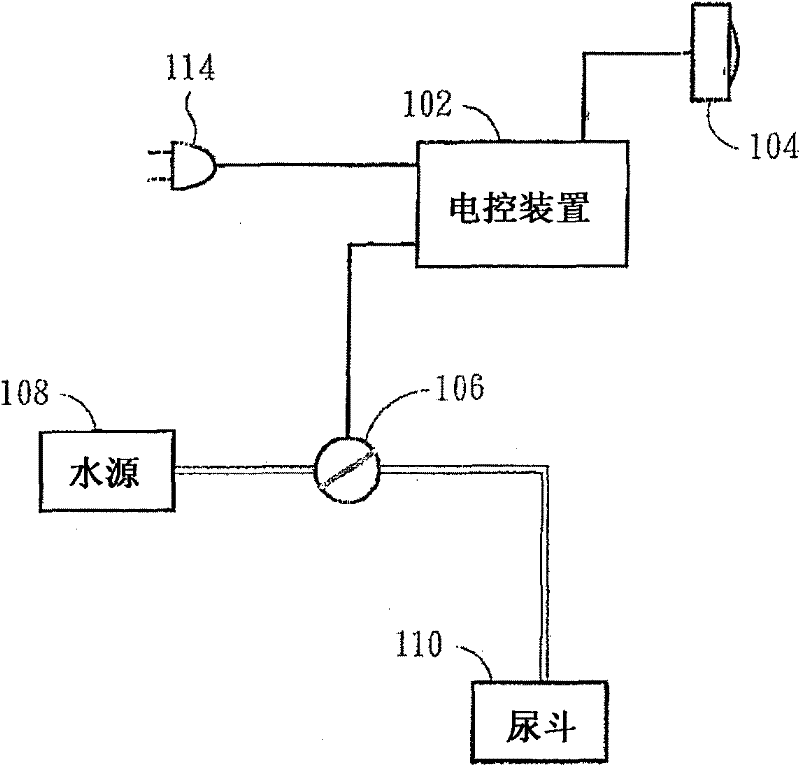

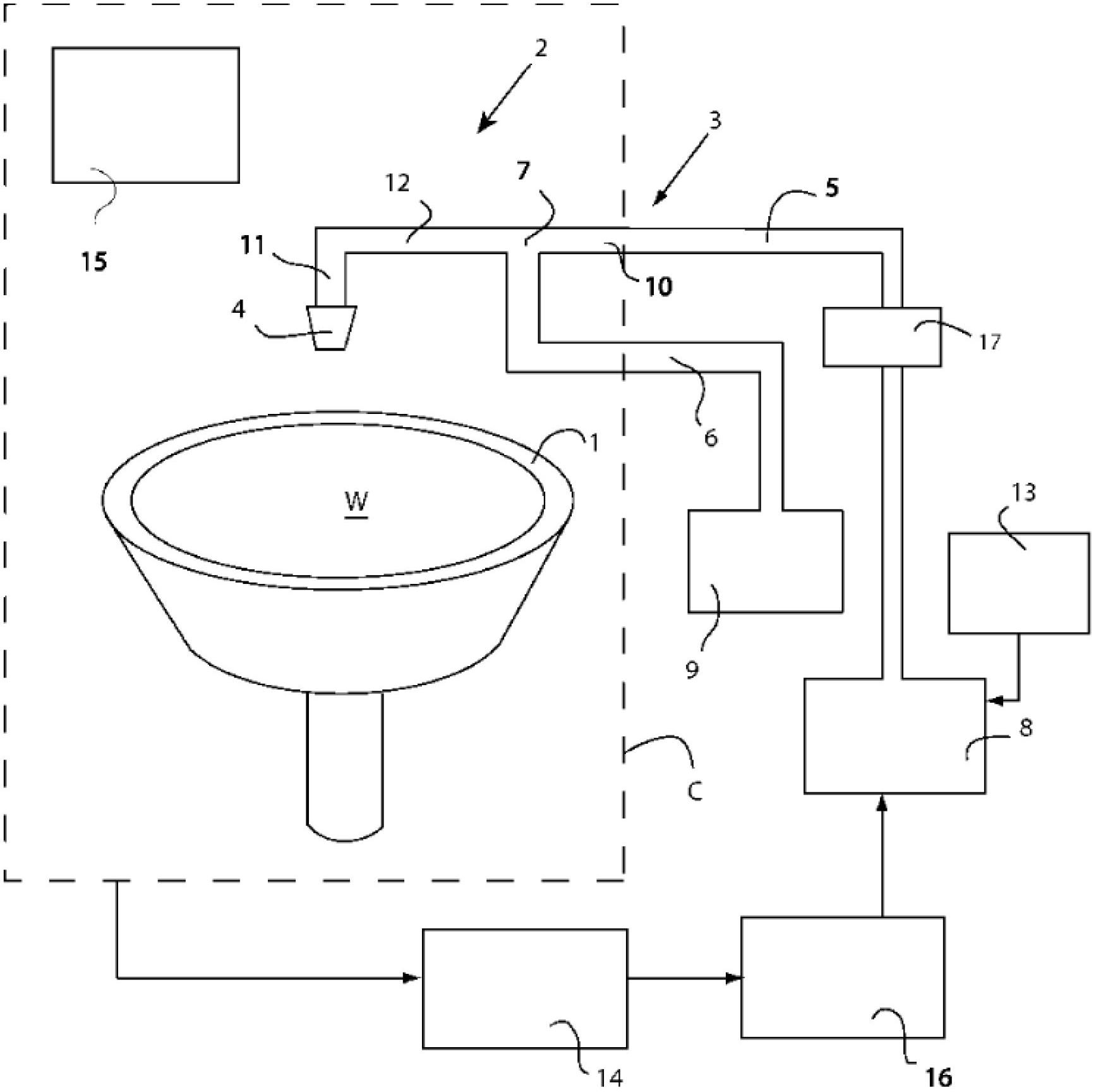

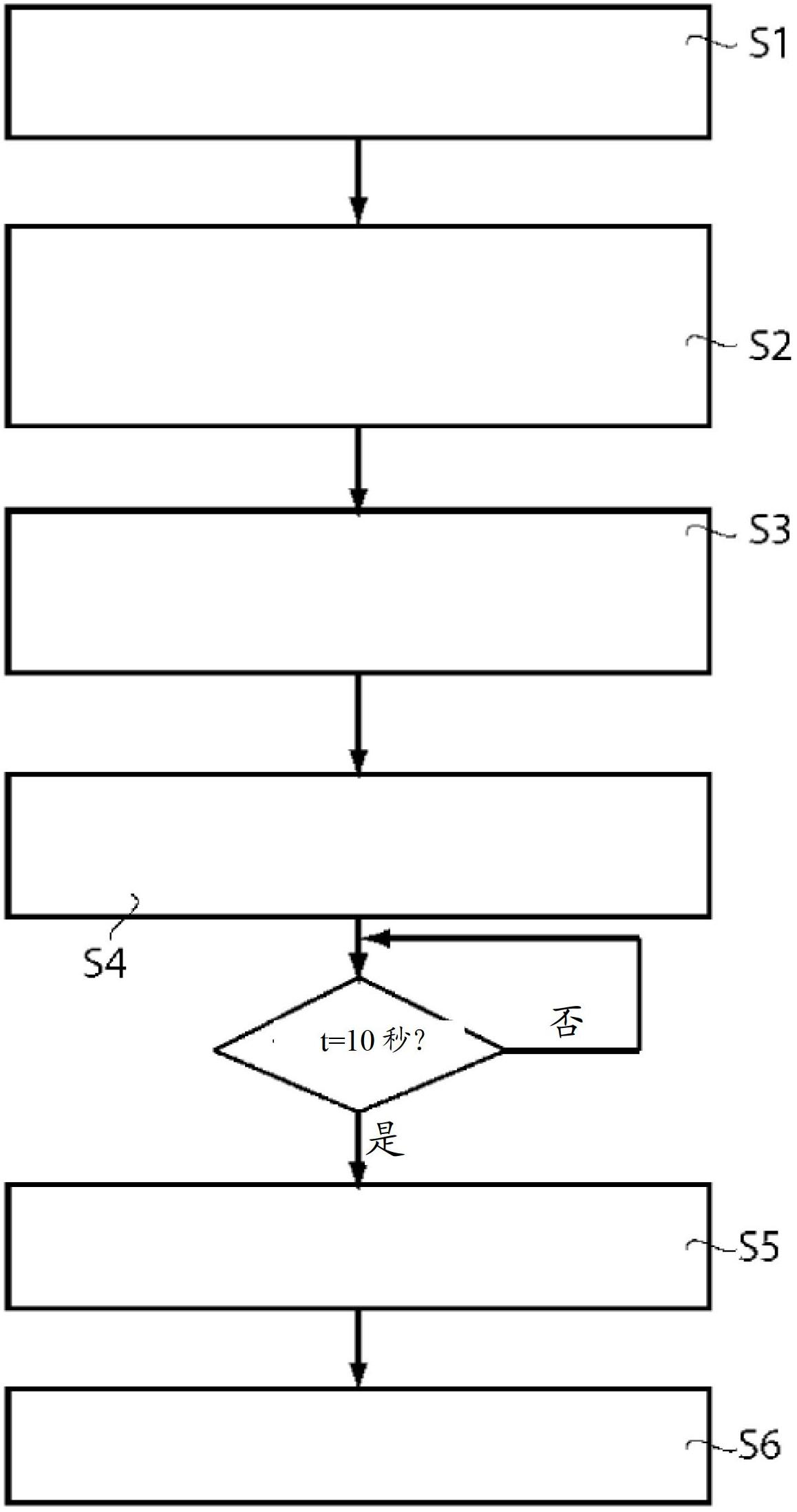

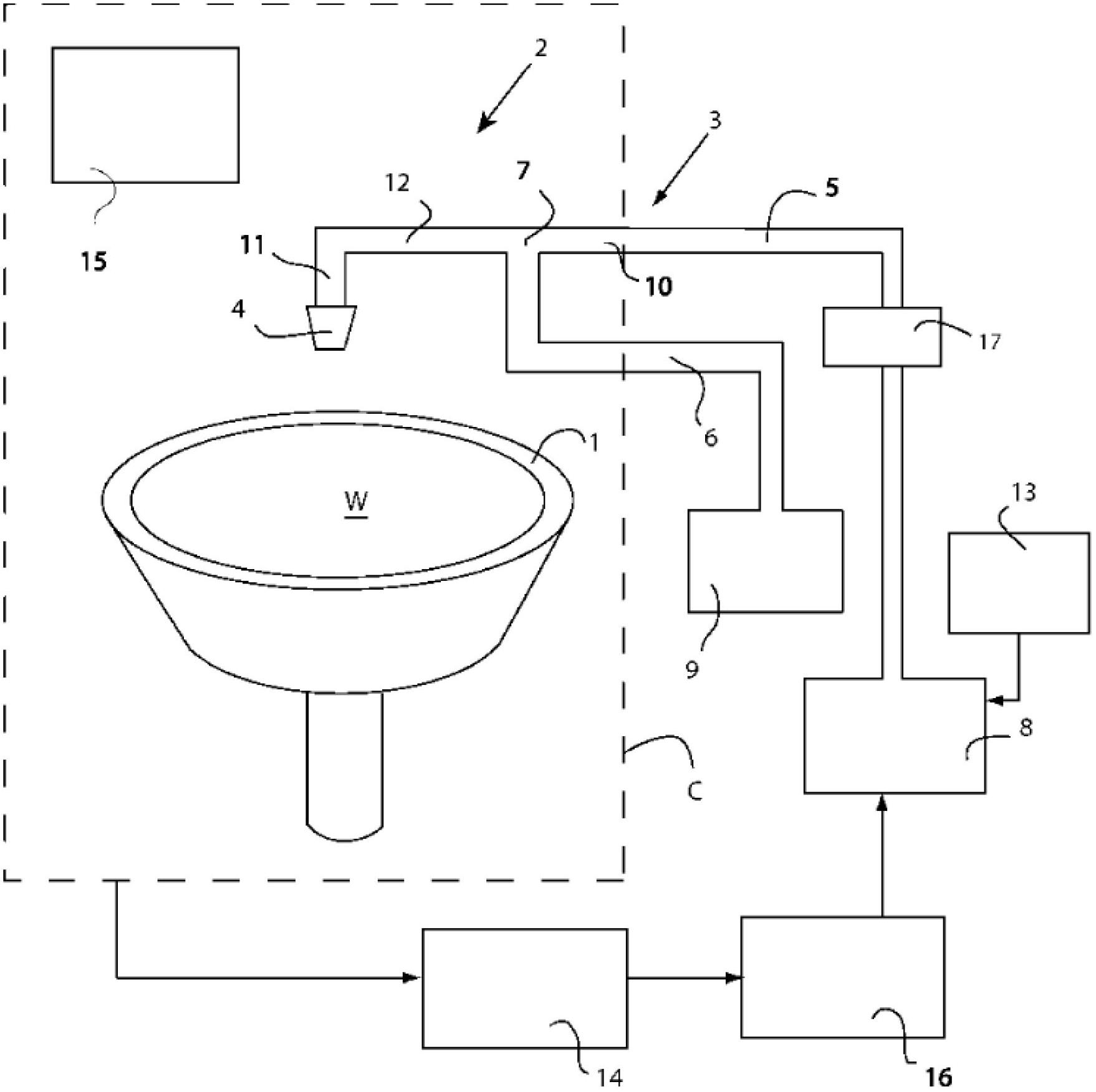

Method and device for automatically sterilizing and cleaning pedestal pan

InactiveCN102191808AFresh environmentEliminate pathogensLavatory sanitoryWater flowEnvironmental engineering

The invention provides a method and a device for automatically sterilizing and cleaning a pedestal pan. The method at least comprises the following steps of: providing the pedestal pan, an electric control device, a sensor, a switching valve, a front water pipe, an ozone device and a rear water pipe, wherein one part of the rear water pipe is higher than the ozone device, the electric control device is connected with the sensor, the ozone device and the switching valve, and the water flow is communicated with the ozone device and the rear water pipe through the switching valve and the front water pipe and reaches the pedestal pan when the switching valve is opened; when the sensor detects that a user is close to the pedestal pan, performing flushing of a first stage; when the sensor detects that the user leaves the pedestal pan, performing flushing of a second stage, wherein the ozone device generates ozone water to flush the pedestal pan; and finally, closing the switching valve by the electric control device in the predetermined time. Other agents are not needed in the device, and only a little ozone is dissipated to the air so that possible human body discomfort caused by gaseous ozone can be avoided.

