PVA non -woven embroidery dyeing method and its dyeing device

A technology for non-woven fabrics and embroidery products, which is applied in the field of dyeing and finishing methods and dyeing and finishing devices for PVA non-woven fabrics and embroidery products, can solve the problem of no sterilization, flame retardant and fragrance enhancement, no cloth compaction, and anti-oxidation properties. Not good and other problems, to achieve the effect of keeping the color unchanged, increasing the oxidation resistance, and improving the color fixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

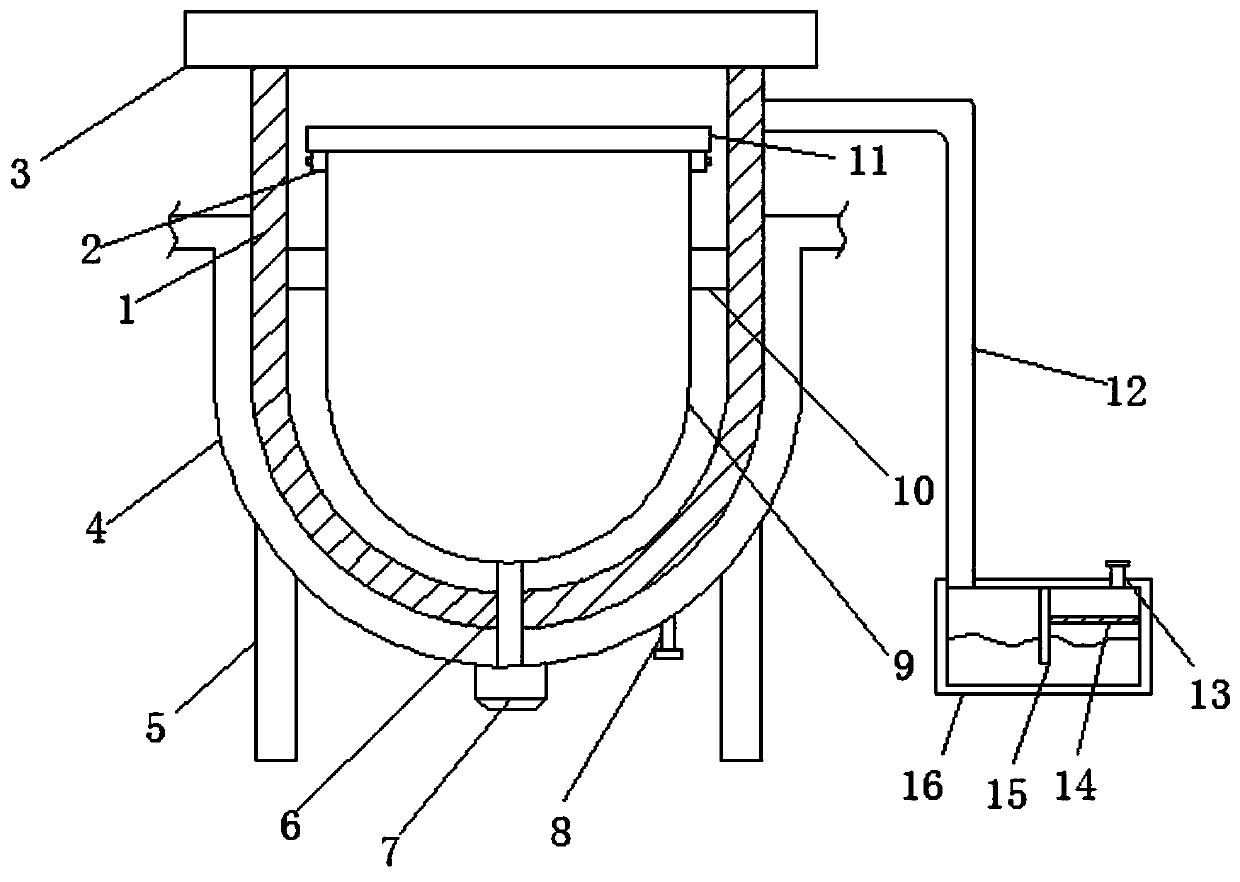

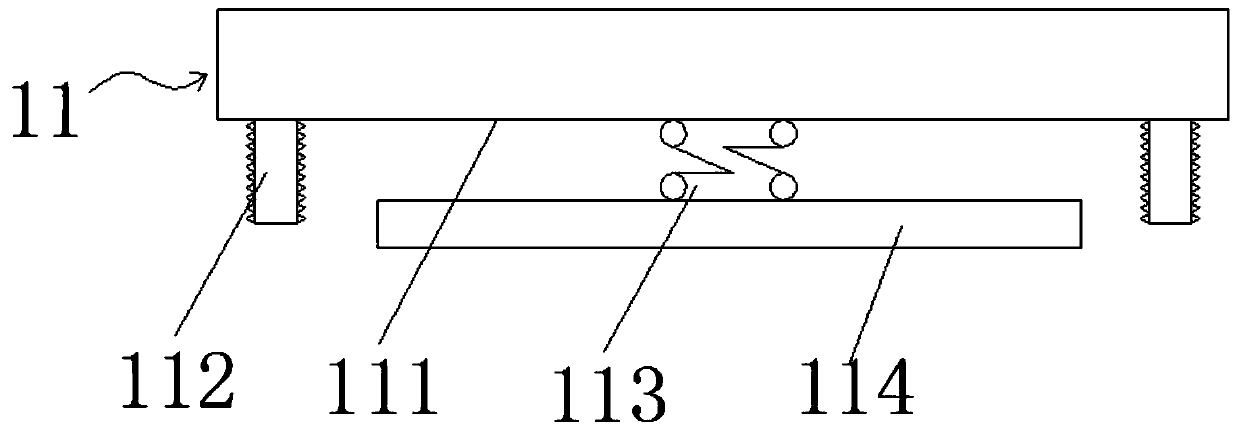

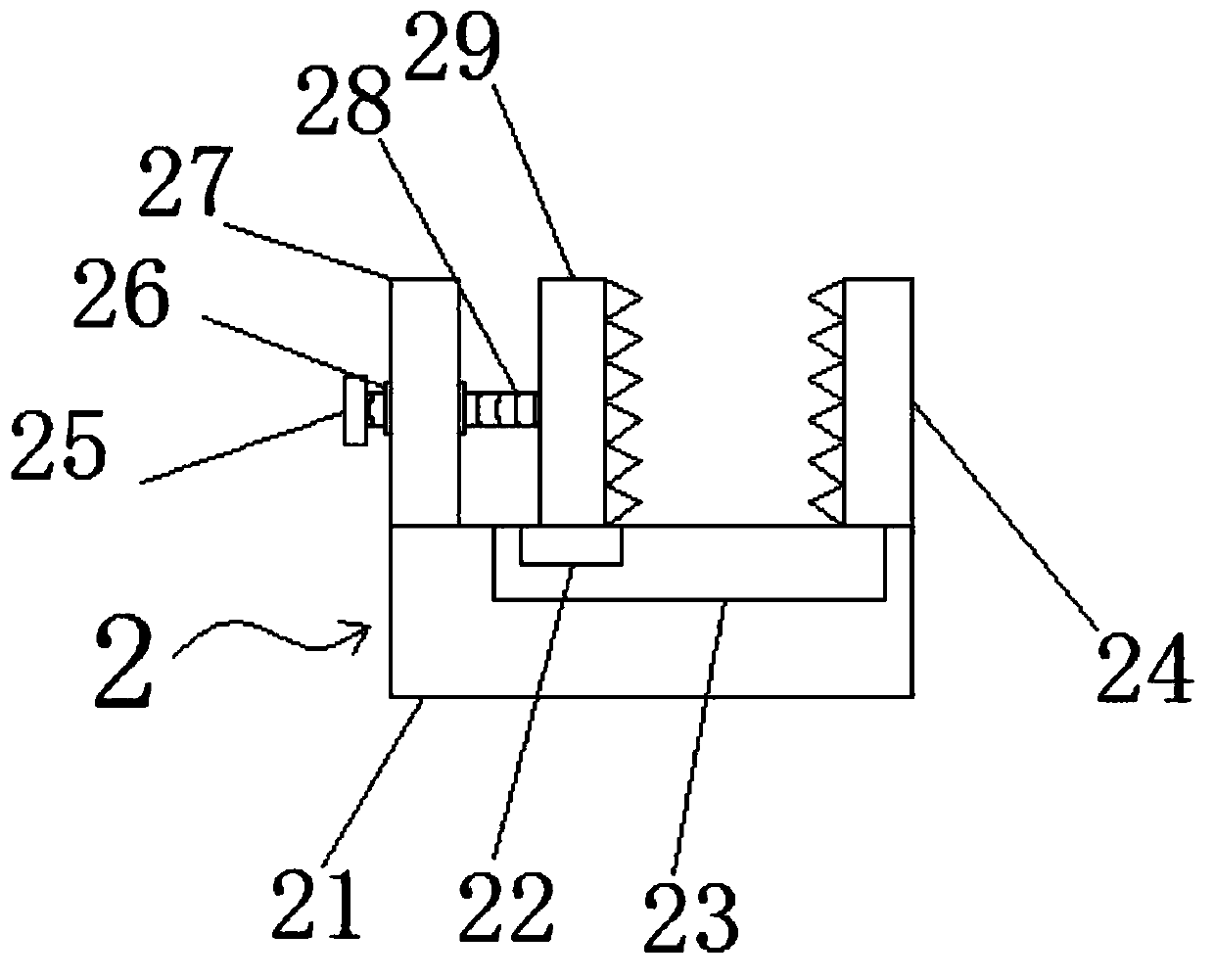

Image

Examples

Embodiment 1

[0035] The present invention provides a kind of dyeing and finishing method of PVA non-woven fabric embroidery, and the dyeing and finishing method comprises the following steps:

