Process for preparing chitosan base macroporous high water absorptive resin

A technology of superabsorbent resin and chitosan, applied in the field of preparation of resin with macroporous structure, chitosan-based macroporous superabsorbent resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

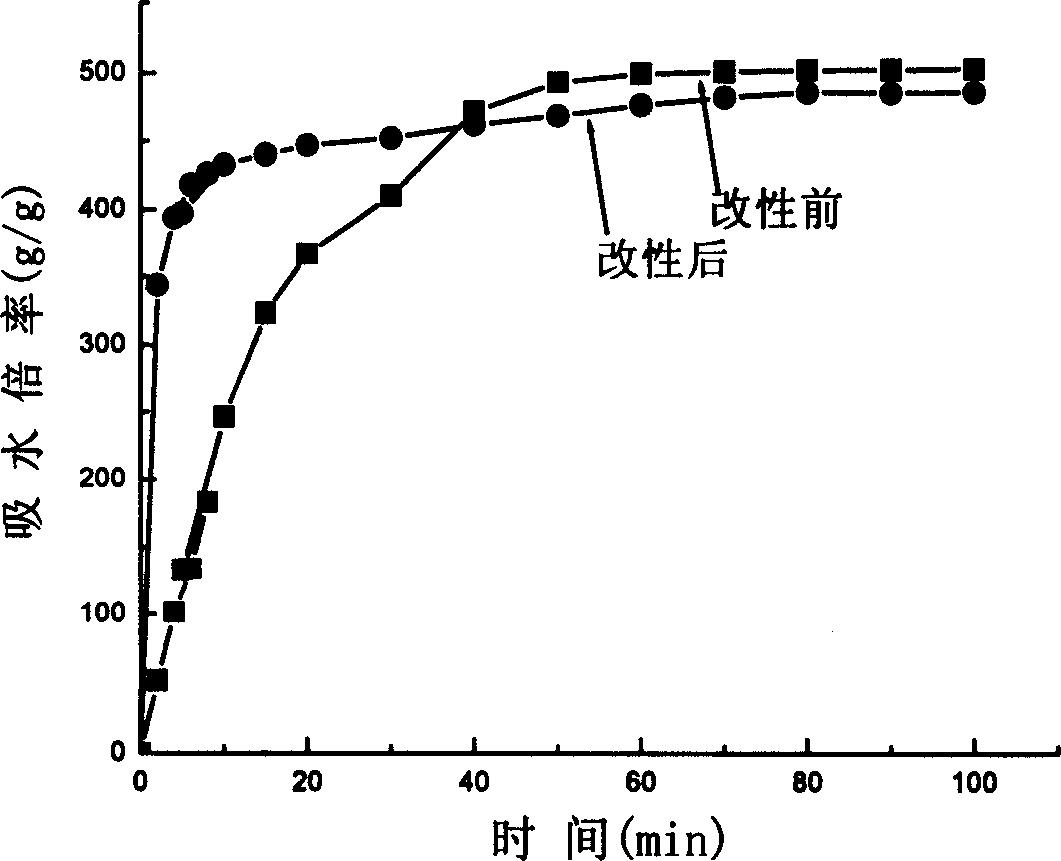

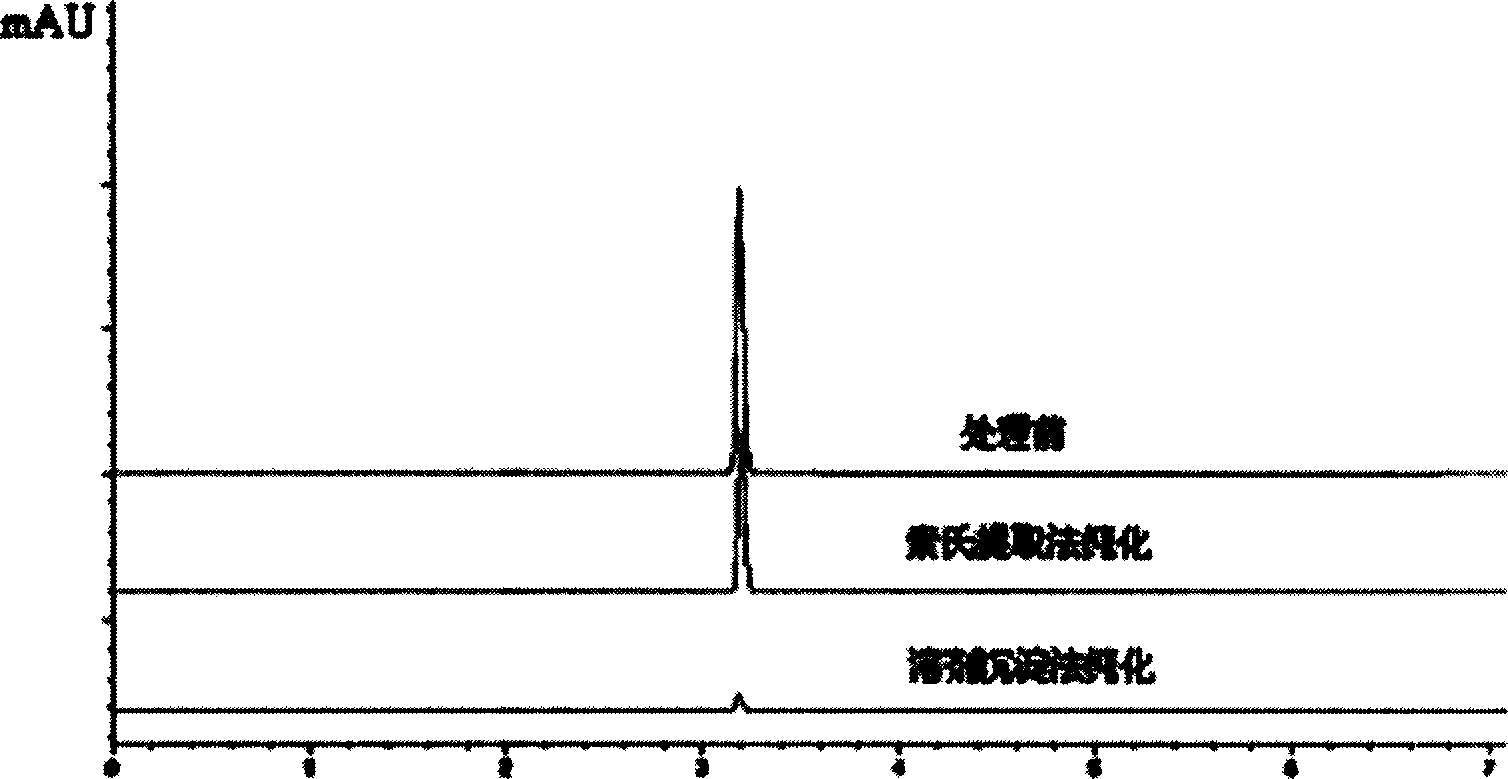

[0024] After the chitosan powder is fully dissolved in 120 milliliters of 2% dilute acetic acid aqueous solution, add monomer 3.3wt% ammonium persulfate initiator under the protection of nitrogen and react at 65 ℃ for 30 minutes and then add the mass of chitosan Ratio is 10:1 acrylic acid monomer and monomer 0.16wt% N, N'-methylenebisacrylamide, stop reaction after reacting at 65 ℃ for 5.5 hours, the reaction system is washed with 20% sodium hydroxide aqueous solution After neutralization, use ethanol to precipitate the product, break the precipitate by stirring at a high speed of 2500 rpm, wash with ethanol repeatedly at this stirring speed, filter with suction and disperse the filter cake in a mixture of ethanol / water with a volume ratio of 4:1 Soak in a solvent for 24 hours for further purification, and vacuum-dry the filter cake after suction filtration to obtain a white powdery product. The distilled water absorption rate of this product can reach 1180 g / g, and the absorp...

Embodiment 2