Owner:HAN YANG APPLY MATERIAL TECH

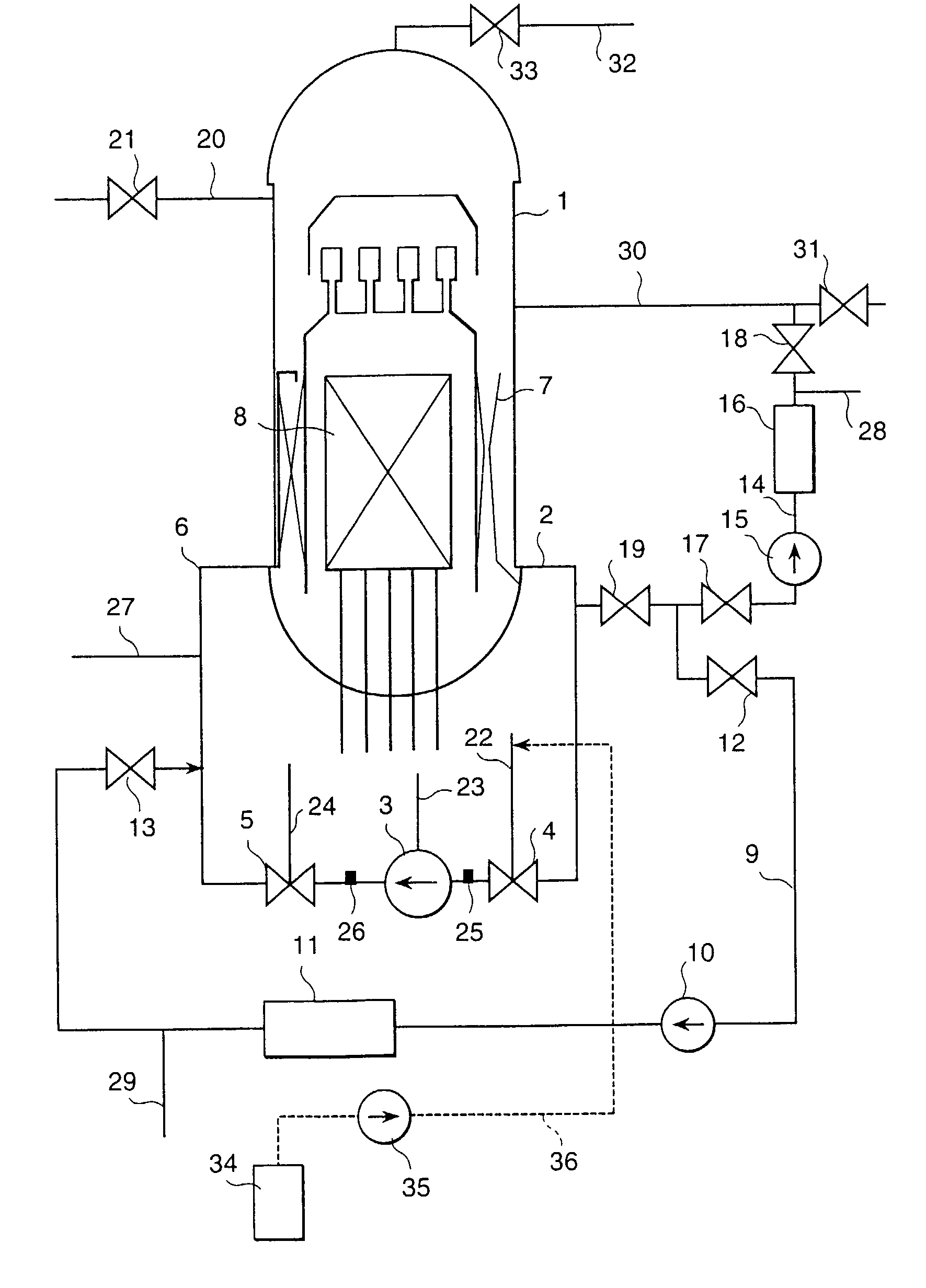

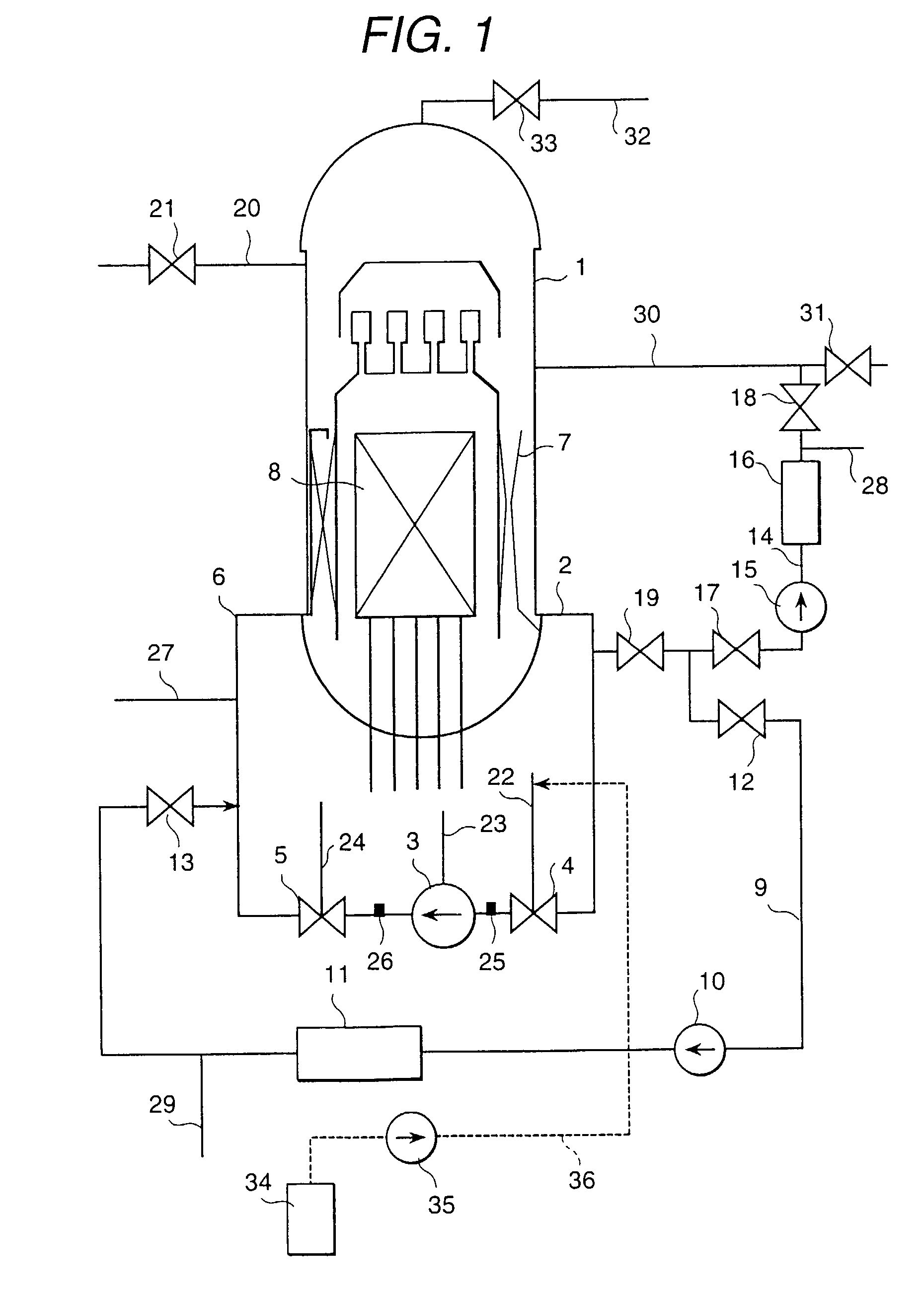

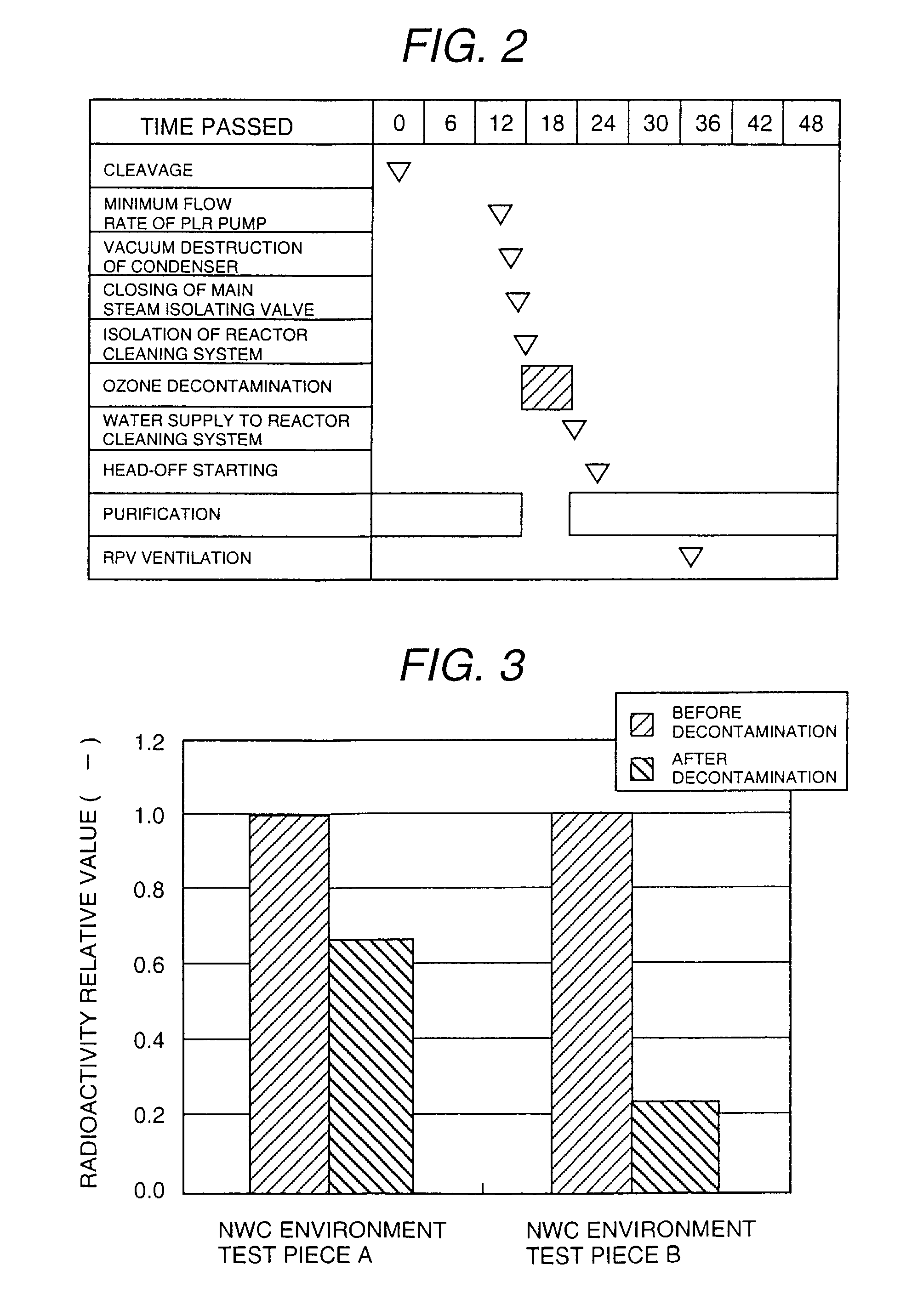

Method of decontaminating by ozone and a device thereof

InactiveUS20030058982A1Remove most of radioactive materialsEasily decomposed into oxygenNuclear energy generationWater/sewage treatment by ion-exchangeRadioactive agentGaseous ozone

The present invention provides a simple and inexpensive decontaminating method without producing any secondary waste due to decontamination. A method comprising steps of evaporating liquid ozone, feeding the gaseous ozone into a re-circulation line 2 in the upstream side of the re-circulation pump 3 to make ozone-rich water, circulating the ozone-rich water in the reactor-water re-circulation system, and remove radioactive materials from metallic surfaces.

Owner:NAGASE MAKOTO +4

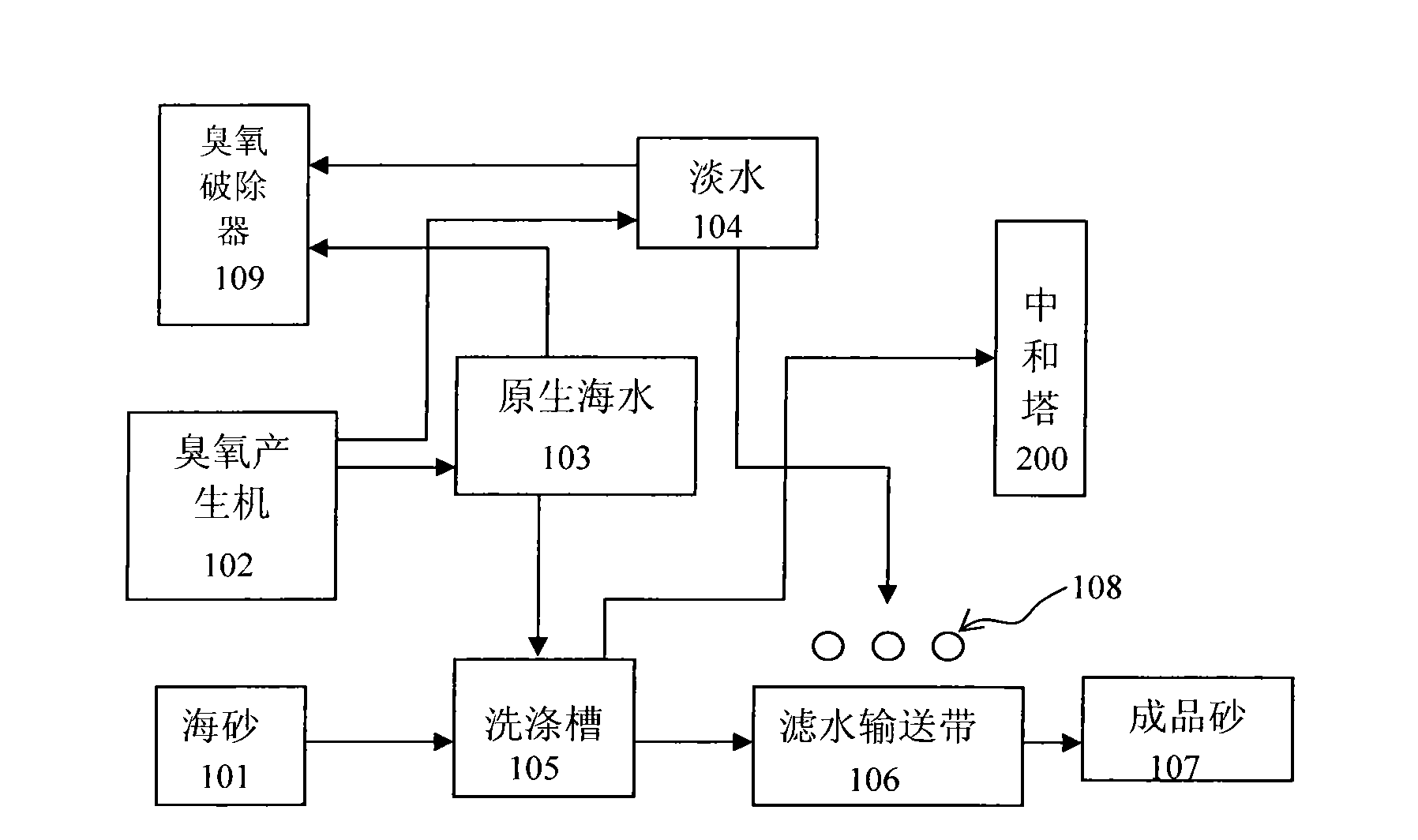

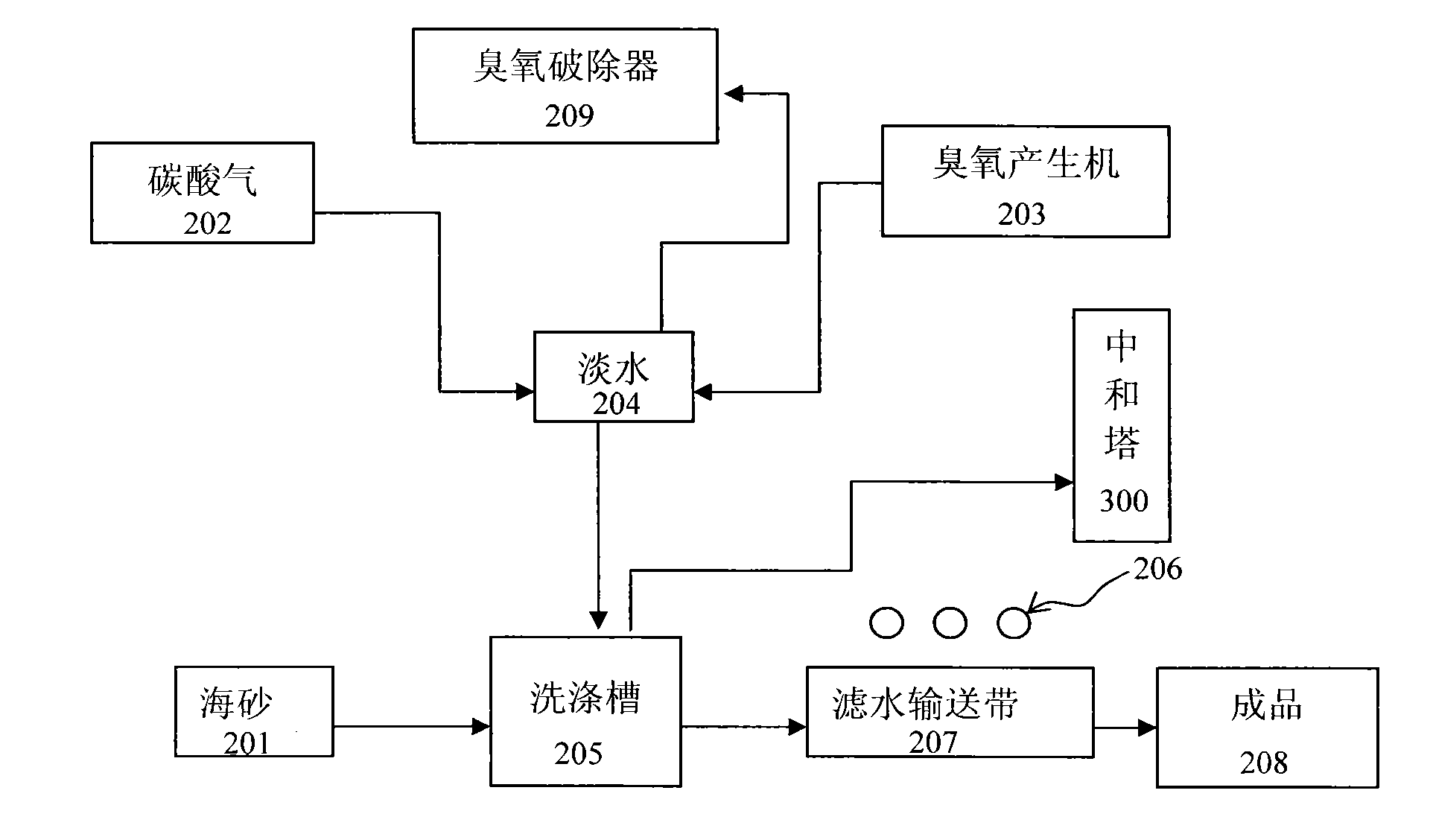

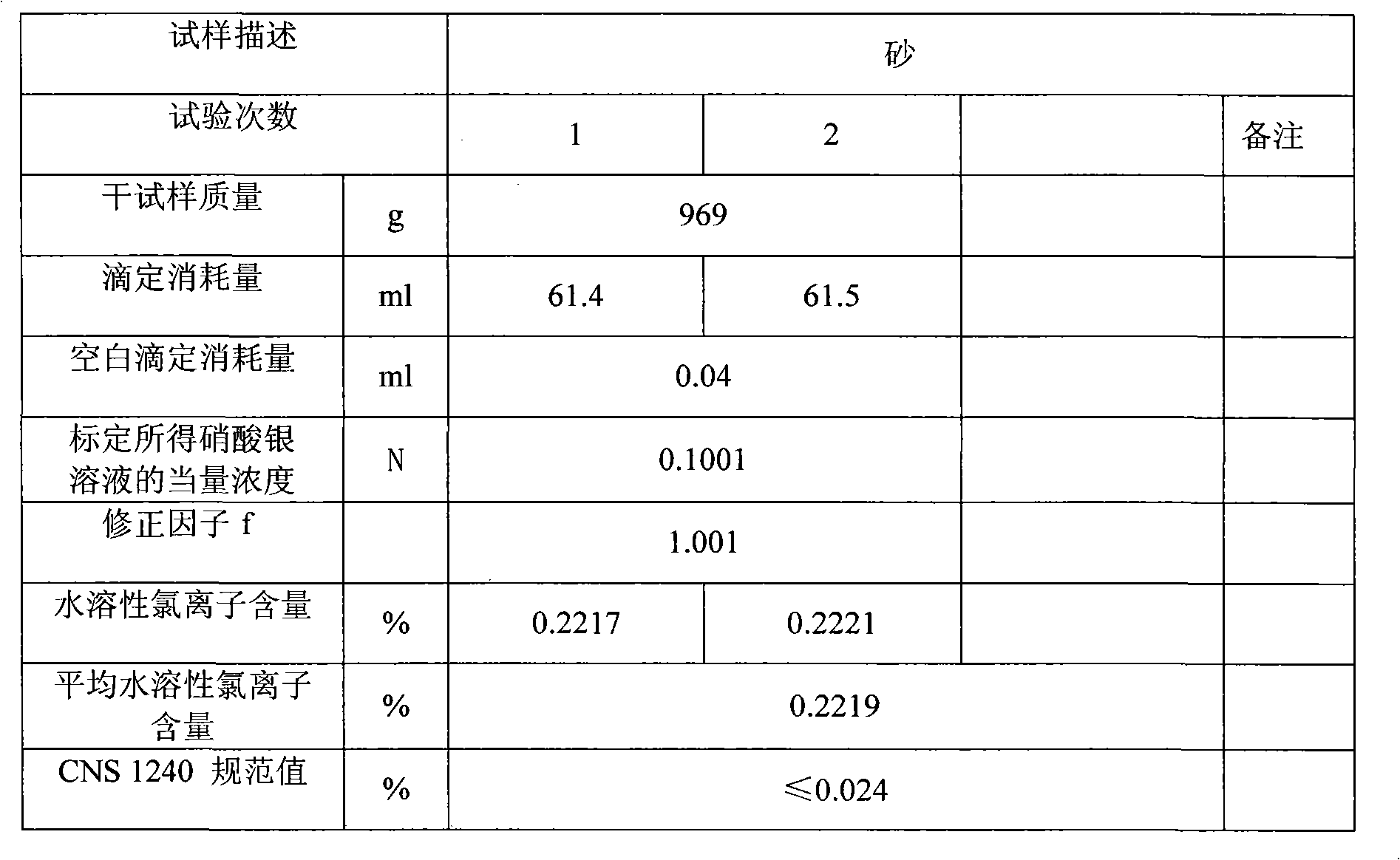

Method for supercritically washing sea sand, river sand and hill sand

InactiveCN101537414AOvercome physical propertiesReduce viscosityCleaning using liquidsHigh concentrationHazardous substance

