Far-infrared enamel material and preparation method and application thereof

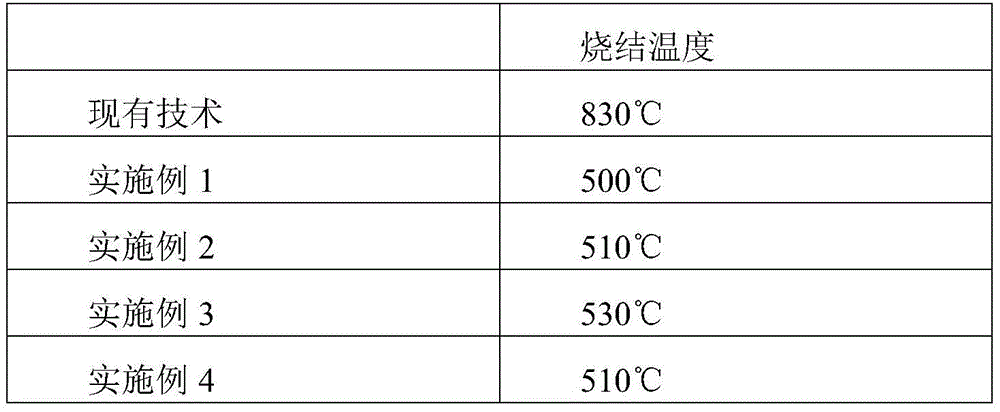

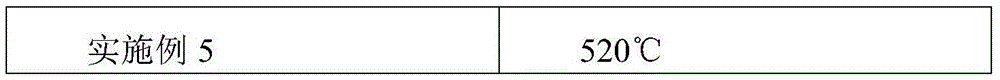

A far-infrared and far-infrared powder technology, applied in the field of materials, can solve the problems of no far-infrared performance, poor baking effect, low energy utilization rate, etc., so as to reduce the glaze sintering temperature, reduce energy consumption, and improve the finished product. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

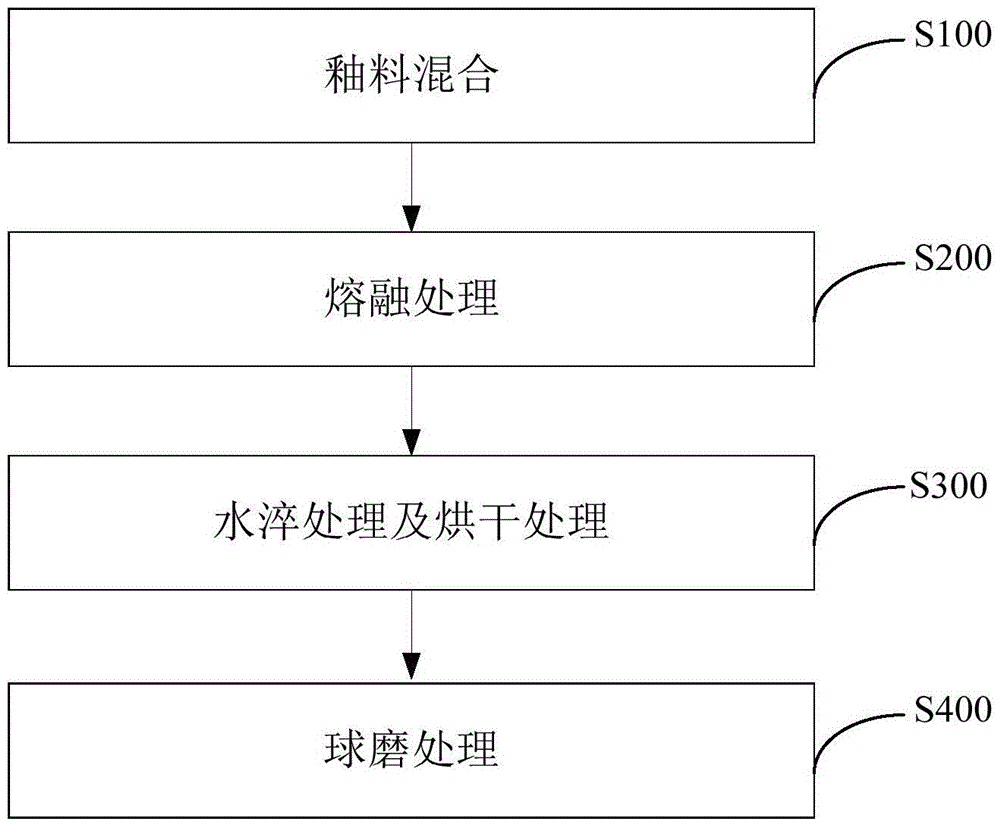

[0060] Prepare the far-infrared enamel material according to the following method:

