Patents

Literature

31results about How to "Reduce dye content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

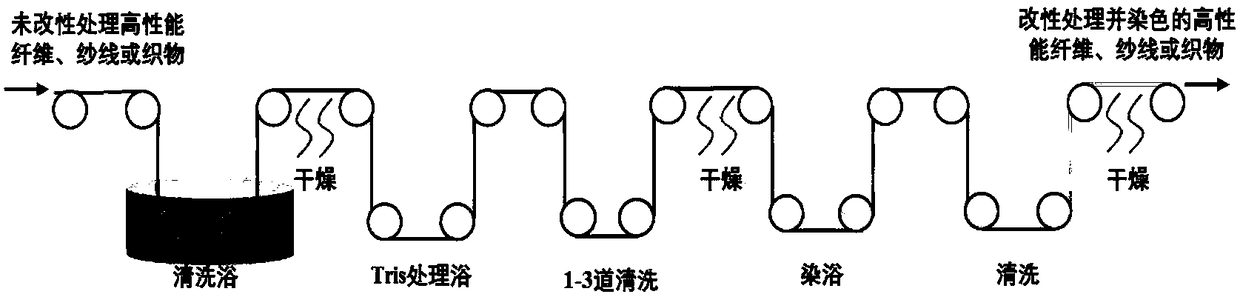

Dopamine-assisted dyeing high performance fiber, yarn or fabric and preparation method thereof

The invention provides a dopamine-assisted dyeing high performance fiber, yarn or fabric and a preparation method thereof, in order to overcome the defects of single color and difficulty in dyeing ofthe present high performance fibers. The preparation method comprises the following steps: putting the cleaned high performance fiber, yarn or fabric into a dopamine Tris solution treating bath, treating for 5-120min, and then cleaning and drying, and performing dyeing treatment, thereby acquiring the dopamine-assisted dyeing high performance fiber, yarn or fabric. According to the invention, theprocess is simple, safe, efficient and harmless to mechanical properties of fiber main body, and meanwhile, the dyeing performance of fiber is obviously promoted, the dyestuff universality is high andthe development of colored high performance fiber product can be boosted.

