Multi-crystalline silicon wafer texturization additive

A polycrystalline silicon wafer and additive technology, applied in sustainable manufacturing/processing, crystal growth, final product manufacturing, etc., can solve the problems of increasing pit depth, difficult process, poor light trapping property of suede, and achieve improved wettability, The effect of stable process and fine concave and convex surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

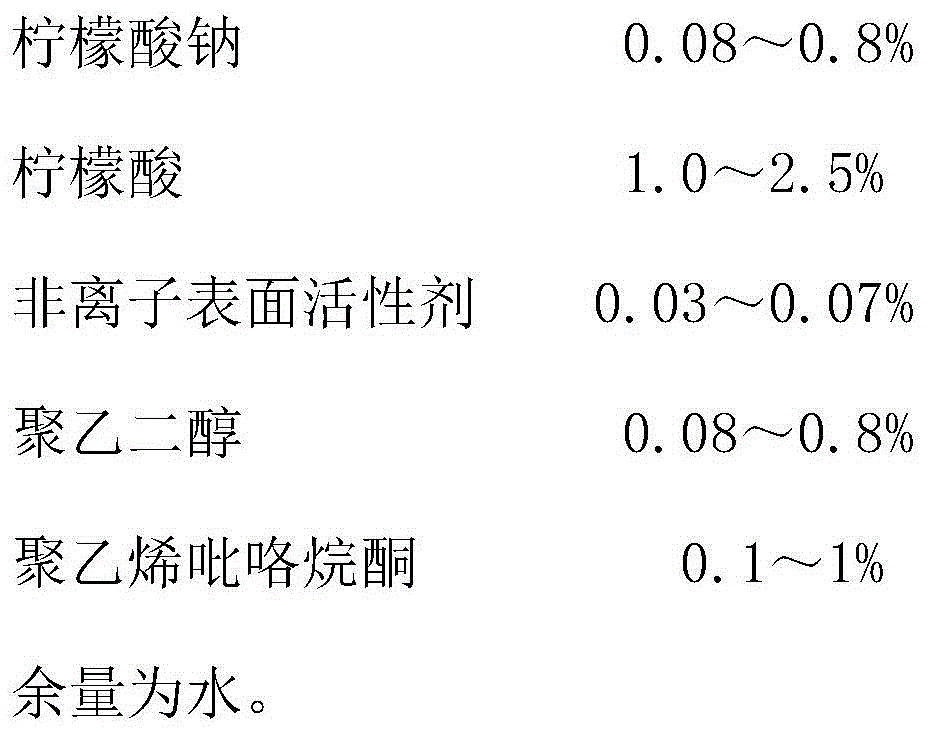

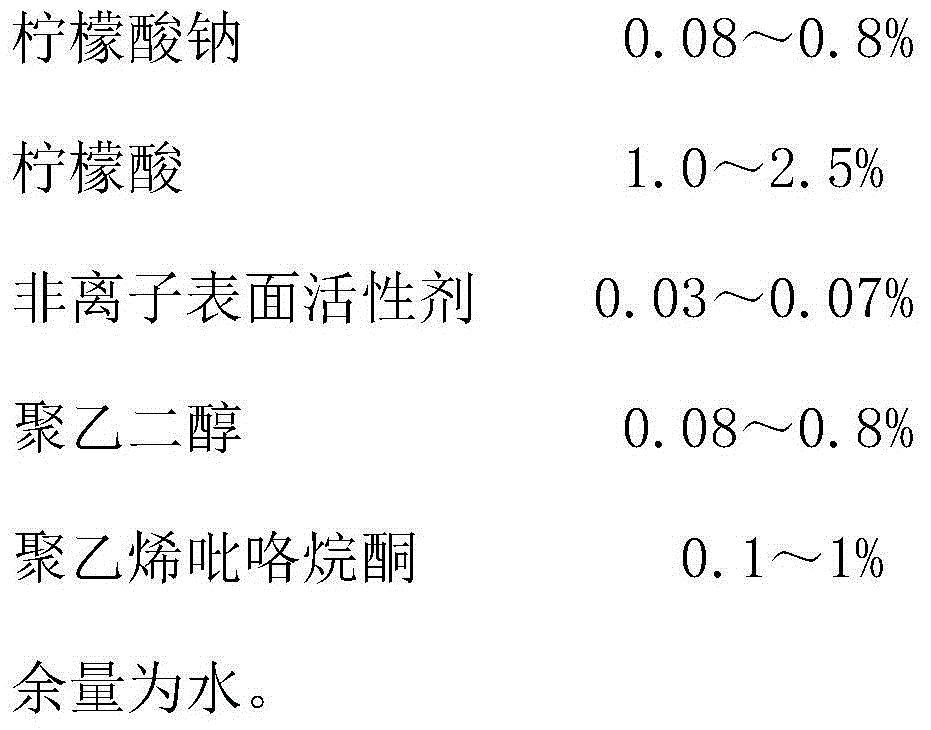

[0021] Add 0.5g of sodium citrate, 2g of citric acid, 0.05g of fluorocarbon surfactant, 0.4g of polyethylene glycol, and 0.6g of polyvinylpyrrolidone into the remaining water, mix and stir until uniform to obtain the preparation fleece additives. Add 100 g of this texturing additive into 19 kg of acid texturing liquid, and mix and stir evenly.

[0022] The polycrystalline silicon wafer is immersed in the above-mentioned acid texturing solution containing texturing additives for texturing, the temperature is controlled at 10°C, and the texturing time is 200s.

Embodiment 2

[0024] Add 0.7g of sodium citrate, 2.3g of citric acid, 0.06g of fluorocarbon surfactant, 0.6g of polyethylene glycol, and 0.5g of polyvinylpyrrolidone into the remaining water, mix and stir until uniform Texturing additives. Add 100 g of this texturing additive into 22 kg of acid texturing liquid, and mix and stir evenly.

[0025] The polycrystalline silicon wafer is immersed in the above-mentioned acid texturing solution containing texturing additives for texturing, the temperature is controlled at 15°C, and the texturing time is 140s.

Embodiment 3

[0027] Add 0.8g of sodium citrate, 2g of citric acid, 0.05g of fluorocarbon surfactant, 0.6g of polyethylene glycol, and 0.8g of polyvinylpyrrolidone into the remaining water, mix and stir until uniform to obtain the preparation fleece additives. Add 100 g of this texturing additive into 15 kg of acid texturing liquid, and mix and stir evenly.

[0028] The polycrystalline silicon wafer is immersed in the above acid texturing solution added with texturing additives for texturing, the temperature is controlled at 9° C., and the texturing time is 160 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com