[0026]After chitosan powder is fully dissolved in 120 milliliters of 2% dilute acetic acid aqueous solution, under nitrogen protection, add the potassium persulfate of monomer 2.5wt% and react at 60 ℃ after 30 minutes and add and chitosan mass ratio is 12:1 acrylic acid monomer and 0.14wt% N,N'-methylene bisacrylamide, stop the reaction after reacting at 60°C for 6 hours, and neutralize the reaction system with 20% aqueous sodium hydroxide solution Finally, precipitate the product with ethanol, crush the precipitate by stirring at a high speed of 2500 rpm, wash it repeatedly with ethanol at this stirring speed, filter with suction and disperse the filter cake in a mixed solvent of ethanol / water with a volume ratio of 4:1 After soaking for 24 hours for further purification, after suction filtration, the filter cake was vacuum-dried and crushed to obtain a white powdery product. The distilled water absorption rate of this product can reach 1065 g / g, and the absorbing rate of phy...

Embodiment 3

[0028] The reaction process of this embodiment is the same as that of Example 1, but the step of soaking the filter cake with ethanol / water mixed solvent for 24 hours is omitted. The distilled water absorption rate of the product prepared under this condition is 930 g / g, and the absorption rate of physiological saline can reach 102 g / g, and the residual amount of acrylic acid in the resin is 8.33×10 -3 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com