A class of high-fixation rate phthalocyanine azo dichromate reactive dyes and its preparation method and application

A reactive dye and azo-based technology, applied in reactive dyes, azo dyes, dyeing methods, etc., can solve the problem of low color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

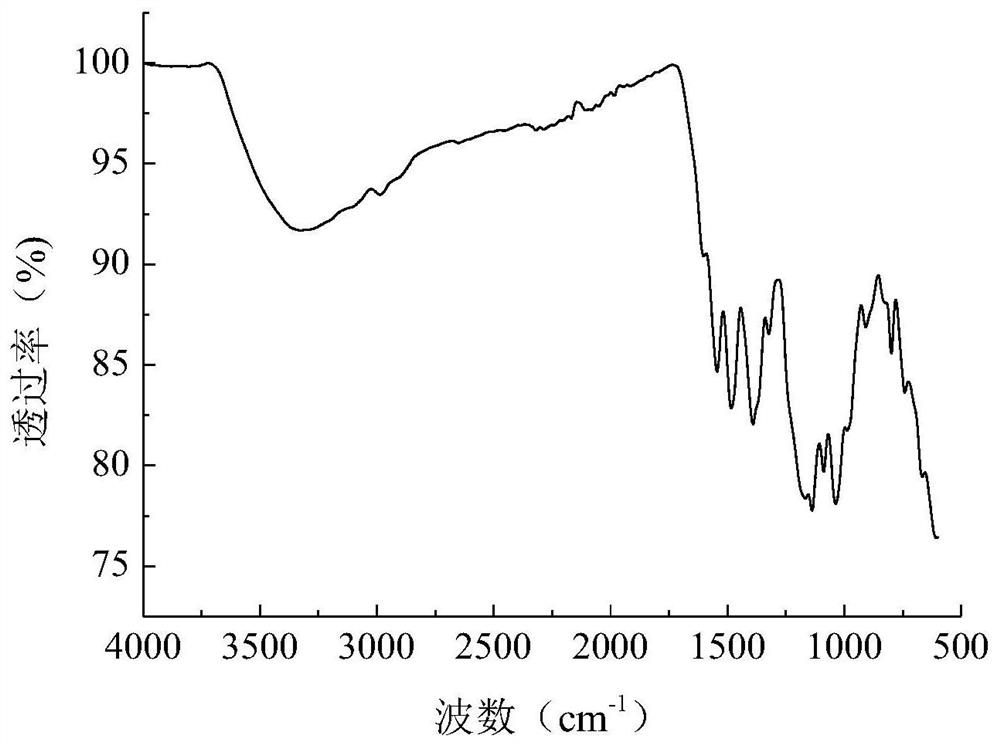

Embodiment 1

[0039] Synthesis of high fixation rate mixed color body reactive dyes with the following structure:

[0040]

[0041] (1) Preparation of copper phthalocyanine sulfonyl chloride: at room temperature, add 80 mL of chlorosulfonic acid to a three-necked flask equipped with a reflux condenser and a tail gas absorption device, add 15 g of copper phthalocyanine under stirring, and then heat up to 135 ° C for reaction 5h, then lower the temperature to 60°C, add 22mL of thionyl chloride to it, then raise the temperature to 100°C for 2h, then lower the temperature to below 30°C, slowly add the system to ice water while stirring, filter with suction, and use an appropriate amount of Wash with ice water to obtain 58 g of copper phthalocyaninesulfonyl chloride filter cake.

[0042] (2) Preparation of copper phthalocyanine turquoise blue base: the copper phthalocyanine sulfonyl chloride in step (1) was beaten for 1 h in an ice-water bath. Accurately weigh 5.04g of sodium 2,4-diaminobenz...

