Formula of direct current zinc oxide resistance chip

A zinc oxide resistor chip, zinc oxide technology, applied in the direction of varistor, varistor core, etc., can solve the problem of unable to meet the aging performance requirements of resistor chip, thermal collapse, etc., to improve volt-ampere characteristics, prevent The effect of absorbing moisture and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

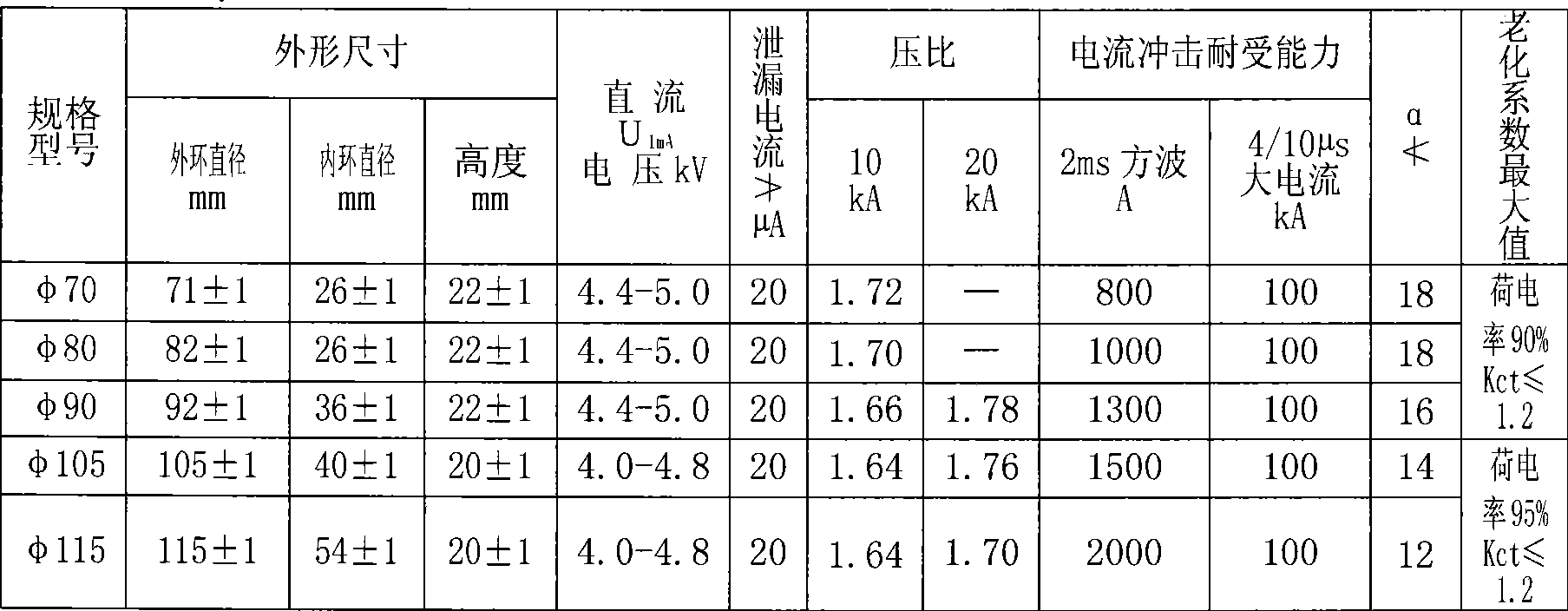

Image

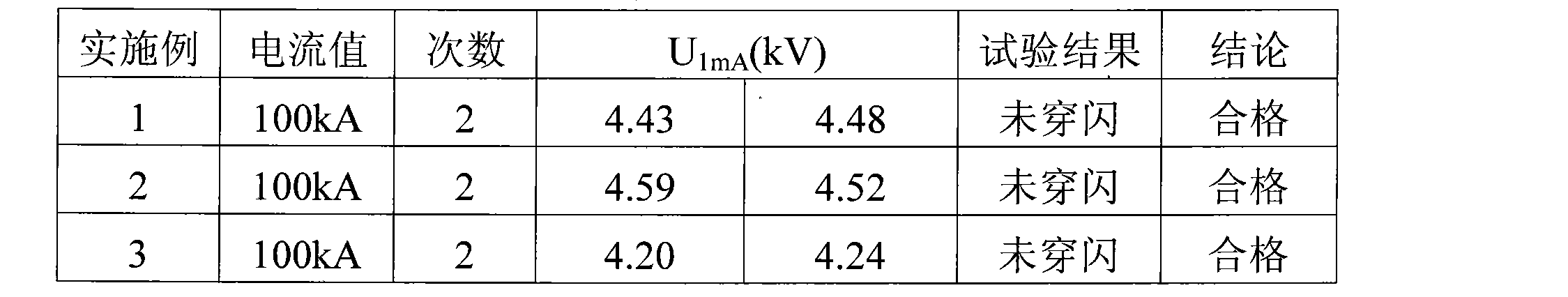

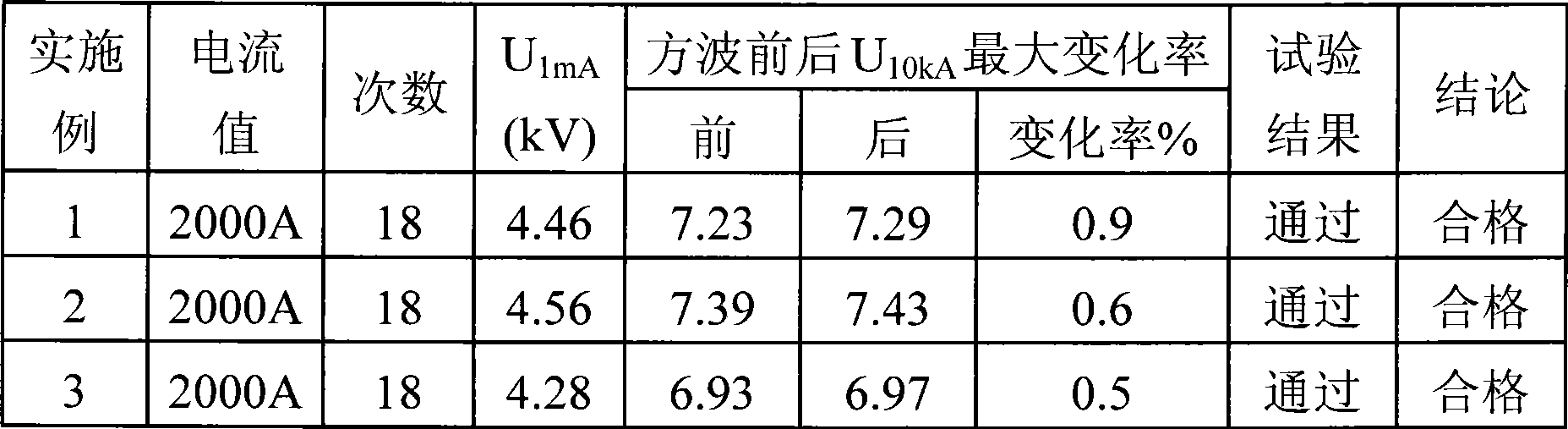

Examples

Embodiment 1

[0023] Embodiment 1: comprise following component and weight percent:

