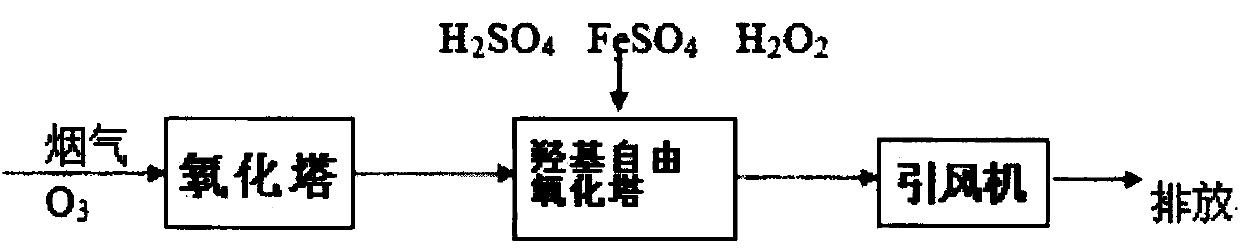

Ozone-hydroxy free radical dry-wet combined desulphurization and denitration technology

A technology of desulfurization and denitrification combined with dry and wet, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as few cases, and achieve the effect of preventing pollution and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

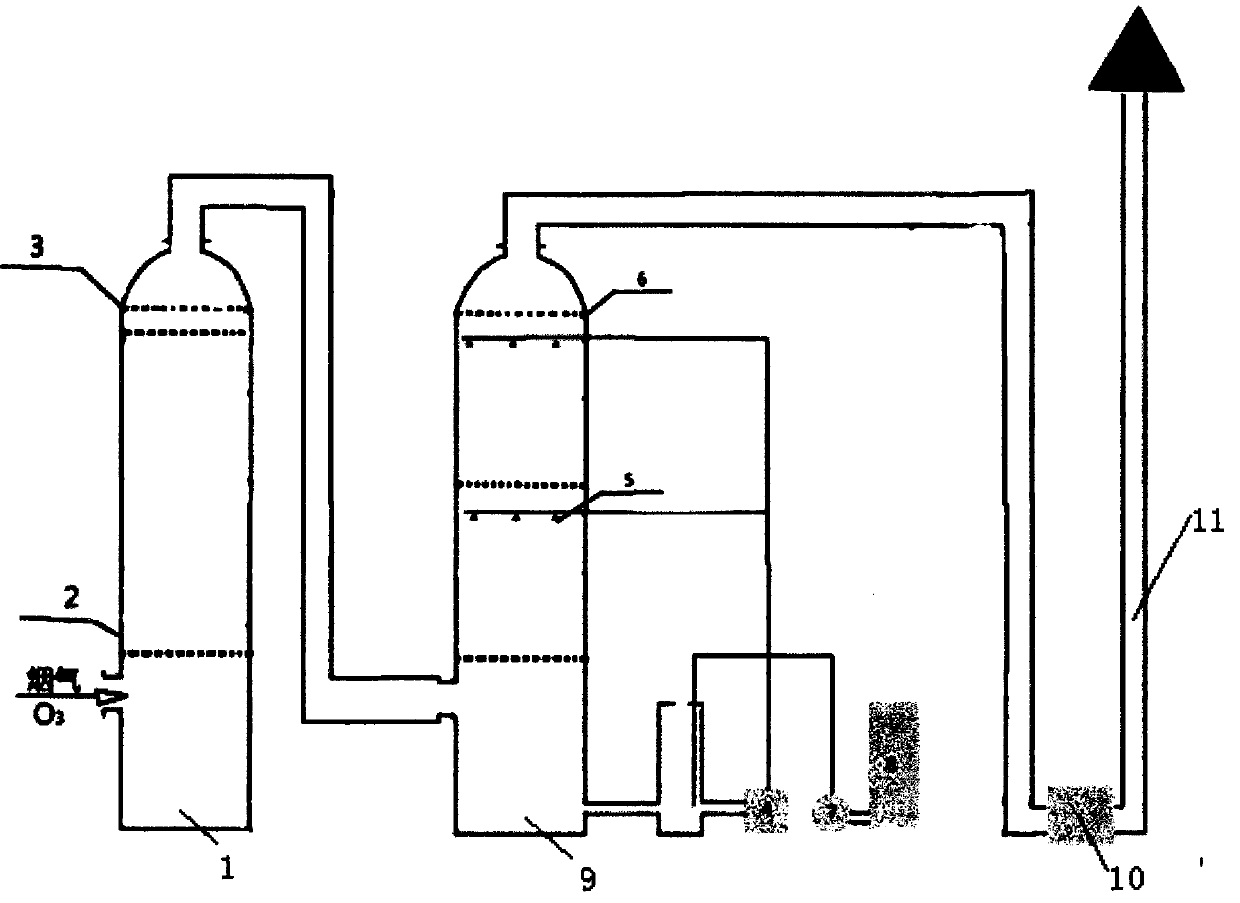

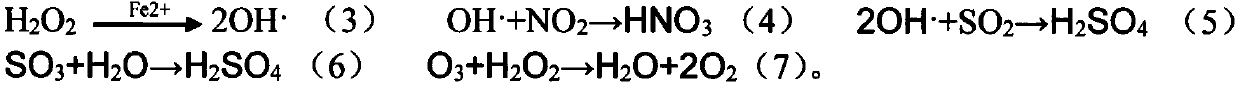

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Company 1 has a flue gas volume of 45,000 m 3 / h, flue gas component SO 2 3000mg / m 3 NO1100mg / m 3 , the remainder is O 2 , nitrogen and water vapor. The flue gas temperature is 70°C and the pressure is 1 atmosphere. Ozone / NO≈0.95 (molar ratio), H 2 SO 4 Concentration 5%, FeSO 4 0.1% (weight percent), H 2 o 2 The concentration is 28% (percentage by weight). After implementing the patented ozone-hydroxyl radical dry-wet combined desulfurization and denitrification process of the present invention, the SO 2 The concentration is 50mg / m 3 , NOx is 80mg / m 3 , The average desulfurization and denitrification rate is above 90%. Discharge 12 tons of acid medium wastewater every three months.

Embodiment 2

[0029] Example 2: Company 2 has a flue gas volume of 15,000 m 3 / h, the flue gas composition is as follows: SO 2 2700mg / m 3 , NOx760mg / m 3 , and the rest are N 2 , CO 2 and water vapor, the flue gas temperature is 75°C, the pressure is 1 atmosphere, and the amount of ozone is 0.94 , 0.1%H 2 o 2 20%, exhaust NOx reduced to 75mg / m after treatment by this process 3 , SO 2 down to 45mg / m 3 , desulfurization and denitrification reached over 90%. 4 tons of acidic medium wastewater is discharged about every three months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com