Preparation method for 4,4'-dichlorodiphenyl sulfone

A technology of dichlorodiphenyl sulfone and dichlorodiphenyl sulfoxide, which is applied in the field of preparation of 4,4'-dichlorodiphenyl sulfone, which can solve the problem of unsatisfactory oxidation strength and oxidation effect of oxidants, increase solvent recovery, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] At 25°C, add 5.3g of glacial acetic acid, 5g of hydrogen peroxide (mass fraction 30%), and 0.5g of concentrated sulfuric acid into a 250mL four-neck flask equipped with a stirrer, thermometer and condenser, and stir the reaction at ≤25°C After 12 hours, it is used as an oxidizing agent and transferred to a balance feeder for use. At 80°C, add 10g of 4,4'-dichlorodiphenyl sulfoxide and 17g of glacial acetic acid to a 250mL four-neck flask equipped with a balance feeder, agitator, thermometer and condenser, and then gradually Add the above-mentioned oxidant dropwise (the dropwise addition is completed within 0.5h), and then continue to react for 1h. After the reaction is completed, cool down to below 5°C, filter, wash, and dry to obtain 10.37g of crude product of 4,4'-dichlorodiphenylsulfone. The weight is 3.7%, the crude product yield is 97.95%, and the melting range is 146-148°C. White crystals are obtained by ethanol recrystallization. ).