[0024] Bi 2 o 3 : 4.00%; Sb 2 o 3 : 3.18; SiO 2 : 0.80%; Co 2 o 3 : 2.29%; Cr 2 o 3 : 0.70%; MnCO 3 : 0.70%; NiO: 0.80%; aluminum nitrate: 0.05%; glass powder: 0.14%; B 2 o 3 : 0.10%; ZnO: 87.24%.

Embodiment 2

[0025] Embodiment 2: comprise following component and weight percent:

[0026] Bi 2 o 3 : 4.49%; Sb 2 o 3 : 3.59; SiO 2 : 0.50%; Co 2 o 3 : 2.00%; Cr 2 o 3 : 0.70%; MnCO 3 : 0.60%; NiO: 0.70%; aluminum nitrate: 0.05%; glass powder: 0.14%; B 2 o 3 : 0.10%; ZnO: 87.13%.

Embodiment 3

[0027] Embodiment 3: comprise following component and weight percent:

[0028] Bi 2 o 3 : 4.69%; Sb 2 o 3 : 3.50%; SiO 2 : 0.80%; Co 2 o 3 : 2.50%; Cr 2 o 3 : 0.70%; MnCO 3 : 0.70%; NiO: 0.70%; aluminum nitrate: 0.05%; glass powder: 0.14%; B 2 o 3 : 0.10%; ZnO: 86.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com