Deep low temperature oxide thermosensitive resistor material

A thermistor, oxide technology, applied in the direction of oxide conductors, resistors with negative temperature coefficient, non-metallic conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

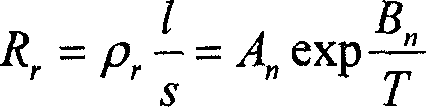

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. First, weigh strontium oxide (produced by decomposing strontium carbonate at 900°C) with cobalt trioxide in a molar ratio of 1:1 to carry out direct solid-state reaction, grind in an agate mortar, grind and mix well, and then preheat at 800°C Sintered for 4 hours, pre-sintered and then ground into powder;

[0019] b. Add 10% starch solution to the prepared powder as a binder, use platinum wire as an electrode, and the distance between the two electrodes is 0.2mm, and the point beads are formed, and the size of the beads is 0.8mm; The beads were buried in a corundum crucible filled with analytically pure alumina powder, and sintered at a constant temperature of 1075°C for 6 hours to form porcelain; the sintered beads were spot-welded with a platinum wire electrode to the outer lead of the Dumet wire with a spot welder. Glass package, measure the parameters as the thermistor material, its B value is 35k, and the resistance value is 8Ω at 25°C.

Embodiment 2

[0021] a. First, weigh strontium oxide (produced by decomposing strontium carbonate at 900° C.) and nickel sesquioxide in a molar ratio of 1:1 to carry out direct solid-state reaction, grind in an agate mortar, grind and mix well, and then preheat at 850° C. Sintered for 6 hours, pre-sintered and then ground into powder;

[0022] b. Add 8% starch solution to the prepared powder as a binder, use platinum wire as an electrode, and the distance between the two electrodes is 0.1mm, and the point beads are formed, and the size of the beads is 1.0mm; The beads are buried in a corundum crucible filled with analytically pure alumina powder, and sintered at a high temperature of 1100°C for 4 hours to form porcelain; the sintered porcelain beads are spot-welded with a platinum wire electrode on the outer lead of the Dumet wire with a spot welder. Adopt glass encapsulation, measure the parameter as the thermistor material, its B value is at 35k, 25 ℃ resistance value is 0.5Ω.

Embodiment 3

[0024] a. First weigh strontium carbonate and dicobalt trioxide in a molar ratio of 1:1 and grind them in an agate mortar, grind and mix them evenly, then pre-sinter at 900°C for 4 hours, and then grind them into powder after pre-sintering;

[0025] b. Add 5% starch solution to the prepared powder as a binder, use platinum wire as an electrode, and the distance between the two electrodes is 0.2mm, and the point beads are formed, and the size of the beads is 1.2mm; The beads are buried in a corundum crucible filled with analytically pure alumina powder, and sintered at a high temperature of 1000°C for 6 hours to form porcelain; the sintered porcelain beads are spot-welded with a platinum wire electrode on the outer lead of the Dumet wire with a spot welder. Using glass package, measure the parameters as the thermistor material, its B value is 35k, and the resistance value is 50Ω at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com