Preparation method of rare earth nickel-based oxide polycrystalline film material

A thin film material, oxide technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high pressure process complexity, expensive oxide single crystal substrate, high cost, etc. Excellent thermotropic and hydrogen-induced properties, simple and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

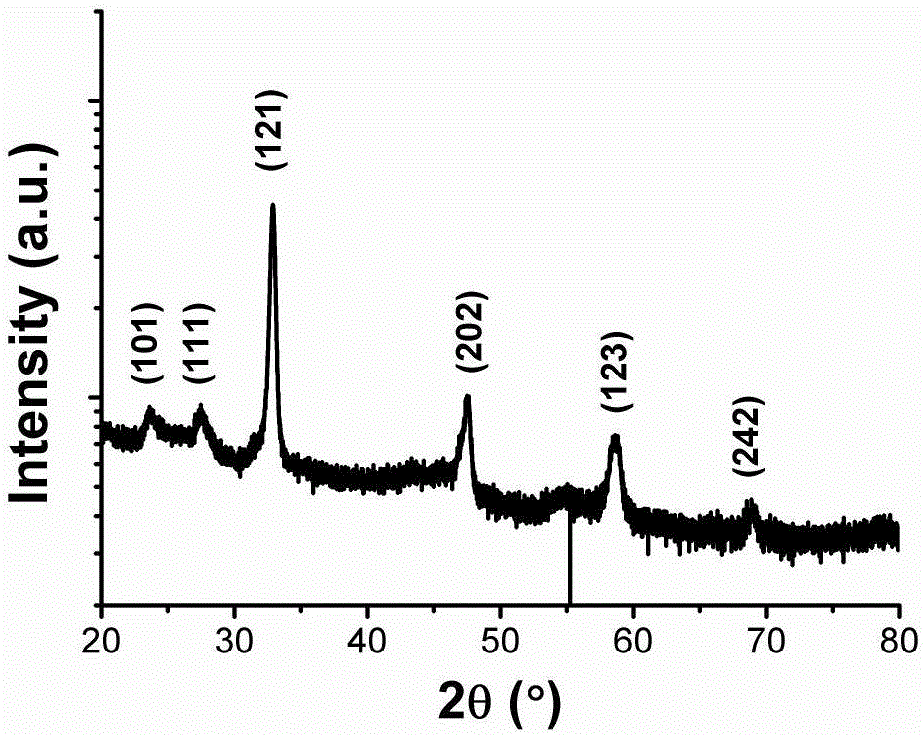

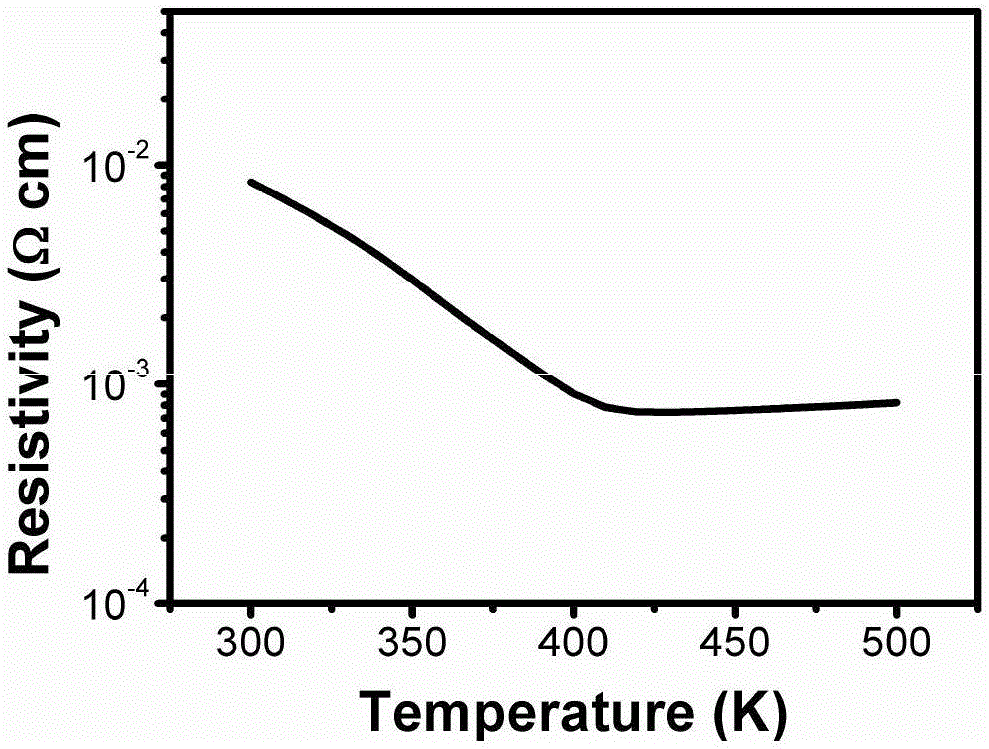

[0034] A 30nm strontium rubidium oxide buffer layer was grown on a 1 cm by 1 cm square silicon substrate by pulsed laser deposition (deposition pressure was 10 Pascal oxygen atmosphere, substrate temperature was 500 degrees Celsius); and then a 100 nm layer was grown by pulsed laser deposition Samarium nickel oxide (SmNiO 3 ) polycrystalline film (deposition pressure is 10 Pascal oxygen atmosphere, substrate temperature is 500 degrees Celsius). The prepared samarium nickel oxide film has a pure phase structure (such as figure 1 shown), its surface is flat, and a sudden change in the resistivity of the material is observed at a temperature of 400-410 Kelvin (such as figure 2 shown), consistent with the literature [Nat.Commun., 2014,5,4860], which proves that the material has temperature-induced phase transition properties; under hydrogen atmosphere, the resistivity increases by 6 orders of magnitude, proving that the material has hydrogen-induced phase transition properties ...

Embodiment 2

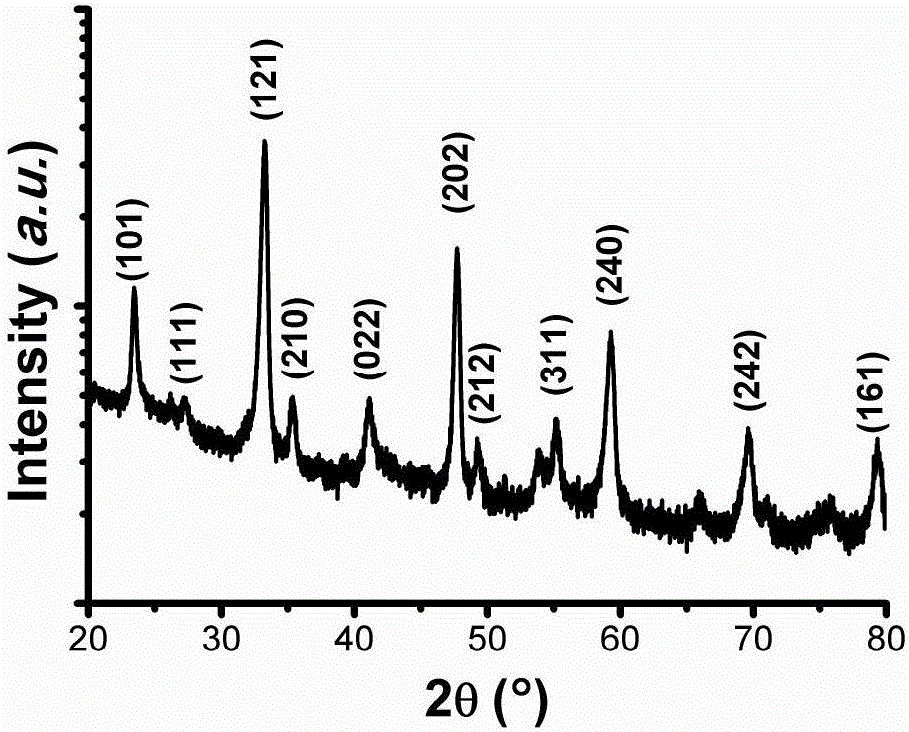

