Stray light absorbing glass for optical fiber image inverter and preparation method of stray light absorbing glass

An image-inverting, stray light technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve the problem of ineffective absorption of stray light, etc., achieve strong anti-devitrification ability, high glass gloss, Good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

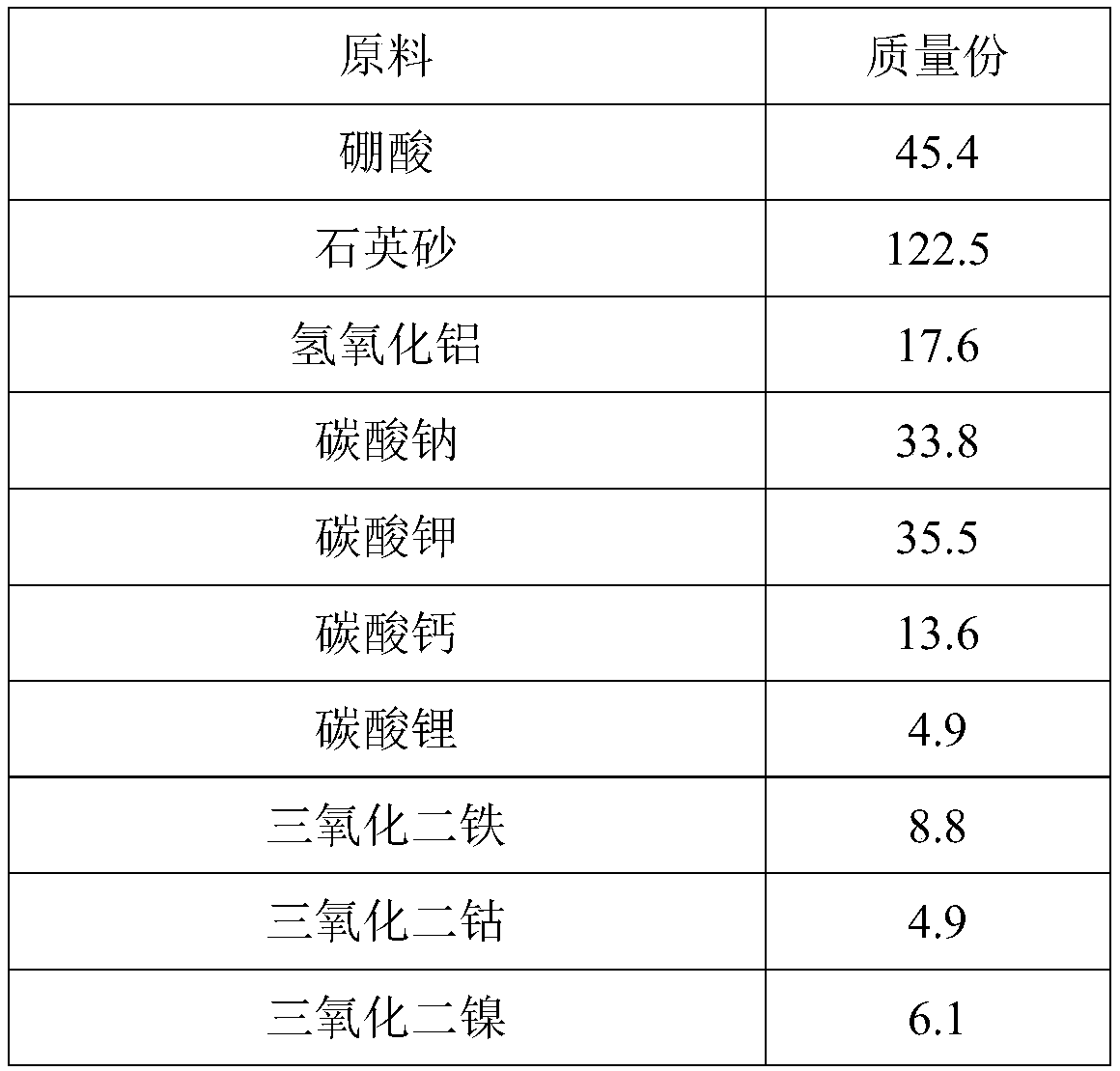

[0031] Example 1 The composition (parts by mass) of the raw materials of the stray light absorbing glass for the fiber optic image inverter is shown in Table 1.

