Heat-sealable waterproof and oil-proof acrylic emulsion

An acrylic emulsion, waterproof and oil-proof technology, applied in the field of coatings, can solve the problems of poor oil-proof performance of polylactic acid, limited promotion, high cost, etc., to achieve the effect of promoting waterproof and oil-proof, ultra-fine emulsion particle size, and improve water resistance and oil resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

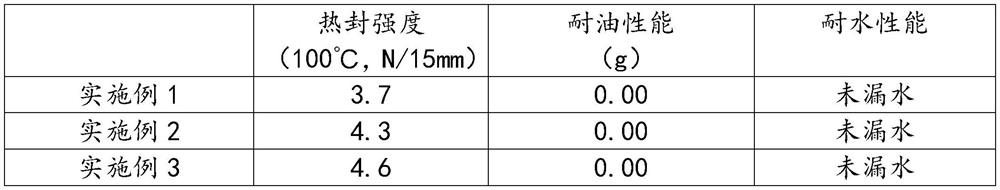

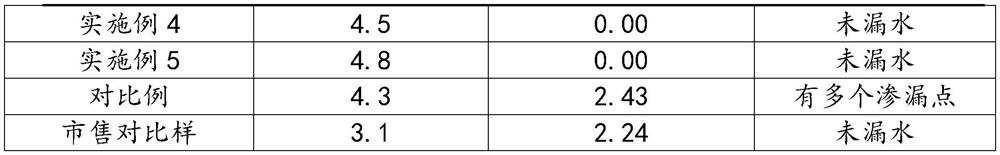

Examples

Embodiment 1~ Embodiment 5

[0030] The synthesis technique of embodiment 1~embodiment 5, comparative example is:

[0031] (1) Preparation of core pre-emulsion: add deionized water 1, emulsifier 1 (OP-10 is used as emulsifier in the comparative example), acrylic monomer, silicone monomer, cross-linking monomer and ferrous sulfate into the beaker in turn 1. Emulsify at 700 rpm for 30 minutes to obtain a core pre-emulsion;

[0032] (2) Preparation of shell pre-emulsion: add deionized water 2, emulsifier 2 (OP-10 is used as emulsifier in the comparative example), soft monomer, hard monomer, functional monomer and ferrous sulfate 2 into the beaker in turn, Emulsify at 700rpm for 30 minutes to obtain shell pre-emulsion;

[0033] (3) 200g of water was added to the four-necked flask, the stirring was turned on, and the rotating speed was 200rpm, and heated to 65°C;

[0034] (4) dropwise addition of core pre-emulsion and hydrogen peroxide 1: start to dropwise add core pre-emulsion and hydrogen peroxide 1 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com