Reactive dye moist fixation and dyeing method

A technology of reactive dyes and dyeing methods, which is applied in the field of moisture fixation after dyeing with reactive dyes, can solve problems such as dull color and heavy black gas, and achieve the effects of flexible application of varieties, reducing swelling, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

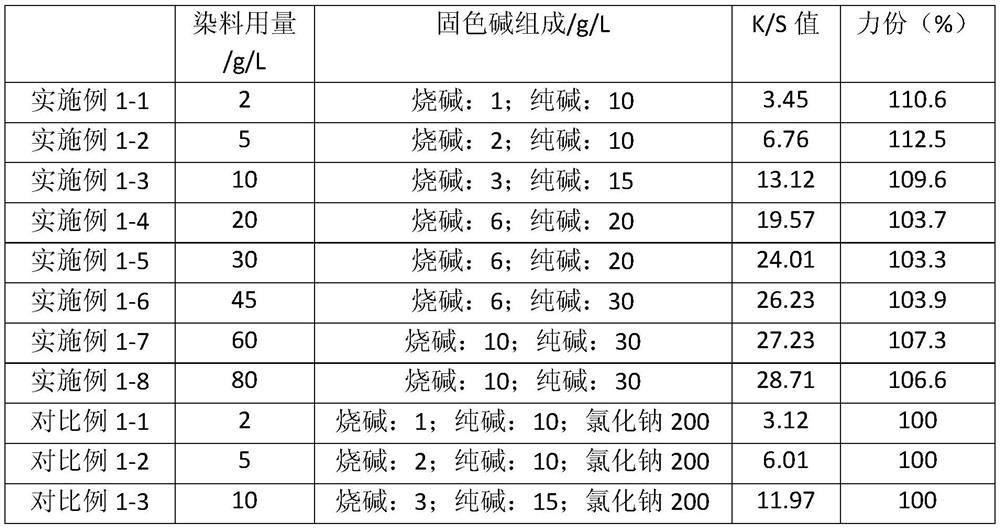

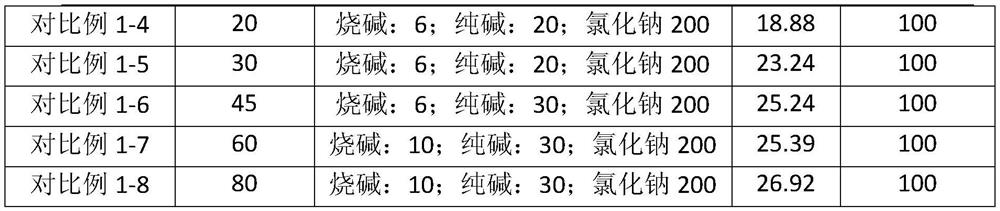

Embodiment 1 and comparative example 1

[0091] Example 1 and Comparative Example 1: respectively adopt the moisture-fixing dyeing method and the traditional pad-drying-pad-steaming process to dye cellulose fibers Fabric (different dye dosage)

[0092] Fabric: Cotton Fabric, Size: C 20s×16s 128×60 57 / 8”, Gingham

[0093] In Example and Comparative Example 1, Annuosu Navy Blue L-3G, Annuosu Yellow L-3R and Annuosu Red L-S were selected for color matching, and the proportions of the three dyes by weight are as follows:

[0094] Anosul Navy Blue L-3G 86%

[0095] Anoxin Yellow L-3R 6.5%

[0096] Anosol Red L-S 7.5%

Embodiment 1

[0098] The tide-fixed color technological process that embodiment 1 adopts:

[0099] Weighing (according to the process prescription to weigh the dye and color-fixing alkali respectively)→chemical material (the dye is chemically mixed in one chemical material tank; caustic soda and soda ash are chemically materialized in another chemical material tank to form a color-fixing alkali solution)→ Feeding (add the dye solution and color-fixing alkali solution to the same rolling tank through a proportional pump according to the ratio of 4:1) → padding dye and color-fixing alkali mixed solution (passing ratio 65%) → pre-baking (80°C , control the moisture content of the cloth surface to 20%) → synchronous rolling → plastic film sealing → stacking (stacking temperature 30°C, stacking time 24h) → washing → soaping → washing → drying.

Embodiment 2 and comparative example 2

[0108] Embodiment 2 and comparative example 2: respectively adopt moisture-fixed color dyeing method and traditional pad-drying-pad-steaming process to dye cellulose fiber Fabric (different cold pad batch process)

[0109] Fabric: Cotton Fabric, Size: C 20s×16s 128×60 57 / 8”, Gingham

[0110] The formulas of the dyeing solutions of Example 2 and Comparative Example 2 are: destaramase RGB golden yellow 20g / L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com