Owner:DONGHUA UNIV

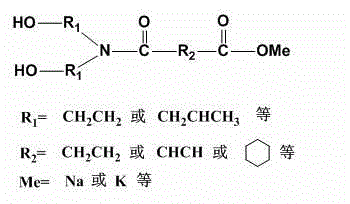

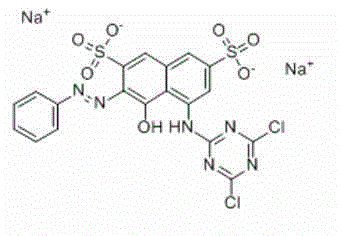

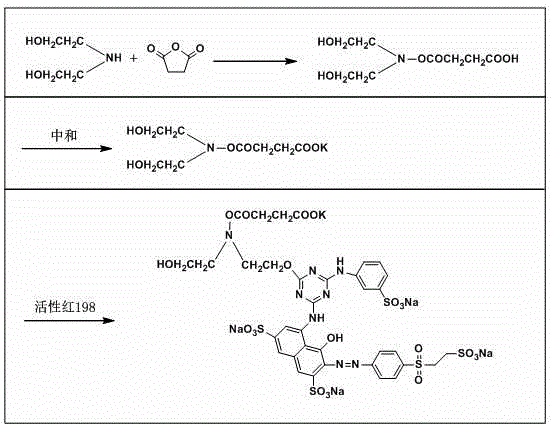

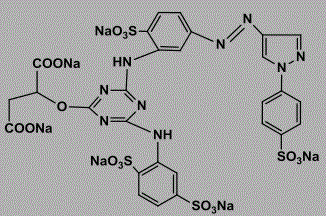

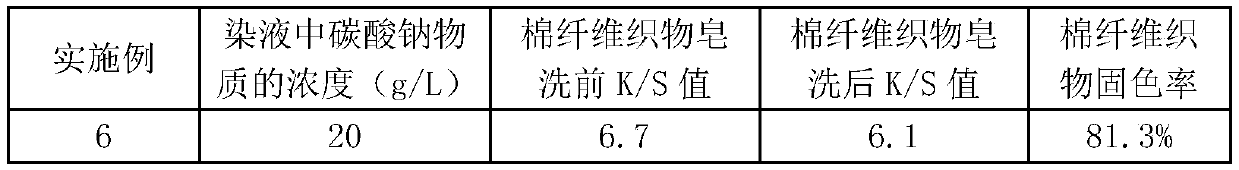

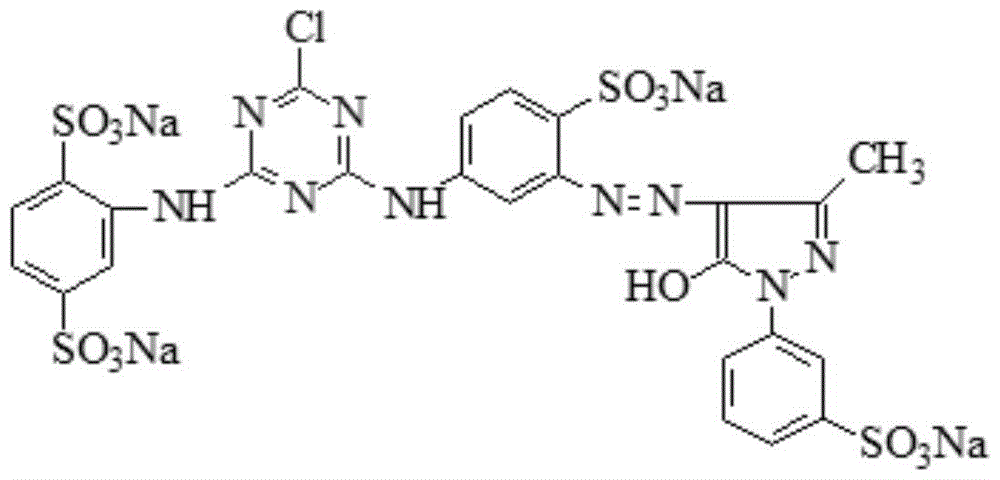

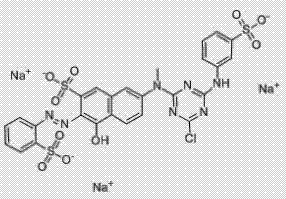

Reactive dye and preparation method thereof

ActiveCN104448930ASolve difficult-to-apply leather dyeing problemsHigh color fastnessOrganic dyesDyeing processCarboxylic saltSolvent

