Method and apparatus for surface treatment using a mixture of acid and oxidizing gas

An oxidative, fluid treatment technology, applied to the surface of objects, can solve the problem of reducing the reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

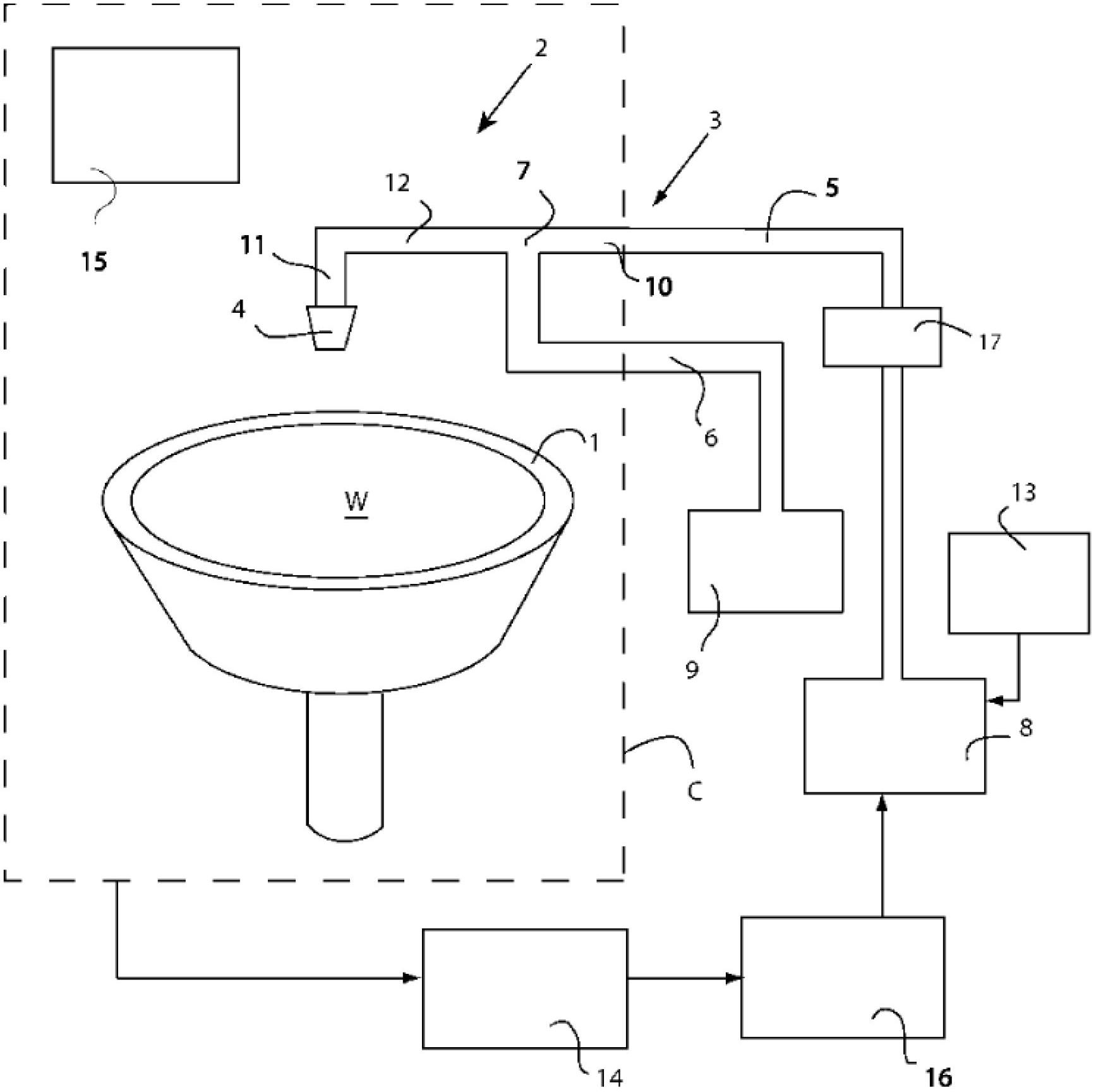

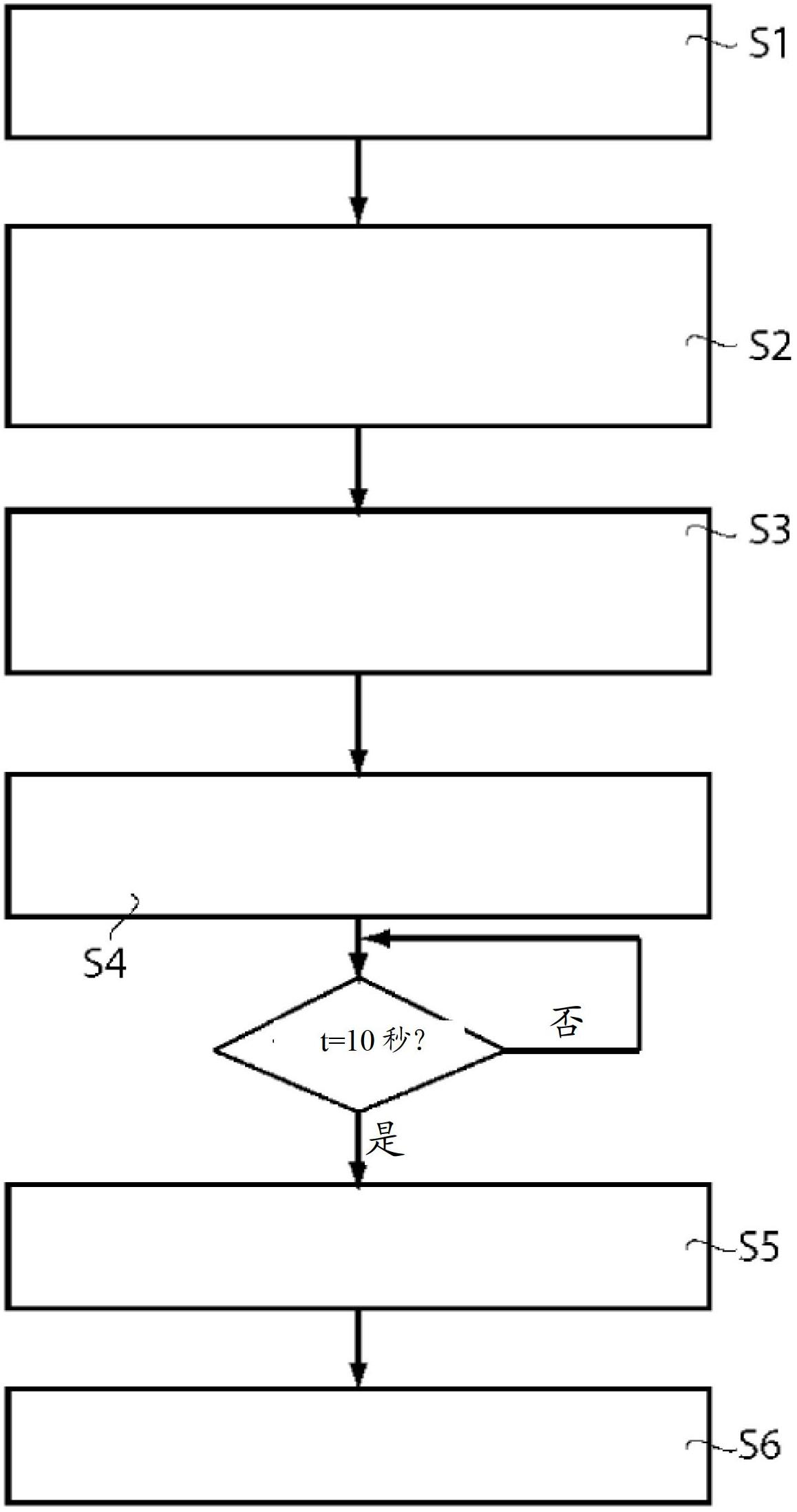

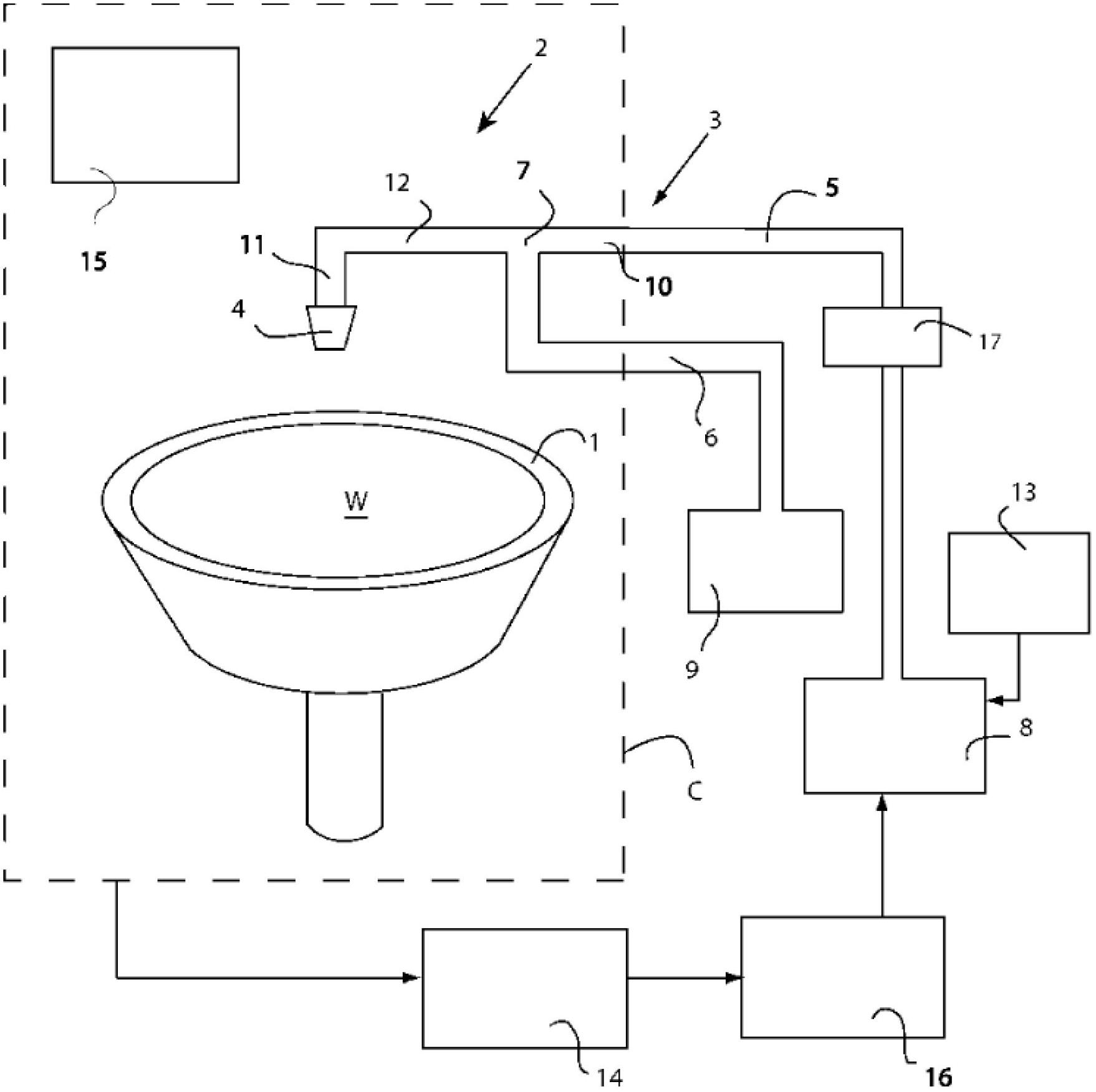

Method used

Image

Examples

Embodiment 1

[0045] The temperature of the gas / liquid mixture is 150℃

[0046] The temperature of the liquid (sulfuric acid) before being introduced into the mixing joint is 150°C

[0047] The cross-sectional area of the orifice of the dispensing nozzle is 72mm 2 (For 3 / 8" hole)

