Method for supercritically washing sea sand, river sand and hill sand

A technology of supercritical and sea sand, applied in the field of mountain sand, river sand, and supercritical washing sea sand, can solve the problems of poor quality stability, unclean addition and washing, and inability to be washed, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The sea sand obtained by the seaside is standby (this embodiment is used to illustrate this washing method, and is not used to limit the scope of the invention):

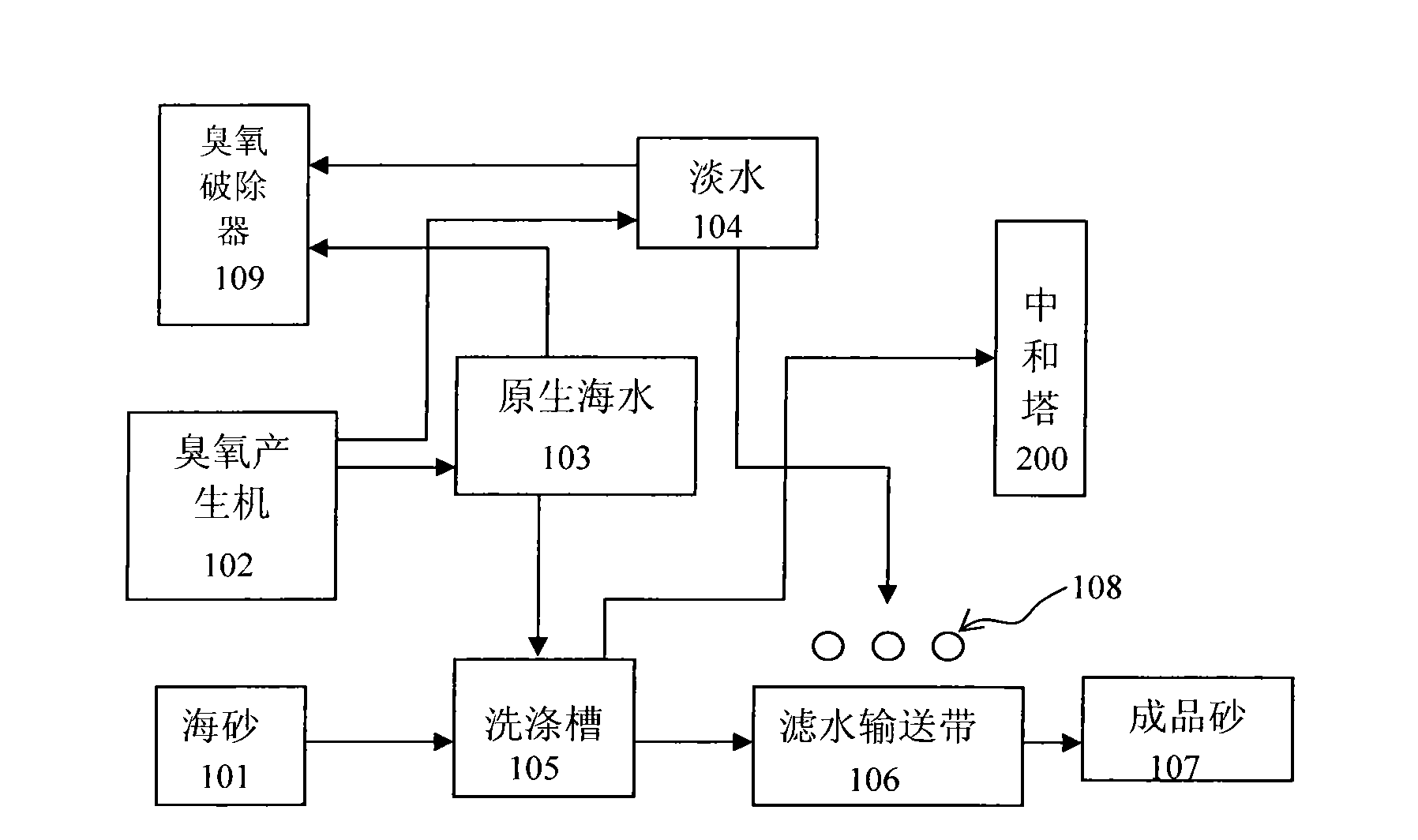

[0027] (1) the primary seawater 103 (PH<7) that has filtered out the pollutants, start the ozone generator 102 to make ozone, pass through ozone in the seawater for 15 minutes, and the ozone concentration reaches 5ppm for standby, and excess ozone is imported in 109 ozone eliminators, and Manganese oxide neutralizes and destroys in the destroyer.

[0028] (2) The clean fresh water 104 is fed with ozone for 15 minutes to make the ozone concentration reach 5ppm for standby, and the excess ozone is introduced into the ozone eliminator 109 to be neutralized and eliminated with the manganese oxide in the eliminator.

[0029] (3) Naturally dried sea sand 101 reduces the content of primary seawater for future use.