The invention discloses a method for supercritically washing sea sand, river sand and hill sand, which mainly applies two-phase coexistence washing water formed by mixing gaseous ozone, carbonic acid gas and liquid water, overcomes the capillary phenomenon caused by physical characteristics viscosity and surface tension of water, and generates supercritical washing to remove substances on the surface of the sea sand which are harmful to cement, reinforcing steel bar and the like, such as chloride, sulfate, organic substances, algae and the like. The ozone as a strong oxidizing agent plays a role in decomposing the organic substances, so when high-concentration ozone water is used as washing water, the ozone water has high efficiency and low cost in removing harmful ions of the sea sand or the river sand, and has the characteristic of no harmful substance residue; and the washed sea sand does not have odor, and has low content of ash, and can become high quality sand for construction and engineering.

Owner:汤奇岳

Refrigerator Crisper and Ozonation System and Method

ActiveUS20140342064A1Delaying postharvest produce deteriorationSufficient sizeFruit and vegetables preservationMilk treatmentOzone generatorEnvironmental engineering

A crisper drawer for postponing postharvest produce deterioration having a drawer housing that substantially defines the size and shape of the crisper drawer and fits within a residential refrigerator. A chamber within the drawer housing is cooled by the refrigerator. An ozone generator provides gaseous ozone to the chamber, and an ethylene scrubber reduces levels of ethylene in the chamber. An ozone level control with the ozone generator controls ozone levels.

Owner:ARRIGO VINCENT

Method of descenting hunter's clothing

A method for removing the human scent and any other scent that is not advantageous to the environment you are in from clothing and equipment used by sportsmen by the use of gaseous ozone or hydroxyl and hydroperoxide ions. The gas is applied directly or indirectly to the clothing, equipment and body while the hunter is in the field and / or prior to or after the hunt. The method can also be used by fishermen to eliminate fish odor. The method of delivering a gas in compressed / generated form from a container.

Owner:PARAH

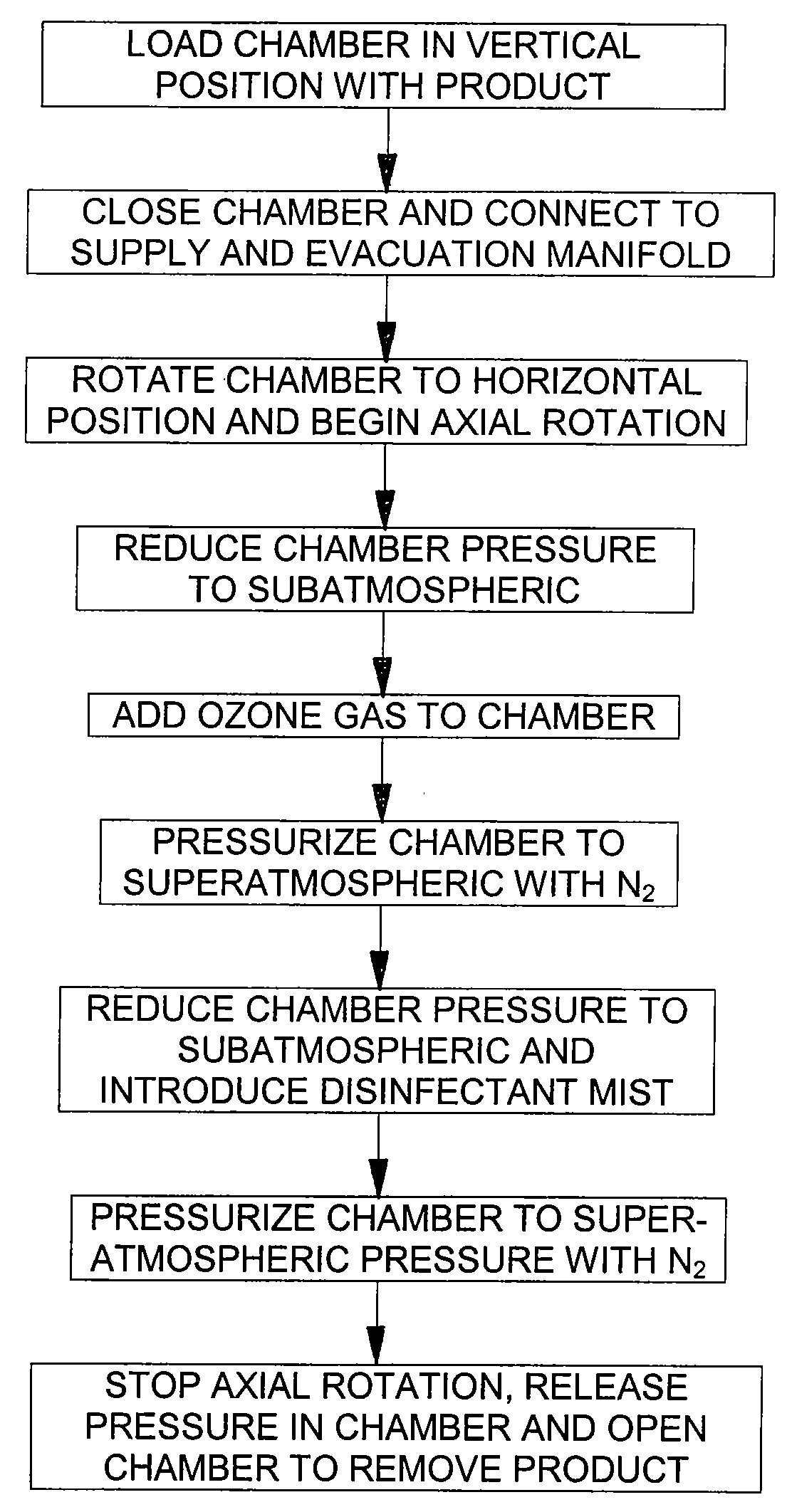

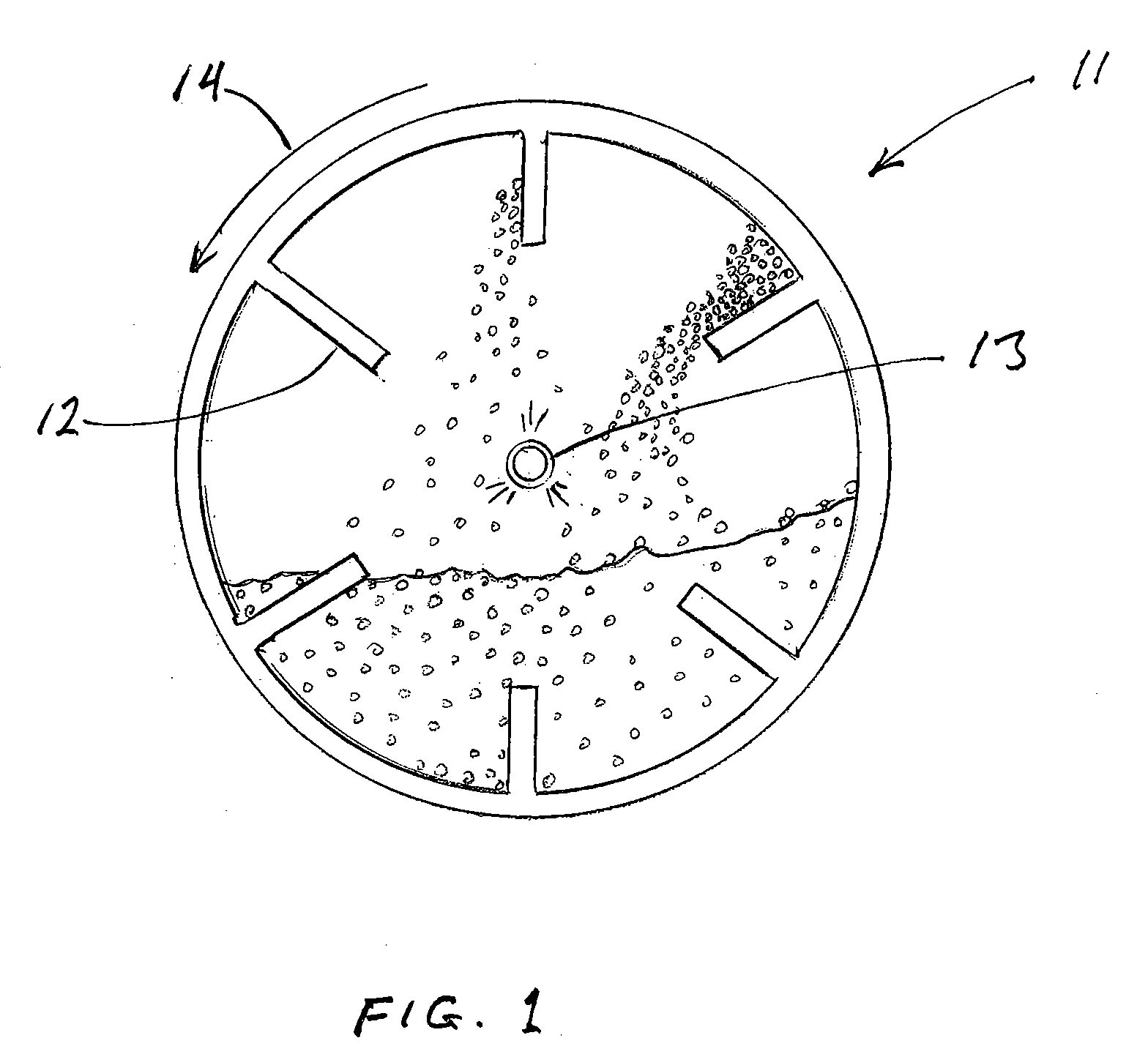

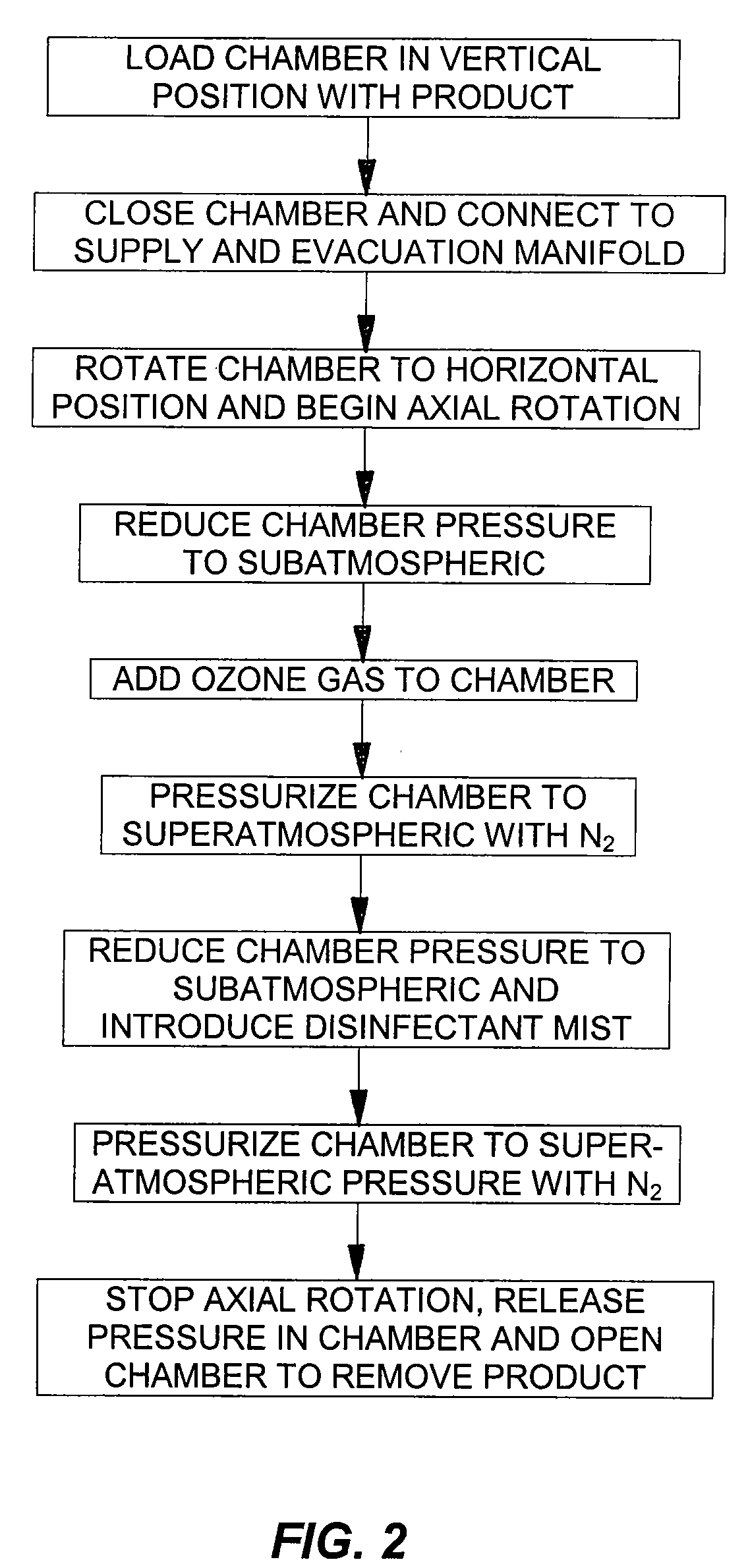

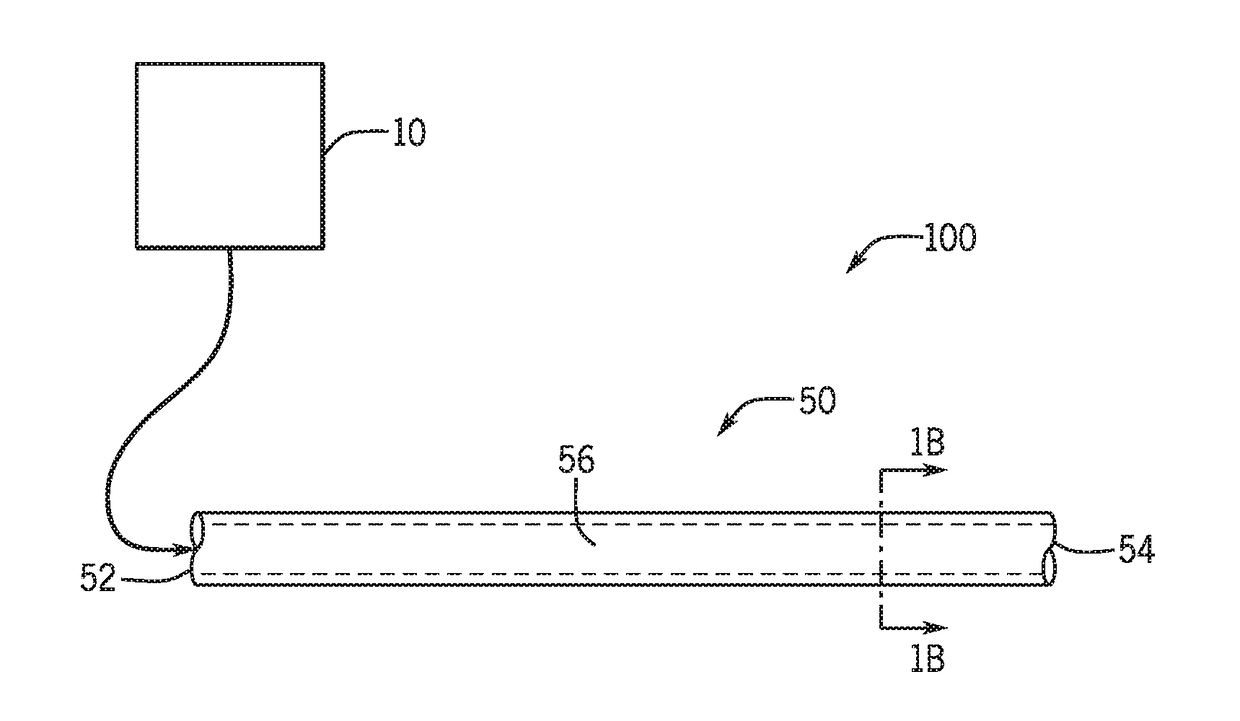

Disinfection of dried foodstuffs

Nuts, grains, seeds and other dry or dried foodstuffs are disinfected by a process that entails infusion with gaseous ozone and treatment with liquid non-ozone disinfectant, each treatment being preceded by a decompression of the foodstuffs to a pressure below atmospheric and each treatment utilizing an inert gas to achieve the exposure to the treatment agents at a pressure above atmospheric. The process achieves control of infestations at substantially all stages of the life cycle of pests, bacteria, and mold byproducts with which the product may be infested, and can do so in less than an hour.

