Blue zirconium oxide ceramic and preparation method thereof

A technology of zirconia ceramics and blue, which is applied in the field of ceramics, can solve the problems of inability to mix colorants evenly and uneven color distribution of ceramics, and achieve the effects of improving color uniformity, shortening mass transfer distance, and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of blue zirconia ceramics, comprising the following steps:

[0032] (1) mixing dicobalt oxide, aluminum oxide, silicon dioxide, a dispersant and water to obtain a primary slurry with a solid content of 50% to 60%;

[0033] (2) Sanding the primary slurry to obtain a primary slurry;

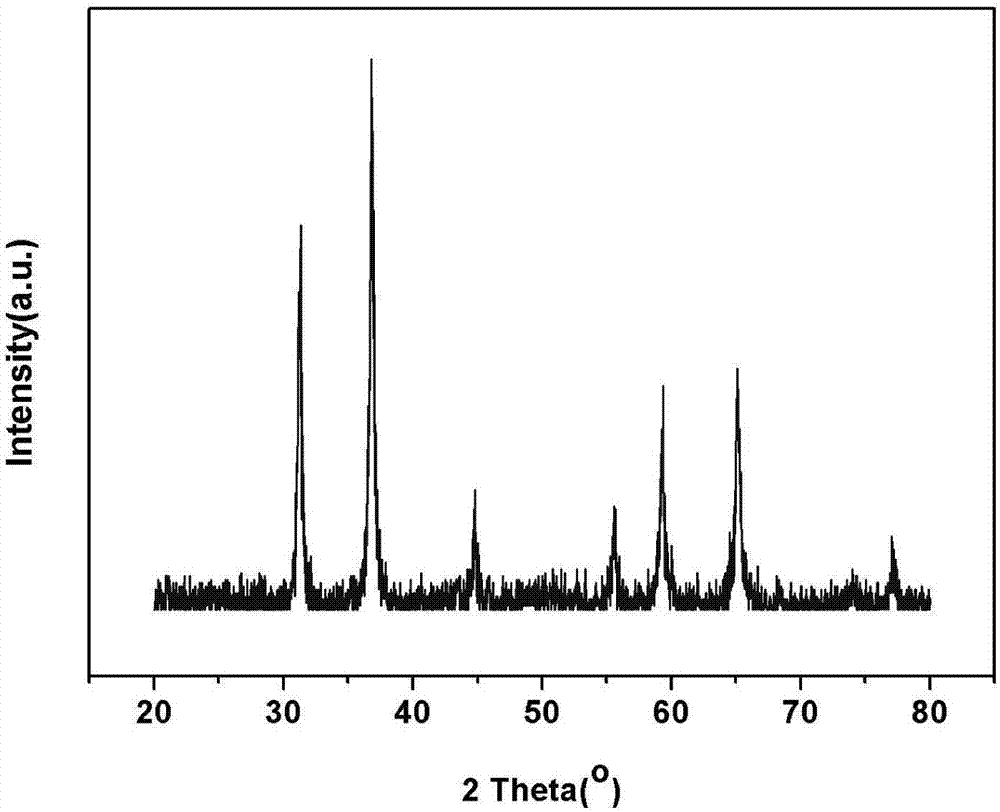

[0034] (3) roasting after drying the primary slurry to obtain a blue base material with a cobalt-aluminum spinel structure;

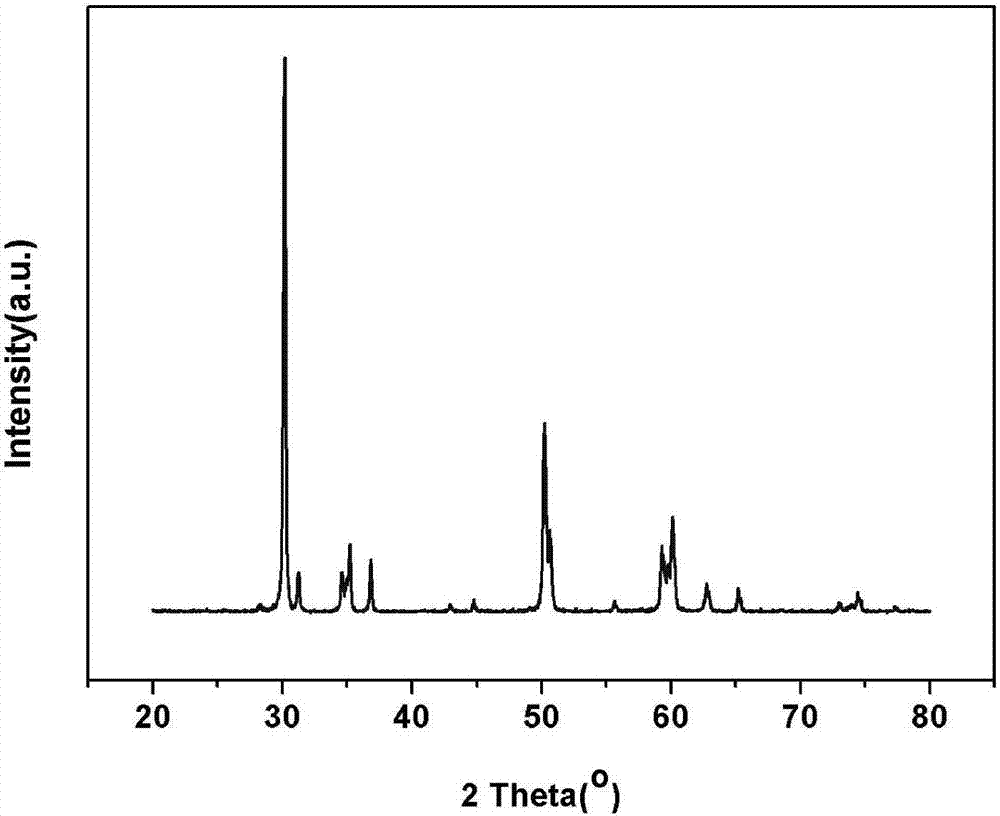

[0035] (4) mixing the blue base material of the cobalt-aluminum spinel structure with zirconia, yttrium oxide, a dispersant and water to obtain a secondary slurry with a solid content of 60-70%;