[0048] The rotation speed of the wafer 150rpm

[0049] Liquid volume flow rate 1.6l / min

[0050] Volumetric flow rate of gas 0.6l / min

[0051] The volumetric flow rate of the mixture is 2.2l / min

[0052] Distribution speed of orifice 1m / s

[0053] The ratio of gas to liquid in the gas / liquid mixture is 27vol.%

[0054] The mass percentage concentration of sulfuric acid 97-80% (mass percentage)

[0055] Ozone in the gas (10% by mass), the rest is oxygen and unintentional impurities

Embodiment 2

[0057] The temperature of the gas / liquid mixture is 153℃

[0058] The temperature of the liquid (sulfuric acid) before being introduced into the mixing joint is 140°C

[0059] The cross-sectional area of the orifice of the dispensing nozzle is 30mm 2 (For 1 / 4" hole)

[0060] The rotation speed of the wafer 100rpm

[0061] Liquid volume flow rate 0.6l / min

[0062] The volumetric flow rate of gas 1.6l / min

[0063] The volumetric flow rate of the mixture is 2.2l / min

[0064] Distribution speed of orifice 1m / s

[0065] The ratio of gas to liquid in the gas / liquid mixture is 70vol.%

[0066] The mass percentage concentration of sulfuric acid 96-88% (mass percentage)

[0067] Ozone in the gas (12% by mass), the rest is oxygen and unknown impurities

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com