Method for preparing strontium titanate nanometer powder of one-dimensional structure

A technology of nanopowder and strontium titanate, which is applied in the field of preparation of one-dimensional structure strontium titanate nanopowder, can solve the problems of low product purity, difficulty in controlling particle size and shape, and achieve simple equipment and easy process conditions Controlled, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

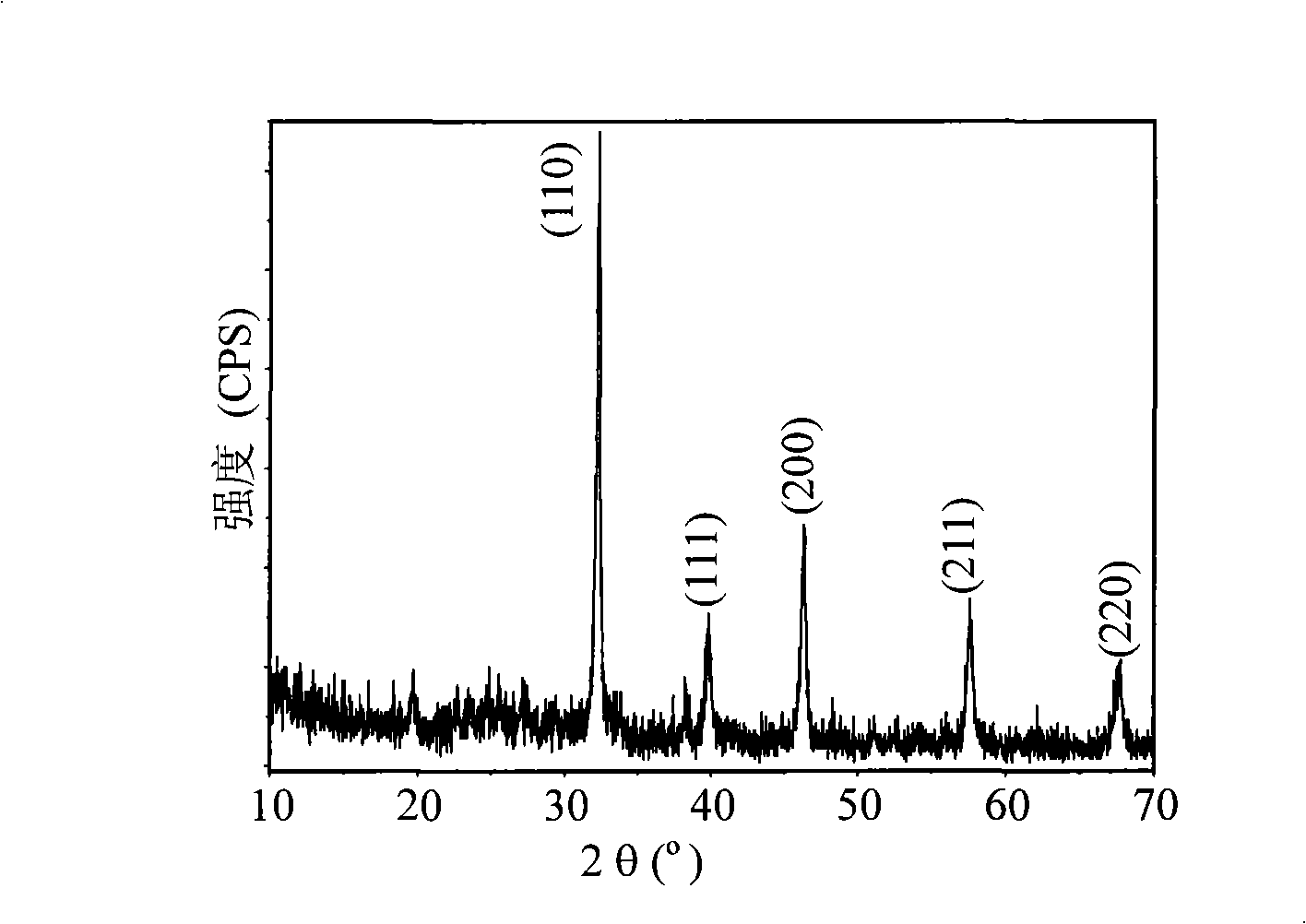

Embodiment 1

[0024] 1) Weigh 1.702g of tetrabutyl titanate, add it to 10ml of absolute ethanol, and magnetically stir until dissolved;

[0025] 2) Under stirring, add 1 ml of ammonia solution with a mass concentration of 30% to the ethanol solution of tetrabutyl titanate prepared in step 1), precipitate, filter, and wash to obtain a precipitate of titanium oxyhydroxide;

[0026] 3) Weigh 0.529g of strontium nitrate, add it to 10ml of deionized water, and magnetically stir until dissolved;

[0027] 4) Weigh 0.016g of polyvinyl alcohol, add it into 10ml of deionized water, heat, and magnetically stir until dissolved;

[0028] 5) The oxyhydroxide precipitation of titanium, the aqueous solution of strontium nitrate, the aqueous solution of polyvinyl alcohol and 1.710g of potassium hydroxide solids are added in the reaction kettle liner with a volume of 60ml, and the volume of the precursor slurry is adjusted with deionized water to 80% of the volume of the inner tank of the reaction kettle, s...

