A high-quality printing and dyeing mechanism for textile fabrics

A textile fabric, high-quality technology, applied in the direction of processing textile material equipment configuration, spraying/jetting textile material processing, etc., can solve the problems of uneven dyeing, adhesion of impurities, poor dyeing effect, etc., to improve the utilization rate and structural setting. Ingenious and reasonable, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

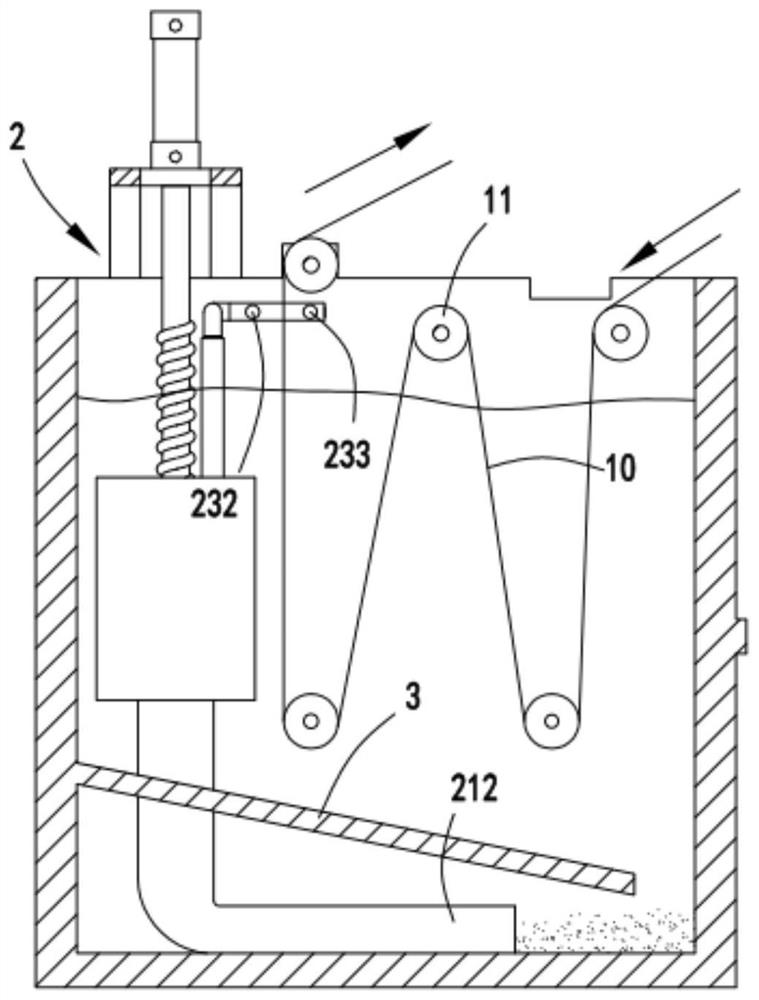

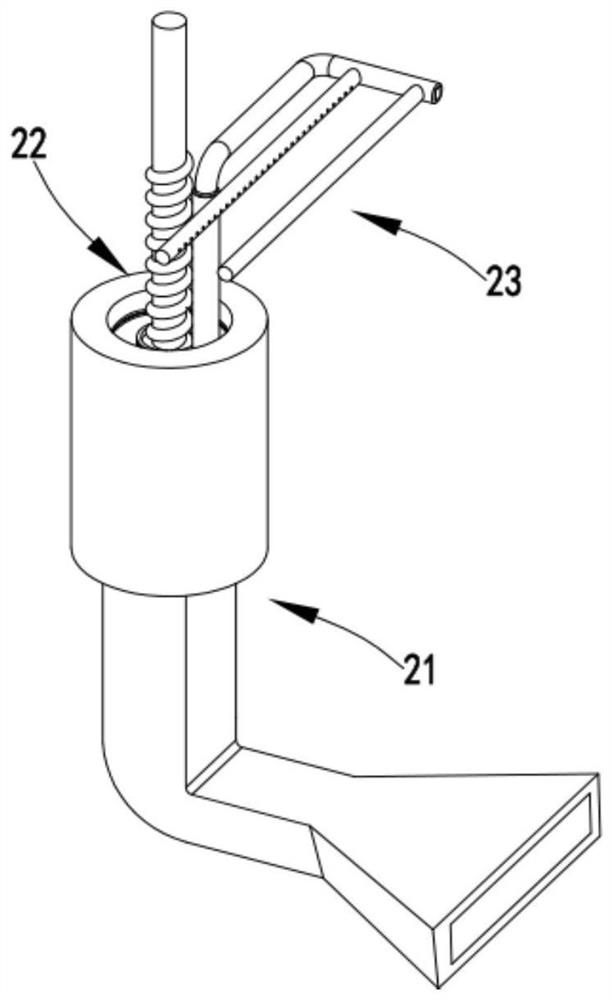

[0042] Such as Figure 1 to Figure 11 As shown, a high-quality printing and dyeing mechanism for textile fabrics includes a dye box 1, and a spraying mechanism 2 is arranged in the dye box 1, and the spraying mechanism 2 includes a filter assembly 21 fixed on the inner wall of the dye box 1. The grinding assembly 22 in the filter assembly 21 and the spraying assembly 23 arranged on the upper end of the filter assembly 21;

[0043]When the grinding assembly 22 moves upwards, the filter assembly 21 extracts the dye liquor at the bottom of the dye box 1. When the grinding assembly 22 moves downward, it squeezes