[0030] (4) Put the sea sand 101 into the cleaning tank 105 .

[0031] (5) Import the ozone water in...

Embodiment 2

[0042] Taking river sand as a raw material for subsequent use, the implementation is as follows (this embodiment is used to illustrate the washing method, and is not intended to limit the scope of the invention):

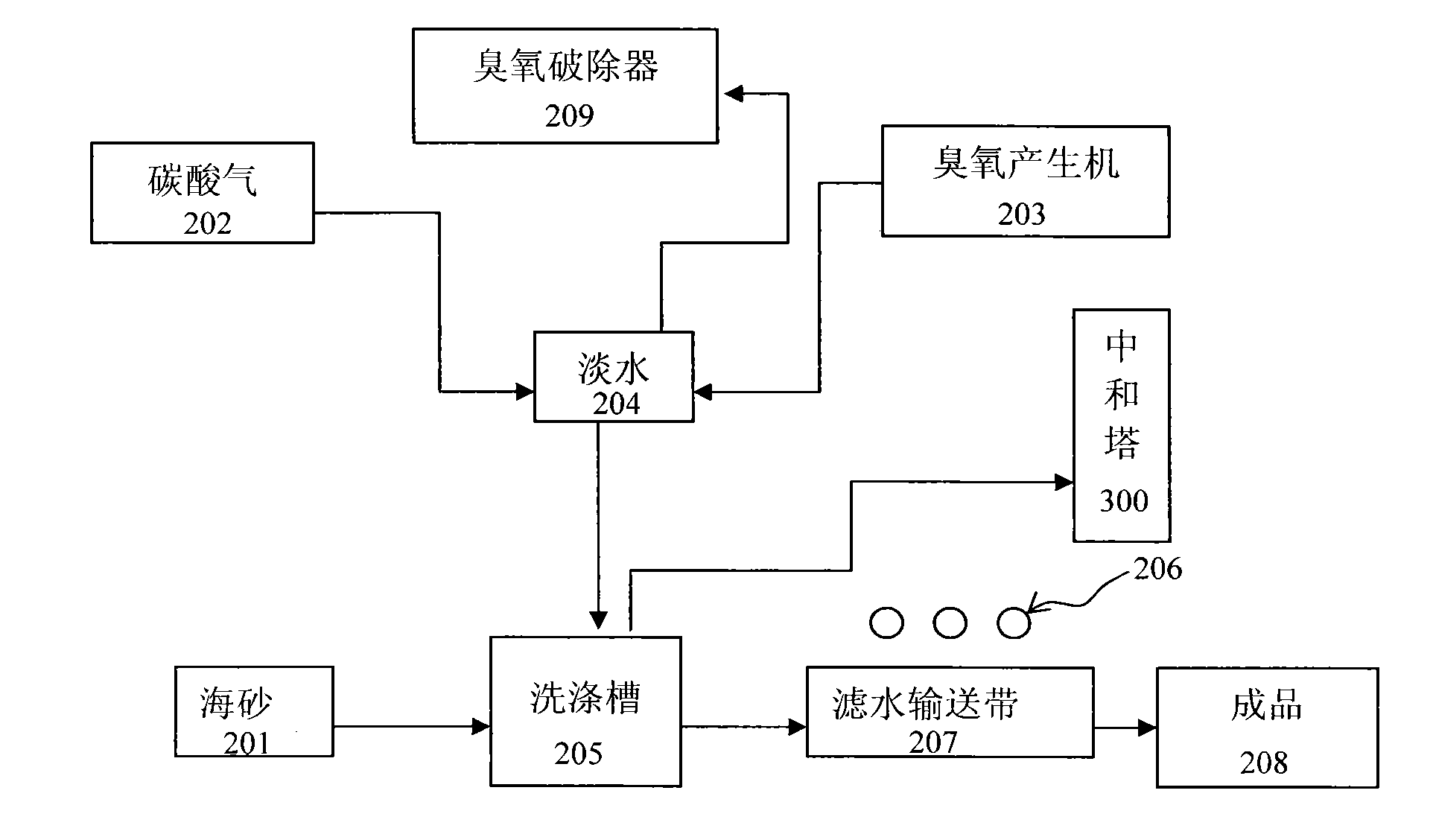

[0043] (1) clean fresh water 204, feed carbonic acid gas 202 to make the pH value reach 5 for standby.

[0044] (2) Start the ozone generator 203 to produce ozone, and pass ozone into the water for 15 minutes to make the ozone concentration reach 5ppm for standby. Excess ozone is introduced into the 209 ozone eliminator and neutralized with manganese oxide in the eliminator.

[0045] (3) Naturally dried river sand 201 reduces the impurity content of primary river water for future use.

[0046] (4) Put the river sand into the cleaning tank 205 for standby.

[0047](5) Introduce the step 1 ozone water into the cleaning tank 205, after the water level is about 1 / 3 of the cleaning tank, slow down the introduction speed of the ozone water.

[0048] (6) Start the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com