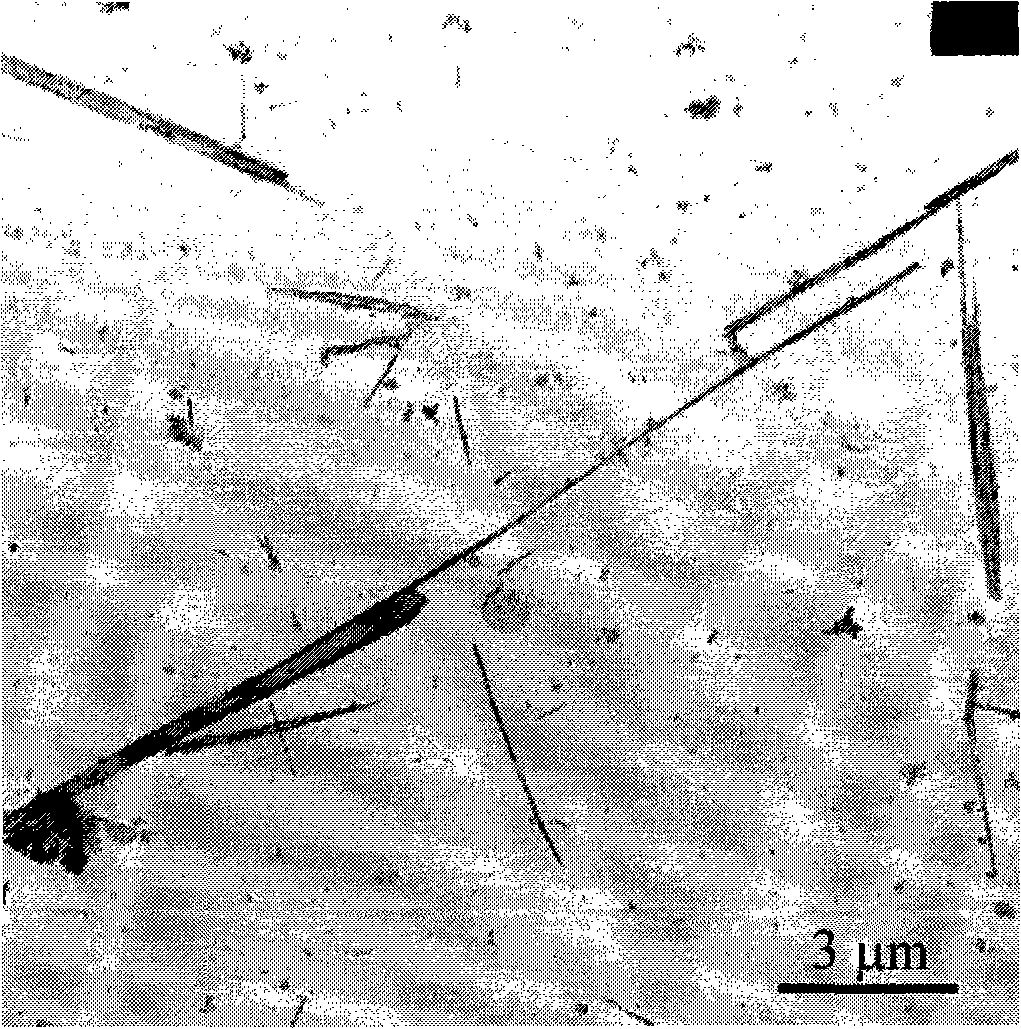

Embodiment 2

[0031] 1) Weigh 1.702g of tetrabutyl titanate, add it to 10ml of absolute ethanol, and magnetically stir until dissolved;

[0032] 2) Under stirring, add 1 ml of ammonia solution with a mass concentration of 30% to the ethanol solution of tetrabutyl titanate prepared in step 1), precipitate, filter, and wash to obtain a precipitate of titanium oxyhydroxide;

[0033] 3) Weigh 1.058g of strontium nitrate, add it to 10ml of deionized water, and magnetically stir until dissolved;

[0034] 4) Weigh 0.016g of polyvinyl alcohol, add it into 10ml of deionized water, heat, and magnetically stir until dissolved;

[0035] 5) The oxyhydroxide precipitation of titanium, the aqueous solution of strontium nitrate, the aqueous solution of polyvinyl alcohol and 1.710g of potassium hydroxide solids are added in the reaction kettle liner with a volume of 60ml, and the volume of the precursor slurry is adjusted with deionized water to 80% of the volume of the inner tank of the reaction kettle, s...

