Assembled outer floating disc for storage tank

An assembled and floating plate technology, which is applied in packaging, transportation, packaging, containers, etc., can solve the problems of heavy workload, danger of sinking plate, failure to meet the specification requirements, etc., achieve short construction period, reduce labor intensity, avoid The effect of lightning accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

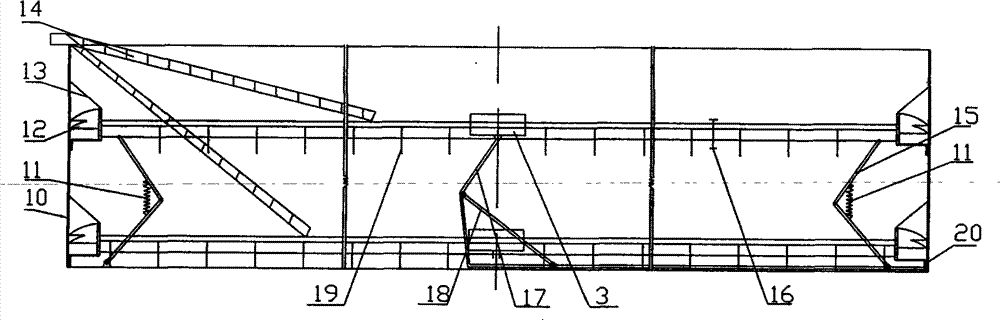

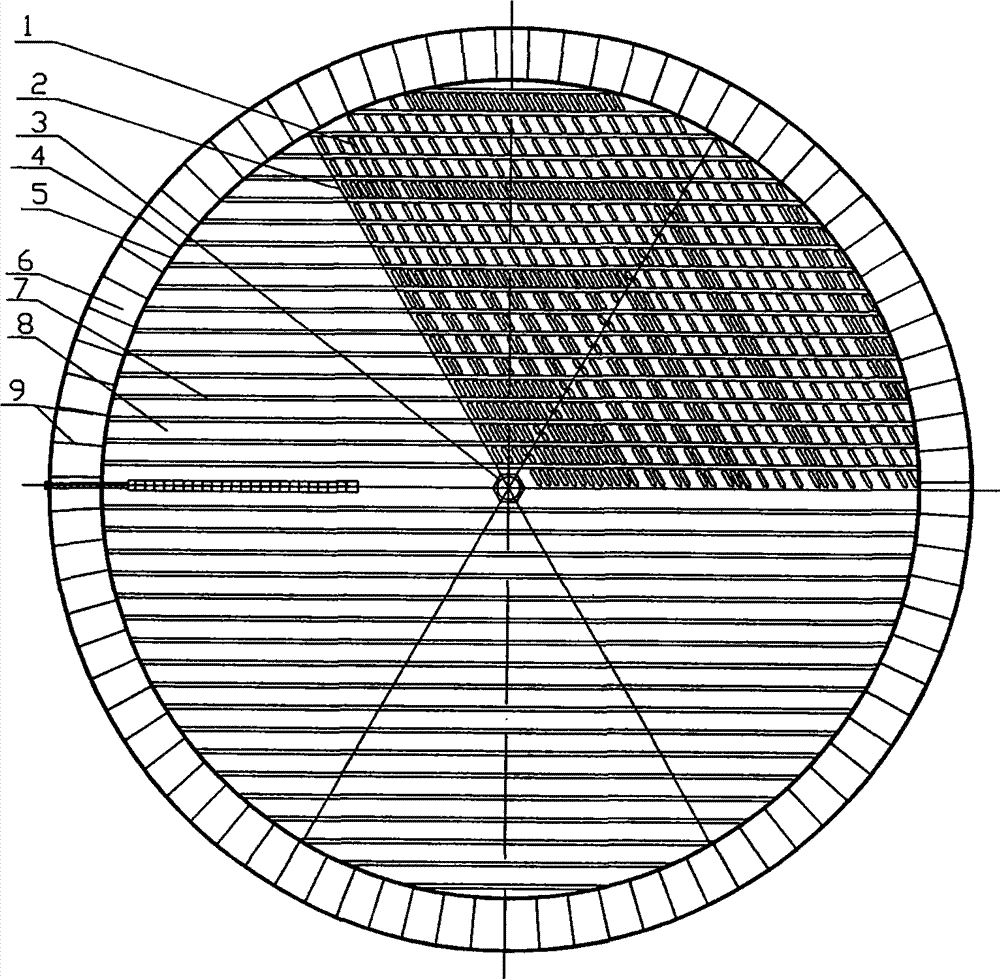

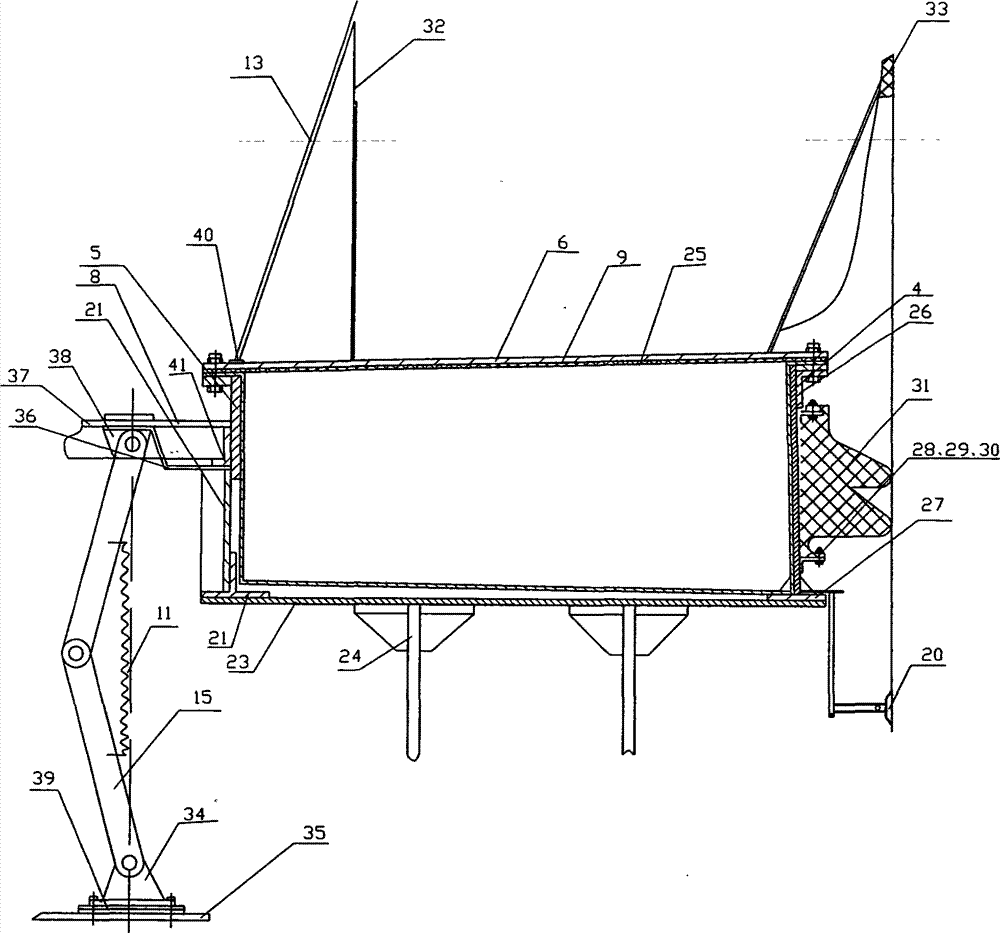

[0029] Depend on figure 1 , 2. There are reinforcing ribs 23 connecting the outer ring beam 4 and the inner ring beam 5, the cabin float 9 is placed between the inner ring beam 5 and the outer ring beam 4, and the metal skeleton has 6 main beams 2 arranged in a 60-degree distribution , forming a network structure, one end of the main beam 2 is connected with the inner ring beam 5, and the other end is connected with the center drainage device 3, the cabin cover plate 6 is installed on the cabin, the middle float 1 is installed between the main beams 2, and the rainproof baffle 12 and sealing device 13, are contained in an end of outer floating plate, and support leg 19 is connected at the bottom of floating plate, and middle drainage device 3 connects a middle drain pipe 17 and drain pipe 18, and emergency drain pipe 16 is housed in addition on outer floating plate. The bottom of the outer floating plate is connected with living hinge legs 15, stage clips 11 are connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com