Black micro-crystalline glass plate made of gold ore tailings and manufacturing method thereof

A technology of glass-ceramic and a manufacturing method, applied in the field of glass-ceramic manufacturing, can solve the problems of excessive addition of alkali chemical raw materials, corrosion of furnace refractories, and high melting temperature of glass, so as to improve furnace efficiency and improve melting temperature. The effect of speed and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

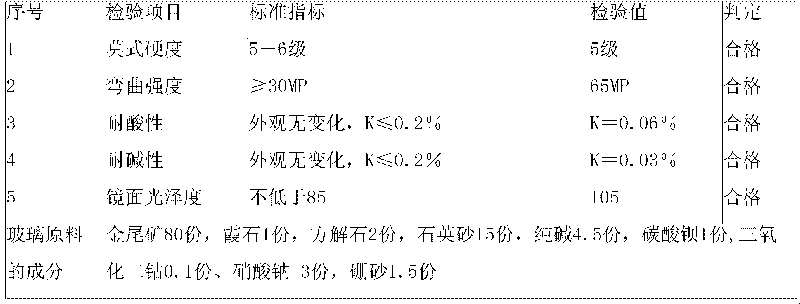

Embodiment 1

[0047] First, gold tailings, quartz sand, calcite and nepheline are crushed and screened. The fineness of gold tailings can be over 40 mesh, the fineness of calcite is 80 mesh, and the calcium oxide content is 55.5%; the fineness of quartz sand is 60-80 mesh, and the silicon oxide content is 98%; the fineness of nepheline is 60-80 mesh; silicon content 54%, alumina content 28%. The soda ash is industrial-grade soda ash, and the rest of the raw materials meet the national industry quality inspection standards. The cyanide in the gold tailings is removed by ion exchange, and then the mixture is made by weighing and mixing. The weight parts of each raw material are: 80 parts of gold tailings, 1 part of nepheline, 2 parts of calcite, and quartz sand 15 parts, 4.5 parts of soda ash, 1 part of barium carbonate, 0.1 part of dicobalt trioxide, 3 parts of sodium nitrate, and 1.5 parts of borax.

[0048] Put the above mixture in a mullite crucible and melt it in a box-type electric fu...

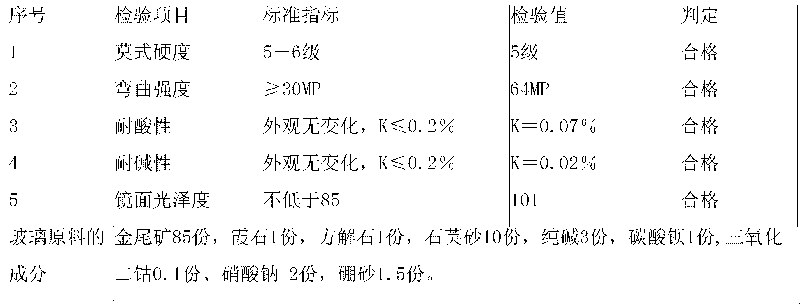

Embodiment 2

[0050] First, gold tailings, quartz sand, calcite and nepheline are crushed and screened. The cyanide in the gold tailings is removed by ion exchange, and then weighed to make a mixture. The weight parts of each raw material ratio are: 85 parts of gold tailings, 1 part of nepheline, 1 part of calcite, and 10 parts of quartz sand. 3 parts of soda ash, 1 part of barium carbonate, 0.1 part of dicobalt trioxide, 2 parts of sodium nitrate, and 1.5 parts of borax.

[0051] The above-mentioned glass raw materials were melted in a glass tank furnace with a temperature of 1350° C. for 3.5 hours. After the melting was completed, the molten glass was directly poured into water to become glass pellets. Spread 15 kg of glass pellets in a refractory mold with a size of 6000×9000 mm and crystallize in a shuttle kiln fueled by liquefied petroleum gas at a crystallization temperature of 1050°C. Thereby, a black glass-ceramic product of 600×900×7 mm can be obtained.

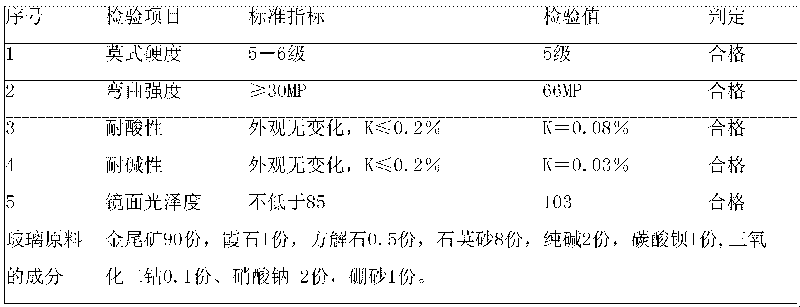

Embodiment 3

[0053]First, gold tailings, quartz sand, calcite and nepheline are crushed and screened. The cyanide in the gold tailings is removed by ion exchange, and then weighed to make a mixture. The weight parts of the raw materials are: 90 parts of gold tailings, 1 part of nepheline, 0.5 parts of calcite, and 8 parts of quartz sand. 2 parts of soda ash, 1 part of barium carbonate, 0.1 part of dicobalt trioxide, 2 parts of sodium nitrate, and 1 part of borax.

[0054] The above-mentioned glass raw materials were melted in a glass tank furnace with a temperature of 1350° C. for 3.5 hours. After the melting was completed, the molten glass was directly flowed into water to become glass pellets. Spread 50 kg of glass granules flat in a refractory mold with a size of 6000×9000 mm and carry out crystallization in a shuttle kiln fueled by liquefied petroleum gas at a crystallization temperature of 1050°C. Thereby, a black glass-ceramic product of 600×900×35 mm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com