Optical pigment and its preparation method

A pigment and optical technology, which is applied in the field of optical pigments and its preparation, can solve the problems of reduced interference color saturation, weak pigment light interference, and increased scattering rate, and achieve the effects of reduced dosage, good hiding power, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

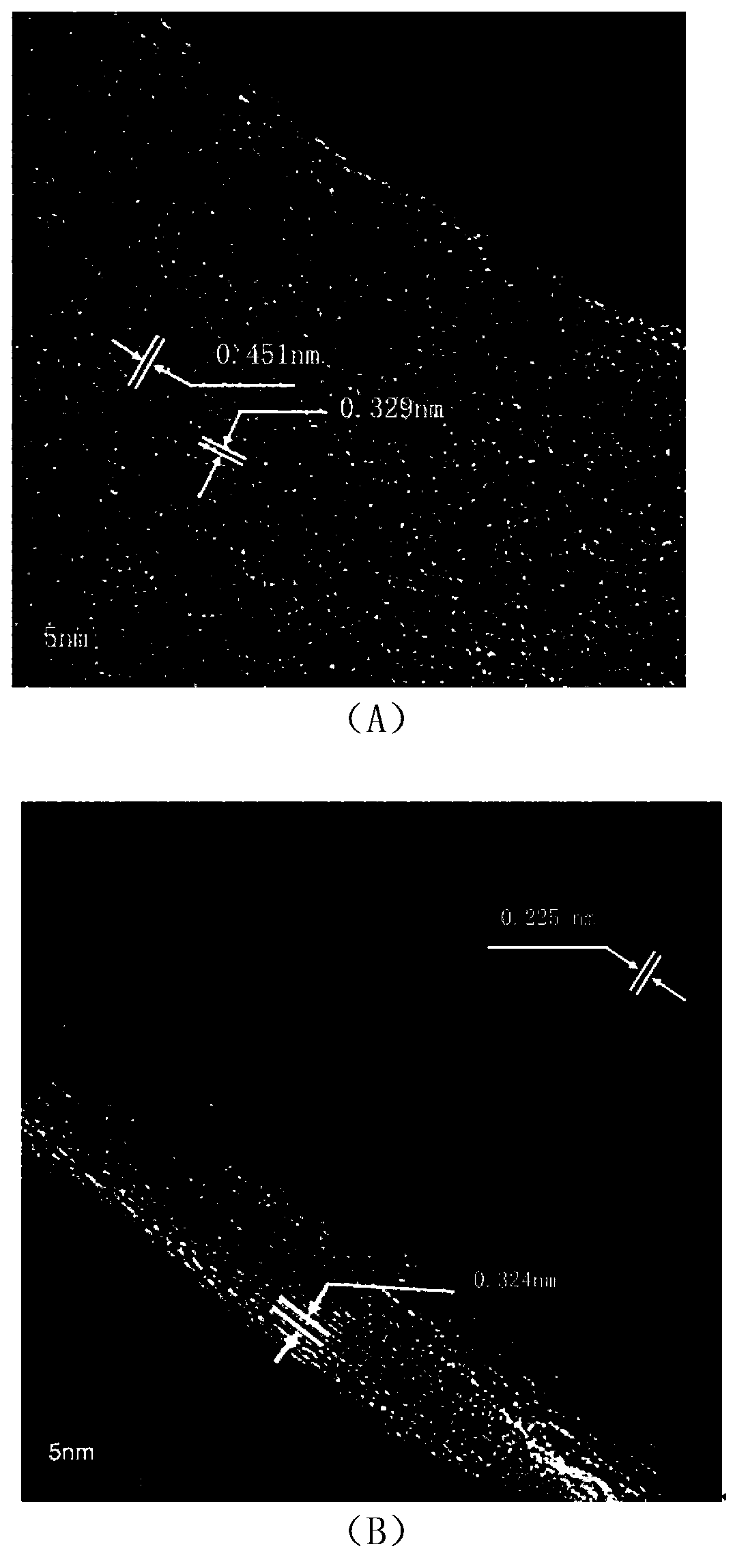

Image

Examples

Embodiment 1

[0068] This example illustrates how the optical pigments of the present invention are prepared.

[0069] Put a certain amount of substrate into the reaction kettle, add an appropriate amount of pure water, stir and heat up to 70-80°C, adjust the kettle liquid to a certain pH value with acid or alkali, and then add it in at a certain rate A certain concentration of high refractive index metal salt solution (such as titanium tetrachloride or ferric chloride), while adding lye dropwise to maintain the pH value of the kettle liquid, when coating a certain interference color, stop feeding; then slowly add The lye raises the pH value of the still liquid to 8-9, then metering in a certain concentration of water glass solution at a certain rate, and at the same time metering in a metal salt (a soluble metal that can generate high refractive index oxides) at a certain rate Salt) aqueous solution, the feeding rate can be changed according to the needs, and then add dilute hydrochloric a...

Embodiment 2

[0075] This example further illustrates how the optical pigment of the present invention is prepared.

[0076] Put a certain amount of substrate into the reaction kettle, add an appropriate amount of pure water, stir and heat up to 70-80°C, adjust the pH value of the kettle liquid to 8-9 with lye, and then slowly drop in at a certain rate A certain amount of water glass solution is added dropwise to maintain the pH value of the kettle liquid at the same time. After adding, adjust the kettle liquid to a certain pH value with the acid solution, and then add a high Refractive index metal salt solution (such as titanium tetrachloride or ferric chloride), while adding lye dropwise to maintain the pH value of the kettle liquid, when coating a certain interference color, stop feeding; then slowly add lye to raise the kettle The pH value of the solution reaches 8-9, and then metered in a certain concentration of water glass solution at a certain rate, and at the same time metered in a...

Embodiment 3

[0085] Take 100 grams of synthetic mica powder with a particle size of 10-60 microns as the substrate, and put it into a 2000 ml reaction kettle, stir and raise the temperature to 75°C, adjust the pH value of the kettle liquid to 3.2 with hydrochloric acid (30%), and then Add dropwise ferric chloride solution (100g (FeCl 3 ) / L), while adding sodium hydroxide solution (NaOH, 15%) dropwise to maintain a constant pH until the interference color of the substrate is light yellow, and then adjust the pH of the kettle liquid with sodium hydroxide solution (NaOH, 15%) to 9, then drip water glass solution (30g (SiO 2 ) / L), while adding dropwise titanium tetrachloride solution (200g(TiCl 4) / L), the dropping rate makes the ratio of silicon dioxide to titanium dioxide 100:12, and at the same time, drop hydrochloric acid solution (30%) to keep the pH of the kettle liquid constant until the substrate reaches the interference color green, and then use hydrochloric acid solution (30%) the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com