Plate-type ozone generating device

An ozone generating device and plate-type technology, which are applied in the fields of ozone preparation, preparation of ozone by discharge method, oxygen/ozone/oxide/hydroxide, etc., can solve the problems such as the inability to quantitatively manufacture pharmaceutical doses of ozone, and the difficulty in controlling sewage treatment. Highly feasible and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

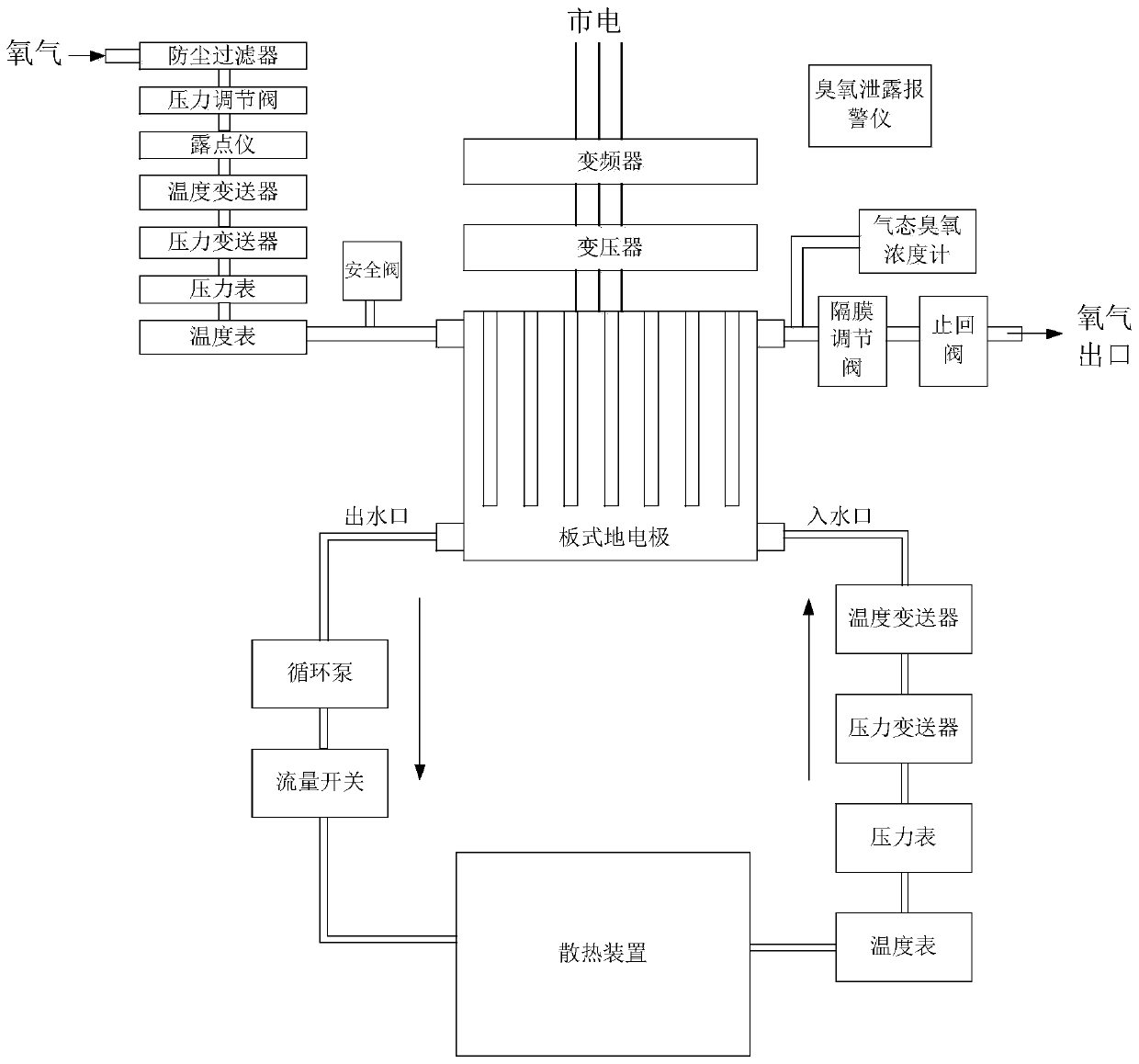

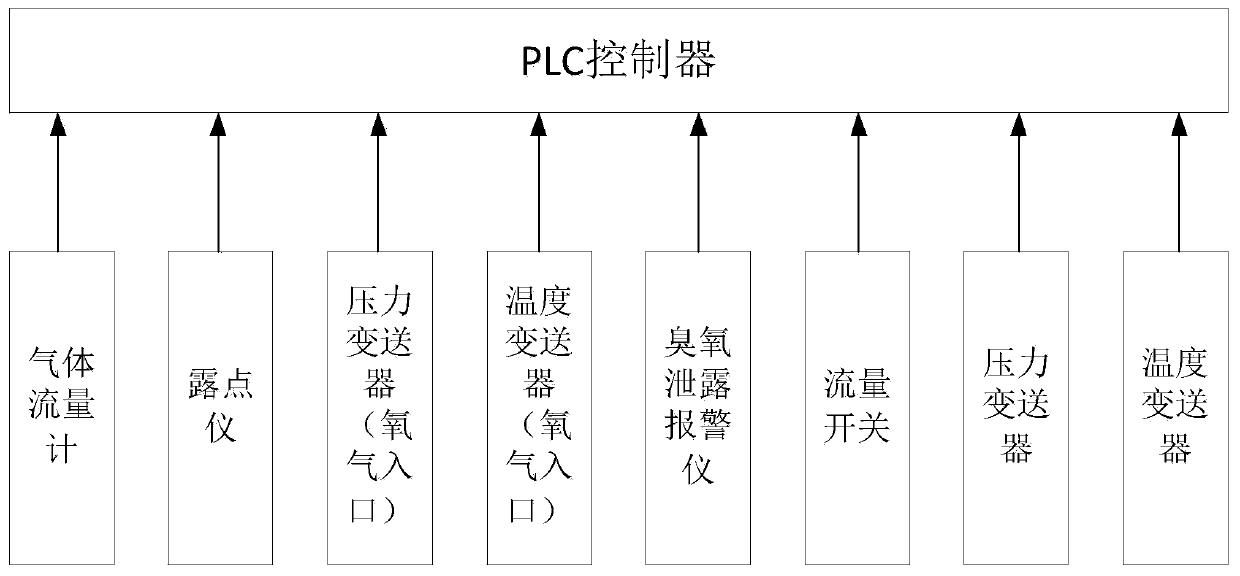

[0030] see figure 1 , a plate-type ozone generating device, the generating device includes an oxygen inlet monitoring module, a plate-type ground electrode, an ozone outlet control module, a circulating water cooling module, and a power supply adjustment module;

[0031] Oxygen inlet monitoring module, including dust filter, pressure regulating valve, leak point detector, temperature transmitter, pressure transmitter, pressure gauge, temperature gauge and safety valve;

[0032] Plate-type ground electrode, including oxygen inlet interface, ozone outlet interface, water cooling cycle water inlet and water cooling cycle water outlet;

[0033] Ozone outlet control module, including gaseous ozone concentration meter, diaphragm regulating valve and check valve;

[0034] Circulating water cooling module, including circulating pump, flow switch, cooling device, thermometer, pressure gauge, pressure transmitter and temperature transmitter;

[0035] Power supply regulation module, in...

Embodiment 2

[0054] During specific implementation, when the cooling effect of the circulating water cooling device is not good, a fan can be installed on the heat dissipation device to increase convection heat dissipation.

Embodiment 3

[0056] During specific implementation, when the oxygen flux of the oxygen inlet monitoring device is insufficient, a booster pump is added to increase the oxygen flux.

[0057] A plate-type ozone generating device proposed by the present invention solves the problem that the addition of additives cannot be precisely controlled by using chemical methods to treat sewage by using ozone to treat sewage, and is more environmentally friendly and practical. At the same time, through the pertinence of ozone generating devices The design realizes the quantitative production of ozone, which makes the use of ozone in sewage treatment more feasible and economical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com