Anti-re-ignition dry powder fire extinguishing agent and preparation method thereof

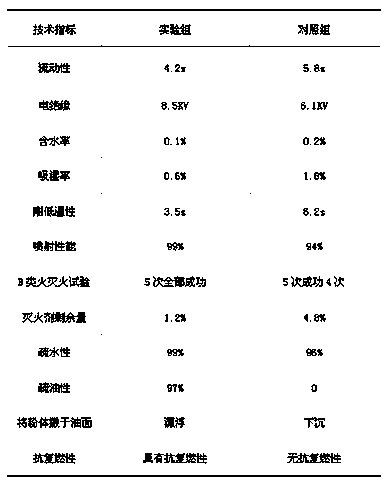

A dry powder fire extinguishing agent and anti-resurgence technology, which is applied in fire prevention equipment and other fields, can solve the problems of poor fire extinguishing performance and anti-resurgence performance, complex preparation process of anti-resurgence fire extinguishing agent, etc., and achieve good spray performance and simple production process path , high fire extinguishing performance and the effect of anti-reburning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 The anti-resurgence dry powder fire extinguishing agent is prepared from the following raw materials, all in parts by weight (900g / part): 130 parts of alkali slag, 45 parts of sodium bicarbonate, 65 parts of zinc borate, 15 parts of marl, carbonic acid 18 parts of magnesium powder, 10 parts of silicone oil, 16 parts of gypsum, 2 parts of potassium iodate, 12 parts of tin oxide, 8 parts of silicon nitride, and 9 parts of glass fiber.

[0028] The preparation method of anti-recombustion dry powder fire extinguishing agent is:

[0029] (1) Mix alkali slag, sodium bicarbonate and gypsum, vacuum dehydrate at 100°C for 1 hour, and set aside;

[0030] (2) Add magnesium carbonate powder, marl, silicon nitride and glass fiber to the raw materials treated in step (1), grind for 20 minutes, heat up to 70°C and stir for 0.8 hours, and then pulverize with a superfine pulverizer , through a 80-mesh sieve to obtain the mixed material, and set aside;

[0031] (3) Add 0.2 ti...

Embodiment 2

[0033] Example 2 The anti-resurgence dry powder fire extinguishing agent is prepared from the following raw materials, all in parts by weight (500g / part): 152 parts of alkali slag, 66 parts of sodium bicarbonate, 80 parts of zinc borate, 20 parts of marl, carbonic acid 24 parts of magnesium powder, 15 parts of silicone oil, 21 parts of gypsum, 5 parts of potassium iodate, 18 parts of tin oxide, 10 parts of silicon nitride, and 12 parts of glass fiber.

[0034] The preparation method of anti-recombustion dry powder fire extinguishing agent is:

[0035] (1) Mix alkali slag, sodium bicarbonate and gypsum, vacuum dehydrate at 120°C for 3 hours, and set aside;

[0036] (2) Add magnesium carbonate powder, marl, silicon nitride and glass fiber to the raw materials treated in step (1), grind for 40 minutes, heat up to 90°C and stir for 1.4 hours, and then pulverize with a superfine pulverizer , passed through a 200-mesh sieve to obtain the mixed material, and set aside;

[0037] (3)...

Embodiment 3

[0039] Example 3 The anti-resurgence dry powder fire extinguishing agent is prepared from the following raw materials, all in parts by weight (800g / part): 134 parts of alkali slag, 50 parts of sodium bicarbonate, 70 parts of zinc borate, 16 parts of marl, carbonic acid 20 parts of magnesium powder, 12 parts of silicone oil, 17 parts of gypsum, 3 parts of potassium iodate, 14 parts of tin oxide, 8.5 parts of silicon nitride, and 10 parts of glass fiber.

[0040]The preparation method of anti-recombustion dry powder fire extinguishing agent is:

[0041] (1) Mix alkali slag, sodium bicarbonate and gypsum, vacuum dehydrate at 105°C for 1.5 hours, and set aside;

[0042] (2) Add magnesium carbonate powder, marl, silicon nitride and glass fiber to the raw materials treated in step (1), grind for 25 minutes, heat up to 75°C and stir for 1.0 hour, and then pulverize with a superfine pulverizer , passed through a 120-mesh sieve to obtain the mixed material, and set aside;

[0043] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com