Broadband absorber and preparation method thereof

An absorber and broadband technology, which is applied in the field of photothermal material preparation, can solve the problems of high price, difficulty in wide application, and non-environmental protection, and achieve excellent photothermal conversion efficiency, high photothermal conversion efficiency, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

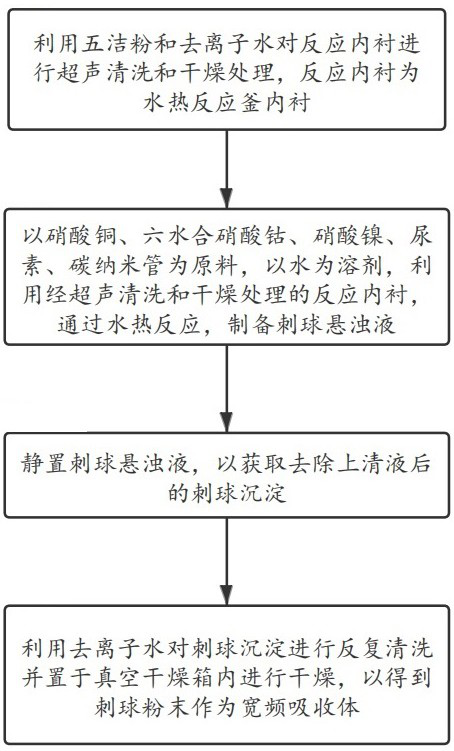

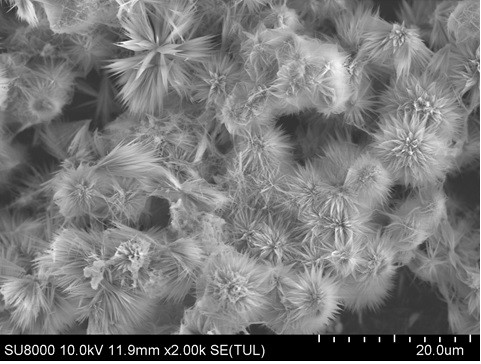

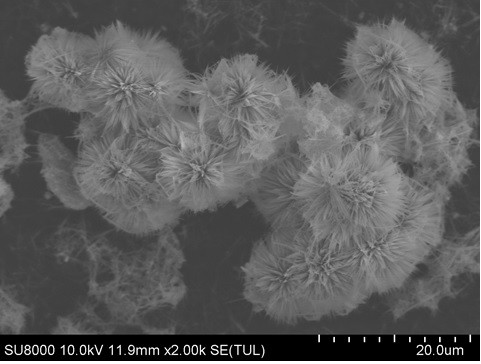

[0037] The first aspect of the present invention provides a method for preparing a broadband absorber, the broadband absorber is used for broadband absorption from the visible light band to the middle and far infrared band. figure 1 It is a flowchart of a preparation method of a broadband absorber according to an embodiment of the present invention, such as figure 1 As shown, the method specifically includes: step S1, using five cleaning powder and deionized water to ultrasonically clean and dry the reaction lining, the reaction lining is a hydrothermal reaction kettle lining; step S2, using copper nitrate , cobalt nitrate hexahydrate, nickel nitrate, urea, and multi-walled carbon nanotubes are raw materials, and water is used as a solvent to prepare Cu 0.48 Ni 0.16 co 2.36 o 4 / CuO-MWCNT thorn ball suspension, wherein MWCNT is a multi-walled carbon nanotube; step S3, standing the Cu 0.48 Ni 0.16co 2.36 o 4 / CuO-MWCNT spiked ball suspension to obtain Cu after removing t...

Embodiment 1

[0044] Embodiment one: Cu 0.48 Ni 0.16 co 2.36 o 4 / CuO-MWCNT spine ball preparation method.

[0045] Weigh 0.18 g of Cu(NO 3 ) 2 , 0.16 g Ni(NO 3 ) 2 , 0.33 g Co(NO 3 ) 2 ·6H 2 O, 0.12 g of urea, and 0.017 g of multi-walled carbon nanotubes (MWCNT) were dispersed in 40 ml of deionized water, and stirred at a rate of 370 rpm for 10 minutes on a magnetic stirrer.

[0046] The obtained solution was transferred to a hydrothermal reaction kettle, and the reaction kettle was placed in an oven to be heated, and the temperature of the oven was set to 120 degrees Celsius, and the time was set to 15 hours.

[0047] After the oven is cooled, the suspension obtained by the hydrothermal treatment is left to settle and the supernatant is removed, and then fully washed with deionized water for 3 times.

[0048] Finally, the resulting precipitate was dried in a vacuum drying oven at a drying temperature of 70 degrees Celsius and a drying time of 12 hours to obtain a composite Cu ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com