Thermosensitive ceramic powder, NTC thermosensitive chip, temperature sensor and preparation method

A technology of heat-sensitive ceramics and powders, applied to thermometers, thermometers, instruments, etc. that are directly sensitive to heat-sensitive electrical/magnetic components, can solve problems affecting the magnetism of the motor rotor, loss of magnetism, and high internal power of the motor, and achieve good performance. Good electrical performance, compactness, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

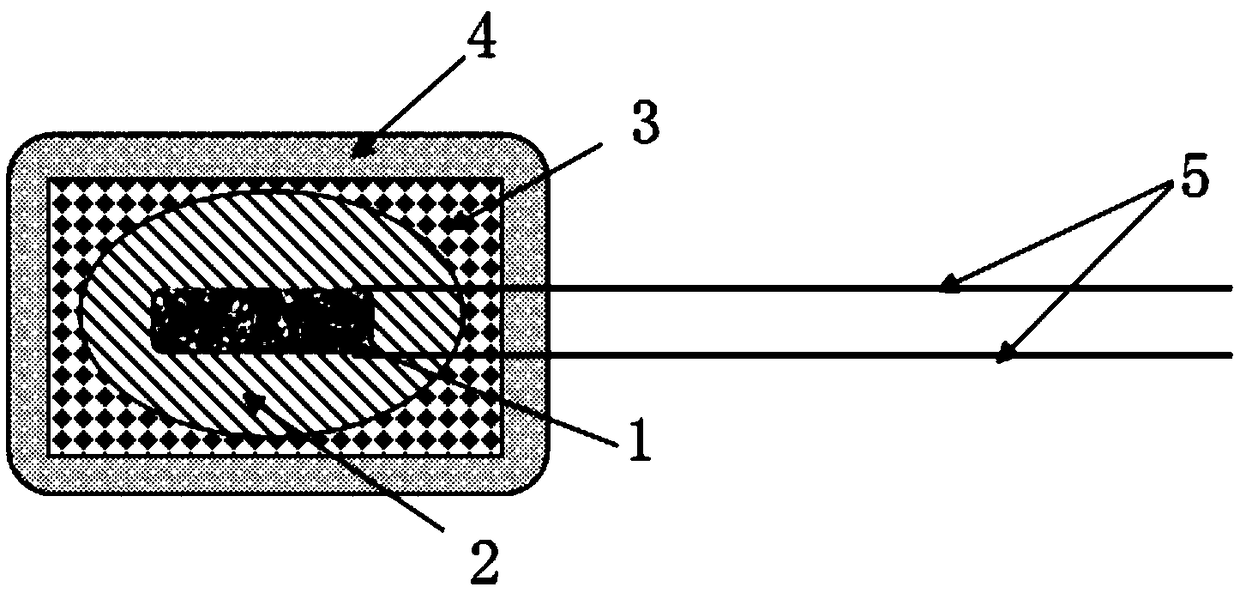

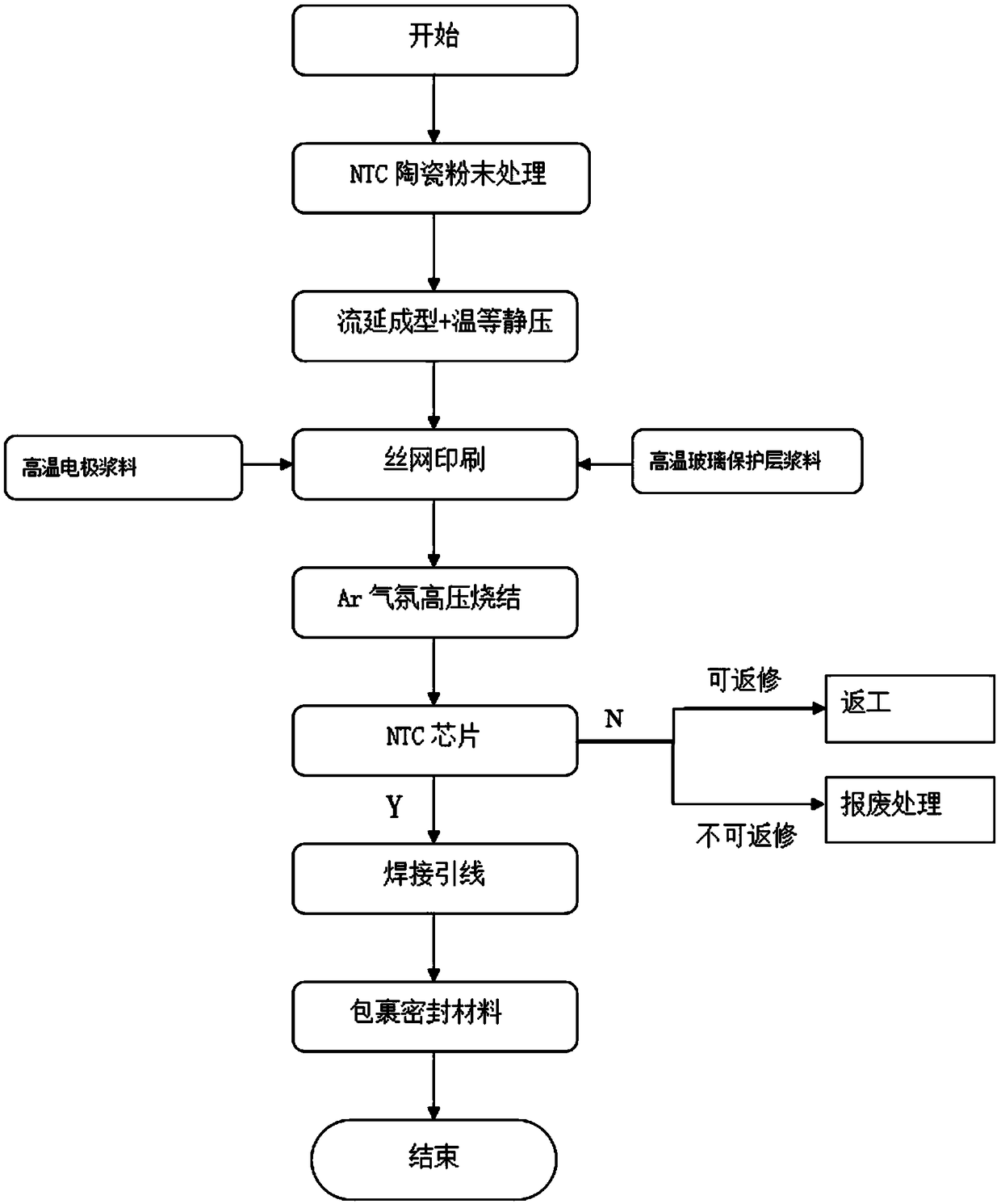

[0052] The preparation method of the NTC thermosensitive chip provided by the application, the steps are as follows:

[0053] Prepare a ceramic green sheet, and make a ceramic green sheet from a heat-sensitive ceramic slurry, the thickness of the ceramic green sheet is 0.1-0.6mm;

[0054] Preparation of ceramic green bodies, using warm isostatic pressing technology to press ceramic green bodies into ceramic green bodies;

[0055] Prepare an NTC thermal chip, print the electrode paste and glass protective glaze on the ceramic green body, and then sinter the printed ceramic green body into a whole in an inert gas atmosphere furnace to obtain NTC heat sensitive chip.