Owner:INVENX

Sustained-release ozone sol and preparation method applications thereof

The invention provides a sustained-release ozone sol. The slow-released ozone sol comprises ozone with the concentration of 0.5-30mg / L, peptizator with the concentration of 0.1-10mg / L and stabilizer with the concentration of 0.01-1g / L. Through the sustained-release ozone sol, the half life of ozone in water can be improved by more than 60 times and ozone can be slowly released; after being applied to agriculture, the sustained-release ozone sol can safely and efficiently prevent soil-borne disease of crops without residues and also can effectively prevent the corrosion of gaseous ozone to the metal skeleton of facility agriculture greenhouse. The preparation method is simple and is easy and convenient to operate.

Owner:BEIJING UNIV OF AGRI

Apparatus for Ozone Gas Disinfection of Closed Conduits

PendingUS20180193507A1Improve disinfection effectShort exposure timeWater treatment parameter controlSpecific water treatment objectivesGaseous ozoneChemistry

Methods and systems for disinfecting conduits using gaseous ozone are disclosed. The systems and methods include an ozone generation apparatus capable of producing gaseous ozone to be introduced into conduits. The gaseous ozone can then disinfect the conduit. Some embodiments of the systems and methods further comprise an ozone destruction apparatus capable of destroying the ozone after a certain stage of the disinfection process is reached.

Owner:CLEARWATER TECH

Sterilizing process of animal feed

InactiveCN103371308AHigh in nutrientsUndamagedAnimal feeding stuffFood preparationHigh concentrationAdditive ingredient

The invention relates to the technical field of disinfection methods of feeds, and particularly relates to a sterilizing process of an animal feed. The sterilizing process comprises the steps of: a, liquefying high-concentration gaseous ozone by water mist spraying to obtain high-concentration liquid ozone; b, loading a dried feed in a high-pressure sealed disinfection tank, adding the liquid ozone in the high-pressure sealed disinfection tank, uniformly stirring, simultaneously introducing the high-concentration gaseous ozone, and sterilizing by an ultraviolet lamp; c, adding quaternary ammonium salt in the disinfection tank; d, after disinfecting, introducing high-temperature steam in the disinfection tank, and stirring the feed to thoroughly remove ozone residues; and e, adding active bacteria into the disinfection tank for fermenting the animal feed. The sterilizing process is scientific, reasonable and safe, has an environment protection effect, and is strong in maneuverability, is thorough in sterilization, convenient to operate, free of toxicity, odor and irritation and strong in bacterial property as adopting a physical and chemical combined mode for sterilization; nutrient substances in the feed are protected from being damaged, nutritional ingredients of the feed increase, the feed is safe and reliable, and no economic loss is caused.