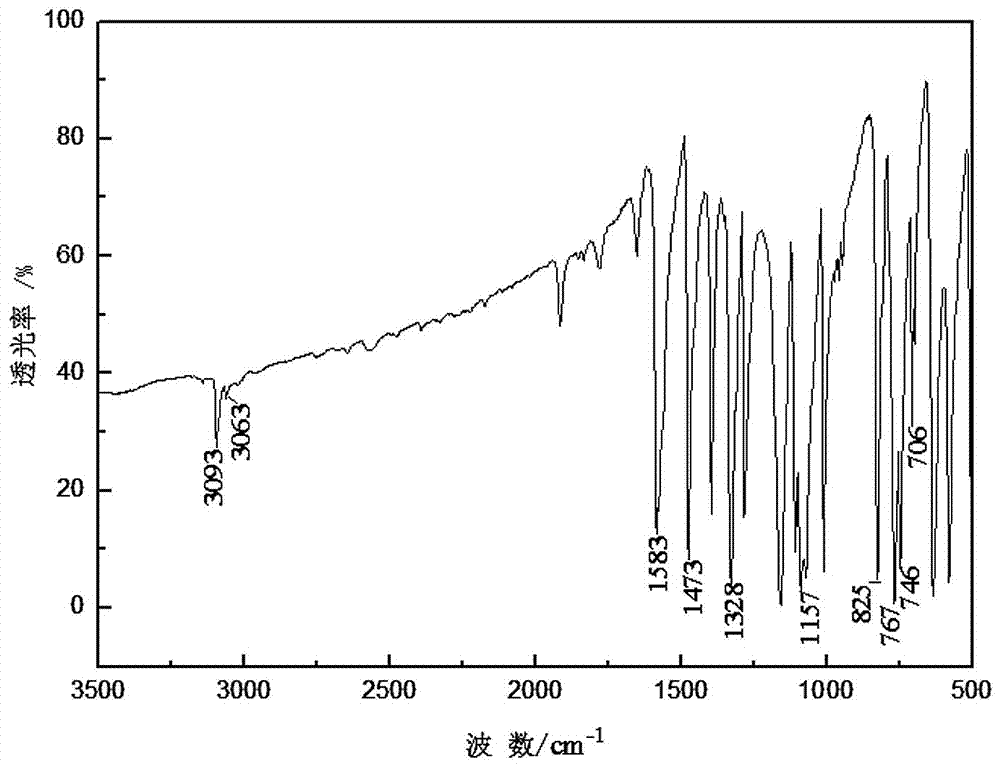

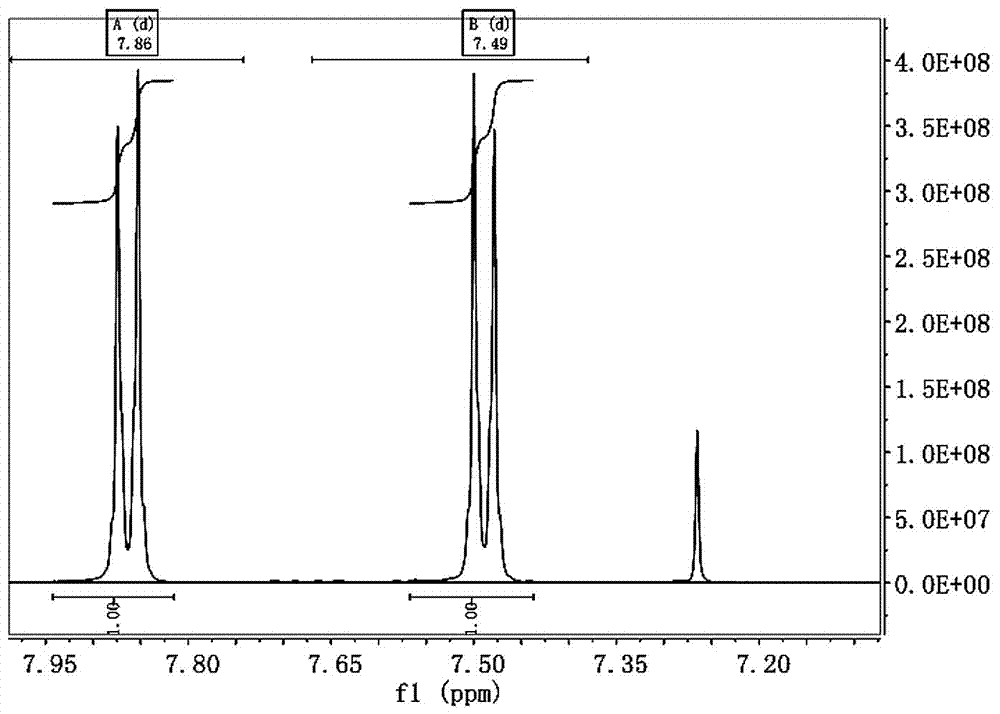

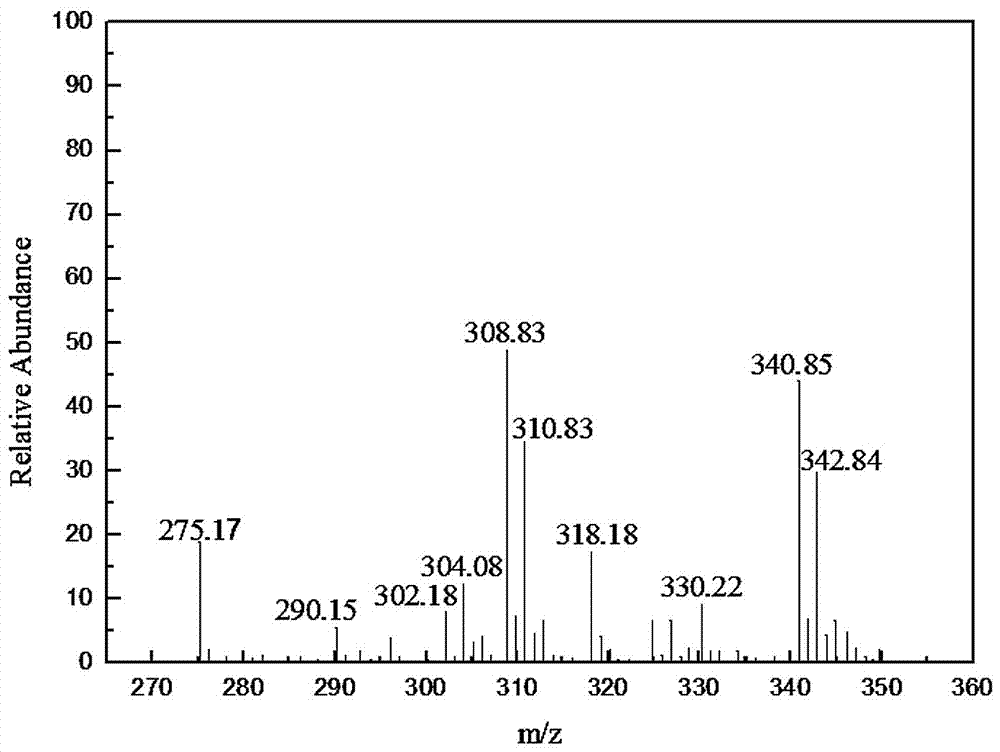

[0020] Structural characte...

Embodiment 2

[0028] At 25°C, add 24g of glacial acetic acid to a 250mL four-necked flask equipped with a balance feeder, stirrer, thermometer and condenser, and drop 2.5g (0.022mol) of hydrogen peroxide at ≤25°C in 0.25g of concentrated sulfuric acid to catalyze After generating peracetic acid under the action, add 5g (0.018 mol) raw material 4,4'-dichlorodiphenyl sulfoxide at 60°C, cool down to below 5°C after the reaction, filter, wash and dry to obtain 4,4' - The crude product of dichlorodiphenyl sulfone was 5.09g, the weight gain was 1.8%, the yield of the crude product was 96.40%, and the melting range was 146.5~148.5°C.

Embodiment 3

[0030] At 25°C, add 30g of glacial acetic acid to a 250mL four-necked flask equipped with a balance feeder, stirrer, thermometer and condenser, and add 2.5g of hydrogen peroxide dropwise at ≤25°C. Catalyze with (0.25g) concentrated sulfuric acid After generating peracetic acid at low temperature, add 5g of raw material 4,4'-dichlorodiphenyl sulfoxide at 40°C, cool down to below 5°C after the reaction, filter, wash, and dry to obtain 4,4'-dichlorodiphenyl The crude product of sulfone is 5.06g, the weight gain is 1.2%, the yield of the crude product is 95.83%, and the melting range is 146.5~148°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com