Cobalt material doping with ferrous acid bismuth multi-iron and preparation method thereof

A technology of multiferroic materials and bismuth ferrite, which is applied in the direction of magnetism of inorganic materials, can solve the problems of no major improvement, difficult saturation polarization of ferroelectricity, and limited application, and achieve low cost, stable crystal quality, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

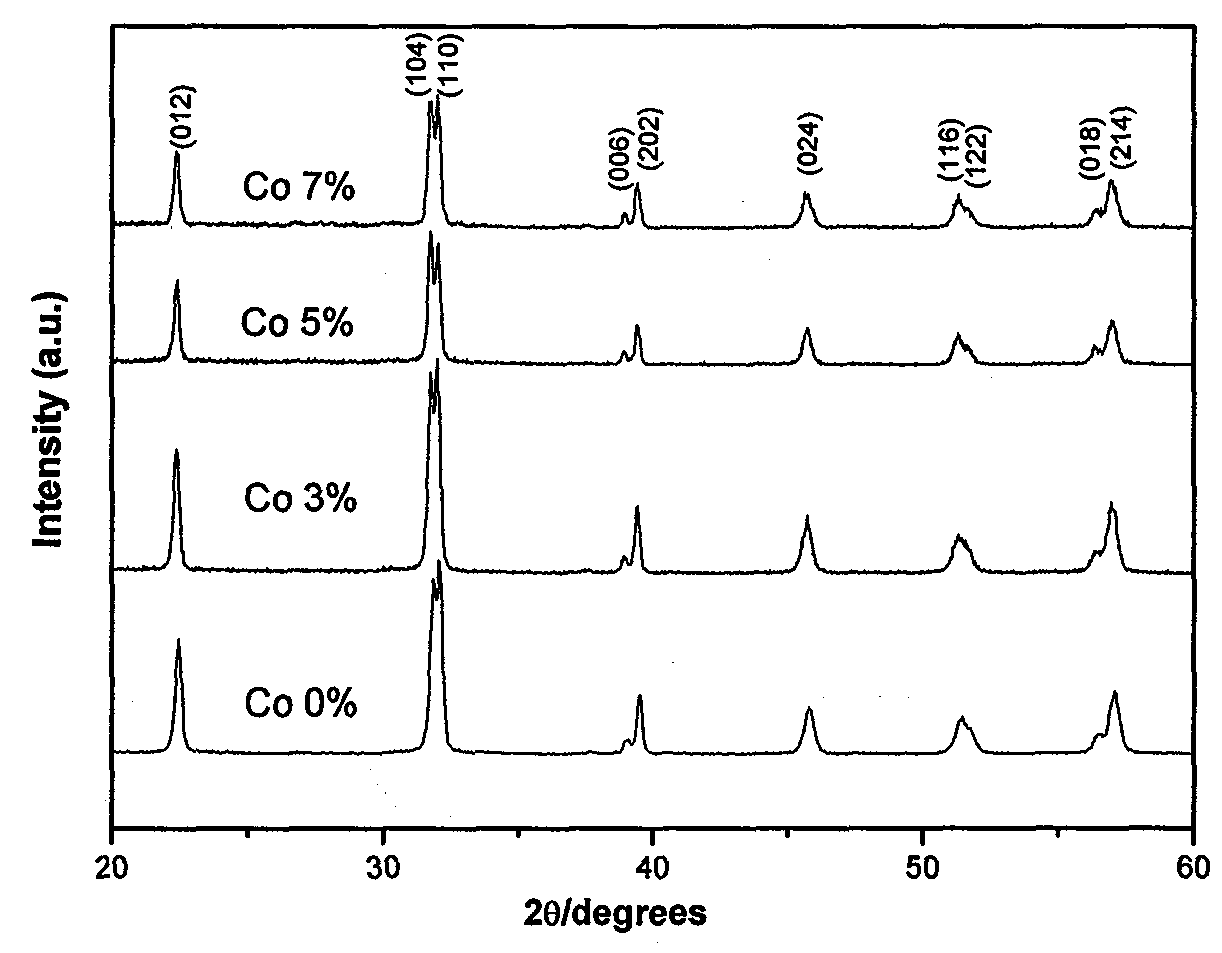

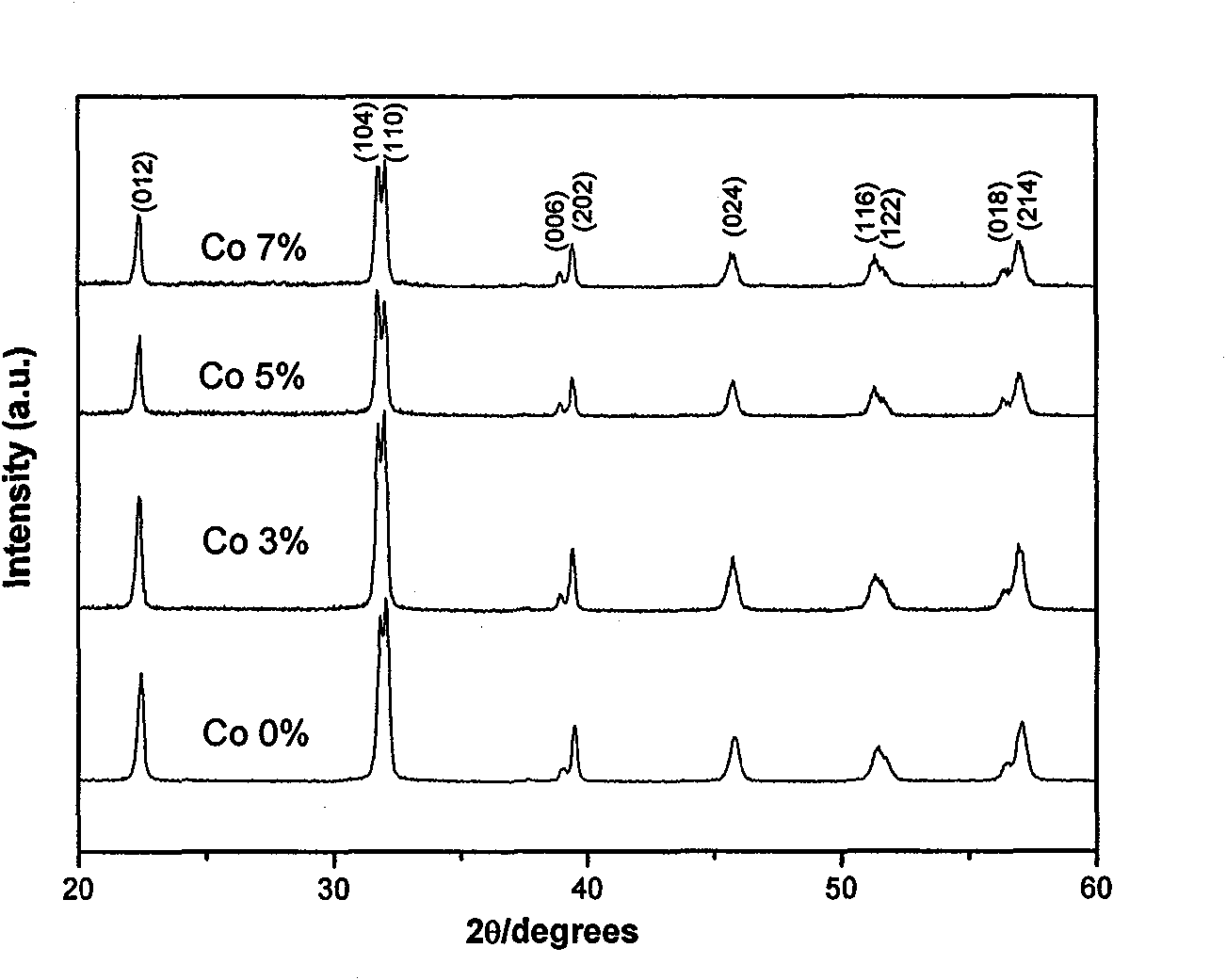

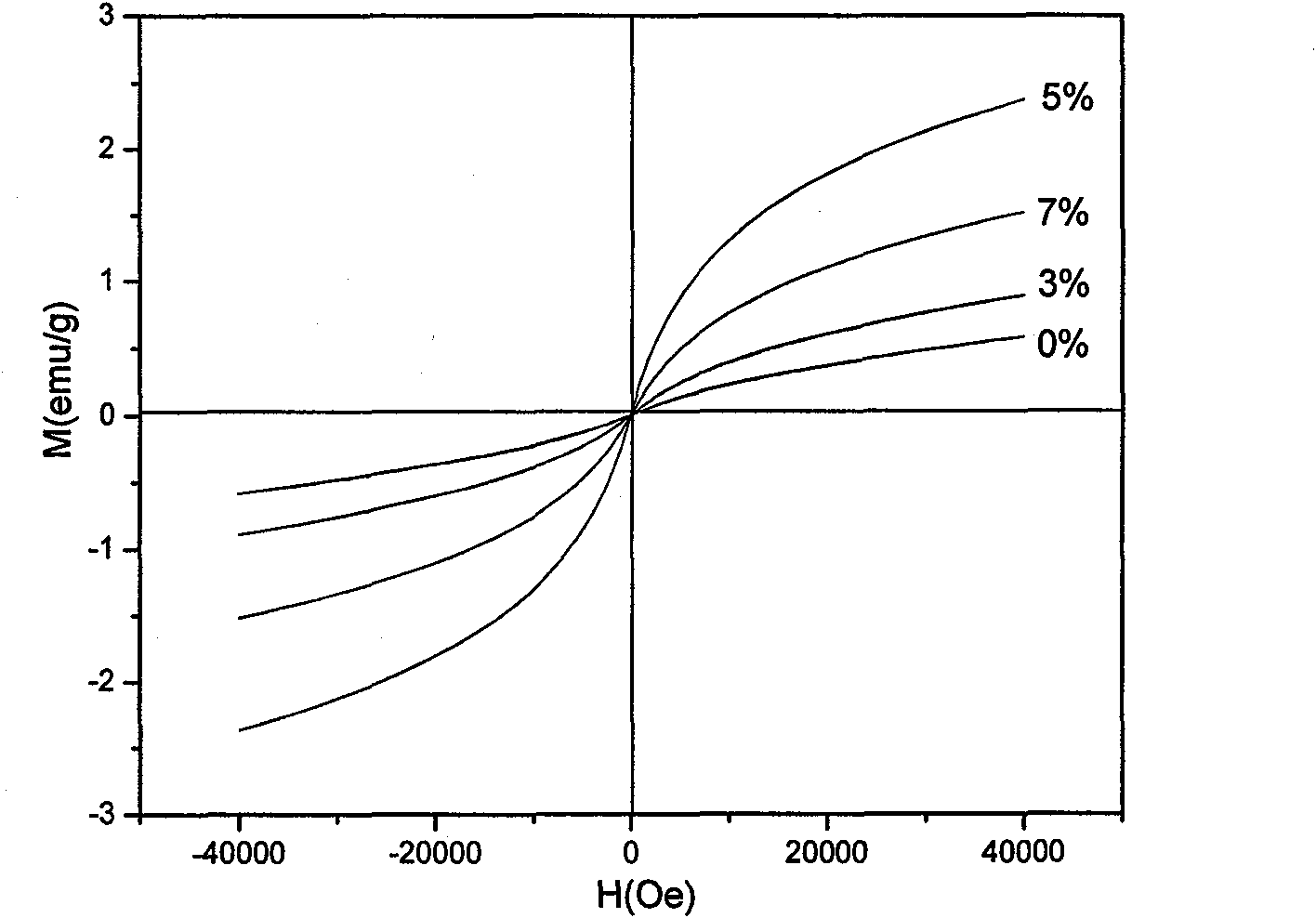

[0019] 1) According to the chemical formula BiCo of the cobalt-doped bismuth ferrite to be synthesized x Fe 1-x o 3 , x=0.05, measure and weigh bismuth nitrate, iron nitrate and cobalt nitrate, be dissolved in dilute nitric acid aqueous solution together, form the aqueous solution that contains bismuth nitrate, iron nitrate and cobalt nitrate, and the concentration of metal ion in the adjustment solution is 0.05mol / L ;

[0020] 2) Under stirring, add excess potassium hydroxide aqueous solution to the aqueous solution containing bismuth nitrate, iron nitrate and cobalt nitrate prepared in step 1), filter and wash the precipitate obtained to obtain the oxyhydroxide of bismuth, iron and cobalt precipitation;

