Pink glass-ceramic plate and production method thereof

A production method and technology of glass-ceramic, applied in the field of pink glass-ceramic plate and its production, can solve the problems of high energy consumption, restricting the rapid development and large-scale production of glass-ceramic, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

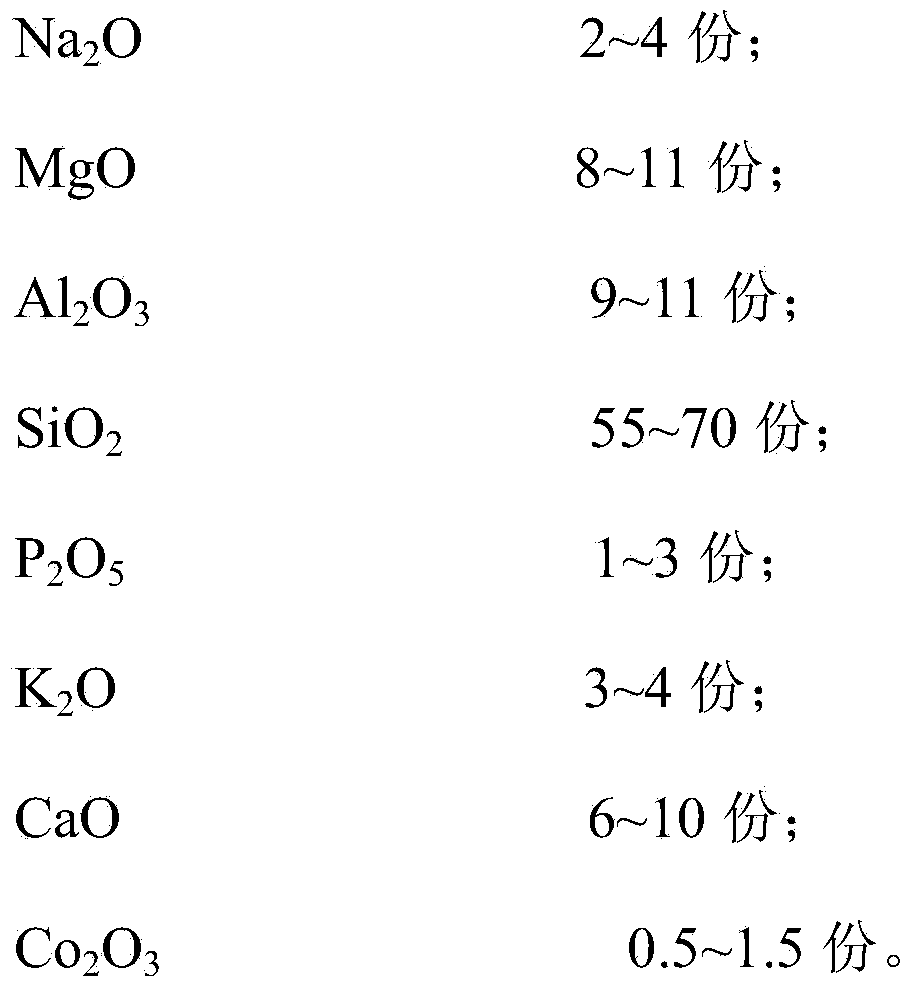

[0037] According to one embodiment of the present invention, the production method of pink glass-ceramics comprises the following steps:

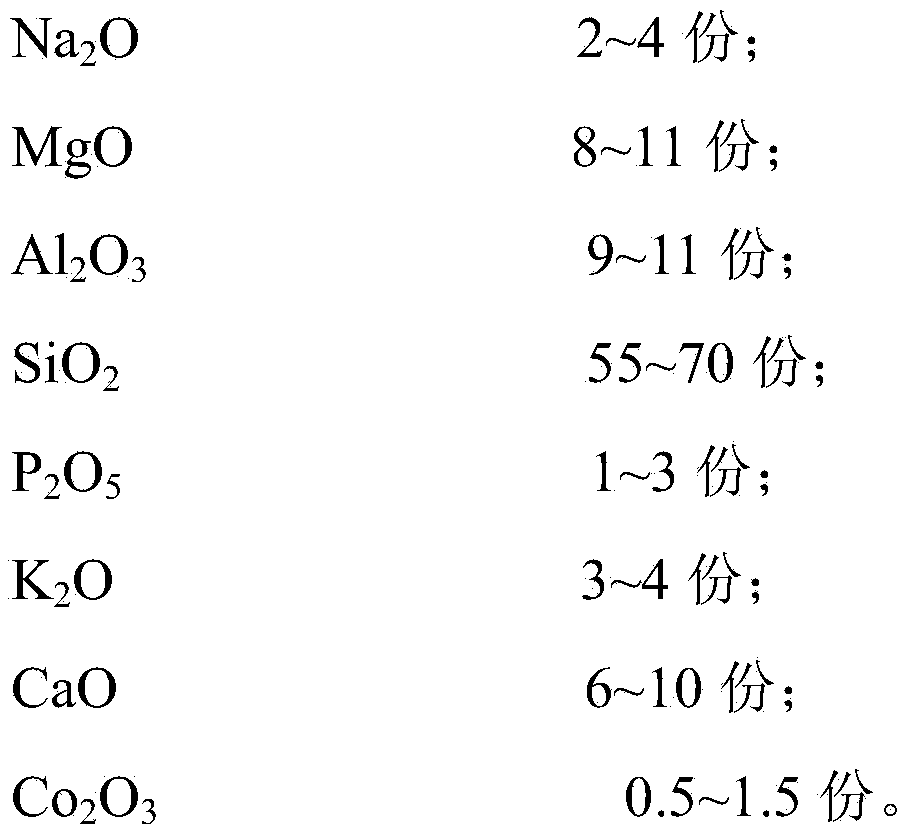

[0038] 1. Select raw materials according to the following parts by weight, and send them to the mixer for mixing. The mixing time is 4 minutes, and 10Kg of water is added.

[0039] raw material name

granite

Light burnt magnesium

Weight (Kg)

119.1

350.0

12.5

31.1

5

[0040] Table 1: Chemical composition (weight percent) of raw materials

[0041] chemical composition

granite

Light burnt magnesium

Na 2 o

0.21

3.706

0

0

0

MgO

21.26

0.2687

0

0

79.6

al 2 o 3

0.32

11.7

0

0

0.2

SiO 2

0.75

77.306

0

0

1.4

P 2 o 5

0

0.01...

Embodiment 2

[0051] According to one embodiment of the present invention, the production method of pink glass-ceramics comprises the following steps:

[0052] 1. Select raw materials according to the following parts by weight, and send them to the mixer for mixing. The mixing time is 4 minutes, and 10Kg of water is added.

[0053] raw material name

dolomite

granite

Light burnt magnesium

Weight (Kg)

152.6

343.5

14.4

14.6

2.5

[0054]2. Send the above-mentioned mixture into the melting pool of the all-electric melting furnace, and melt it into molten glass at a melting temperature of 1400 ° C. The molten glass is clarified and homogenized in the melting pool at a temperature of 1400 ° C. After clarification and homogenization for 8 hours, the clarified and homogenized glass liquid was obtained.

[0055] 3. The clarified and homogenized molten glass enters the forehearth through the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com