Reinforcing cord, method for producing the same, and product using the reinforcing cord

A manufacturing method and coating technology, which are used in rubber products, reinforcement ropes for rubber and their manufacturing fields, can solve fiber fatigue for reinforcement, damage to the coating, lack of heat resistance or creep resistance (shape). Stability coating and other issues, to achieve good water resistance and oil resistance, improve water and oil resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

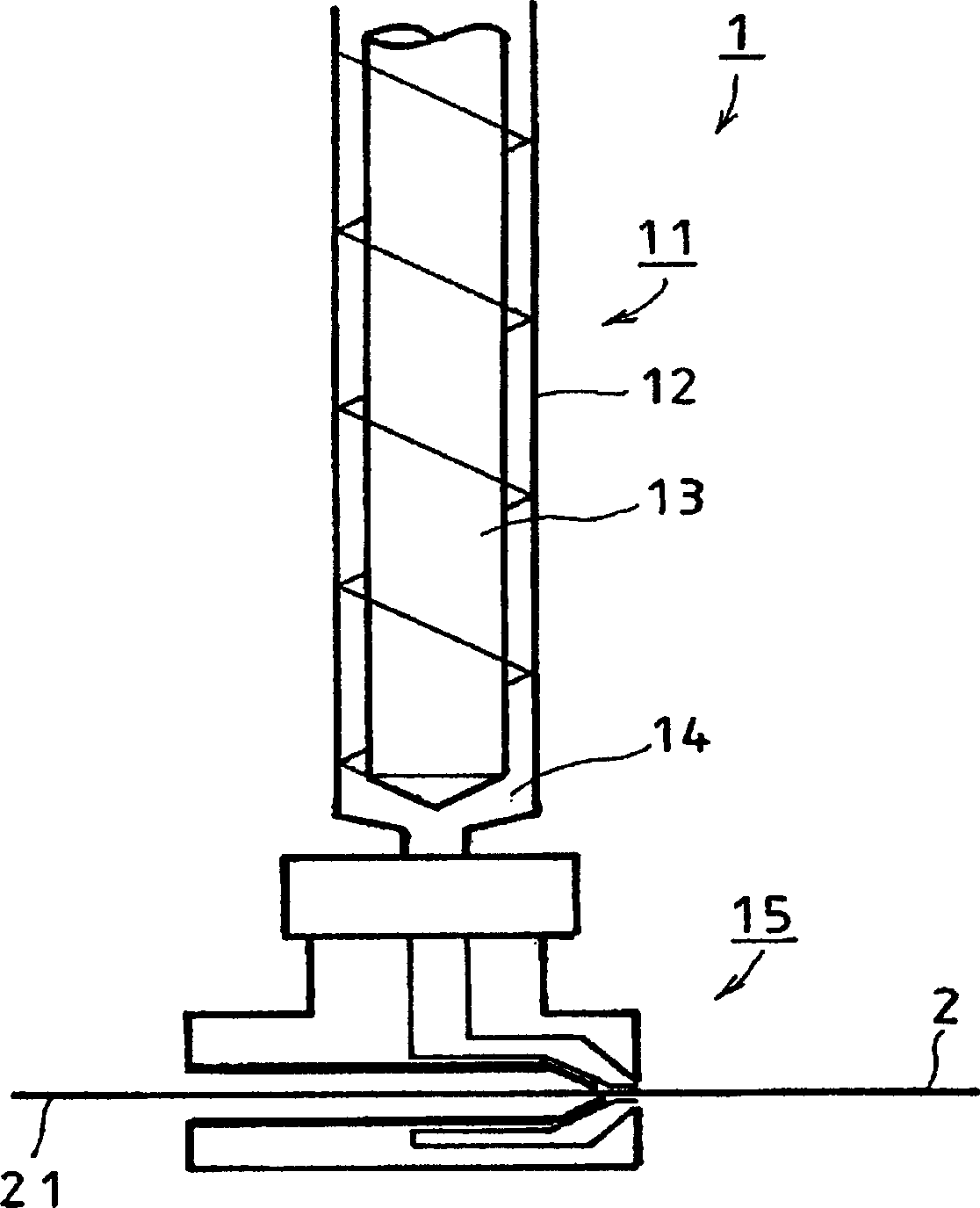

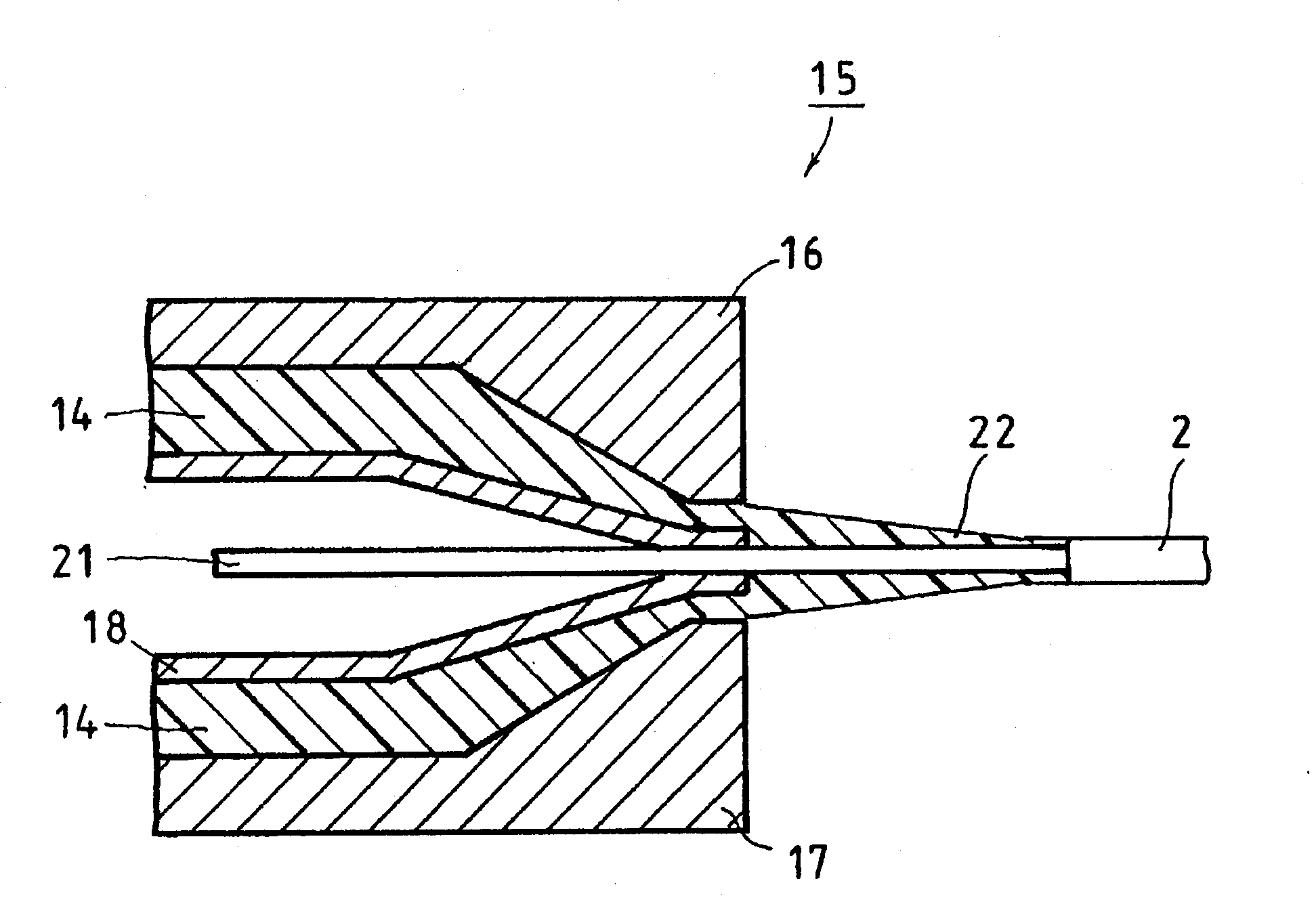

Method used

Image

Examples

Embodiment 1

[0081] In Example 1, three glass fibers (200 filaments with an average diameter of 9 μm in E glass composition) were paralleled, immersed in a water tank filled with the water-based treatment agent shown in Table 1 below, and salvaged. This was dried for 1 minute in a drying oven set at 150° C. to form a base covering layer, which was produced into reinforcing fibers.

[0082] [Table 1]

[0083] Composition of water-based treatment agent ratio H-NBR (solid content mass ratio 40%) ( * 1) 100 quality Resorcinol-formaldehyde condensate 10 quality

[0084] ( * 1) Hydrogenated nitrile rubber latex (ZETPOL LATEX, manufactured by Japan Zeon Co., Ltd.)