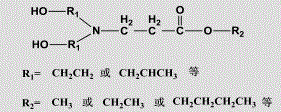

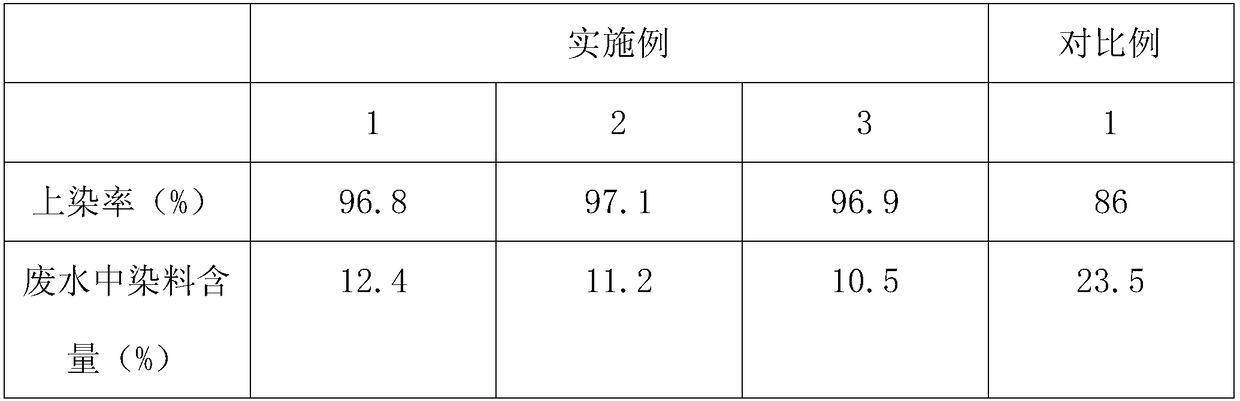

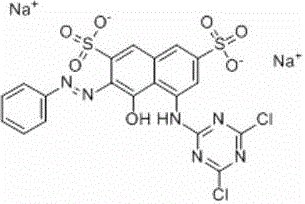

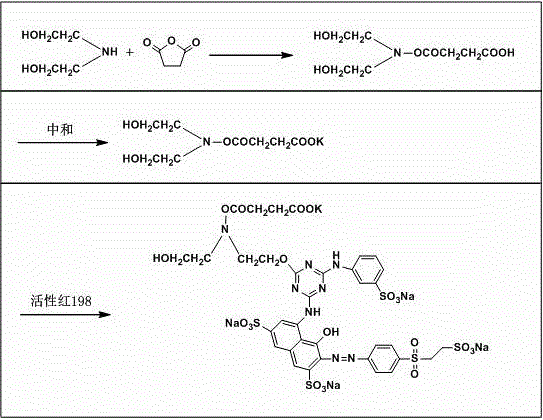

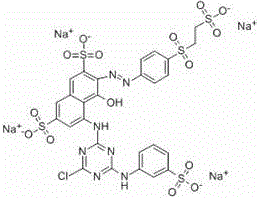

The invention discloses a reactive dye and a preparation method thereof. In order to achieve the above purpose, the reactive dye is prepared from a reactive dye and hydroxy amide carboxylate in a molar ratio N of 0.1: 1 to 2: 1, wherein the hydroxy amide carboxylate is prepared by neutralizing the pH value of a reaction product of hydramine and dicarboxylic anhydride in an equal molar ratio in a solvent to 8-10 by an alkaline solution. The method for preparing the reactive dye comprises the following steps: (1) taking the hydramine and the dicarboxylic anhydride in equal molar ratio to carry out amidation, neutralizing by using the alkaline solution until pH value is 8-10, and removing the solvent to obtain the hydroxy amide carboxylate; (2) reacting the hydroxy amide carboxylate with the reactive dye, and drying and grinding the product to obtain the reactive dye. The reactive dye and the preparation method of the reactive dye can be used for solving the problem that the existing reactive dye is hard to be applied in the leather dye; meanwhile, the color fastness of the leather is improved; the concentration of the residual dye of the dye waste solution is improved.

Owner:广州狮岭皮革皮具产业研究中心有限公司

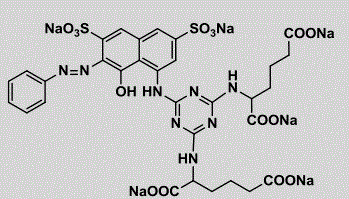

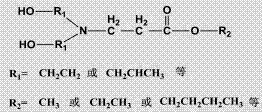

Preparation method for polymeric dye based on hyperbranched polyamine-ester

The invention relates to the technical field of special polymeric dyes for leather, fur and leather and fur products, in particular to a preparation method for a polymeric dye based on hyperbranched polyamine-ester. The preparation method comprises the following steps: by taking alcohol amine and acrylate as raw materials, reacting the alcohol amine and the acrylate, and removing a solvent after the reaction is ended to obtain an AB2 type monomer; reacting the AB2 type monomer, a catalyst and a micromolecular polyhydroxy compound to obtain hydroxyl-terminated hyperbranched polyamine-ester, and performing modification by using acid anhydride; reacting acid anhydride modified hyperbranched polyamine-ester with an active dye to obtain the polymeric dye. Compared with the prior art, the obtained polymeric dye can effectively improve the dyeing fastness, washing resistance, sweat resistance and other performance of the leather, the fur and the leather and fur products, the dye utilization rate is increased, and the content of dyes in waste liquor is reduced.