[0032] The raw material composition of table 1 embodiment 1

[0033]

[0034]

Embodiment 2

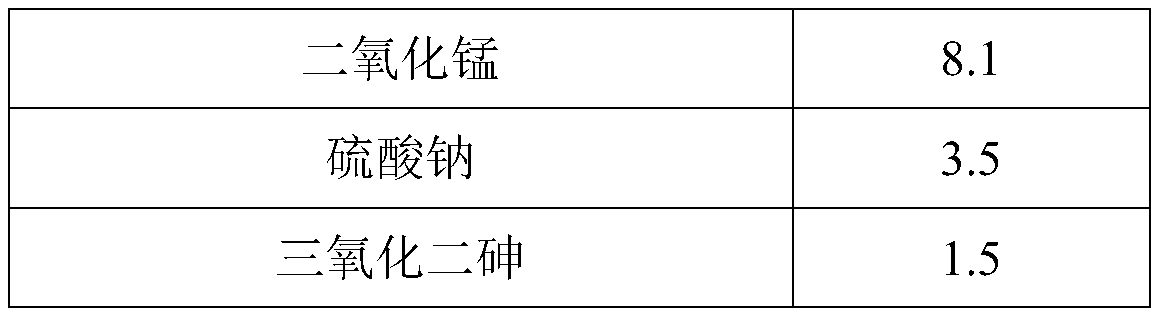

[0036] Example 2 The raw material composition (parts by mass) of the stray light absorbing glass for the fiber optic image inverter is shown in Table 2.

[0037] The raw material composition of table 2 embodiment 2

[0038] raw material

Embodiment 3

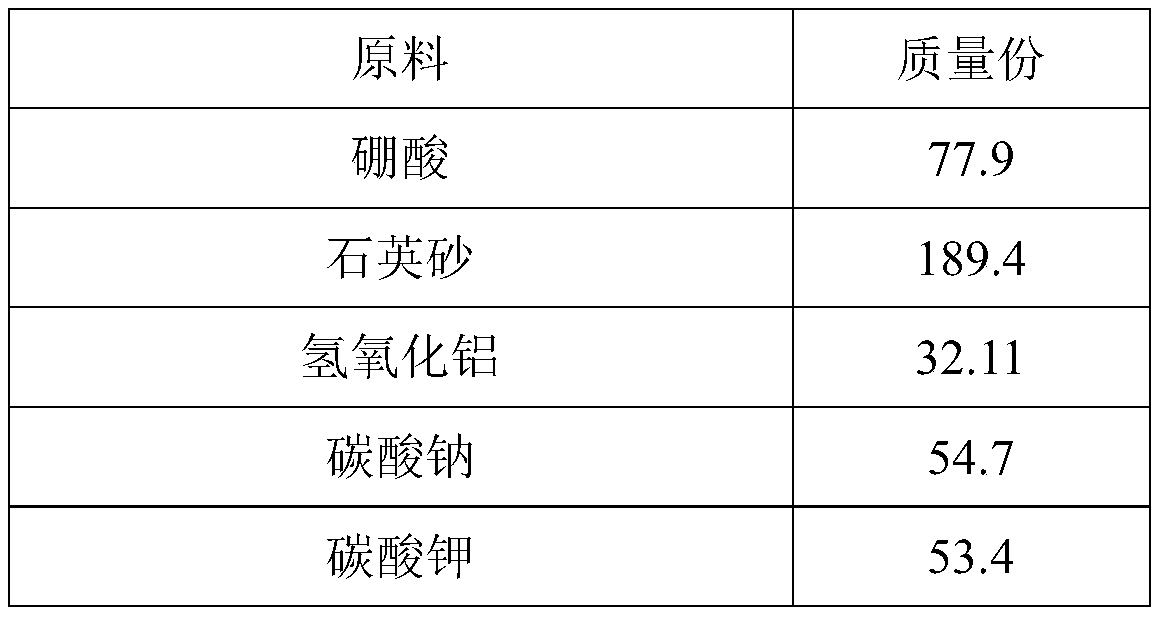

[0040] Example 3 The raw material composition (parts by mass) of the stray light absorbing glass for the fiber optic image inverter is shown in Table 3.

[0041] The raw material composition of table 3 embodiment 3

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com