[0061] 1) The first main group metal oxide 10%Na 2 O, 10%K 2 O, 5% Rb 2 O, the oxide of the third main group element 12% Al 2 o 3 , oxides of the fourth main group elements 22% SiO 2 , 3% SnO 2 16% TiO oxide of the fourth subgroup element 2 , 4% ZrO 2 , the oxide of the fifth main group element 1% Sb 2 o 3 , 2% Bi 2 o 3 , the fifth subgroup oxide 1% V 2 o 5 , The seventh subgroup oxide 3% MnO 2 , Group VIII metal oxide 3% Fe 2 o 3 , 1% CoO, the second subgroup metal oxide 2% ZnO, the second main group element fluoride 1% CaF 2 , oxides of lanthanide elements 0.02% Ce 2 o 3 Mix evenly, melt in a kiln at 900°C, put the melted material into cold water for water quenching, put the water quenched frit in an oven to dry to obtain frit;

[0062] 2) Combine the frit obtained in 1) with far-infrared powder 2% SiC, 1% Co 2 o 3 , and 1% xanthan gum are ball milled together to obtain ...

Embodiment 2

[0064] Prepare the far-infrared enamel material according to the following method:

[0065] 1) The first main group metal oxide 6%Na 2 O, 8%K 2 O, 3% Rb 2 O, the oxide of the third main group element 15% Al 2 o 3 , oxides of the fourth main group elements 20% SiO 2 , 6%SnO 2 13%TiO, the oxide of the fourth subgroup element 2 , 6% ZrO 2 , the oxide of the fifth main group element 2% Sb 2 o 3 , 4% Bi 2 o 3 , the fifth subgroup oxide 2% Nb 2 o 5 , The seventh subgroup oxide 4% MnO 2 , Group VIII metal oxide 3% Fe 2 o 3 , the second subgroup metal oxide 3% ZnO, the second main group element fluoride 1% CaF 2 , oxides of lanthanide elements 0.02% Nd 2 o 3 Mix evenly, melt in a kiln at 1050°C, put the molten material into cold water for water quenching, put the frit after water quenching into an oven to dry, and obtain the frit;

[0066] 2) Combine the frit obtained in 1) with far-infrared powder 2% SiC, 1% MoO 3 , and 1% xanthan gum are ball milled together to o...

Embodiment 3

[0068] Prepare the far-infrared enamel material according to the following method:

[0069] 1) The first main group metal oxide 6% K 2 O, 6% Rb 2 O, the oxide of the third main group element 10% Al 2 o 3 , oxides of the fourth main group elements 25% SiO 2 , 10% SnO 2 , Oxides of the fourth subgroup elements 12% TiO 2 , 8% ZrO 2 , Oxide of the fifth main group element 3% Sb 2 o 3 , 3% Bi 2 o 3 , the fifth subgroup oxide 2% V 2 o 5 , 1% Nb 2 o 5 , The seventh subgroup oxide 5% MnO 2 , Group VIII metal oxide 1% Fe 2 o 3 And 2% CoO, the second subgroup metal oxide 2% ZnO, the second main group element fluoride 1% CaF 2 , oxides of lanthanide elements 0.02% Nd 2 o 3 Mix evenly, melt in a kiln at 1100°C, put the melted material into cold water for water quenching, put the water quenched frit in an oven to dry to obtain frit;

[0070] 2) Combine the frit prepared in 1) with far-infrared powder 1% Co 2 o 3 , 1% MoO 3 , and 1% xanthan gum are ball milled togethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com