Owner:赵建军

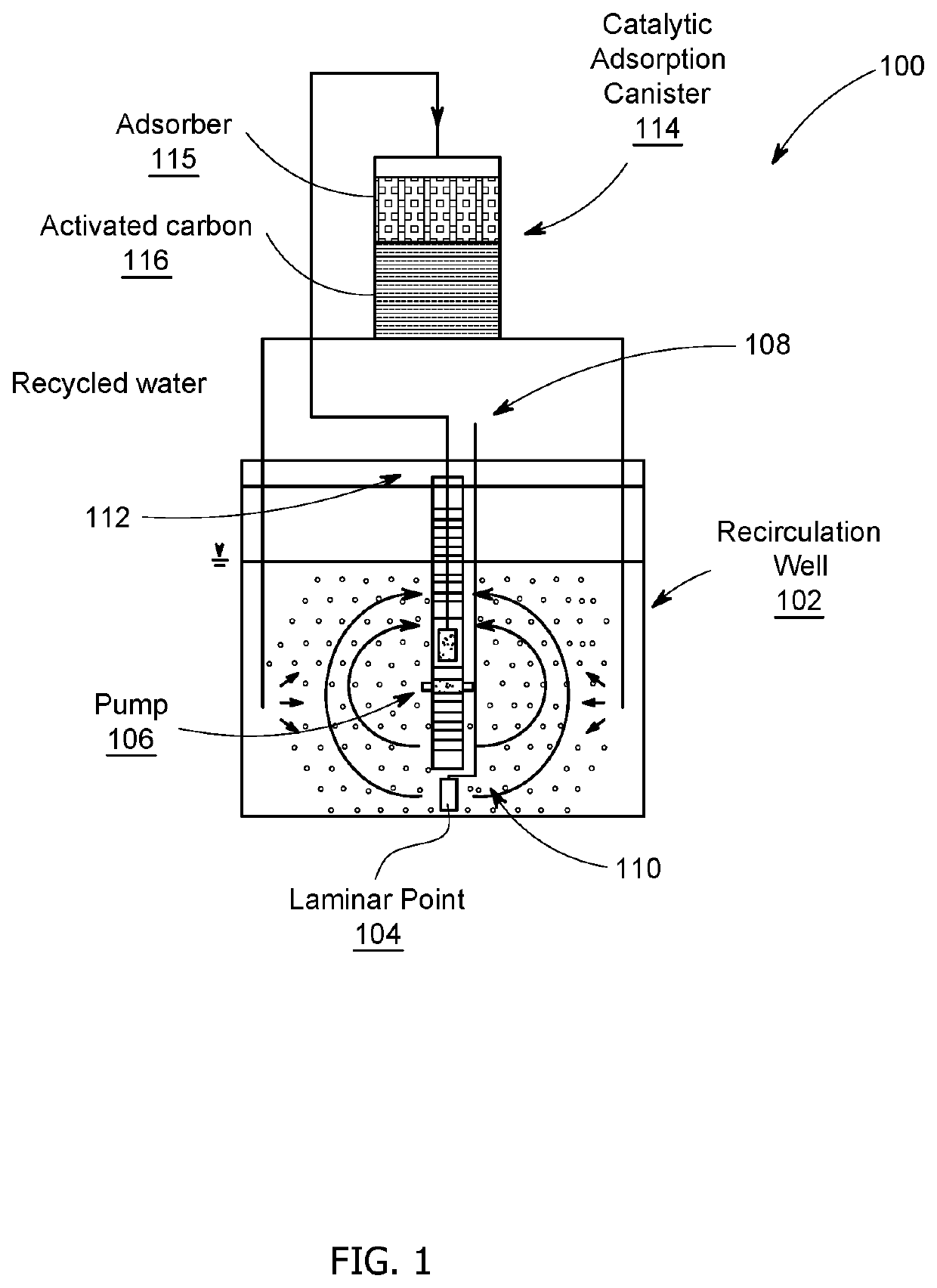

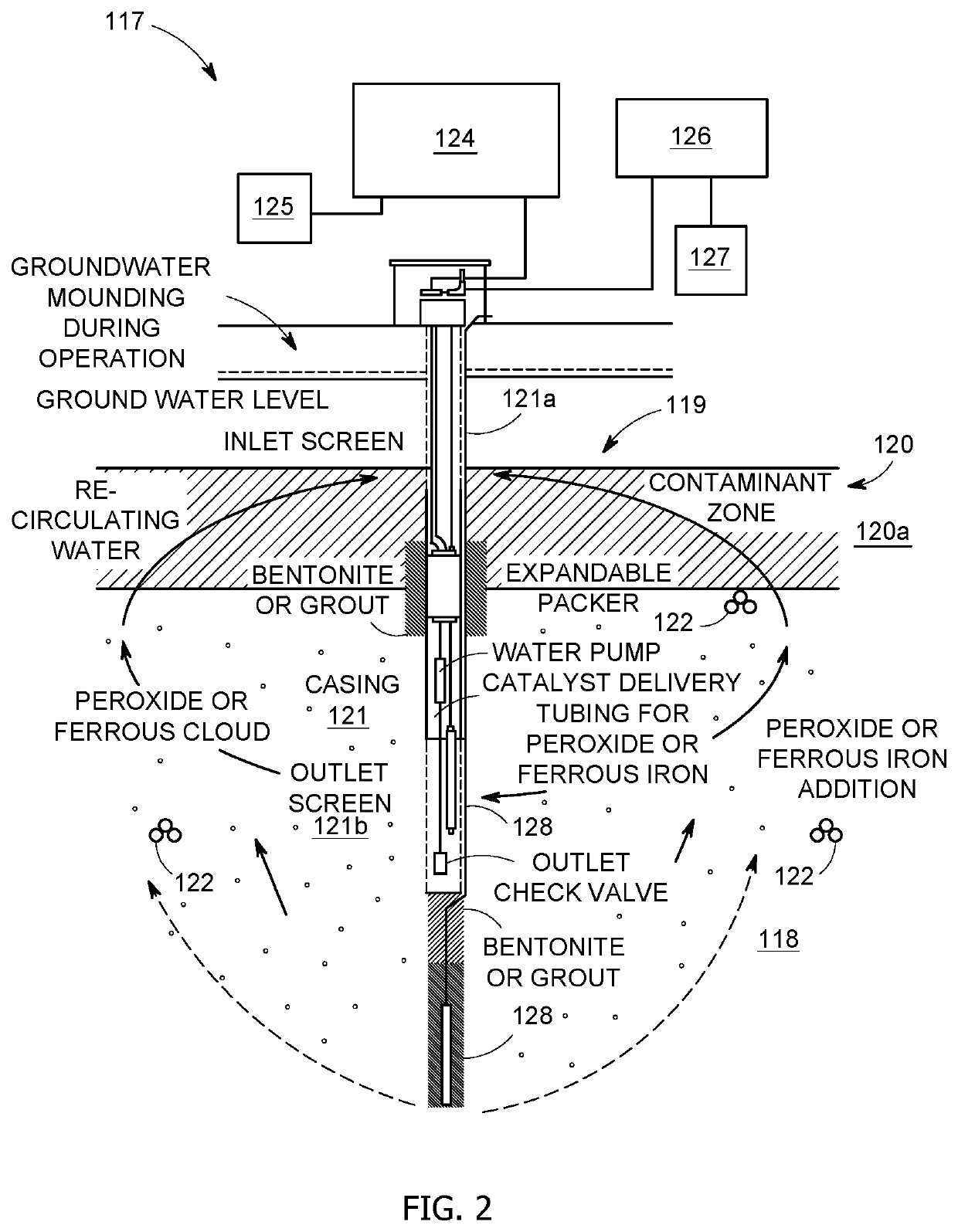

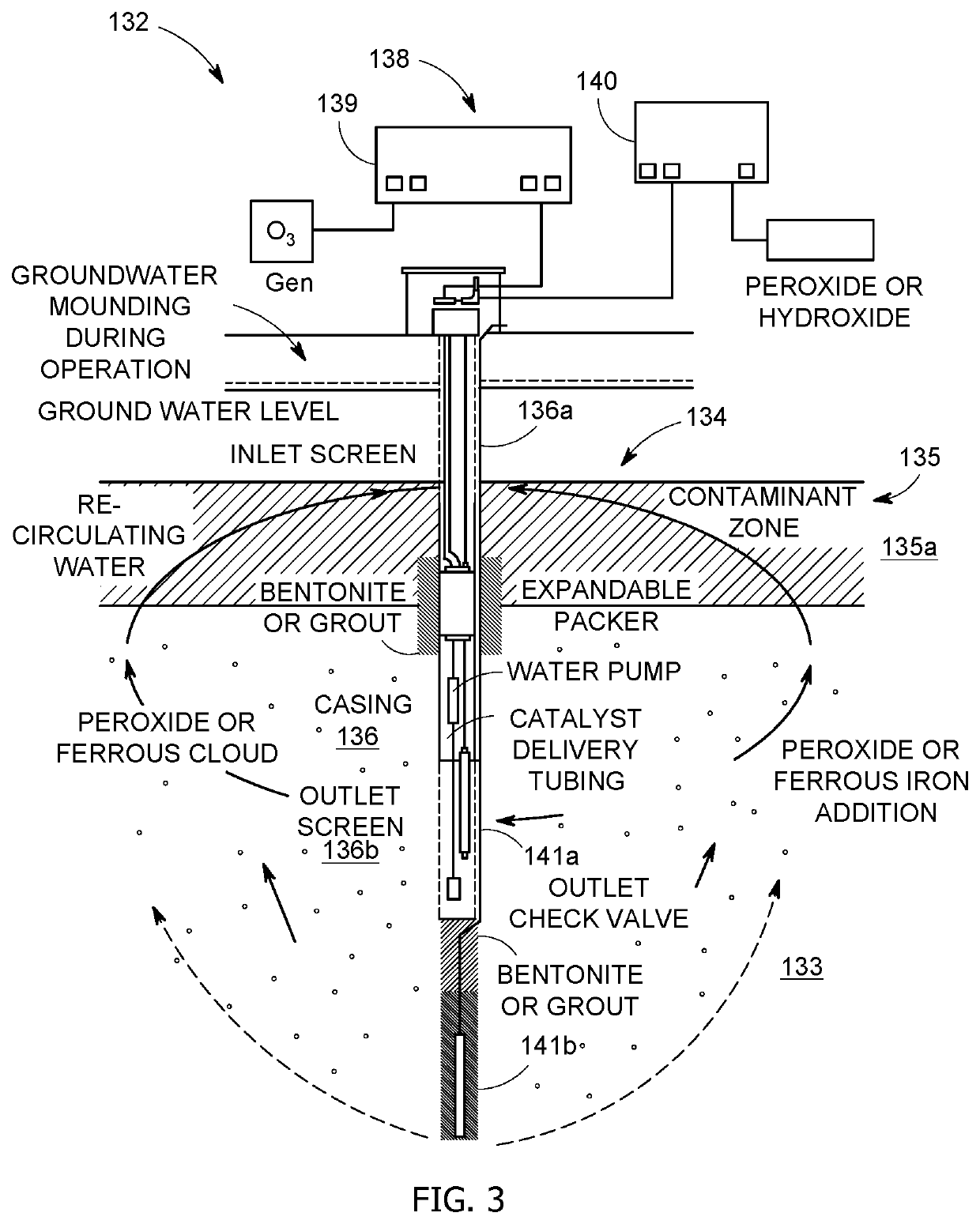

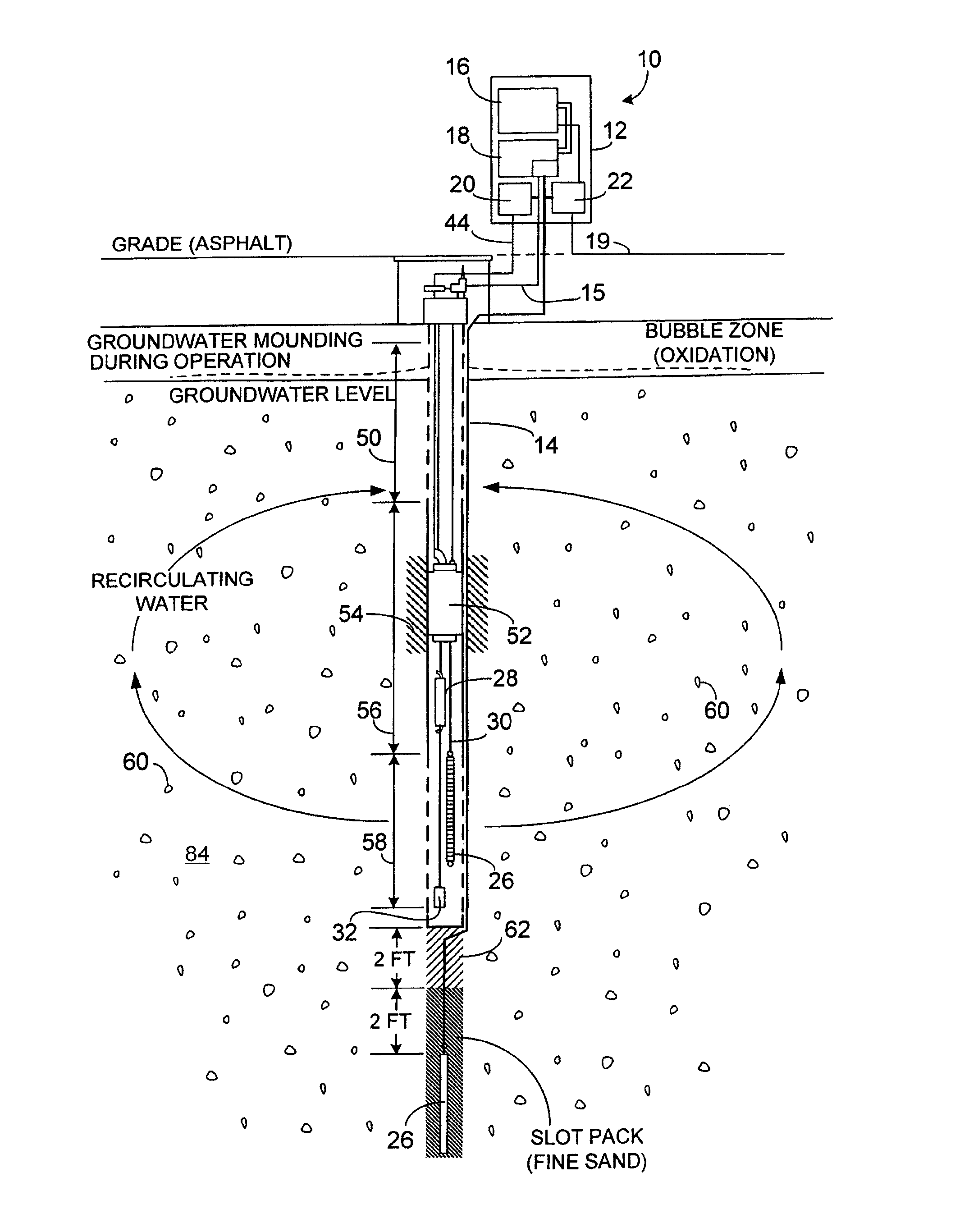

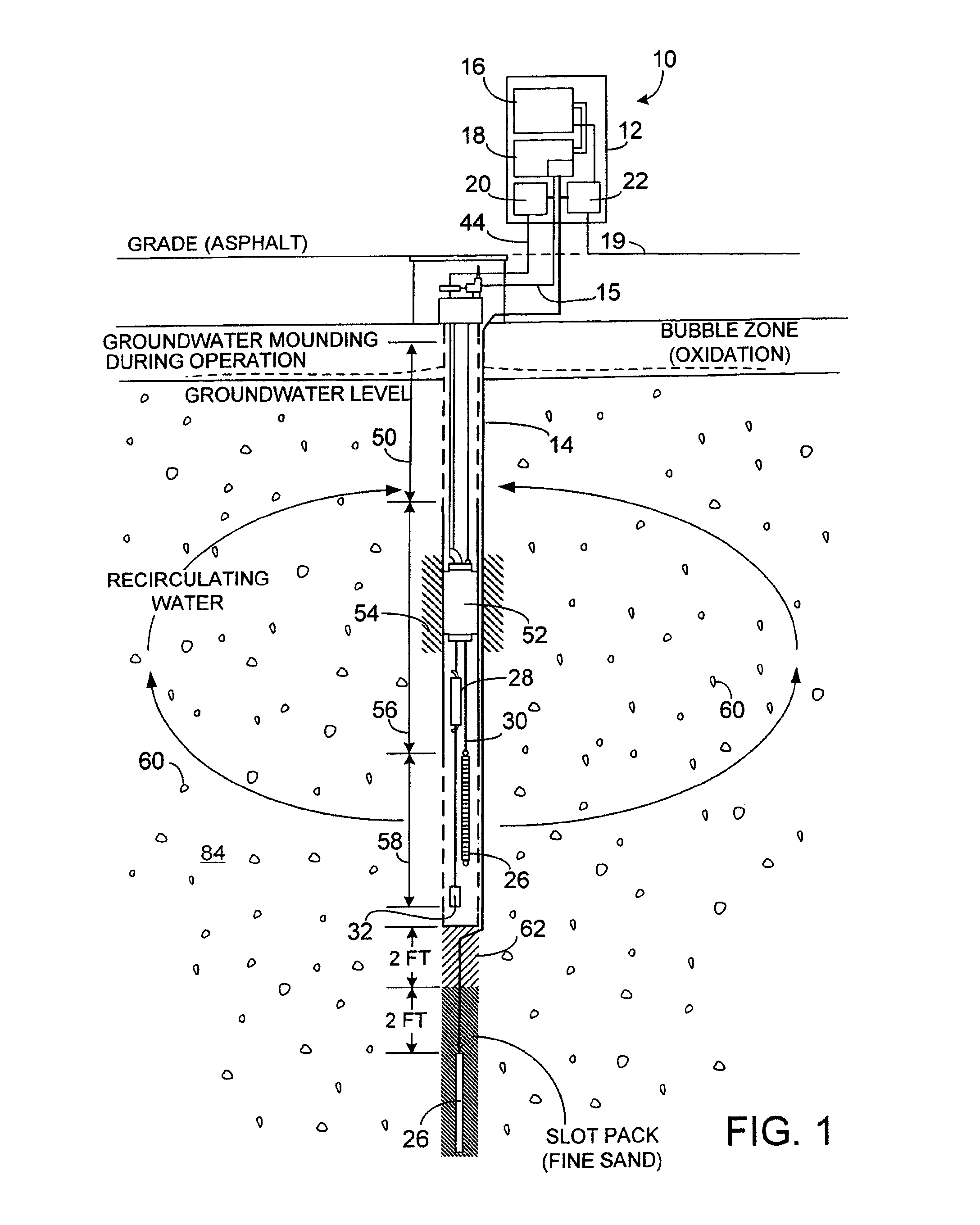

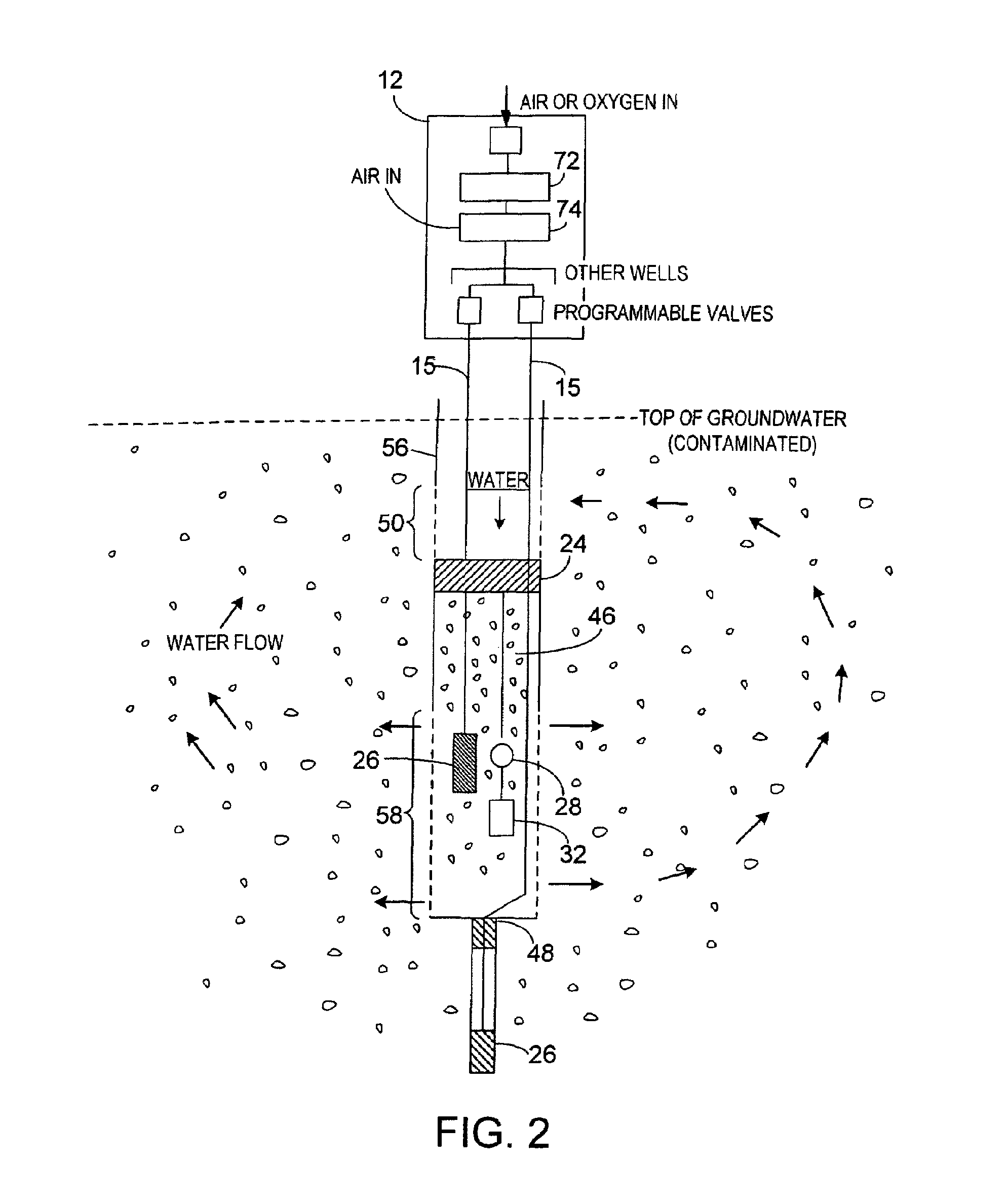

Method and apparatus for in-situ removal of per- and poly-fluoroalkyl substances

PendingUS20210130201A1Improve responseHigh removal rateWater contaminantsContaminated soil reclamationPtru catalystEnvironmental engineering

Apparatus and method for removing PFAS compounds from contaminated groundwater or soil includes a well having diffusers for injecting gaseous ozone as bubbles into water in the groundwater or soil formation, a catalytic adsorption canister having an inlet and at least one outlet coupled to the groundwater or soil formation; a control mechanism for supplying gaseous ozone to the well and the catalytic adsorption canister, and a pump in the well, the pump having an inlet for receiving groundwater from an upper portion of the well, a first outlet coupled to a lower portion of the well and a second outlet coupled to the inlet of the catalytic adsorption canister. The catalytic adsorption canister, which can also be used as a stand-alone system for ex-situ treatment of groundwater, includes a mineral catalyst to adsorb PFAS compounds, which are thereafter mineralized and decomposed by exposure of ozone bubbles.

Owner:KERFOOT TECH

Method for removing sulfur dioxide by joint oxidation of peroxyacetic acid and ozone

InactiveCN107737518AStrong oxidation abilityHigh removal rateDispersed particle separationGas phaseSulfur

The invention discloses a method for removing sulfur dioxide gas by the joint oxidation of peroxyacetic acid and ozone. The method is characterized by including the following steps: (1) sulfur dioxidegas is introduced into a reactor to react with atomized peroxyacetic acid; the molar ratio of the peroxyacetic acid to the sulfur dioxide gas is (3 to 1) to (1 to 1); reaction time is 1 to 3 seconds,and reaction temperature is 25 DEG C to 80 DEG C; (2) after reaction, gaseous ozone is introduced into the reactor for reaction; the molar ratio of the ozone to the sulfur dioxide gas is (3 to 1) to(1 to 1), and reaction temperature is 25 DEG C to 80 DEG C; (3) after reaction, the gas is absorbed by water. The method adopts the joint oxidation of the peroxyacetic acid and the ozone to remove thesulfur dioxide gas, not only is reaction simple and highly efficient, but also the sulfur dioxide removal rate is high, and a reaction product is environment-friendly.

Owner:GUIZHOU UNIV

Method and apparatus for surface treatment using inorganic acid and ozone

InactiveUS8709165B2Increase dissolved ozone concentrationHigh ozone concentrationLighting and heating apparatusSemiconductor/solid-state device manufacturingTreatment usePhotoresist

Improved removal of ion-implanted photoresist in a single wafer front-end wet processing station is achieved by dissolving gaseous ozone into relatively cool inorganic acid, dispensing the acid ozone mixture onto a wafer, and rapidly heating the surface of the wafer to a temperature at least 30° C. higher than the temperature of the acid ozone mixture.

Owner:LAM RES AG

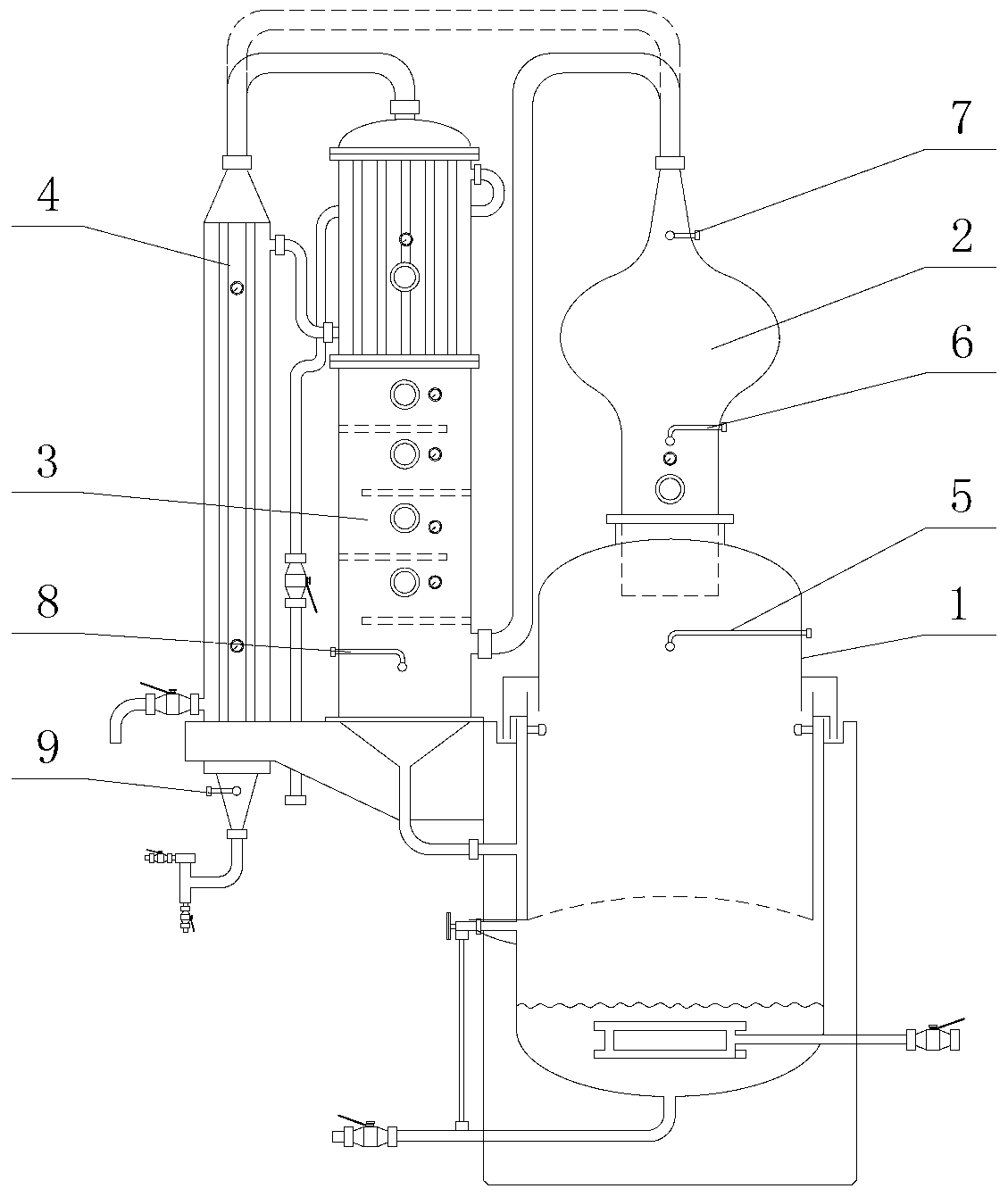

Method and device for deeply purifying distilled liquor by utilizing ozone

InactiveCN103232934AThoroughly oxidizedIncrease contact areaAlcoholic beverage preparationDistillationEnvironmental engineering

The invention discloses a method for deeply purifying distilled liquor by utilizing zone. The method comprises ventilating ozone to liquor steam. The invention further discloses a device for deeply purifying distilled liquor by utilizing ozone. The device comprises a distillation kettle and a condensing tower which are connected with each other, wherein an ozone adding tube I is connected to the kettle head of the distillation kettle; and a gas outlet of the ozone adding tube I is formed in the middle part of the kettle head o the distillation kettle. According to the method and the device for deeply purifying distilled liquor by utilizing ozone, the gaseous ozone and liquor steam are sufficiently mixed, so that the gas-steam mixing contact area is extremely large, and the ozone utilization rate is greatly improved; and the gas-steam mixing does not have ozone dissolving limit, so that the adding amount of the ozone can be adjusted according to the practical needs, and therefore, the purpose of deeply distilling liquor is achieved.