[0021] 3) Add the oxyhydroxide precipitation of bismuth, iron and cobalt and potassium hydroxide into the inner tank of the reactor with an inner tank volume of 60mL, and adjust the volume of the reaction materials in the inner tank of the reactor with deionized water to...

Embodiment 2

[0024] 1) According to the chemical formula BiCo of the cobalt-doped bismuth ferrite to be synthesized x Fe 1-x o 3 , x=0.03, measure and weigh bismuth nitrate, iron nitrate and cobalt nitrate, be dissolved in dilute nitric acid aqueous solution together, form the aqueous solution that contains bismuth nitrate, iron nitrate and cobalt nitrate, and the concentration of metal ion in the adjustment solution is 0.3mol / L ;

[0025] 2) Under stirring, add excess potassium hydroxide aqueous solution to the aqueous solution containing bismuth nitrate, iron nitrate and cobalt nitrate prepared in step 1), filter and wash the precipitate obtained to obtain the oxyhydroxide of bismuth, iron and cobalt precipitation;

[0026] 3) Add the oxyhydroxide precipitation of bismuth, iron and cobalt and potassium hydroxide into the inner tank of the reactor with an inner tank volume of 60mL, and adjust the volume of the reaction materials in the inner tank of the reactor with deionized water to ...

Embodiment 3

[0029] 1) According to the chemical formula BiCo of the cobalt-doped bismuth ferrite to be synthesized x Fe 1-x o 3 , x=0.07, measure and weigh bismuth nitrate, iron nitrate and cobalt nitrate, be dissolved in dilute nitric acid aqueous solution together, form the aqueous solution that contains bismuth nitrate, iron nitrate and cobalt nitrate, and the concentration of metal ion in the adjustment solution is 0.40mol / L ;

[0030] 2) Under stirring, add excess potassium hydroxide aqueous solution to the aqueous solution containing bismuth nitrate, iron nitrate and cobalt nitrate prepared in step 1), filter and wash the precipitate obtained to obtain the oxyhydroxide of bismuth, iron and cobalt precipitation;

[0031] 3) Add the oxyhydroxide precipitation of bismuth, iron and cobalt and potassium hydroxide into the inner tank of the reactor with an inner tank volume of 60mL, and adjust the volume of the reaction materials in the inner tank of the reactor with deionized water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com