[0036] (5) Sanding the secondary slurry to obtain a tertiary slurry;

[0037] (6) After mixing the tertiary slurry and binder, perform granulation, molding, debinding and firing to obtain blue zirconia ceramics.

[0038] The present invention mixes dicobalt oxide, aluminum oxide, silicon dioxide, dispersant and water to obtain a...

Embodiment 1

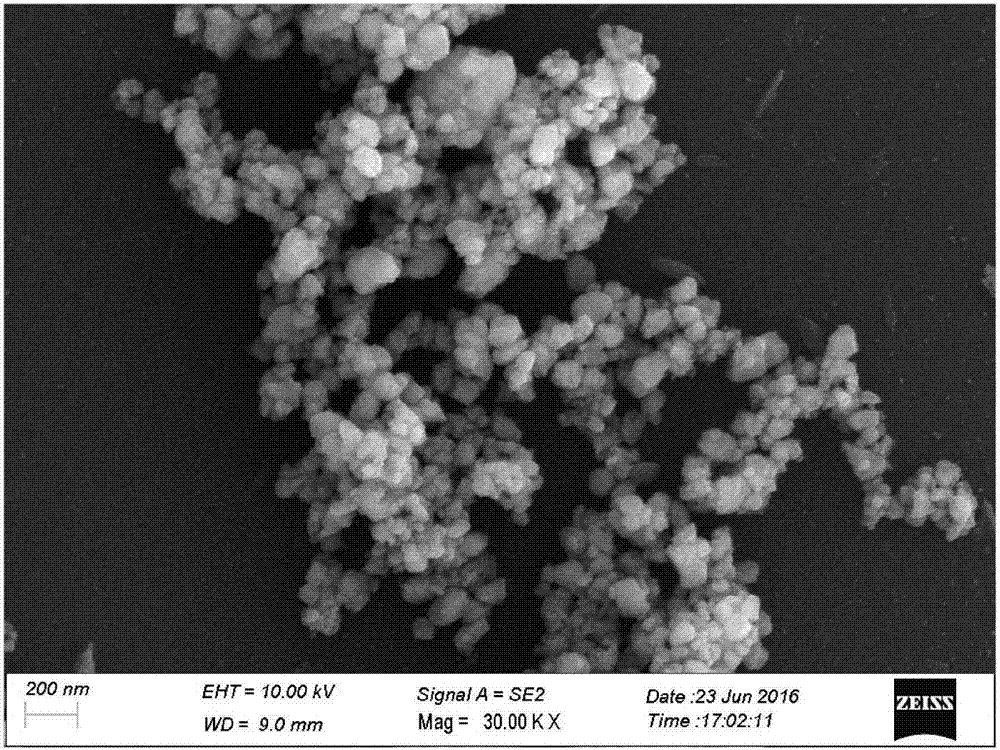

[0054] The total mass of dicobalt, aluminum oxide and silicon dioxide is calculated as 1000 parts. Accurately weigh 460 parts of dicobalt, 539 parts of aluminum oxide, and 1 part of silicon dioxide. Ammonium methacrylate is 2.5 parts, and deionized water is added to adjust the solid content of the slurry to 55%. The material is sanded by a sand mill for 2 hours, the grinding body is zirconia beads with a particle size of 0.6-0.8mm, and the sanding speed is 800r / min. The particle size of the sand-milled material is lower than 80nm.

[0055] Spray and dry the sanded slurry, adjust the atomization frequency to 36 Hz, the inlet air temperature to 300°C, and the outlet air temperature to 90°C. And the dry powder was sintered at 1300°C for 3 hours to form a stable cobalt-aluminum spinel structure blue base material.

[0056] Based on the total mass of cobalt-aluminum spinel structure blue base material, zirconia and yttrium oxide as 1000 parts, accurately weigh 50 parts of cobalt-...

Embodiment 2

[0061] Taking the total mass of dicobalt seoxide, aluminum oxide and silicon dioxide as 1000 parts, accurately weigh 440 parts of dicobalt trioxide, 558 parts of aluminum oxide, and 2 parts of silicon dioxide. Ammonium acrylate is 3 parts, and deionized water is added to adjust the solid content of the slurry to 55%. The material is sanded by a sand mill for 3 hours, the grinding body is zirconia beads with a particle size of 0.5-0.6mm, and the sanding speed is 900r / min. The particle size of the sand-milled material is lower than 80nm.

[0062] Spray and dry the sanded slurry, adjust the atomization frequency to 38Hz, the air inlet temperature to 310°C, and the outlet air temperature to 90°C. And the dry powder was sintered at 1200°C for 4 hours to form a stable blue base material of cobalt-aluminum spinel structure.

[0063] Based on the total mass of cobalt aluminum spinel blue base material, zirconia and yttrium oxide as 1000 parts, accurately weigh 100 parts of cobalt al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com