Wide-temperature and wideband zinc-nickel soft magnetic ferrite material and preparation method thereof

A soft ferrite and broadband technology, which is applied in the field of wide temperature and broadband nickel-zinc soft ferrite material and its preparation, can solve the problems that the Curie temperature and frequency cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

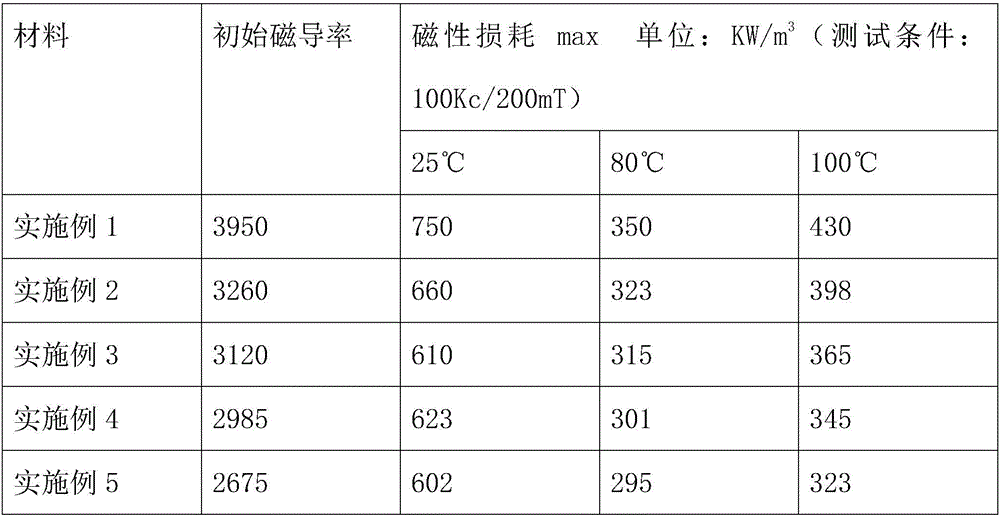

Examples

Embodiment 1

[0021] A wide temperature and broadband nickel-zinc soft magnetic ferrite material proposed by the present invention is prepared from main materials and auxiliary materials at a weight ratio of 1:0.4, wherein the main materials include: chromium oxide 52.8 mol%, zinc oxide 23.0 mol %, nickel carbonate 20.5mol%, iron oxide 5.45mol%, copper oxide 1.0mol%, manganese carbonate 2.0mol%, and the balance is iron powder; based on the weight of the main material, the auxiliary materials include: aluminum oxide 0.0055%, vanadium oxide 0.045%, zirconia 0.05%, tungsten trioxide 0.03%, bismuth oxide 0.10%, dicobalt oxide 0.20%, sintering aid 0.2%, polyvinyl alcohol aqueous solution 0.05%, dispersant 0.07%.

[0022] The sintering aid is made by mixing lithium oxide, lead oxide, vanadium trioxide, tin oxide and molybdenum trioxide in a weight ratio of 2:3.5:4.5:3.5:6.

Embodiment 2

[0024] A wide temperature and broadband nickel-zinc soft magnetic ferrite material proposed by the present invention is prepared from main materials and auxiliary materials at a weight ratio of 1:0.3, wherein the main materials include: chromium oxide 51.15 mol%, zinc oxide 24.8 mol %, nickel carbonate 19.5mol%, iron oxide 7.2mol%, copper oxide 0.5mol%, manganese carbonate 2.5mol%, and the balance is iron powder; based on the weight of the main material, the auxiliary materials include: aluminum oxide 0.003%, 0.06% vanadium oxide, 0.04% zirconia, 0.04% tungsten trioxide, 0.05% bismuth oxide, 0.25% cobalt trioxide, 0.1% sintering aid, 0.04% polyvinyl alcohol aqueous solution with a mass fraction of 0.8%.

[0025] The sintering aid is made by mixing lithium oxide, lead oxide, vanadium trioxide, tin oxide and molybdenum trioxide in a weight ratio of 1:5:3:5:4.

[0026] A kind of preparation method of wide-temperature broadband nickel-zinc soft magnetic ferrite material of the pre...

Embodiment 3

[0034] A wide temperature and broadband nickel-zinc soft magnetic ferrite material proposed by the present invention is prepared from main materials and auxiliary materials at a weight ratio of 1:0.5, wherein the main materials include: chromium oxide 54.45 mol%, zinc oxide 21.2 mol %, nickel carbonate 21.5mol%, iron oxide 3.6mol%, copper oxide 1.5mol%, manganese carbonate 1.5mol%, and the balance is iron powder; based on the weight of the main material, the auxiliary materials include: aluminum oxide 0.008%, 0.03% vanadium oxide, 0.06% zirconia, 0.02% tungsten trioxide, 0.15% bismuth oxide, 0.15% cobalt trioxide, 0.3% sintering aid, 0.06% polyvinyl alcohol aqueous solution with a mass fraction of 0.5%.

[0035] The sintering aid is composed of lithium oxide, lead oxide, vanadium trioxide, tin oxide and molybdenum trioxide in a weight ratio of 3:2:6:2:8.

[0036] A kind of preparation method of wide-temperature broadband nickel-zinc soft magnetic ferrite material of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com