Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

A technology of thermal barrier coatings and turbine blades, which is applied in the direction of testing wear resistance, etc., can solve the problems of not realizing the simulation of thermal barrier coating turbine blades, etc., and achieve wide speed range, fast heating and cooling rates, and convenient heating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides a test device for simulating and testing the erosion of the thermal barrier coating of a turbine blade in real time. The present invention will be further described below through the description of the drawings and the specific implementation.

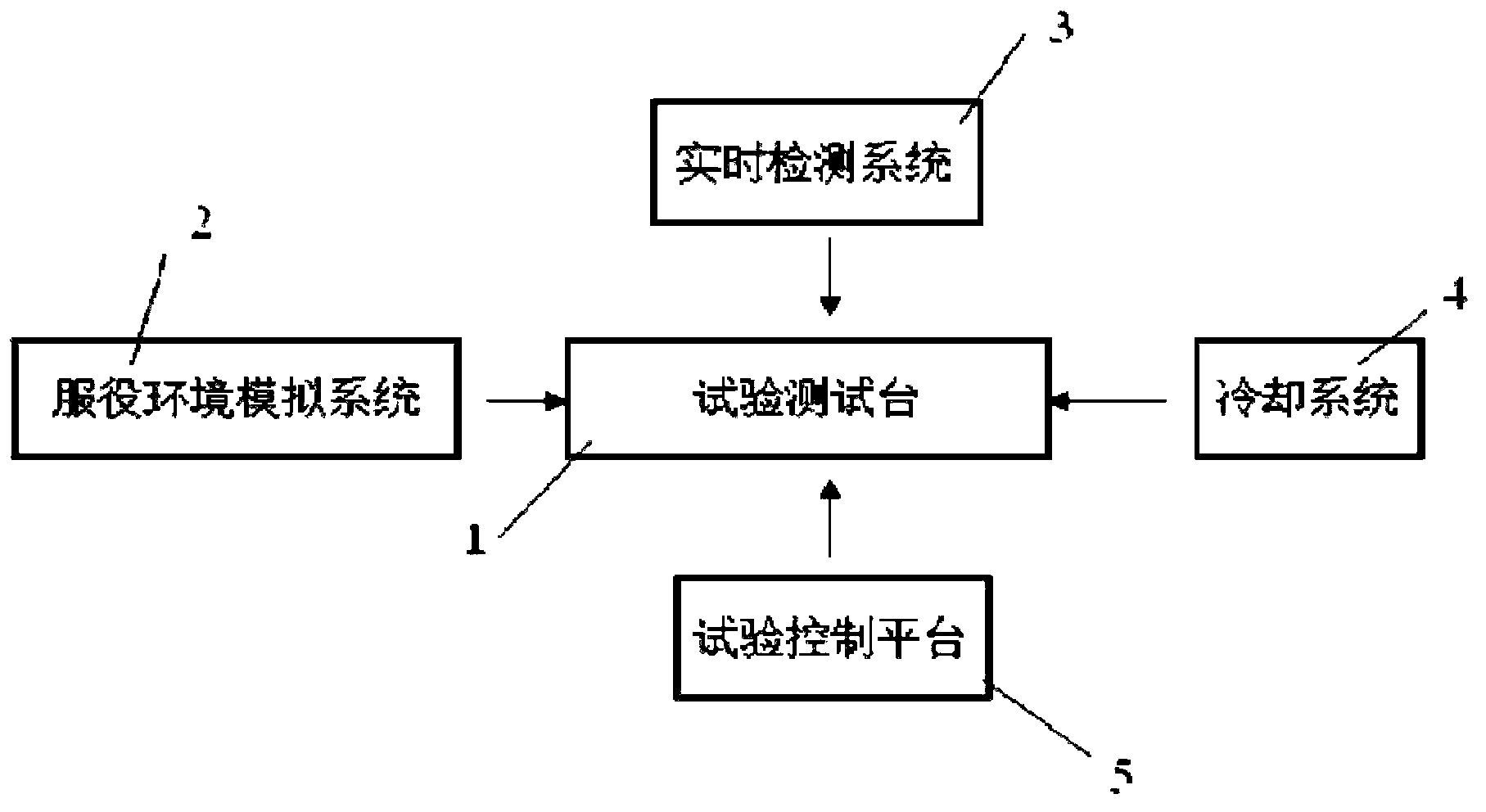

[0029] figure 1 It is a schematic diagram of the overall logical structure of the present invention, such as figure 1 As shown, the structure of the test device includes: test bench, high temperature erosion system, real-time detection module, cooling system and test control system.