Owner:李建东

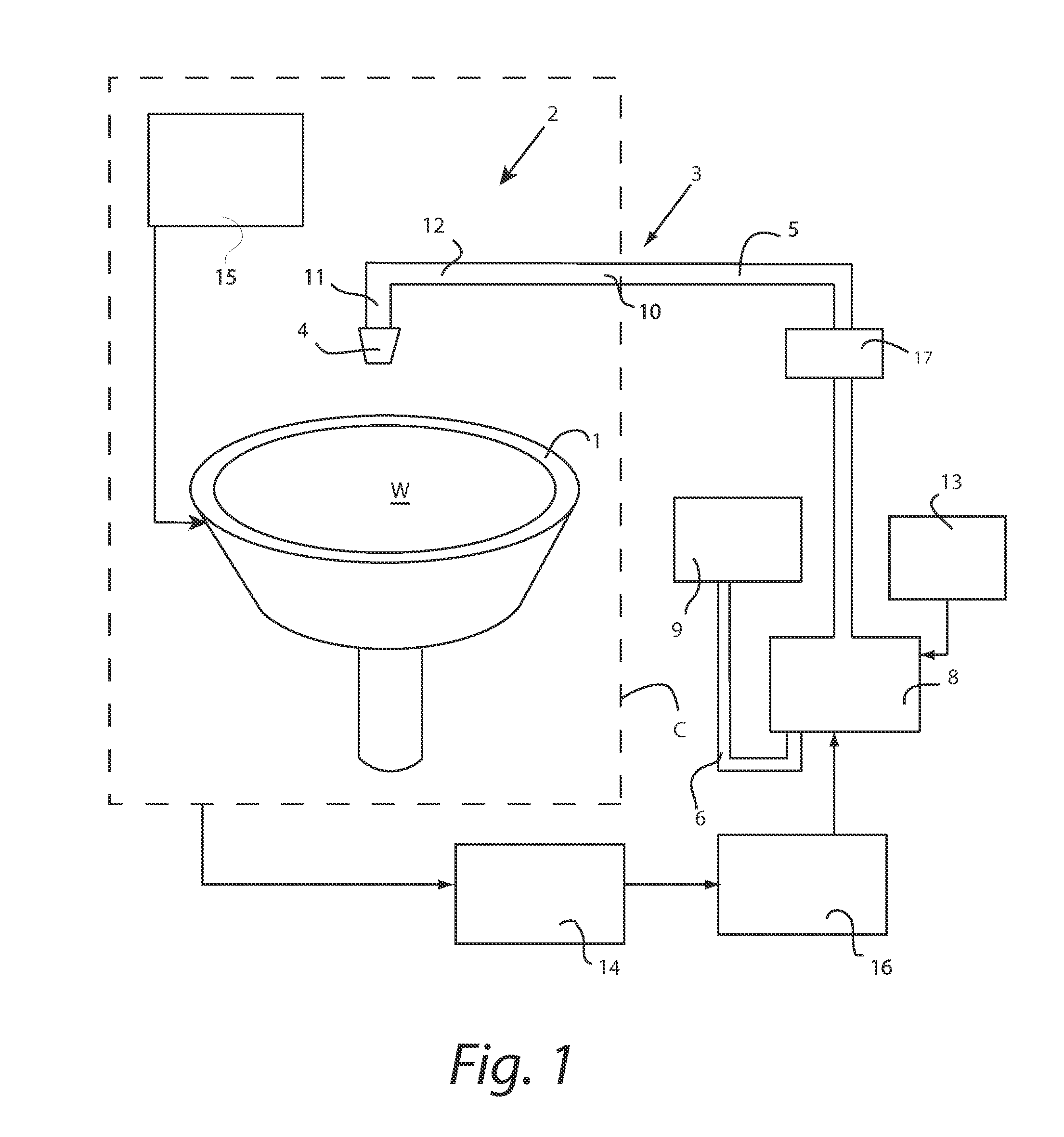

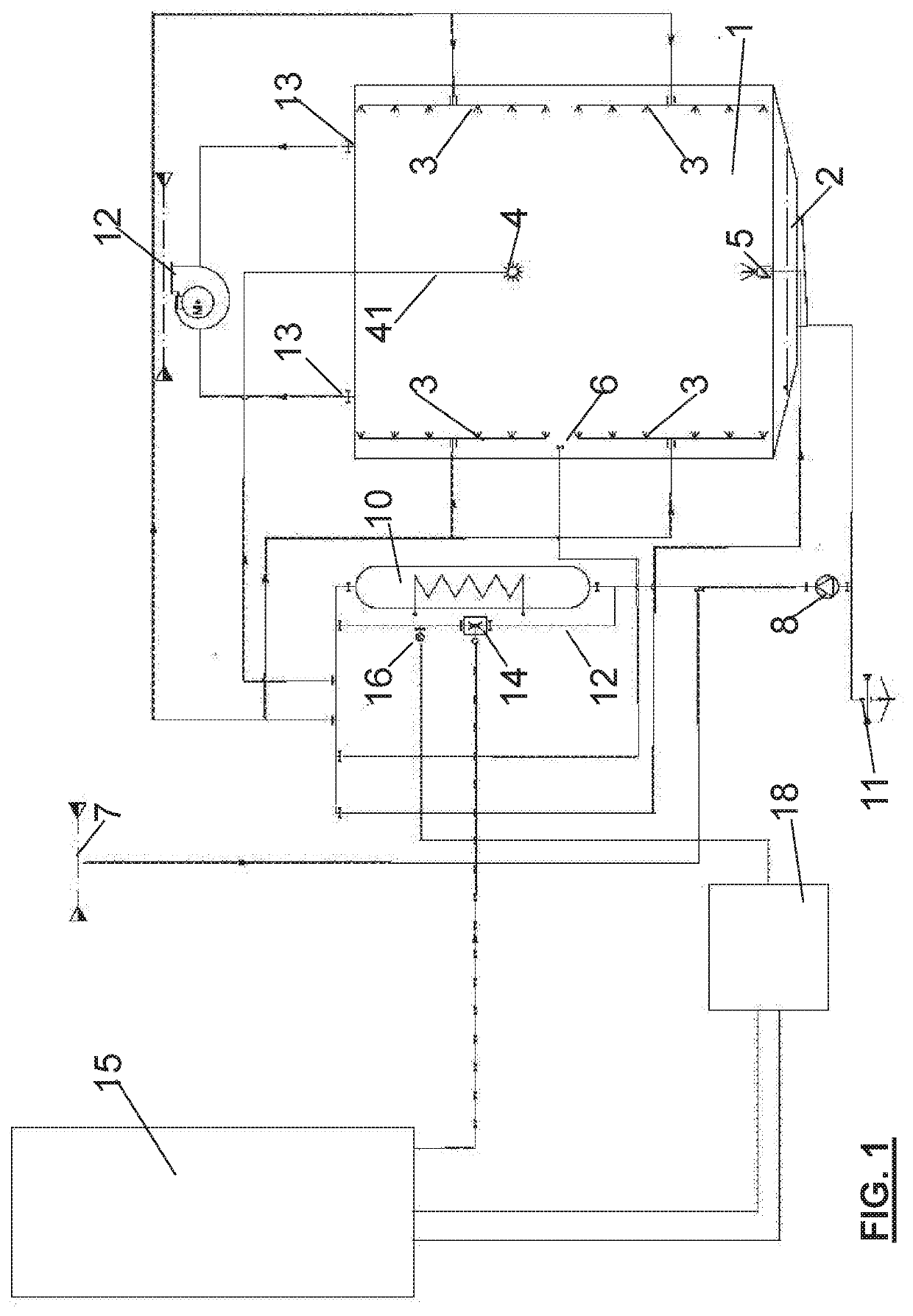

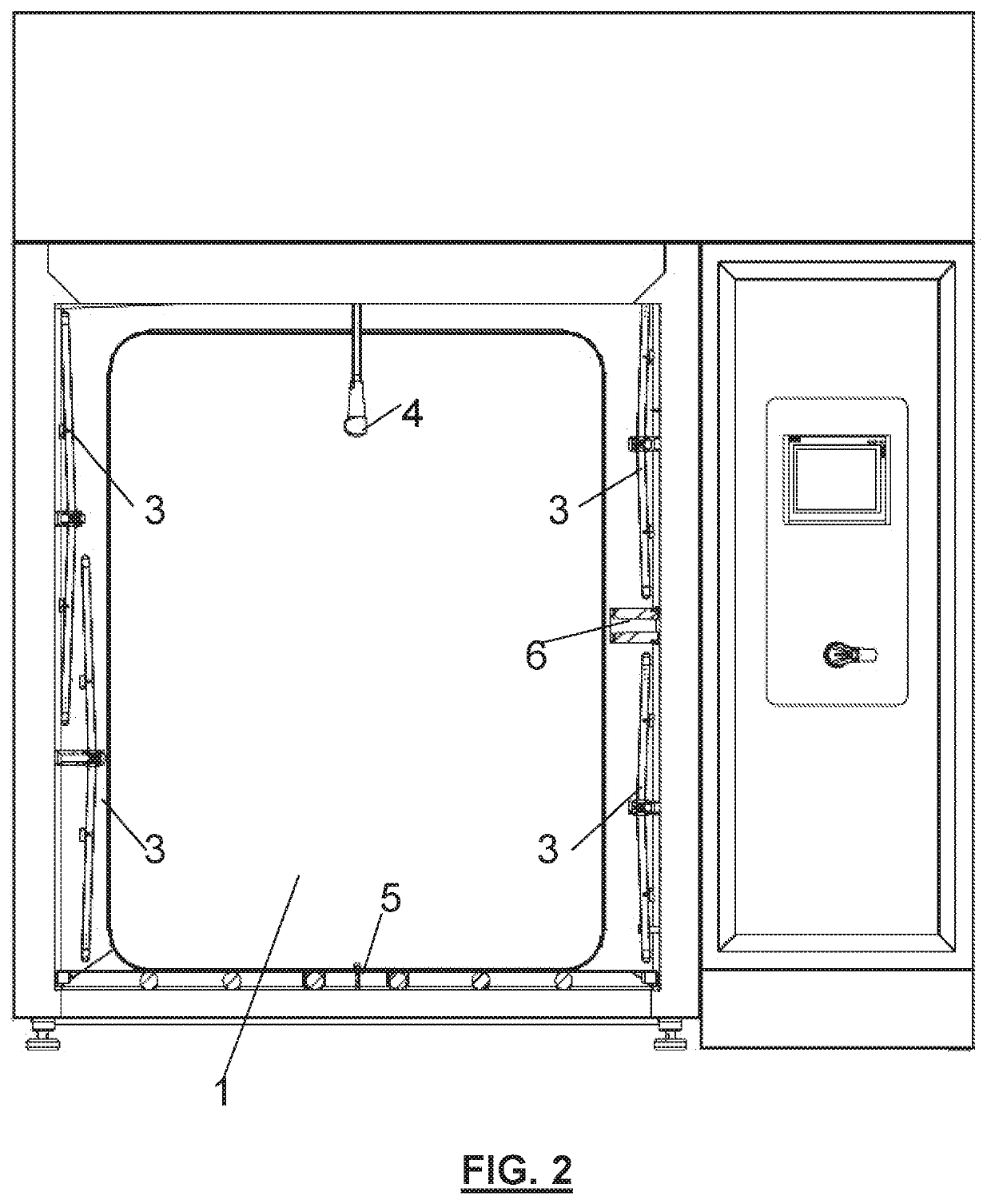

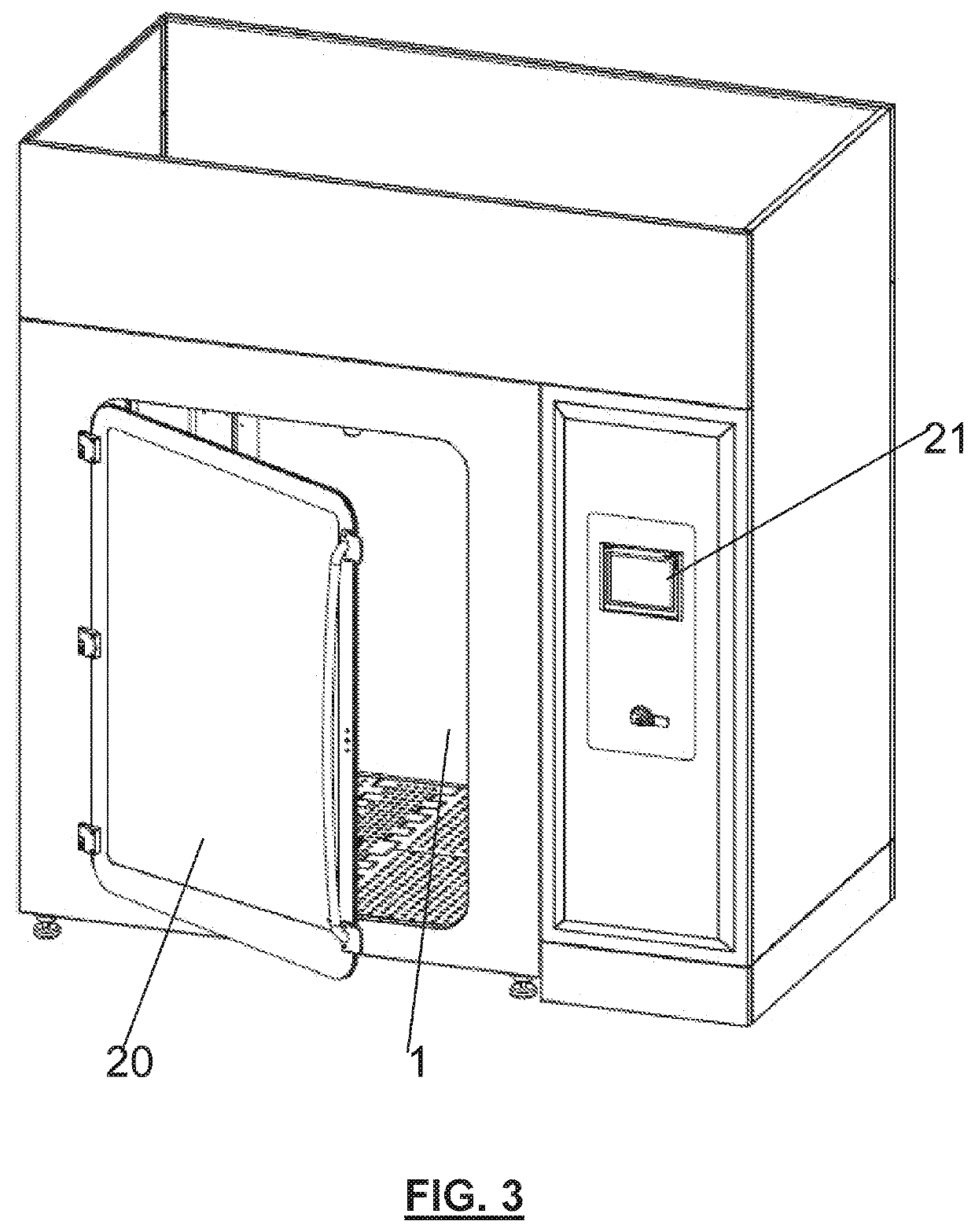

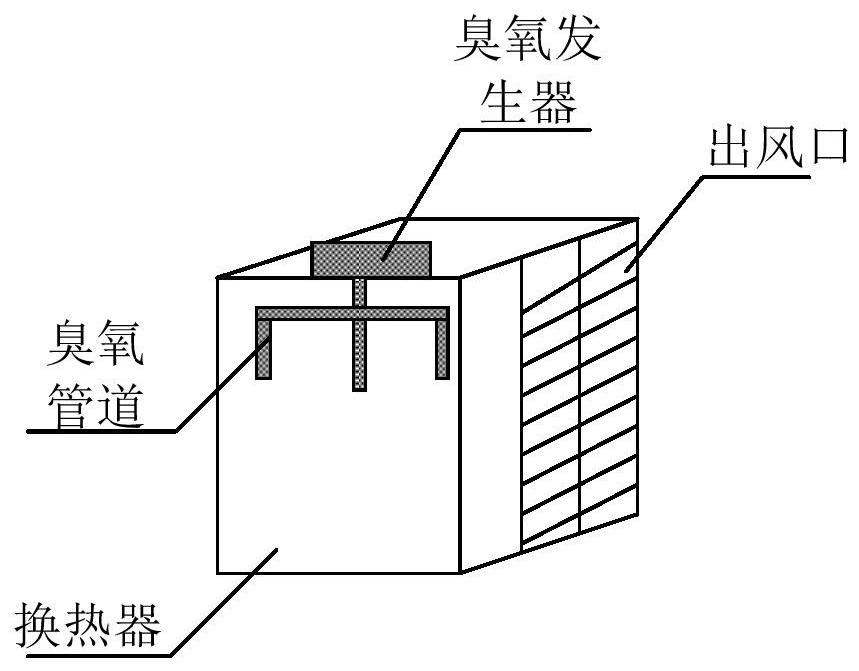

Washing appliance adapted for application in pharmaceutical production and/or preclinical pharmaceutical research centres, for washing parts and components for pharmaceutical production, and method of use of the appliance

InactiveUS20190358682A1Exemption stepsCleaning using liquidsChemicalsControl systemHydraulic circuit

A washing appliance for application in pharmaceutical production and / or preclinical pharmaceutical research centres, and for the execution of washing / rinsing steps on parts and components for pharmaceutical production, comprising a hydraulic circuit for the circulation of washing / rinsing liquid and a recirculation pump in the hydraulic circuit, comprising:a wash chamber adapted to contain said parts and components for pharmaceutical production to be washed, said chamber comprising one or two hermetically closed access doors;one or more washing systems, internal to the wash chamber and connected to said hydraulic circuit, and adapted to supply wash liquid into the chamber;an accumulation basin at the bottom of the wash chamber, for accumulating the washing / rinsing liquid, connected to said recirculation pump;a heat exchanger for heating or maintaining the temperature of the washing / rinsing liquid received through said recirculation pump and supplied to said one or more washing systems;a generator of gaseous ozone;a mixer adapted to mix said gaseous ozone with the washing / rinsing liquid and arranged in said hydraulic circuit;a control system adapted to control said washing / rinsing steps of the appliance, and adapted to control said gaseous ozone generation system for mixing said gaseous ozone during any one of said washing / rinsing steps of the appliance.

