Mixed desalination method and device for wastewater

A wastewater and salinity technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of export influence, accumulation of solid particles, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

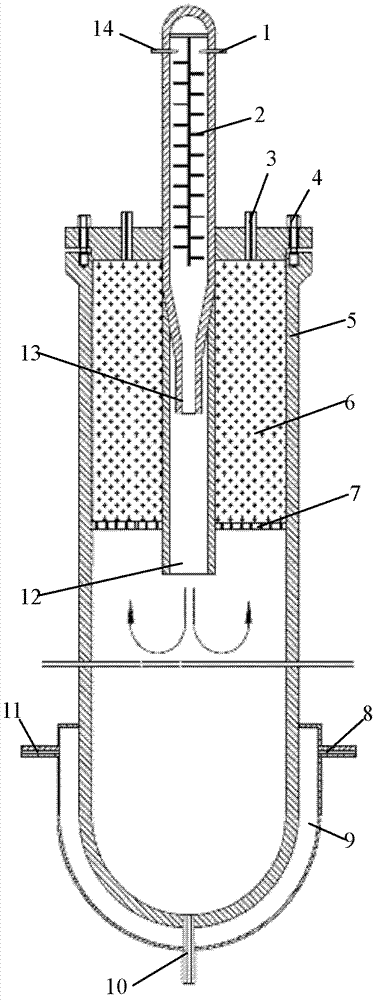

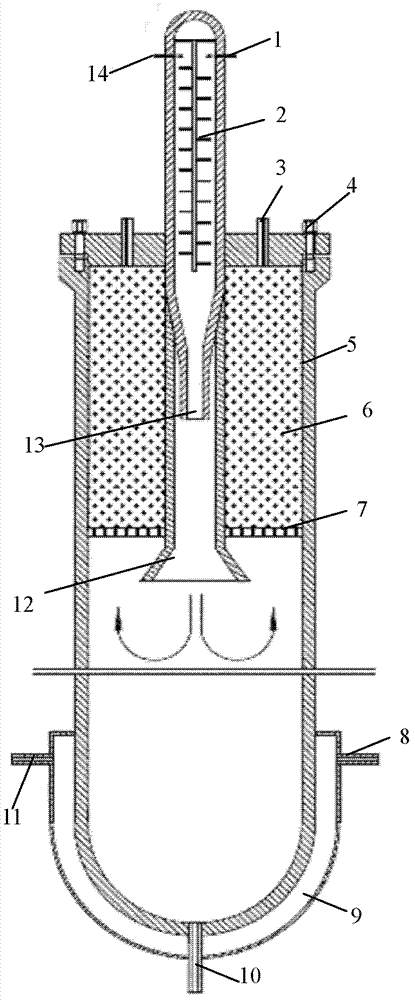

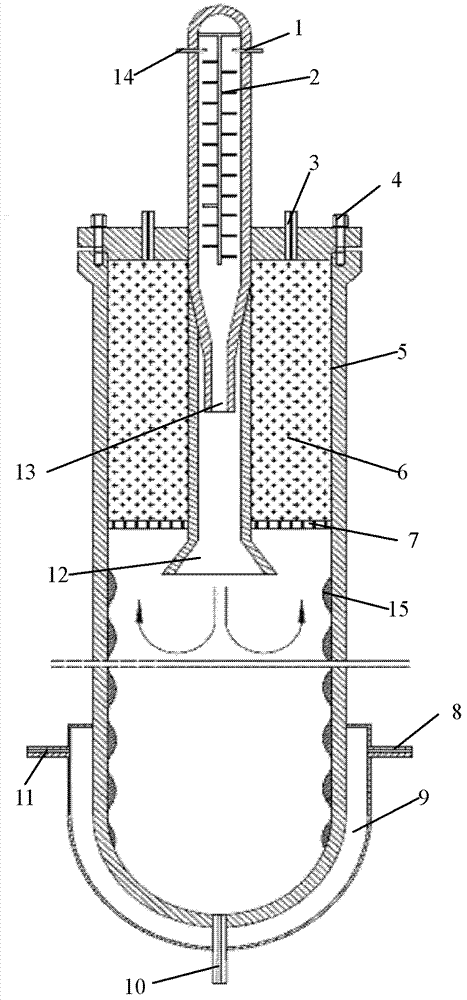

[0084] Referring to the first row of data in the above table, in this example, the conductivity of the raw wastewater is 25906S / m, and the filler 6 in the mixed desalination device uses spherical TiO with a diameter of 6mm 2 and spherical ZrO with a diameter of 10 mm 2 Mix filler. After pressurized preheating, the temperature of the raw wastewater reaches 320°C and the pressure reaches 25MPa. At this time, the raw wastewater is in a subcritical state. The oxidant is liquid oxygen, and the amount of liquid oxygen is 1% of the oxygen consumption of the organic matter contained in the wastewater. The liquid oxygen is pressurized, gasified and preheated, and the pressure reaches 25.5-27.5MPa, and the temperature reaches 300°C. Subcritical raw material wastewater and oxidant enter from the top material inlet 1 and oxidant inlet 14 of the device respectively, and are mixed through the baffle plate 2 and the nozzle 13, and the heat of oxidation reaction occurs, and the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com