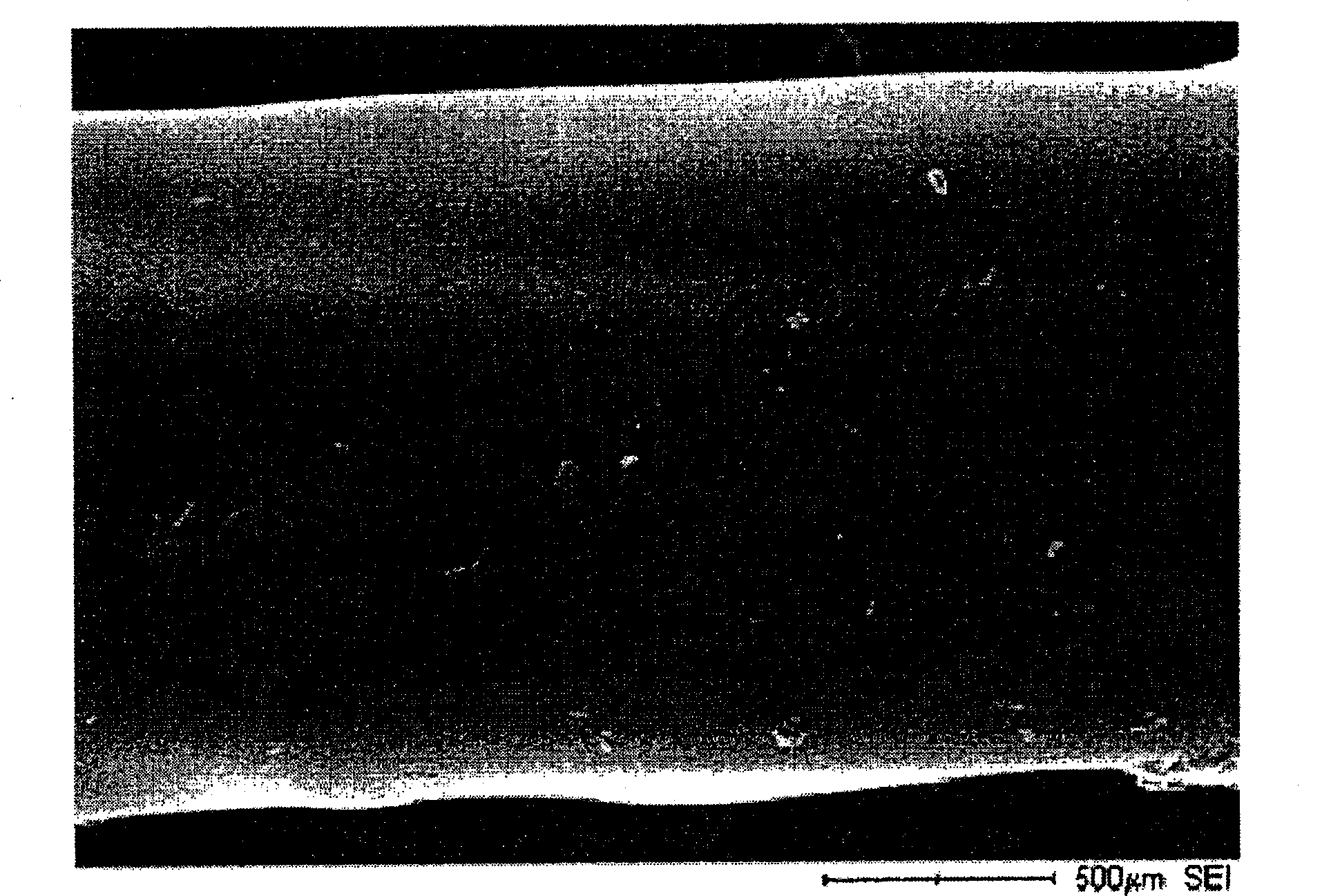

[0085] The glass fibers were subjected to primary twisting 8 times / 10 cm, and 11 of the primary twisted materials were paralleled, and double twisting was performed 8 times / 10 cm to prepare a fiber bundle for reinforcement. The adhesion rate of the base covering layer was 20% by mass relative to the m...

Embodiment 2

[0107] The reinforcing rope of Example 2 is configured such that the base covering layer in the reinforcing rope of Example 1 is omitted (the base covering layer is not provided). However, the other configurations are the same as those of the reinforcement rope of Example 1, and it is produced by the same method. In addition, as a product reinforced with the reinforcing cord of Example 2, a flat transmission belt was manufactured in the same manner as in Example 1.

[0108] The same bending test and immersion test as in the case of Example 1 were performed on the flat transmission belt using the reinforcing cord of Example 2. The results are shown in Table 3 below.

Embodiment 3、4 and comparative example 4

[0121] The reinforcing cords in Examples 3, 4, and Comparative Example 4 were manufactured in the same manner as in Examples 1, 2, and Comparative Example 1, respectively, omitting the overcoat layer and other configurations. In addition, in the reinforcing cord of Example 5, the covering layer was produced using THVX815G manufactured by Sumitomo 3M Corporation, which is a fluororesin-based thermoplastic elastomer. For these reinforcement ropes, water absorption and oil absorption were measured in the same manner as in Example 1. The results are shown in Table 4.

[0122] [Table 4]

[0123]

[0124] ( * 5) Mixture of water-soluble hydrogenated nitrile rubber (H-NBR) and resorcinol-formaldehyde (RF) condensate

[0125] From the results shown in Table 4, it can be seen that even when a fluororesin-based thermoplastic elastomer is used for the cover layer, water absorption and oil absorption can be achieved to the same extent as when a polyester-based thermoplastic elastome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com