Owner:IWT SRL

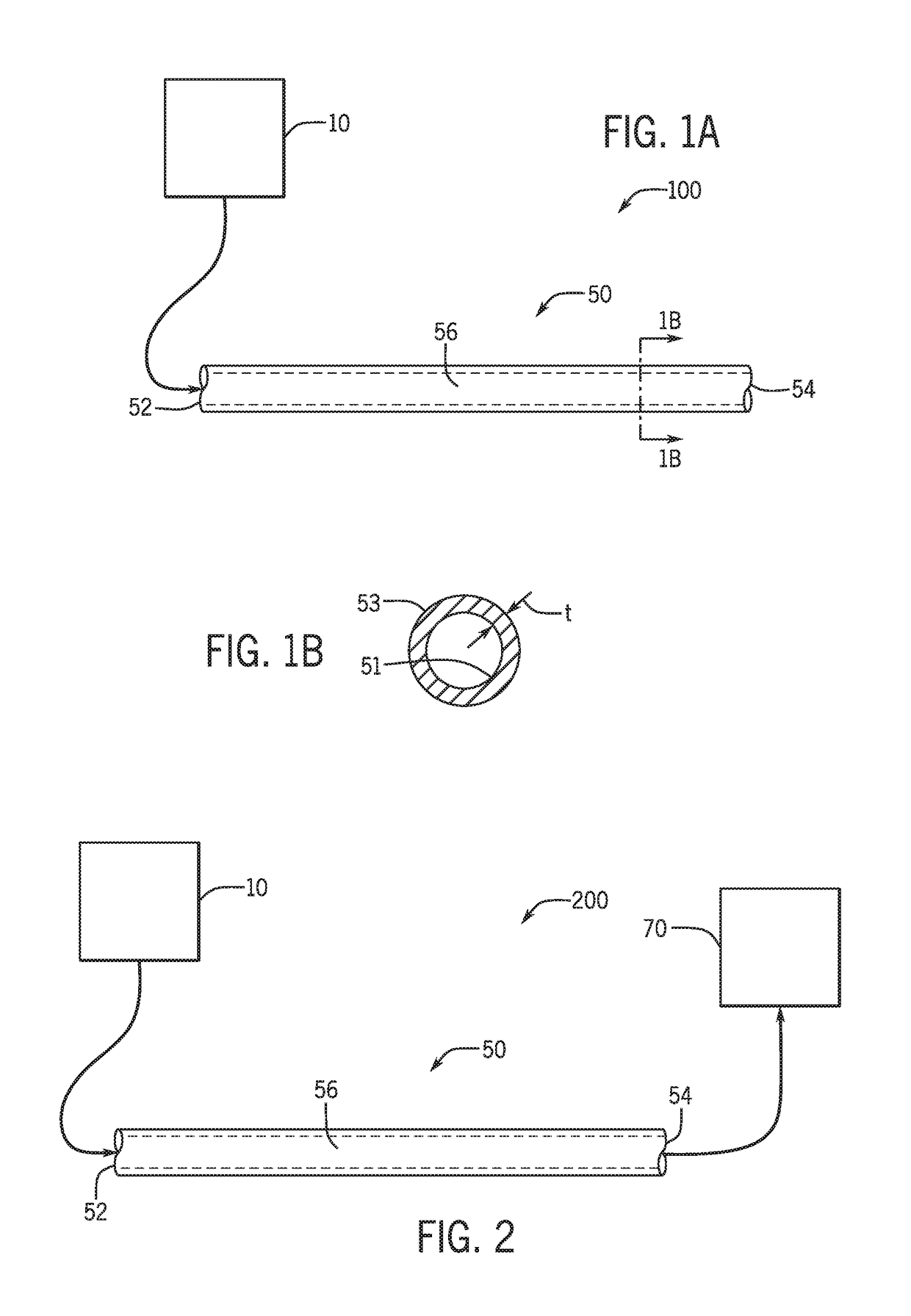

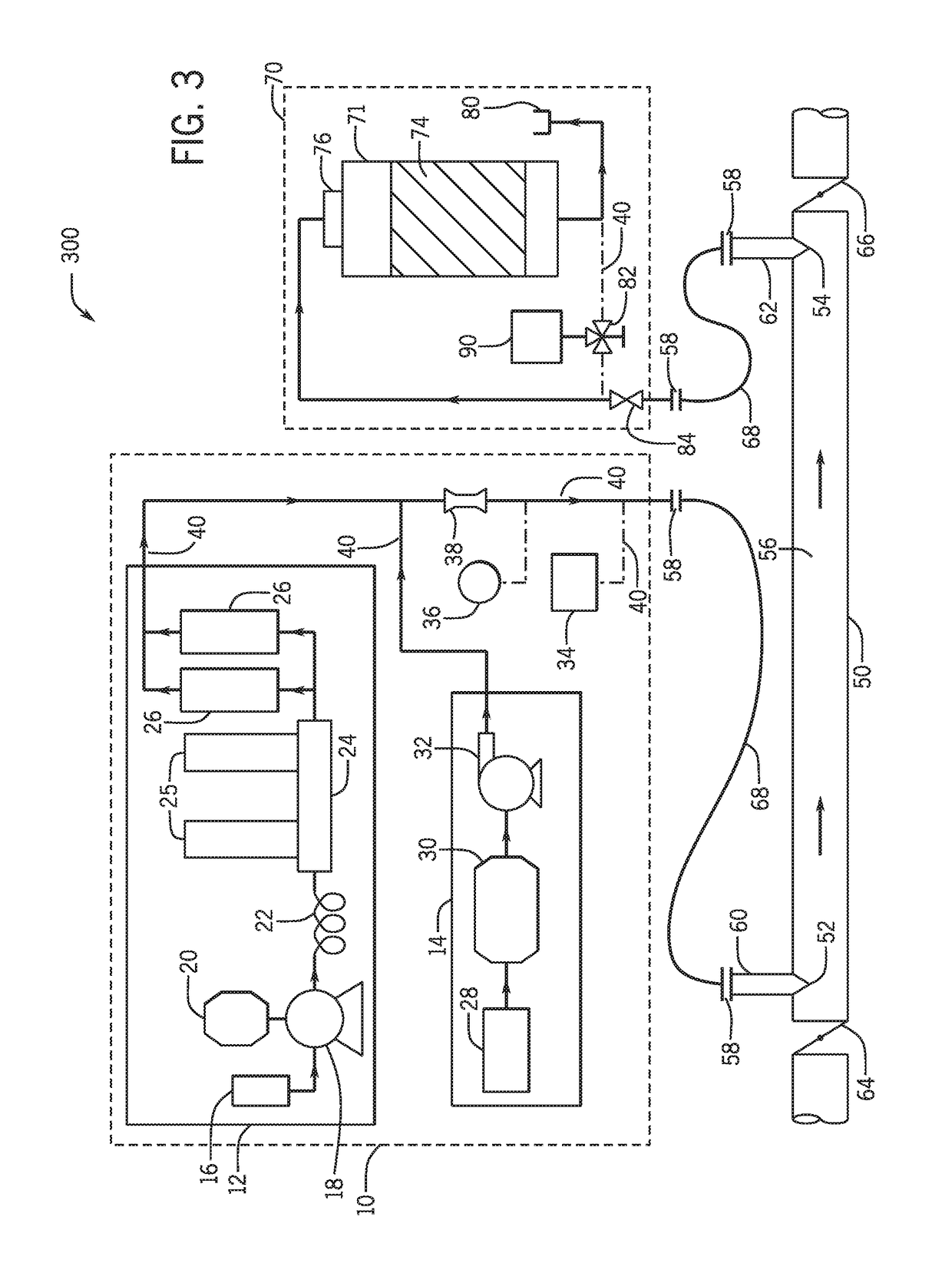

Microporous diffusion apparatus

Apparatuses for removal of volatile organic compounds in a soil formation include a microporous diffuser for injecting air and gaseous ozone as bubbles into water in the soil formation. The gaseous ozone is present at concentrations to effect removal of volatile organic compounds by the gaseous ozone reacting with the volatile organic compound(s). Injection of air and gaseous ozone is controlled by a timer to allow separation of bubbles by size. In various embodiments, a plurality of microporous diffusers may be controlled by a single timer or each of the plurality of microporous diffusers may be controlled by one of a plurality of timers.

Owner:KERFOOT TECH

Method and apparatus for surface treatment using a mixture of acid and oxidizing gas

InactiveCN102640256APhotomechanical apparatusSemiconductor/solid-state device manufacturingProduct gasTreatment use

Improved removal of ion-implanted photoresist in a single wafer front-end wet processing station is achieved by combining gaseous ozone and heated sulfuric acid such that a gas / liquid dispersion or foam of ozone in sulfuric acid is applied in a layer to the wafer surface to be treated.

Owner:LAM RES CORP

Ozone foam capable of being kept for long time and preparation method thereof

PendingCN112841217AImprove the bactericidal effectCause secondary pollutionInorganic/elemental detergent compounding agentsBiocideActive agentEnvironmental engineering

The invention relates to ozone foam capable of being maintained for a long time and a preparation method thereof, the ozone foam comprises ozone and water, and the method is characterized by comprising the following steps: adding a surfactant and / or a film-forming agent into the water to form a mixed liquid; wherein the mass ratio of the surfactant and / or the film-forming agent to the water is (0.01-1): 1; mixing the mixed liquid with ozone, then enabling the mixed liquid to generate foams by using a gas-liquid mixing device, simultaneously mixing gaseous ozone into the generated foams to form ozone foams, and when the diameter of the ozone foams is in a range of 0.03-3mm, keeping the foams for a long time, so that the ozone foams with the sterilizing and cleaning functions can be actually applied. According to the invention, by controlling the diameter of the ozone foam and adding different surfactants and / or film-forming agents, the retention time of the ozone foam is at least more than 30 minutes, so that the ozone foam can be practically applied to various sterilization and cleaning places.

Owner:GUANGZHOU CHUANGHUAN OZONE ELECTRICAL EQUIP CO LTD

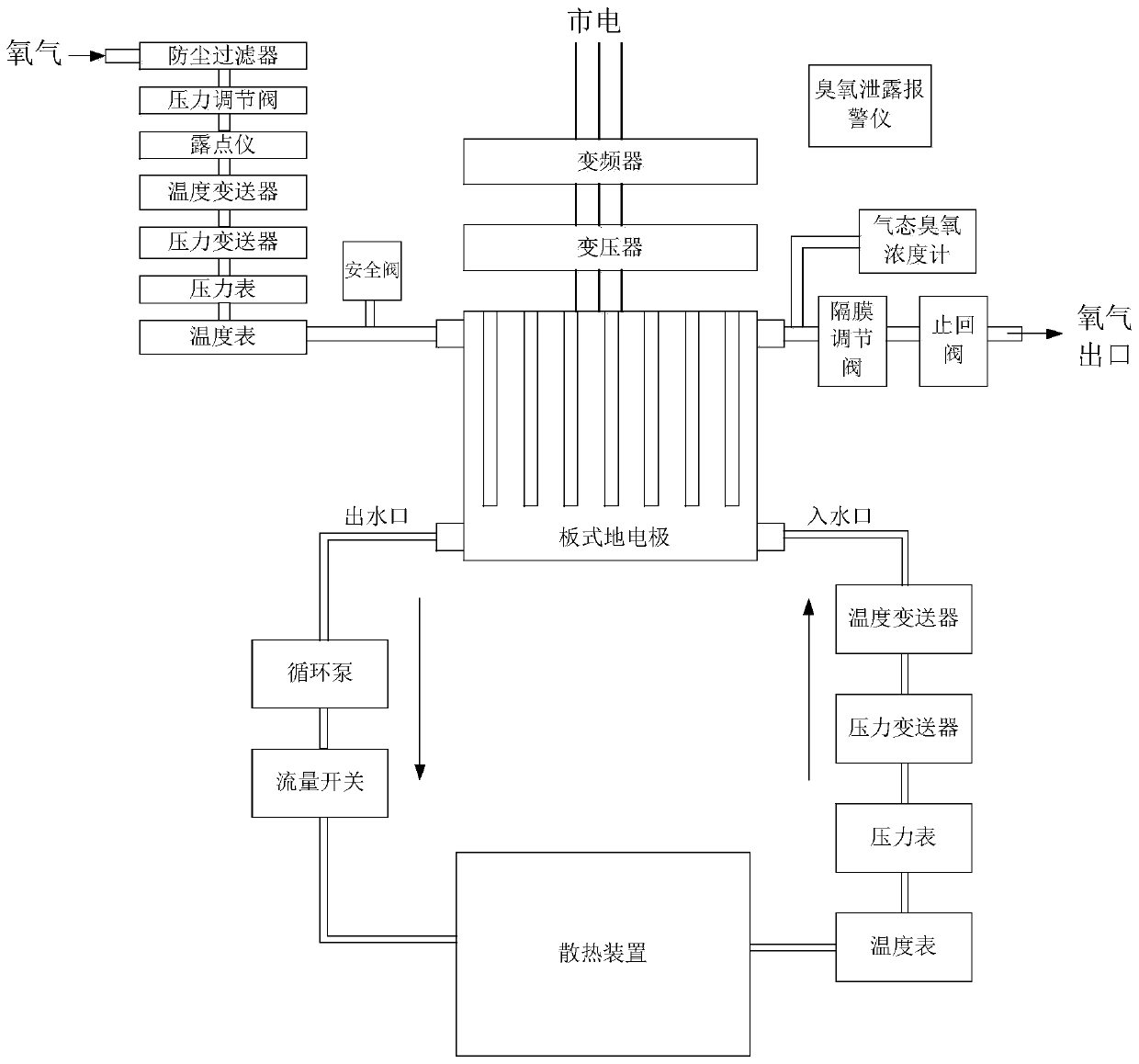

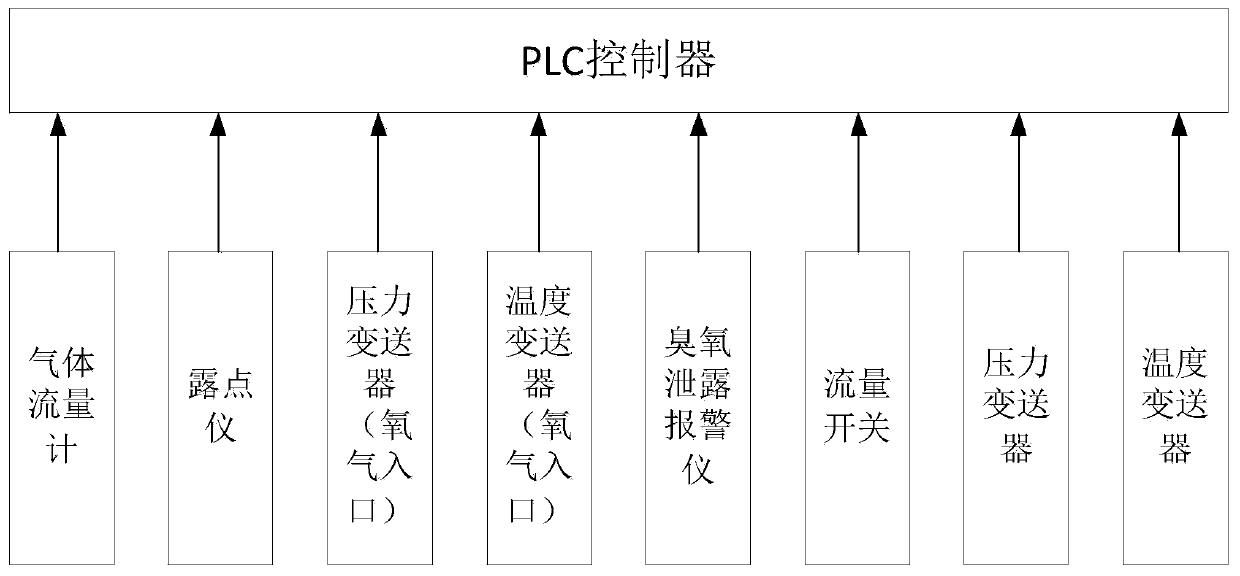

Plate-type ozone generating device

PendingCN111470475ARealize quantitative manufacturingHigh feasibilityElectrical discharge ozone preparationWater/sewage treatment apparatusFrequency changerTransformer

The invention discloses a plate-type ozone generating device which comprises an oxygen inlet monitoring module, a plate-type ground electrode, an ozone outlet control module, a circulating water cooling module and a power supply adjusting module. The oxygen inlet monitoring module comprises a dustproof filter, a pressure regulating valve, a leakage point instrument, a temperature transmitter, a pressure transmitter, a pressure gauge, a thermometer and a safety valve. The plate-type ground electrode comprises an oxygen inlet interface, an ozone outlet interface, a water-cooling circulating water inlet and a water-cooling circulating water outlet. The ozone outlet control module comprises a gaseous ozone concentration meter, a diaphragm regulating valve and a check valve. The circulating water cooling module comprises a circulating pump, a flow switch, a heat dissipation device, a thermometer, a pressure gauge, a pressure transmitter and a temperature transmitter. The power supply adjusting module comprises a frequency converter and a transformer. The power supply adjusting module is used for converting commercial power into high-frequency high-voltage power and then supplying powerto the plate-type ground electrode. The plate-type ozone generating device solves the problems that the chemical dosage is difficult to control and ozone cannot be quantitatively prepared in the existing chemical method for treating sewage.