[0056] Wherein, the above-mentioned electrode paste adopts silver-coated palladium powder instead of silver powder as the conductive agent. Silver-coated palladium is a binary alloy in which silver is added as the base of palladium. Palladium and silver can be dissolved infinitely to form a continuous solid solut...

Embodiment

[0078] 1. Preparation of NTC Thermosensitive Chip

[0079] 1) By weight, according to the design formula, the thermistor components: manganese dioxide powder 35%, dicobalt oxide powder 16%, iron oxide powder 8.5%, nickel oxide powder 36% and rare earth oxide powder 4.5%, mixed Ball milling, drying at low temperature, calcining at high temperature, and crushing by ball milling to obtain heat-sensitive ceramic powder.

[0080] 2) By weight, heat-sensitive ceramic slurry is prepared according to the following proportions for each component: heat-sensitive ceramic powder 76% and organic solvent 10% (butyl carbitol 4%, amyl acetate 3%, isoamyl acetate ester 3%), adhesive polyvinyl butyral 9%, plasticizer dibutyl sebacate 4%, and federal B-329 1.0% in the surface additive are mixed, and the planetary ball mill is used for ball milling and sieving , to obtain heat-sensitive ceramic slurry after vacuum defoaming.

[0081] 3) Form the heat-sensitive ceramic slurry into ceramic green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com