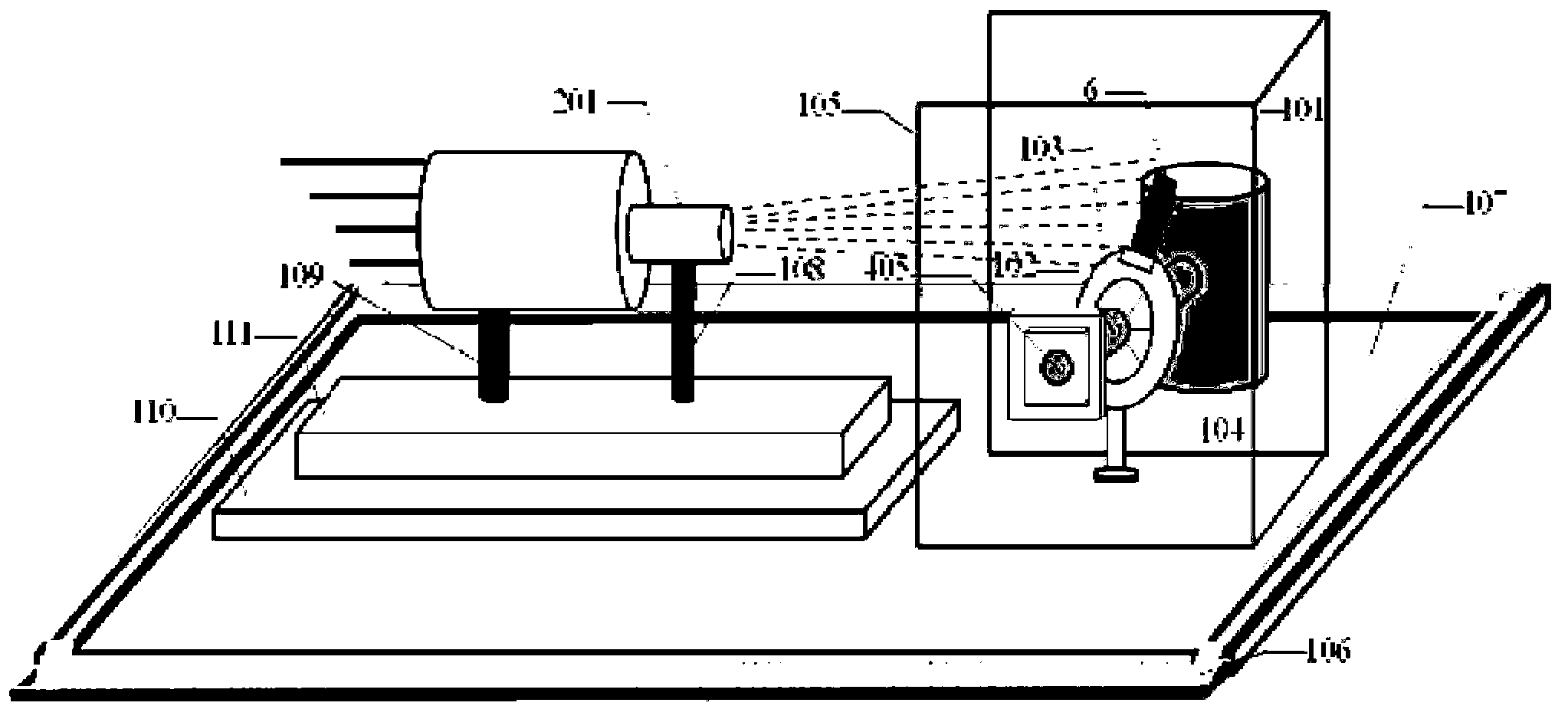

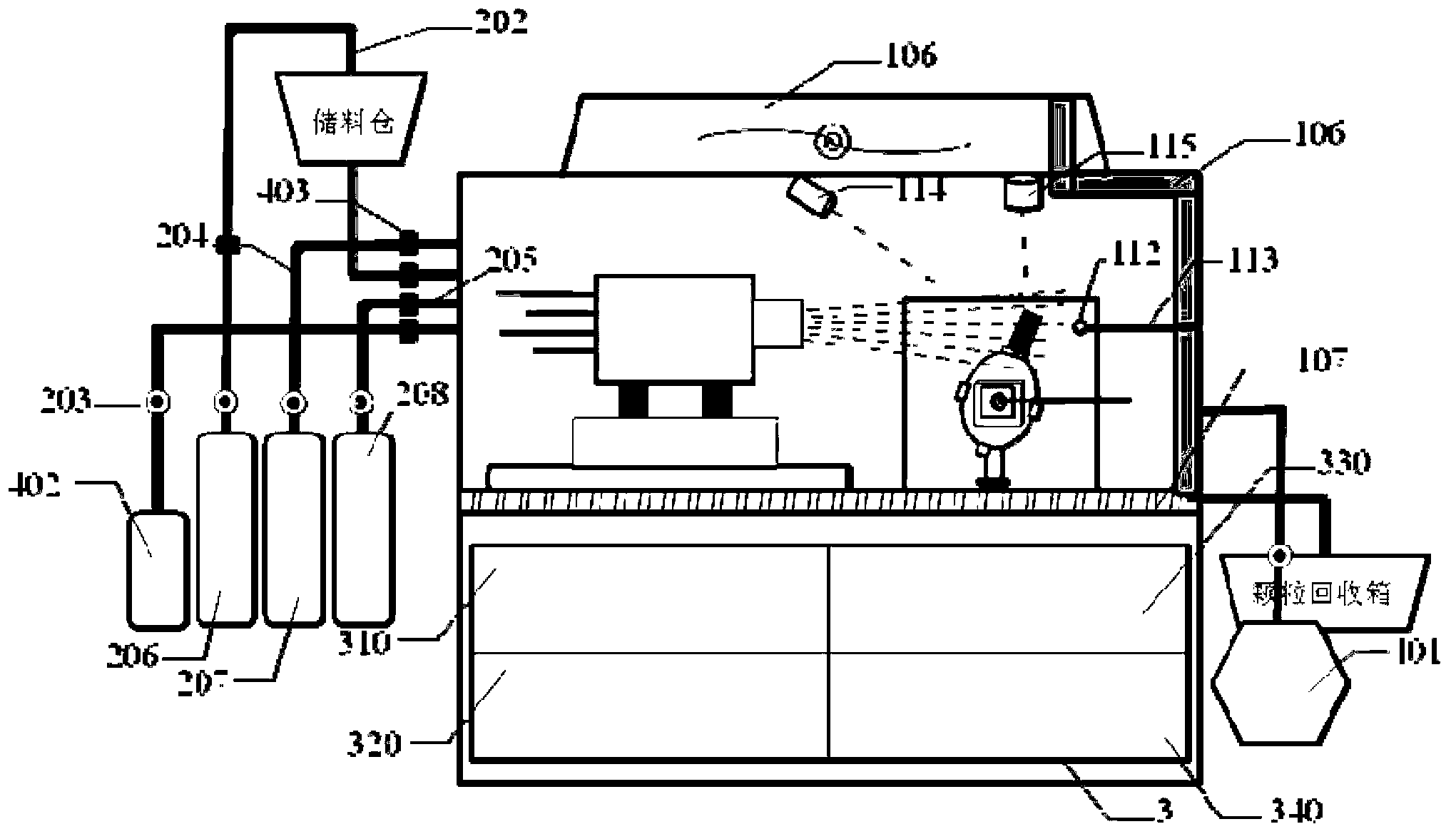

[0030] Such as figure 2 , image 3 as shown, figure 2 It is the structural diagram of the test bench of the present invention, image 3 It is the overall structure diagram of the present invention; the structure of the test bench is as follows: a fixture and a sample disc for clamping the sample are installed at the middle position on the test test platform, and the sample disc is fixed in front of the support s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com