Owner:QILU UNIV OF TECH

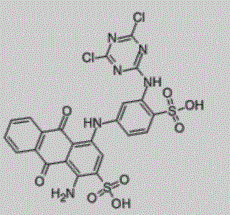

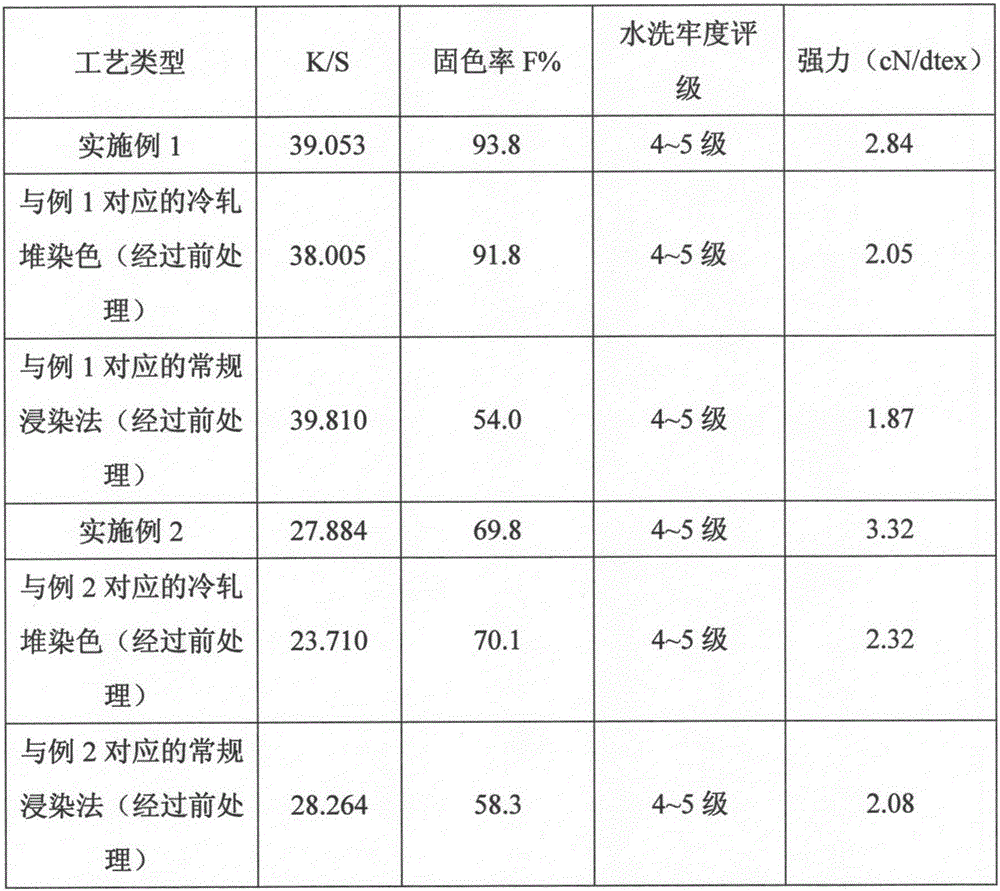

Cold pad batch processing method of cotton fibers through pre-treatment dyeing one-bath method

InactiveCN106368004AAvoid damageIncrease productivityTextile treatment machine arrangementsBiochemical treatment with enzymes/microorganismsFiberBatch processing

The invention provides a cold pad batch processing method of cotton fibers through a pre-treatment dyeing one-bath method. The cold pad batch processing method is characterized by comprising: padding raw cotton loose fibers into impregnation liquid; after padding, stacking at a room temperature for 8h to 20h; washing with hot water at 70 DEG C to 80 DEG C and soaping; washing with cold water and drying, wherein the impregnation liquid contains 10g / L to 80g / L of an active dyestuff, 3g / L to 5g / L of a pre-treatment auxiliary agent, 30g / L to 100g / L of a co-solvent, 5g / L to 18g / L of an alkali agent and 20g / L to 50g / of sodium sulfate, and the alkali agent is one or a compound of more of sodium silicate, sodium carbonate, sodium phosphate and sodium hydroxide. A cold pad batch treatment process provided by the invention is carried out at a room temperature, a formula is simple and the operation is convenient; raw cotton does not need to be independently pre-treated; the auxiliary agent is added and pre-treatment and dyeing can be carried out in one bath, so that the cost is reduced; damage to the fibers is small and the hand feeling is good; the utilization rate of the dyestuff is high, less sewage is discharged, and energy saving and emission reduction are realized.