[0036] A 30nm strontium rubidium oxide buffer layer was grown on a 1 cm by 1 cm square silicon substrate by pulsed laser deposition (the deposition pressure was 5 pascals in an oxygen atmosphere, and the substrate temperature was 800 degrees Celsius), and then a 100 nm layer was grown by pulsed laser deposition. Nano neodymium nickel oxide (NdNiO 3 ) polycrystalline film (deposition pressure is 30 Pascal oxygen atmosphere, substrate temperature is 700 degrees Celsius). The prepared samarium nickel oxide film has a pure phase structure (such as image 3 As shown), a sudden change in the resistivity of the material is observed at the phase transition temperature point, which proves that the material has temperature-induced phase transition properties; under a hydrogen atmosphere, the resistivity increases by 3 orders of magnitude, proving that the material has hydrogen-induced phase transition properties.

Embodiment 3

[0038] A 30 nm strontium rubidium oxide buffer layer was grown on a 1 cm by 1 cm square quartz substrate by pulsed laser deposition (deposition pressure was 20 Pascal oxygen atmosphere, substrate temperature was 800 degrees Celsius), and then pulsed laser deposition was used to grow 90 Nano samarium nickel oxide (SmNiO 3 ) polycrystalline film (deposition pressure is 25 Pascal oxygen atmosphere, substrate temperature is 500 degrees Celsius). The prepared samarium nickel oxide film has a pure phase structure (such as Figure 4 As shown), a sudden change in the resistivity of the material is observed at the phase transition temperature point, which proves that the material has temperature-induced phase transition properties; under a hydrogen atmosphere, the resistivity increases by 6 orders of magnitude, proving that the material has hydrogen-induced phase transition properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com