the dye liquor in the filter assembly 21 and filters the dye liquor. The filtered dye liquor Under the action of pressure, the two surfaces of the fabric 10 are sprayed and dyed through the spraying and dyeing assembly 23, and the grinding assembly 22 continues to move downwards to remove the coarse particle dye remaining in the filter assembly 21 after the dye liquid is s...

Embodiment 2

[0059] Such as figure 1 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, a guide plate 3 is provided below the filter assembly 21 , and the end of the guide plate 3 is inclined downward toward the inlet of the suction pipe 212 .

[0060] In this embodiment, by setting the guide plate 3 at the bottom of the dye tank 1, some deposited coarse particle dyes and impurities flow along the guide plate 3 to the port of the suction pipe 212, thereby improving the efficiency of coarse particle dye collection and grinding.

[0061] The working process is as follows:

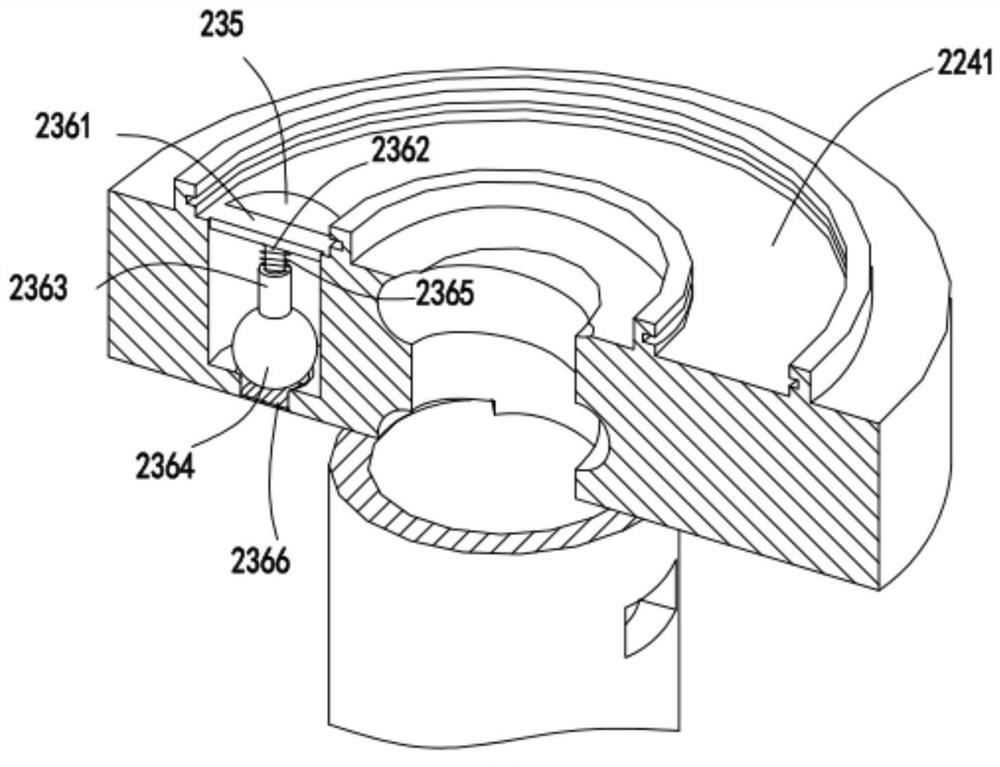

[0062] The lifting member 222 drives the lead screw 223 to move downwards. At this time, the communication groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com