Owner:BEIJING JINGDAWANXIANG ENVIRONMENTAL PROTECTION CO LTD +1

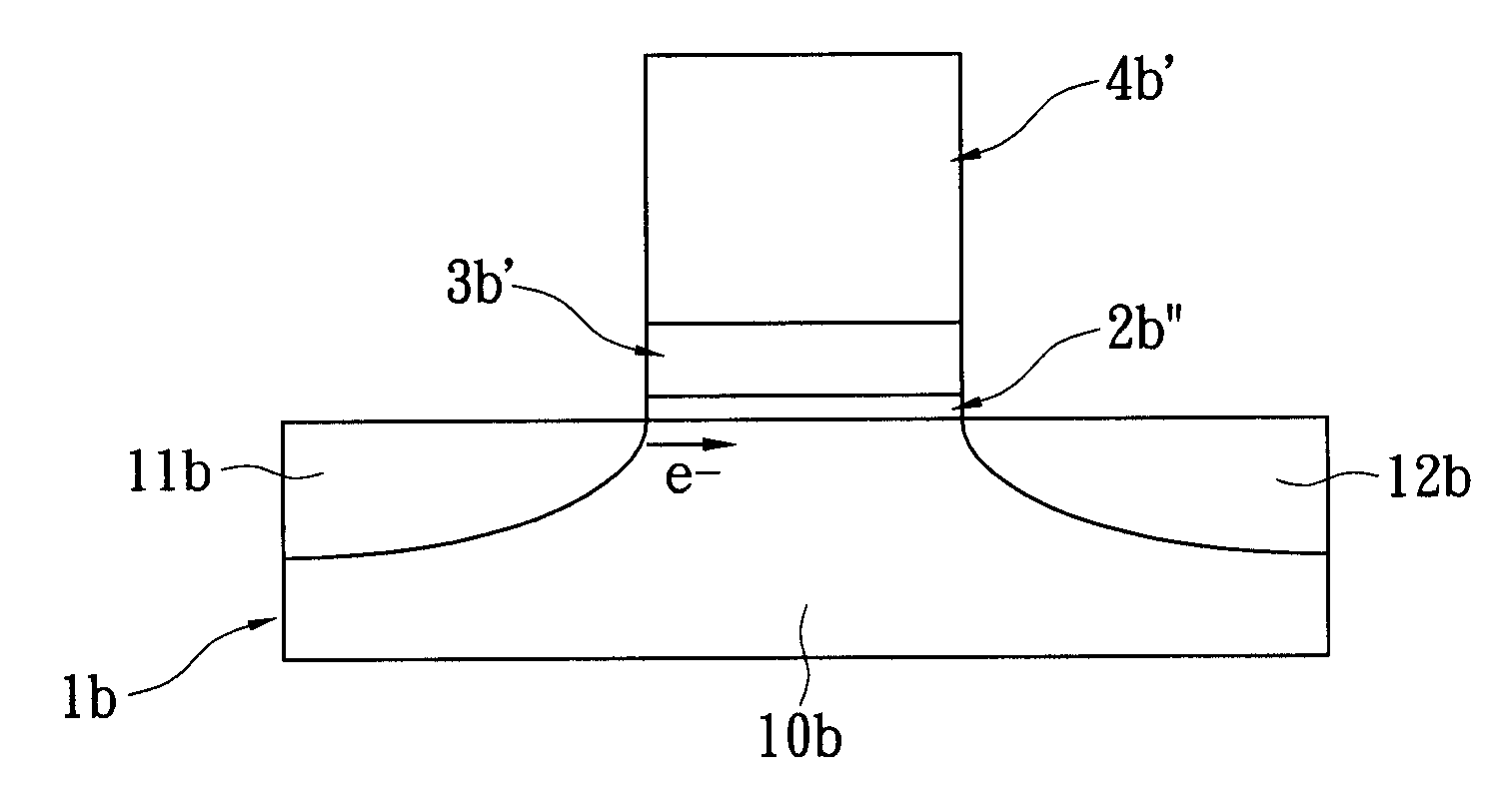

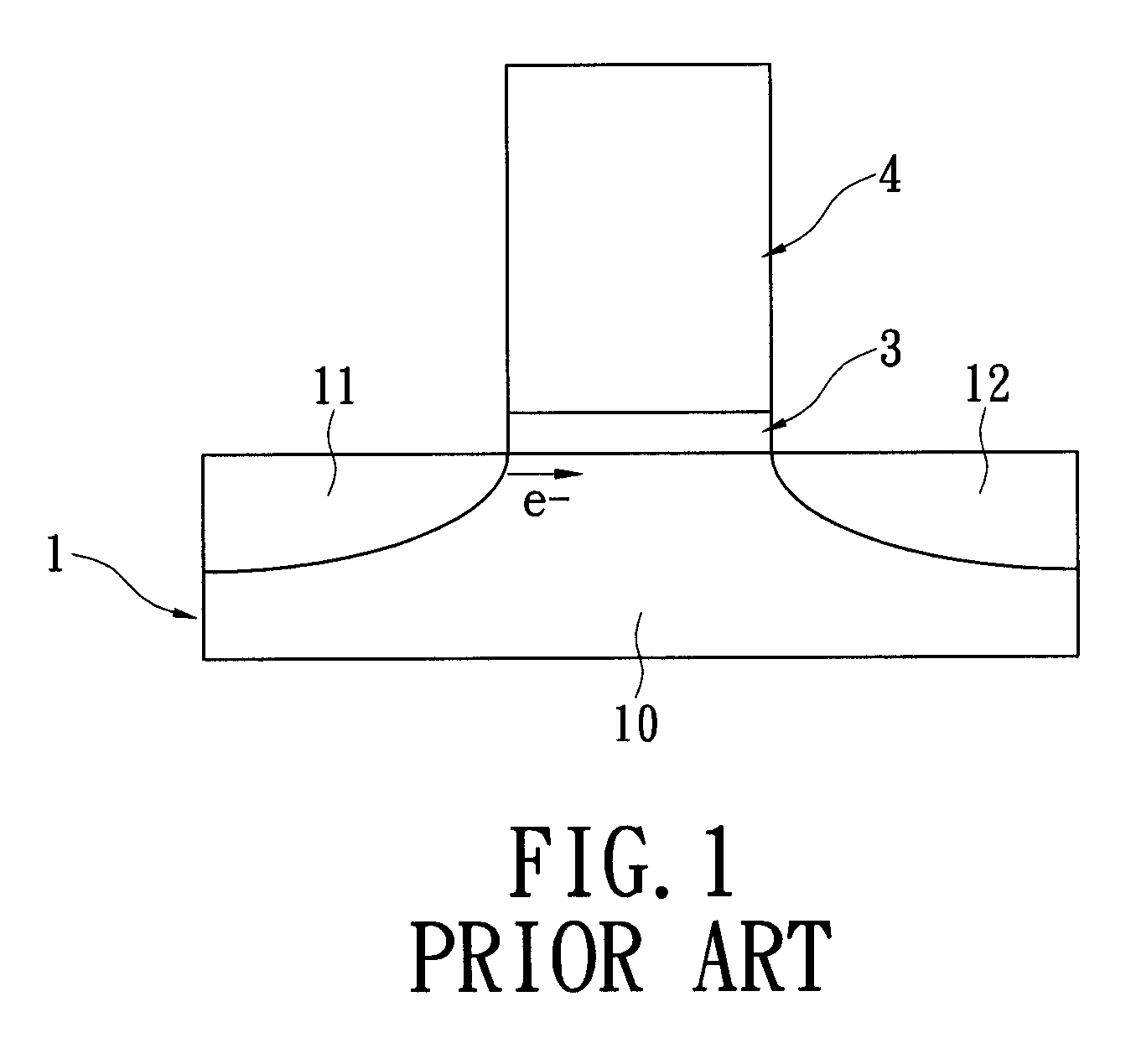

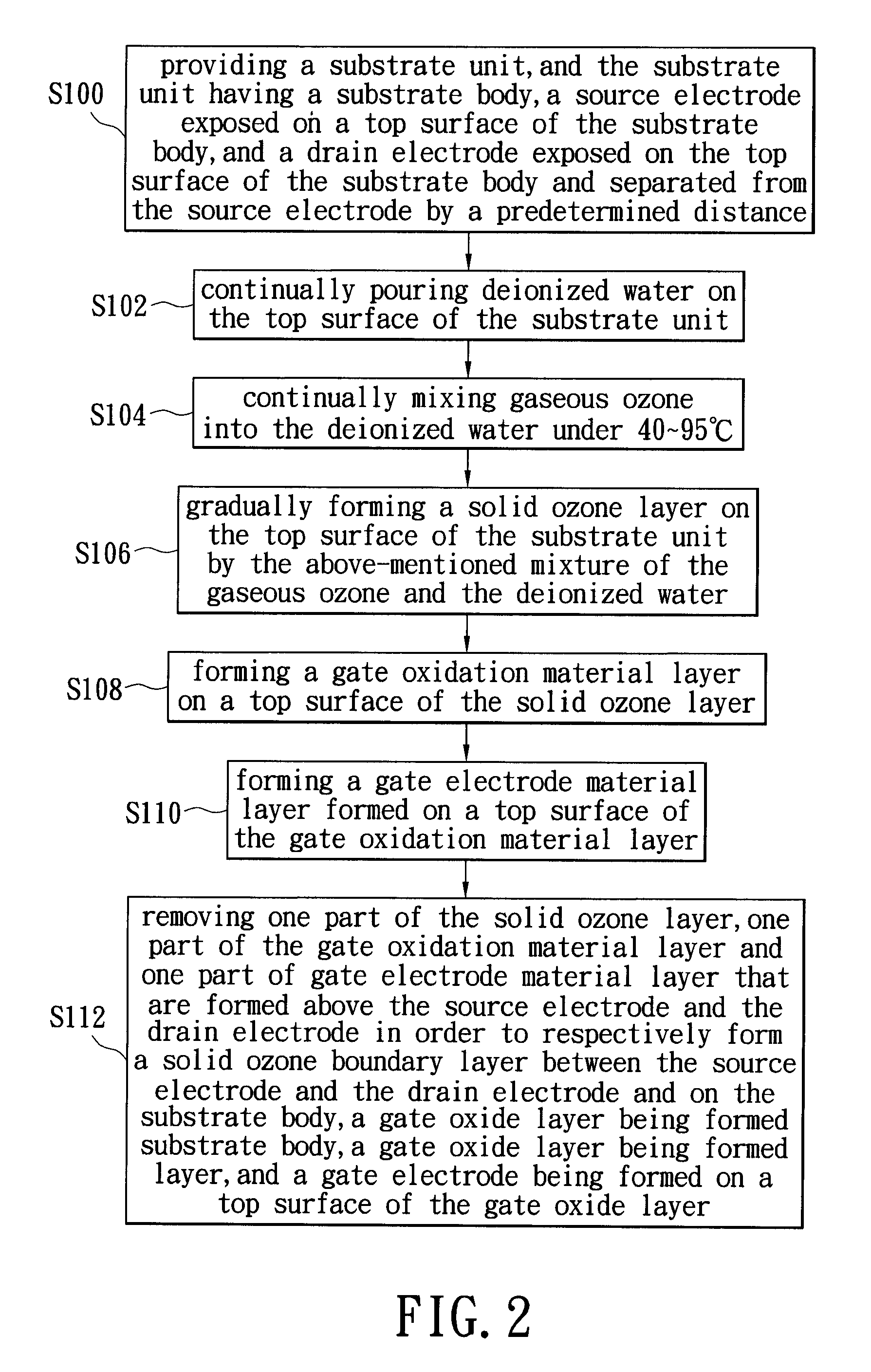

Transistor structure with high reliability and method for manufacturing the same

InactiveUS20100270599A1Improve reliabilityIncrease current velocityTransistorSemiconductor/solid-state device manufacturingEngineeringGate oxide

A transistor structure with high reliability includes a substrate unit, a solid ozone boundary layer, a gate oxide layer and a gate electrode. In addition, the substrate unit has a substrate body, a source electrode exposed on a top surface of the substrate body, and a drain electrode exposed on the top surface of the substrate body and separated from the source electrode by a predetermined distance. The solid ozone boundary layer is gradually grown on the top surface of the substrate body by continually mixing gaseous ozone into deionized water under 40˜95□, and the solid ozone boundary layer is formed between the source electrode and the drain electrode and formed on the substrate body. The gate oxide layer is formed on a top surface of the solid ozone boundary layer. The gate electrode is formed on a top surface of the gate oxide layer.

Owner:INOTERA MEMORIES INC

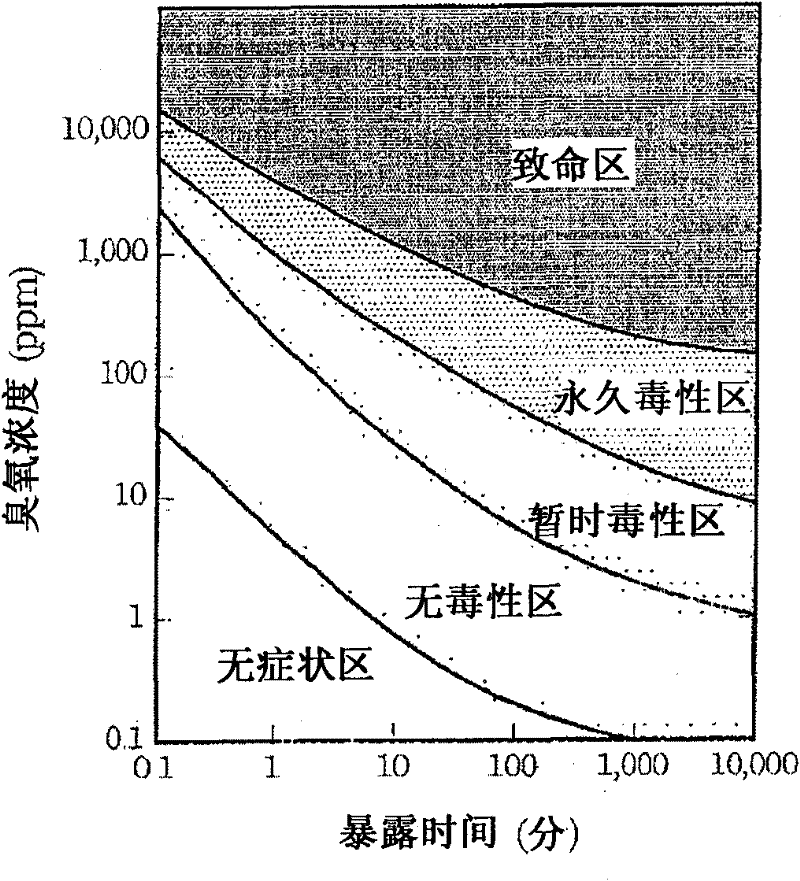

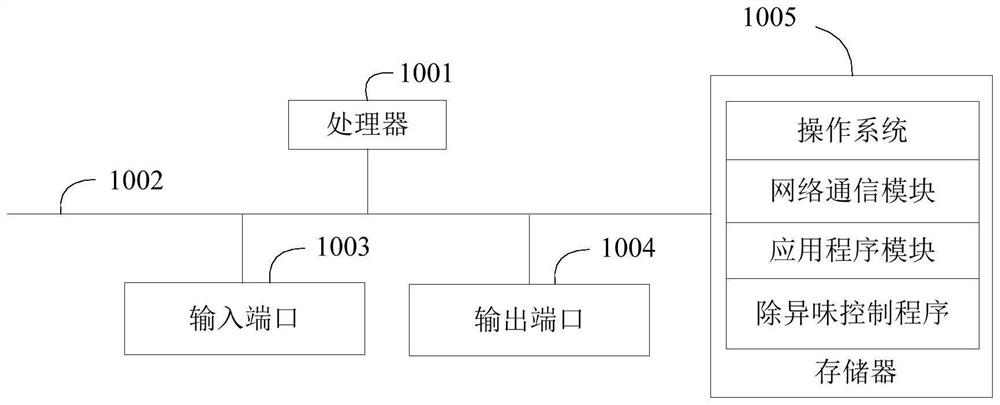

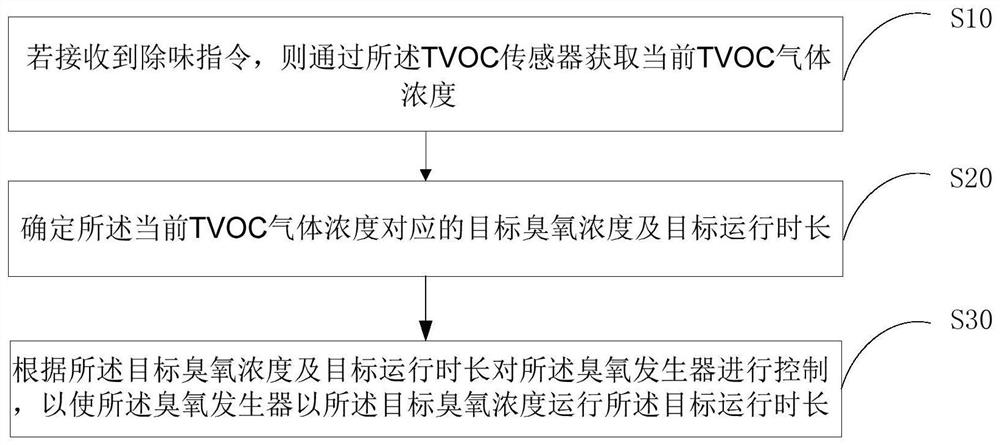

Odor removal control method and device, air conditioner and storage medium

PendingCN114508840AExtend your lifeTechnical issues to avoid corrosion damageMechanical apparatusSpace heating and ventilation safety systemsEnvironmental engineeringGas concentration

The invention relates to the technical field of air conditioners, and discloses an odor removal control method and device, an air conditioner and a storage medium. The method comprises the steps that if an odor removal instruction is received, the current TVOC gas concentration is obtained through a TVOC sensor; and controlling the ozone generator according to the target ozone concentration and the target operation duration, so that the ozone generator operates at the target ozone concentration for the target operation duration, in this way, the ozone generator is used for generating gaseous ozone which can spread all over all places in the air conditioner, the purpose of removing peculiar smell deeply adsorbed in the air conditioner is achieved, and the concentration of ozone generated by the ozone generator and the operation duration of the ozone generator are adjusted and controlled through the TVOC gas concentration detected by the TVOC sensor. The technical problem that parts in the air conditioner are corroded and damaged by high-concentration ozone for a long time is solved, and the service life of the air conditioner is prolonged.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

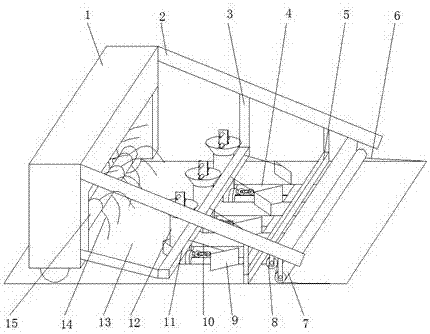

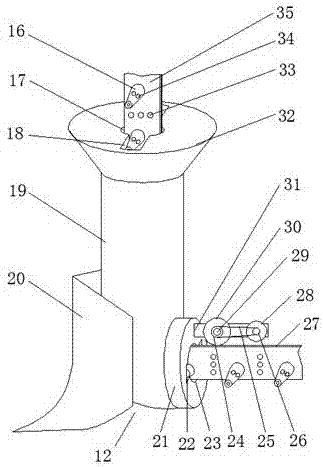

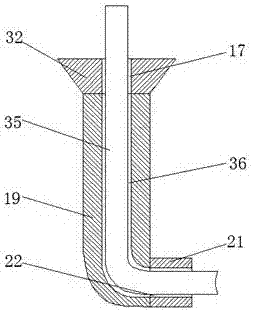

Soil remediation equipment in greenhouse

ActiveCN107185958AImprove repair effectRepair uniformContaminated soil reclamationGreenhouseSoil remediation

The invention discloses soil remediation equipment in a greenhouse, and belongs to the field of soil remediation. The soil remediation equipment in the greenhouse comprises a tractor, and the rear side of the tractor is fixedly connected with a fixed rod; the lower side of the fixed rod is fixedly connected with a pulling rod through a connecting rod, and the front side of the pulling rod is fixedly connected with a plurality of ditch shoveling devices; the rear side of the pulling rod is fixedly connected with a soil pulling burying sheet through a stabilizing rod. The soil remediation equipment can be used for ditching through ditching tools in the ditch shoveling devices, and ozone conveying hoses can be rapidly placed in ditches through truncated-cone-type guiding bodies, main conveying cylinders and auxiliary conveying cylinders of the ditch shoveling devices; retractable telescopic gas pipes on each ozone conveying hose are placed in the ditches and flexibly opened to be inserted into the ground soil; the ditches where the ozone conveying hoses are placed are buried through the soil pulling burying sheet, so that gaseous ozone are transferred into the deep subsoil through the ozone conveying hoses and the retractable telescopic gas pipes to conduct soil remediation with a good remediation effect.

Owner:江苏盐西高新绿色产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com