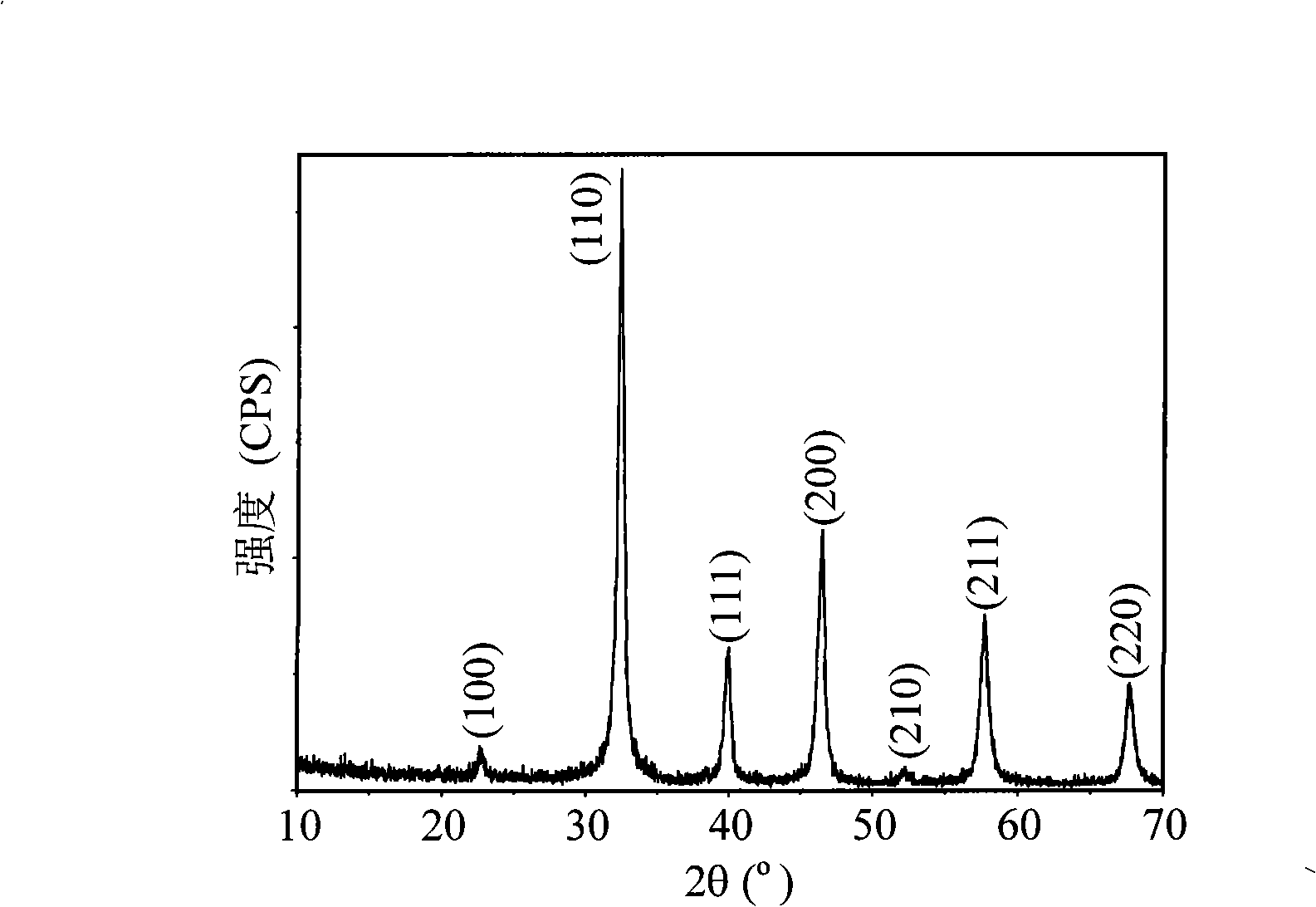

Embodiment 3

[0038] 1) Weigh 0.340g of tetrabutyl titanate, add it to 10ml of absolute ethanol, and magnetically stir until dissolved;

[0039] 2) Under stirring, add 1 ml of ammonia solution with a mass concentration of 30% to the ethanol solution of tetrabutyl titanate prepared in step 1), precipitate, filter, and wash to obtain a precipitate of titanium oxyhydroxide;

[0040] 3) Weigh 0.106g of strontium nitrate, add it into 10ml of deionized water, and magnetically stir until dissolved;

[0041] 4) Weigh 0.016g of polyvinyl alcohol, add it into 10ml of deionized water, heat, and magnetically stir until dissolved;

[0042] 5) The oxyhydroxide precipitation of titanium, the aqueous solution of strontium nitrate, the aqueous solution of polyvinyl alcohol and 1.710g of potassium hydroxide solids are added in the reaction kettle liner with a volume of 60ml, and the volume of the precursor slurry is adjusted with deionized water to 80% of the volume of the inner tank of the reaction kettle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com