Anti-bacterial polythene foamed plastics and preparation method thereof

A technology of foamed plastics and polyethylene, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of complex manufacturing process, unsatisfactory antibacterial plastic antibacterial effect, etc., and achieve simple and convenient equipment operation, good sterilization and antibacterial effect, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

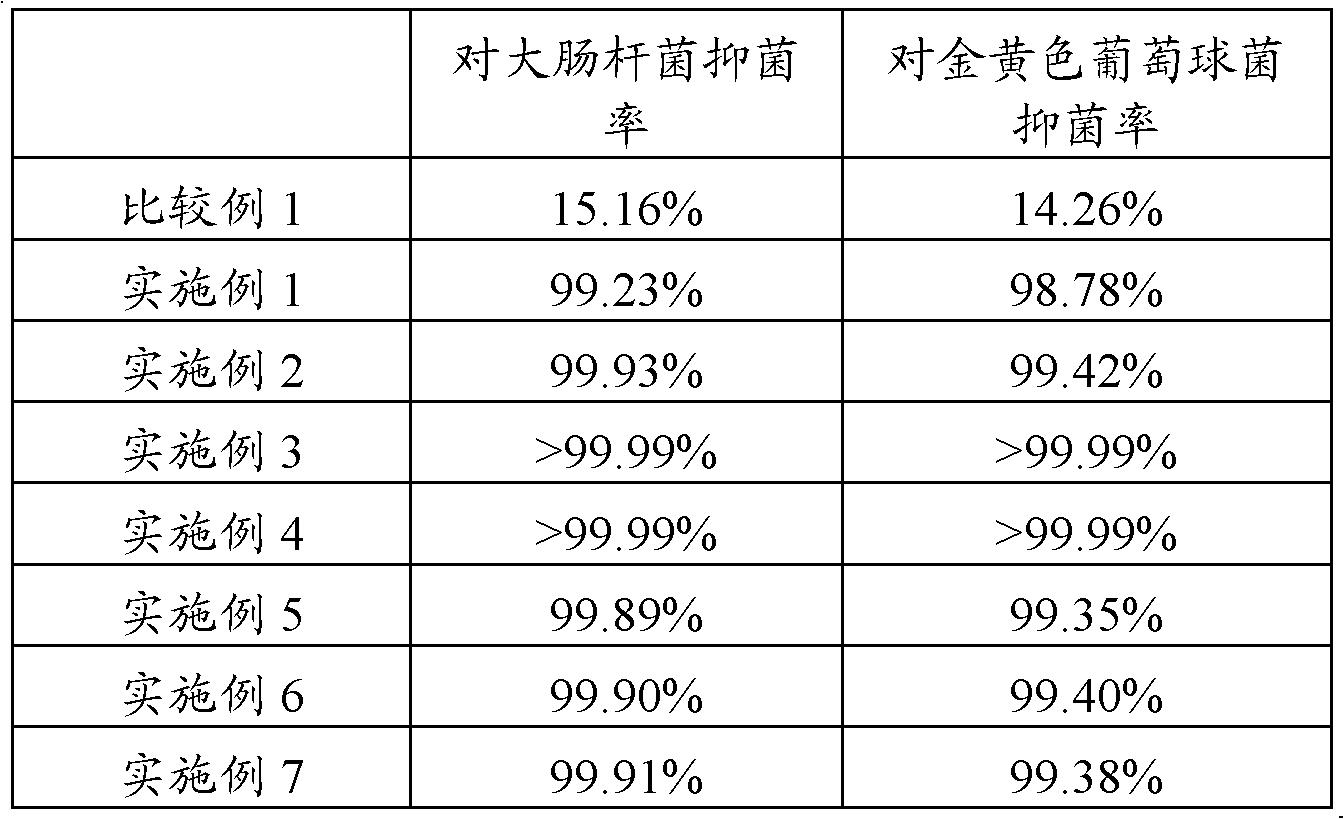

Examples

Embodiment 1

[0043] a. Melt blending: first raise the temperature of the two-roll mill to 115°C, and then mix the dry polyethylene (PE-M-18D) and ethylene-vinyl acetate copolymer (EVA18-3) at 70: After mixing with a mass ratio of 30 to obtain 935g of the mixture, add it into a double-roller mill and knead for 5min, then cut 5g into 3mm silver-plated nylon fibers (resistivity<10Ω cm, Shanghai Pusheng Gold and Silver Silk Textile Co., Ltd.) In the refining machine, kneading 5min, then the zinc stearate of 10g (Wenzhou City Chemical Materials Factory), the azodicarbonamide of 40g (Hangzhou Haihong Fine Chemical Co., Ltd. provides), the diisopropyl peroxide of 10g Benzene (provided by Shanghai Lingfeng Chemical Reagent Co., Ltd.) was sequentially added into the open mill and kneaded for 3 minutes, then sliced and cut into sheet-like samples.

[0044] b. Molding and foaming: place the above-mentioned sheet samples at room temperature for 24 hours, and then perform molding and foaming on a fla...

Embodiment 2

[0046] a. Melt blending: first raise the temperature of the two-roll mill to 115°C, and then mix the dry polyethylene (PE-M-18D) and ethylene-vinyl acetate copolymer (EVA18-3) at 70: After mixing at a mass ratio of 30 to obtain 930g of the mixture, add it to a double-roller mill and knead for 8 minutes, then cut 10g into 3mm silver-plated nylon fibers (resistivity<0.1Ω·cm, Shanghai Pusheng Gold and Silver Silk Textile Co., Ltd.) In the mill, knead for 5min, then pass 10g of zinc stearate (Wenzhou Chemical Material Factory), 40g of azodicarbonamide (Hangzhou Haihong Fine Chemical Co., Ltd.), 10g of cross-linking agent Dicumyl oxide (provided by Shanghai Lingfeng Chemical Reagent Co., Ltd.) was sequentially added into the open mill, mixed for 2 minutes while adding, and then sliced, and cut into sheet-like samples.

[0047] b. Molding and foaming: place the above-mentioned sheet samples at room temperature for 24 hours, and then perform molding and foaming on a flat vulcanizer. ...

Embodiment 3

[0049]a. Melt blending: first raise the temperature of the two-roll mill to 115°C, and then mix the dry polyethylene (PE-M-18D) and ethylene-vinyl acetate copolymer (EVA18-3) at 70: After mixing at a mass ratio of 30 to obtain 910g of the mixture, add it to a double-roller mill and knead for 5 minutes, then cut 30g into 3mm silver-plated nylon fibers (resistivity<0.1Ω·cm, Shanghai Pusheng Gold and Silver Silk Textile Co., Ltd.) In the mill, knead for 5min, then mix 10g of zinc stearate (Wenzhou Chemical Materials Factory), 40g of azodicarbonamide (Hangzhou Haihong Fine Chemical Co., Ltd.), 10g of diisoperoxide Propylbenzene (provided by Shanghai Lingfeng Chemical Reagent Co., Ltd.) was sequentially added into the open mill, mixed for 3 minutes while adding, and then sliced, and cut into sheet samples.

[0050] b. Molding and foaming: place the above-mentioned sheet samples at room temperature for 24 hours, and then perform molding and foaming on a flat vulcanizer. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com