[0036] 1) Sculpting and bleaching process: firstly inspect the original PVA non-woven fabric, turn it over and sew it, and then quickly wipe it on the hot metal surface. It carries out desizing treatment, then configures scouring working fluid, and controls the temperature at 45°C, puts the fabric that has been treated with liquid into a steamer, steams it, fully heats it for 3 times, and then puts the fabric in a mixture of hydrogen peroxide and caustic soda In the aqueous solution, heat at 30°C, rinse for 30 minutes, and finally configure 15mol / L sodium hydroxide solution, put the fabric into the sodium hydroxide solution for reaction, and the reaction time is 15 minutes;

[0037] 2) Dyeing process: Hang out the whole degummed PVA non-woven lace, put it on the hanging basket, and then add water, m...

Embodiment 2

[0044] The dyeing and finishing method of PVA non-woven fabric embroidery, the dyeing and finishing method comprises the following steps:

[0045] 1) Sculpting and bleaching process: firstly inspect the original PVA non-woven fabric, turn it over and sew it, and then quickly wipe it on the hot metal surface. It carries out desizing treatment, then configures scouring working liquid, and controls the temperature at 50°C, puts the fabric treated with liquid into a steamer to steam, fully hot washes 4 times, and then puts the fabric into a mixture of hydrogen peroxide and caustic soda In the aqueous solution, heat at 40°C, rinse for 50 minutes, and finally configure 20mol / L sodium hydroxide solution, put the fabric into the sodium hydroxide solution for reaction, and the reaction time is 30 minutes;

[0046] 2) Dyeing process: hang out the whole degummed PVA non-woven lace, put it on the hanging basket, and then add water, modified reactive dyes, sodium chloride 40g / L, and leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com