Nano emulsion and preparation method by phase inversion temperature process

A nano-emulsion and emulsifier technology, applied in the chemical industry, can solve the problems of equipment limitation and difficult realization, and achieve the effects of easy realization, low production equipment requirements and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A nanoemulsion prepared by a phase transition temperature method, calculated by weight percentage, its raw material composition and content are as follows:

[0028] High HLB emulsifier15% Low HLB emulsifier5% Solid grease5% Liquid grease25% Polyol10% Deionized water to 100%

[0029] The high HLB emulsifier is steareth-21, cosmetics and products provided by Croda (UK);

[0030] The low HLB emulsifier is steareth-2, cosmetics and products provided by Croda (UK);

[0031] The solid oil is pentaerythritol distearate, cosmetics and products provided by Lubrizol Corporation (USA);

[0032] The mixture of the liquid oil myristyl myristate and cetearyl isononanoate is an industrial grade product provided by BASF (Germany);

[0033] The polyol is pentanediol, an industrial grade product provided by Sinopharm Chemical Reagent Co., Ltd.;

[0034] The above-mentioned method for preparing nanoemulsion by a phase transition temperature method specifically includes the following steps: ...

Embodiment 2

[0042] A nanoemulsion prepared by a phase transition temperature method, calculated by weight percentage, its raw material composition and content are as follows:

[0043] High HLB emulsifier12% Low HLB emulsifier3% Solid grease15% Liquid grease15% Polyol8% Deionized water to 100%

[0044] The high HLB emulsifier is Tween-80, an industrial grade product provided by Sinopharm Chemical Reagent Co., Ltd.;

[0045] The low HLB value emulsifier is Ipan-80, an industrial grade product provided by Sinopharm Chemical Reagent Co., Ltd.;

[0046] The solid oil is a mixture of monoglyceride and behenyl alcohol, a cosmetic grade product provided by BASF (Germany);

[0047] The mixture of the liquid oil myristyl myristate and caprylic capric triglyceride is an industrial grade product provided by BASF (Germany);

[0048] The polyol is propylene glycol, an industrial grade product provided by Sinopharm Chemical Reagent Co., Ltd.;

[0049] The above-mentioned method for preparing nanoemulsion ...

Embodiment 3

[0057] A nanoemulsion prepared by a phase transition temperature method, calculated by weight percentage, its raw material composition and content are as follows:

[0058] High HLB emulsifier9% Low HLB emulsifier1% Solid grease10% Liquid grease25% Polyol15% Deionized water to 100%

[0059] The high HLB emulsifier is ceteareth-20, a cosmetic-grade product provided by BASF (Germany);

[0060] The low HLB emulsifier is ceteareth-12, a cosmetic grade product provided by BASF (Germany);

[0061] The solid oil is a mixture of pentaerythritol tetrastearate and monoglyceride. Among them, pentaerythritol tetrastearate is a cosmetic-grade product provided by Lubrizol (USA), and monoglyceride is a BASF company (Germany). ) Cosmetic-grade products provided;

[0062] The liquid oil PPG-15 stearyl ether and 26# white oil is a mixture, wherein PPG-15 stearyl ether is a cosmetic-grade product provided by Degussa Company, and 26# white oil is Shanghai Daoxin Trading Co., Ltd. Cosmetic-grade ...

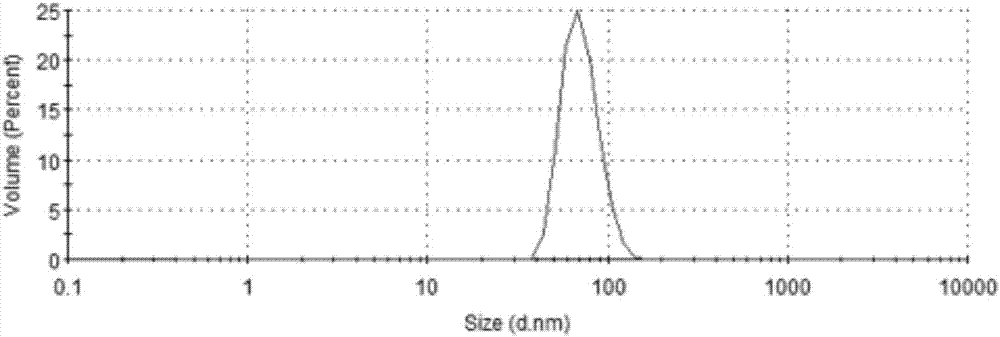

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com