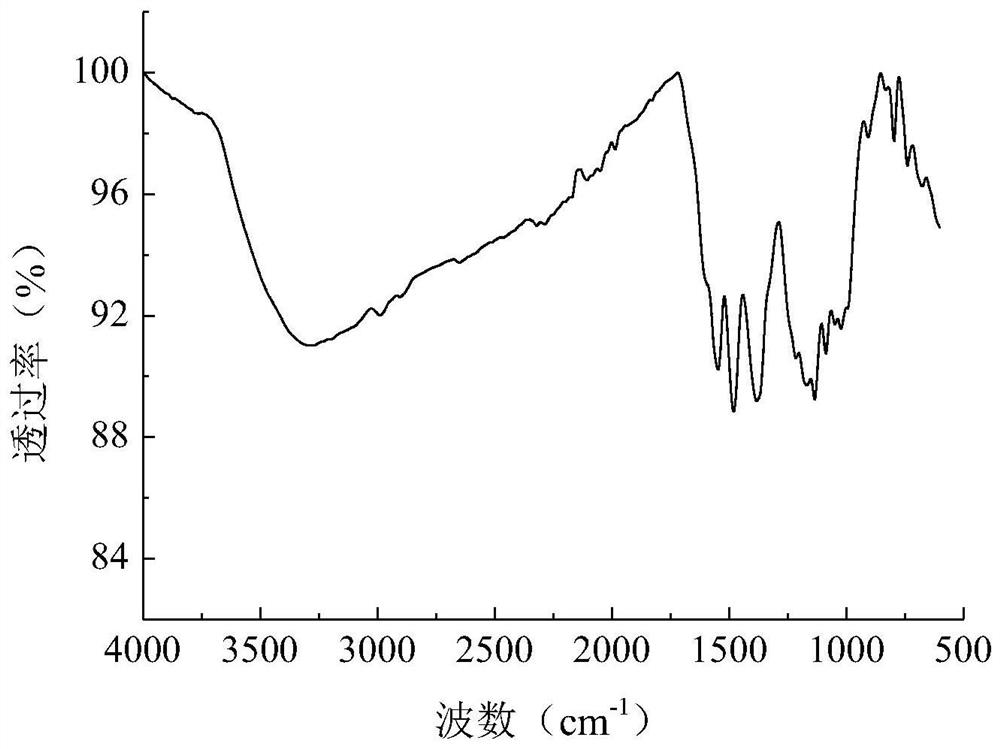

Embodiment 2

[0050] The synthesis process of the high fixation rate mixed color body reactive dye with the following structure:

[0051]

[0052] (1) Preparation of copper phthalocyanine sulfonyl chloride: at room temperature, add 80 mL of chlorosulfonic acid to a three-necked flask equipped with a reflux condenser and a tail gas absorption device, add 15 g of copper phthalocyanine under stirring, and then heat up to 135 ° C for reaction 5h, then lower the temperature to 60°C, add 22mL of thionyl chloride to it, raise the temperature to 100°C for 2h, then lower the temperature to below 30°C, slowly add the system to ice water while stirring, suction filter, filter the cake with an appropriate amount of ice Wash with water to obtain 58 g of copper phthalocyaninesulfonyl chloride filter cake.

[0053] (2) Preparation of copper phthalocyanine turquoise blue base: the copper phthalocyanine sulfonyl chloride in step (1) was beaten for 1 h in an ice-water bath. Accurately weigh 5.04g of 2,4-...

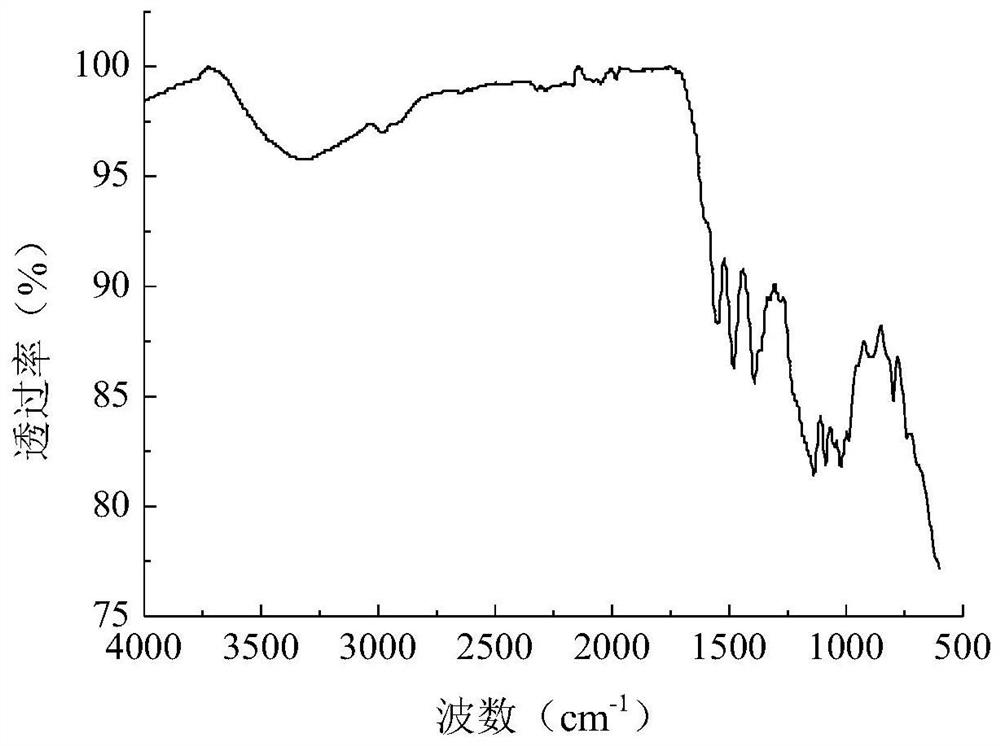

Embodiment 3

[0061] The synthesis process of the high fixation rate mixed color body reactive dye with the following structure:

[0062]

[0063] (1) Preparation of copper phthalocyanine sulfonyl chloride: at room temperature, add 80 mL of chlorosulfonic acid to a three-necked flask equipped with a reflux condenser and a tail gas absorption device, add 15 g of copper phthalocyanine under stirring, and then heat up to 135 ° C for reaction 5h, then lower the temperature to 60°C, add 22mL of thionyl chloride to it, raise the temperature to 100°C for 2h, then lower the temperature to below 30°C, slowly add the system to ice water while stirring, suction filter, filter the cake with an appropriate amount of ice Wash with water to obtain 58 g of copper phthalocyaninesulfonyl chloride filter cake.

[0064] (2) Preparation of copper phthalocyanine turquoise blue base: the copper phthalocyanine sulfonyl chloride in step (1) was beaten for 1 h in an ice-water bath. Accurately weigh 5.04g of 2,4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com