Process for preparing superfine cobalt oxide powder by booster parallel-flow precipitation

A technology of cobalt oxide and powder, which is applied in the field of preparation of ultra-fine uniformly dispersed cobalt oxide, can solve the problems of insufficient consideration of the mixing state of the feeding method, uneven powder particle size, large quality fluctuation, etc., and achieves convenient control, fine product particle size, The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

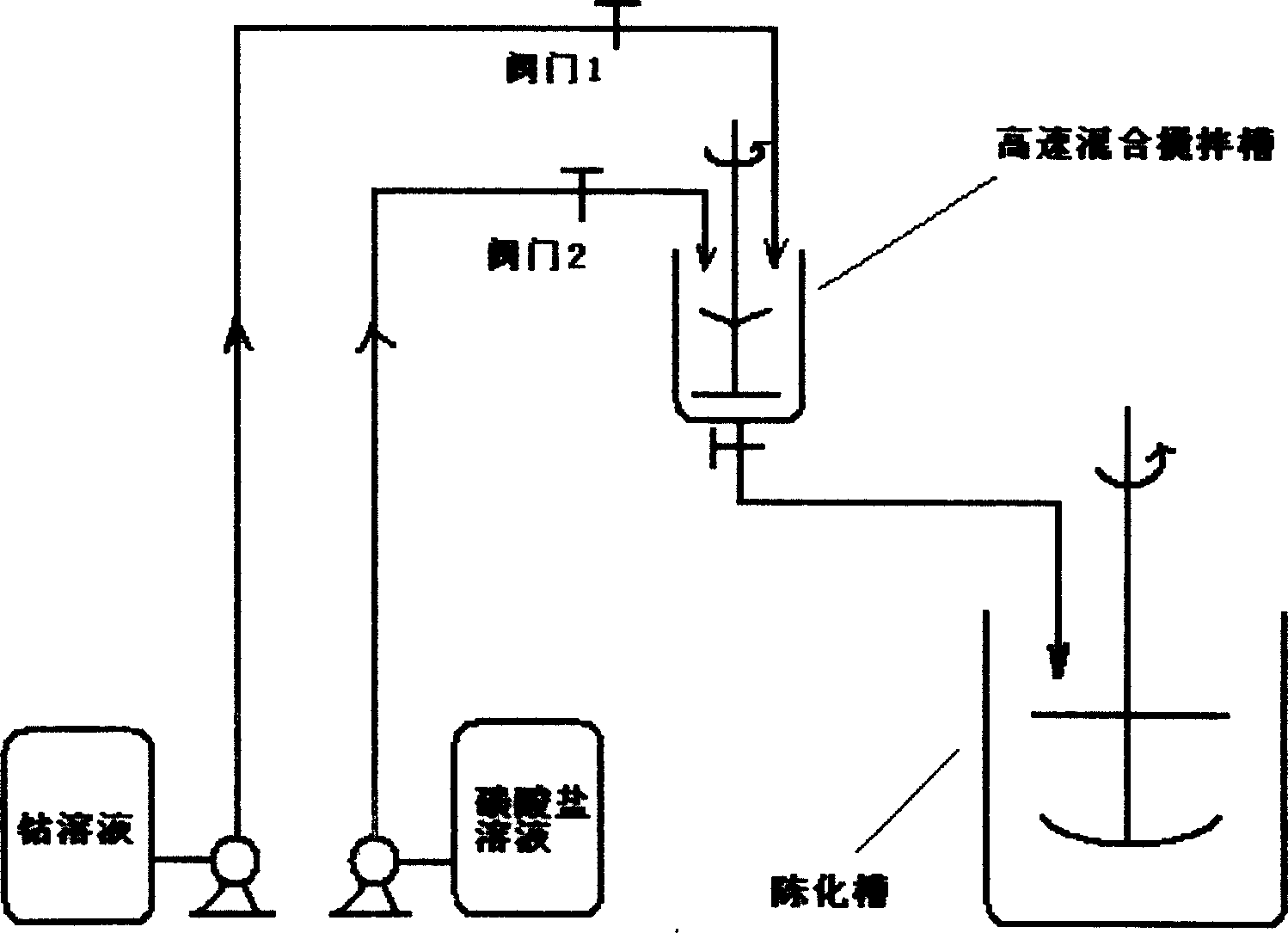

Embodiment 1

[0021] The high-purity cobalt chloride solution obtained after P204 extraction and impurity removal and P507 separation of nickel and cobalt, the content of cobalt in the solution is about 75 g / L, the pH value of the solution is controlled between 4.5-5.0, and the weight ratio of the content of cobalt is added Surfactant OP of 0.5%: Weigh ammonium bicarbonate at a ratio of 3:1 to cobalt chloride, add water to fully mix and dissolve, and adjust the pH value of the solution to be 8.5-9.0; The two feed liquids prepared above are added to a 200-liter high-speed stirring reaction tank (500 rpm) under the effect of a booster pump in parallel with jet flow; realize fast and sufficient mixing in this small-sized stirring tank; Pressure feeding pressure and flow control are based on the final pH value of the mixed solution being about 6.8; after staying in the stirring tank for 3-5 minutes, flow into a large stirring tank with a size of 2 cubic meters (rotating speed is 100 rpm) and con...

Embodiment 2

[0023] The high-purity cobalt sulfate solution extracted and removed by P204, the cobalt content in the solution is about 90 g / L, the pH value of the solution is controlled between 4.5-5.0, and the surfactant Tween-80 is added in an amount equal to the cobalt content in the solution 0.8% of 0.8%; weigh sodium carbonate at a ratio of 1.5:1 to cobalt sulfate, add hot water at 60°C to fully dissolve it, and adjust the pH value of the solution to be 9.0-10.0; Under the action of the booster pump, the two feed liquids are fed into a 200-liter high-speed stirring tank (500 rpm) in parallel in the form of a jet; in this small stirring tank, rapid and sufficient mixing, reaction, and precipitation are realized; pressurization The feeding pressure and flow control are based on the pH value of the mixed solution at the end point of about 8.3; after staying in the stirred tank for 3-5 minutes, it flows into a large stirred tank with a size of 2 cubic meters (rotating speed is 100 rpm), an...

Embodiment 3

[0025] The electrolytic high-purity metal cobalt is added to industrial nitric acid with a concentration of 30% for dissolution in stages, the cobalt content is controlled at about 100 g / L, the pH value of the solution is controlled at about 4.5, and the surfactant Span is added in an amount equal to the cobalt content in the solution 1.0% of 1.0% of cobalt nitrate; weigh ammonium carbonate at a ratio of 3:1 to cobalt nitrate, fully dissolve it in deionized water, and adjust the pH value of the solution to be 9.0-10.0; Under the action of the booster pump, the feed liquid is fed into a 200-liter high-speed stirred reactor (500 rpm) in parallel in the form of a jet; in this small stirred reactor, rapid and sufficient mixing is achieved; boosting the feeding pressure to mix The final pH value of the solution is about 8.0 as the criterion; after staying in the stirring tank for 3-5 minutes, it flows into a large stirring tank with a size of 2 cubic meters (rotating speed is 100 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com