Printing paste for silk fabric and printing technology with printing paste

A printing color paste and printing process technology, which is applied in the field of textile printing, can solve the problems of uneven dye diffusion in time, uneven dyeing, high dye concentration, etc., and achieve the effects of reducing the concentration of the capsule core, improving the effect, and enhancing the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0048] A kind of printing color paste of real silk fabric, its technology comprises the steps:

[0049] S2i, uniformly mixing the dye, urea, paste and other components according to the formula amount at 20-40°C to obtain the capsule core;

[0050] S2ii, on the capsule core obtained by Si, spray the adhesive of formula quantity;

[0051] S2iii, on the mixture obtained by Sii, spray the capsule of the formula amount, and dry at 30-50°C to prepare printing paste;

[0052] Among them, spraying adopts spray drying method or fluidized bed gas suspension method;

[0053] See Table 1 to Table 8 for the statistics of each component and related information of Examples 1-8.

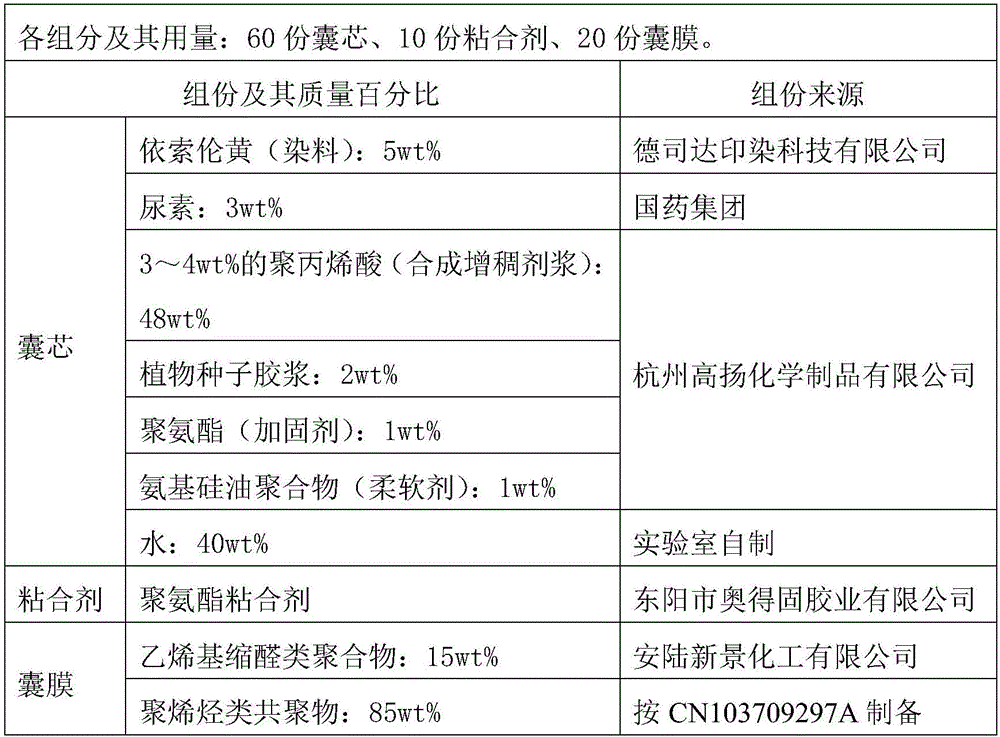

[0054] Each component of the printing paste of table 1 embodiment 1 and relevant information statistics

[0055]

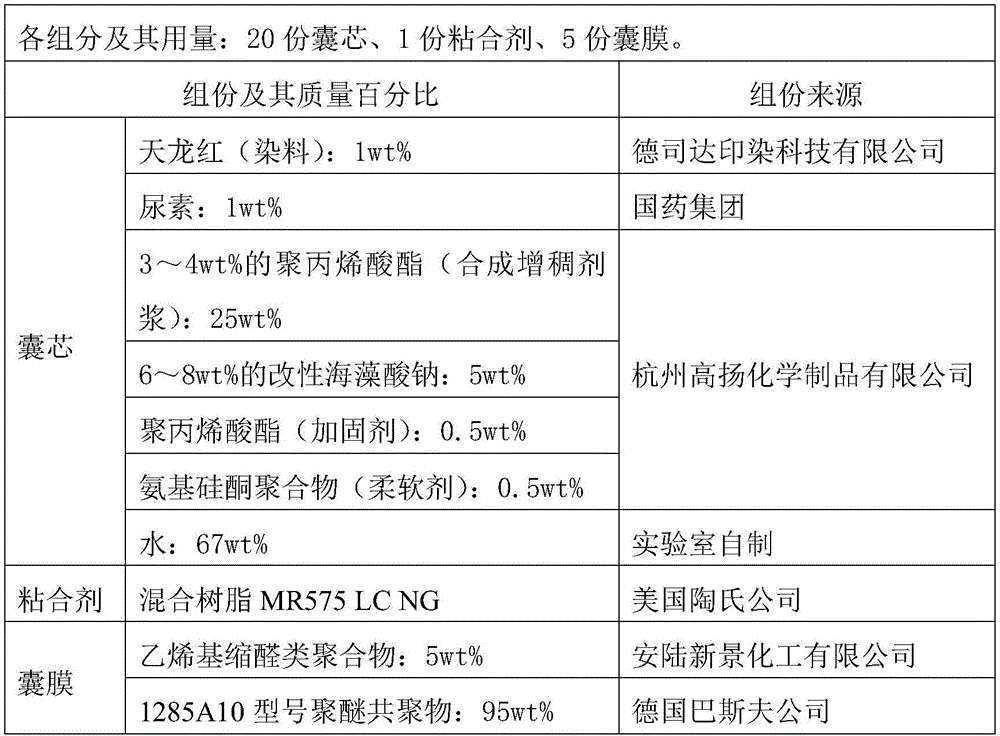

[0056] Each component of the printing paste of table 2 embodiment 2 and relevant information statistics

[0057]

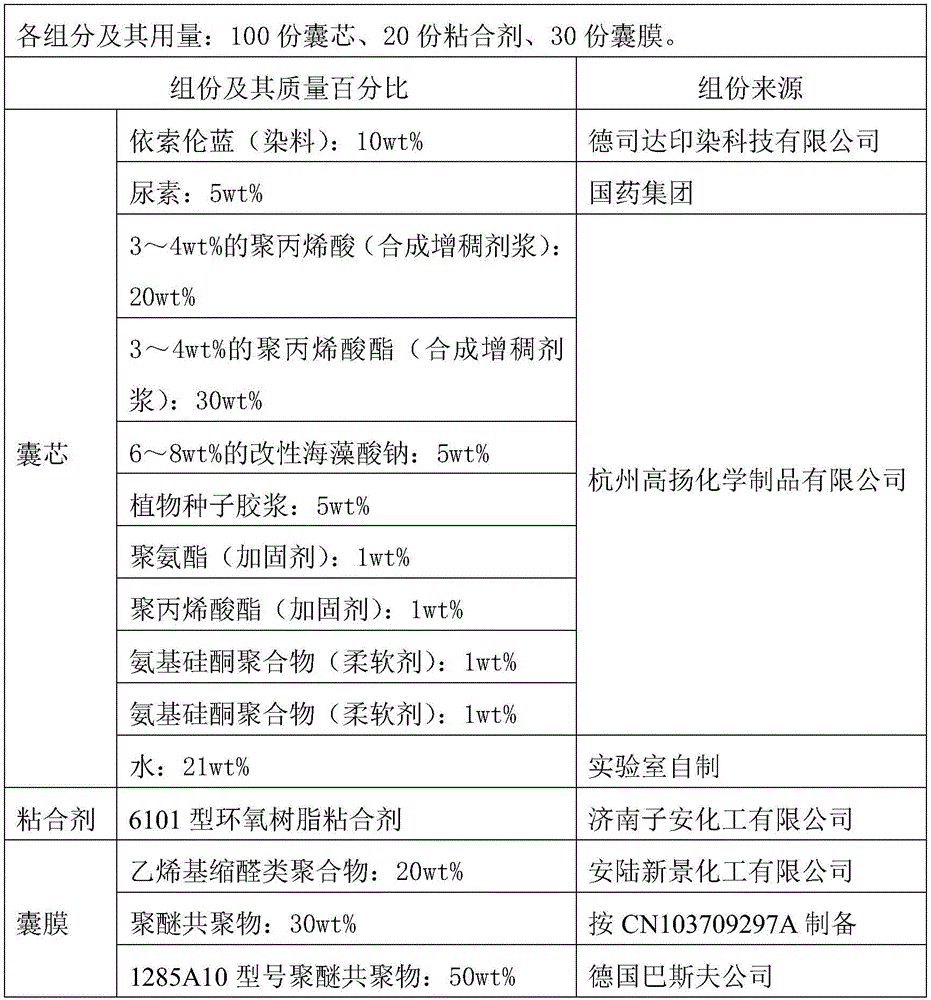

[0058] Each component of the printing paste of table 3 embodiment 3 and relev...

Embodiment 9-16

[0071] A kind of printing, its technique comprises the steps:

[0072] S1, pre-treated silk fabric: Sli, pre-treated slurry treatment: add pre-treated slurry to the silk fabric at 20-40°C, and dry (10-30min) at 50-80°C after treatment, of which the silk The mass ratio of fabric and pretreatment slurry is 1: 5~20; S1ii, graft modification: add grafting agent in the real silk fabric that Sli handles and obtain, at 20~40 ℃, dipping and rolling two times (with liquid 70 ~80wt%), drying (1~5min) under 100~120 ℃, wherein the mass ratio of real silk fabric and grafting agent is 1: 10~50;

[0073] S2, prepare printing paste according to embodiment 1-8;

[0074] S3, at pH=6.0-6.5, apply the printing paste prepared in S2 to the silk fabric obtained in the pretreatment of S1 for printing treatment, wherein the mass ratio of the silk fabric to the printing paste is 1:0.5-5;

[0075] S4, drying, steaming, cleaning and finishing the printed silk fabric obtained in S3.

[0076] See Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com