Owner:DONGHUA UNIV

Making method of high-color fastness dye-free ultrafine fiber synthetic leather base

The invention relates to a making method of a high-color fastness dye-free ultrafine fiber synthetic leather base. The making method comprises the following steps: base cloth decrement, impregnation in colored aqueous polyurethane, polyurethane solidification and post-treatment. The ultrafine fiber synthetic leather base made in the invention has the advantages of full color, high color fastness and no dyeing. The making method of the ultrafine fiber synthetic leather base has the advantages of small dye use amount in the making process, high dye utilization rate, and no use of toluene, dimethyl formamide or other organic solvents, and is environmentally friendly.

Owner:山东济清科技服务有限公司

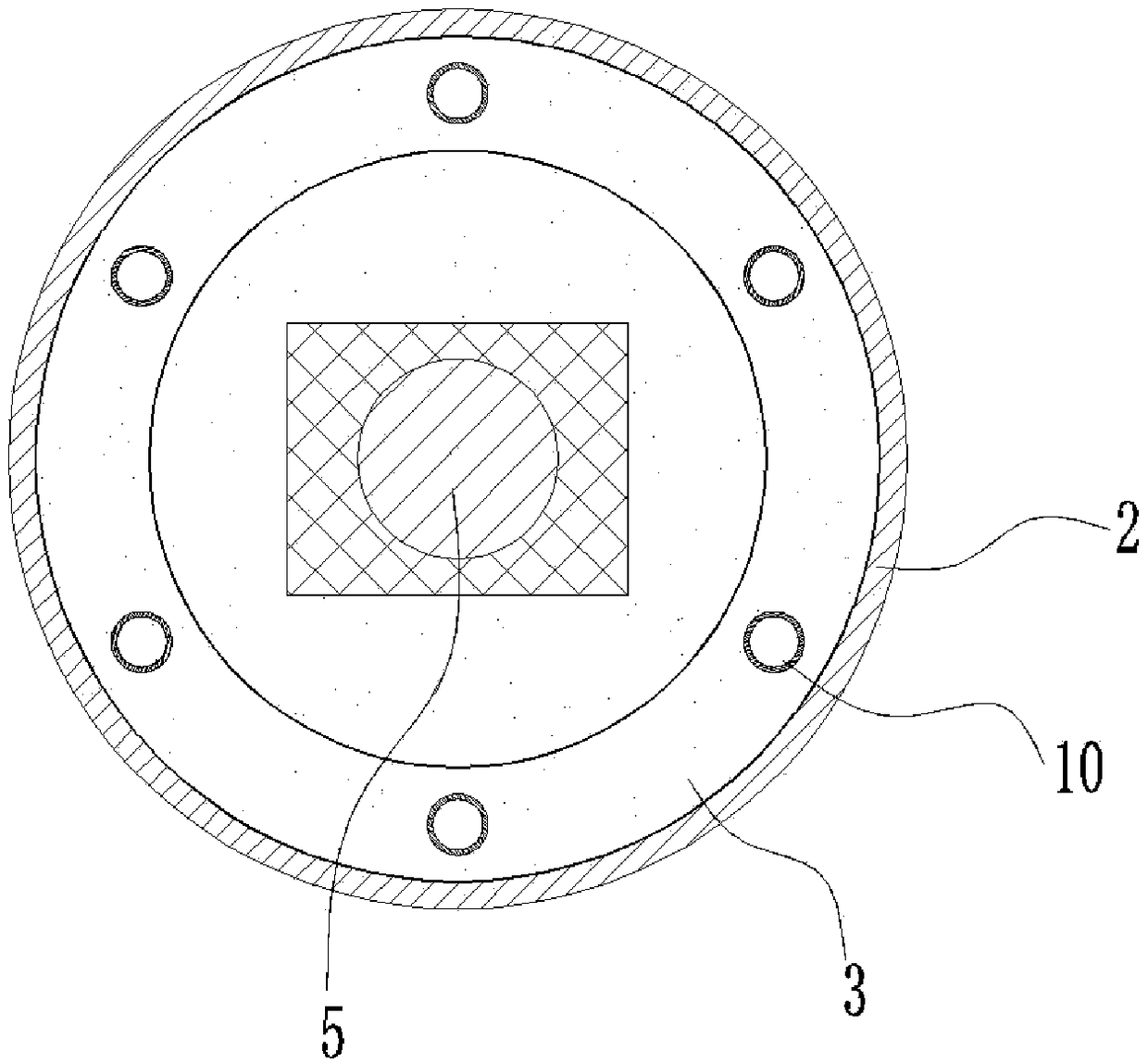

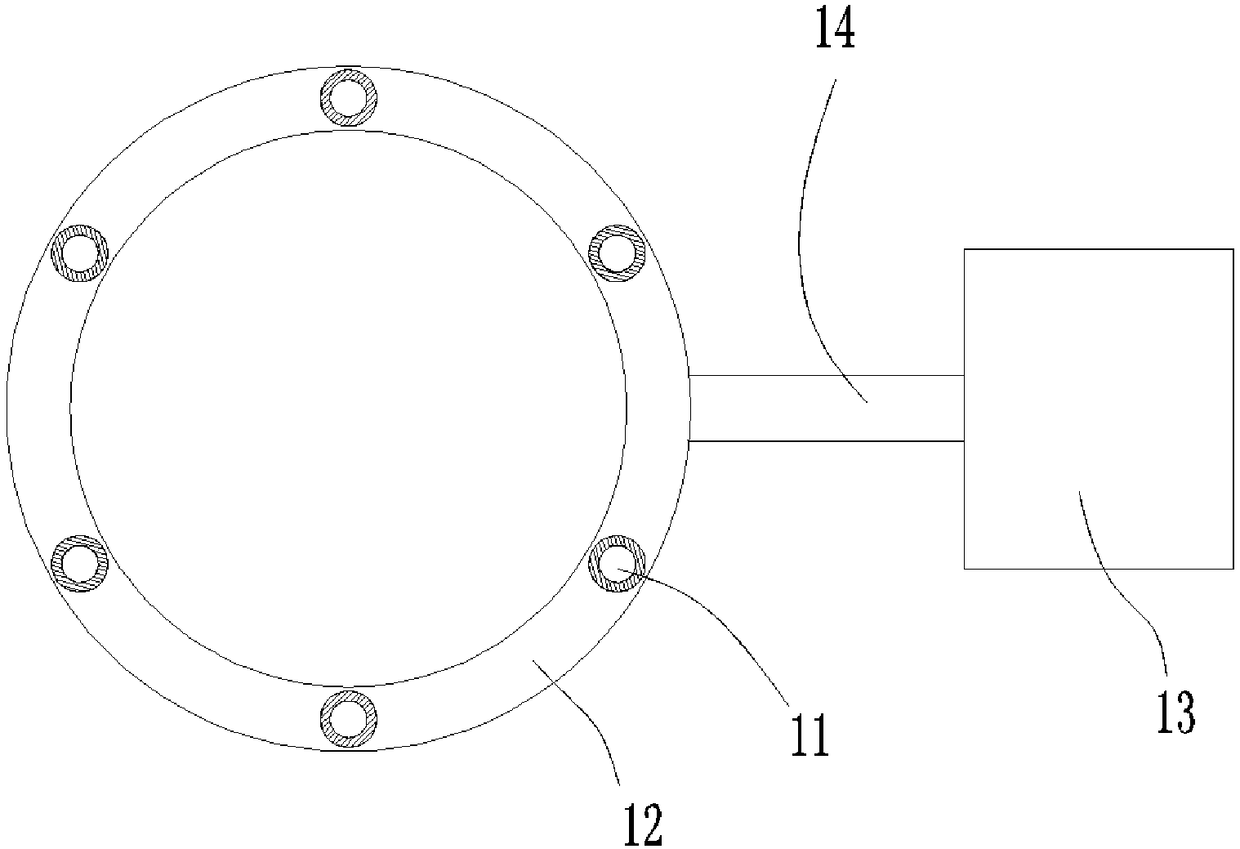

Dye stirring apparatus of fabric printing and dyeing equipment

InactiveCN108554303AReduce gas pressureIncrease air pressureTransportation and packagingMixer accessoriesEngineeringVertical cylinder

The invention discloses a dye stirring apparatus of fabric printing and dyeing equipment. The dye stirring apparatus comprises a housing, inside which a stirring chamber is arranged. A base plate is arranged on the inner wall of the bottom of the stirring chamber. A motor is arranged on the bottom of the stirring chamber. 4-6 vertical cylinders are inserted in the bottom of the stirring chamber. Apiston is arranged inside each cylinder. A spring is installed on the top of each piston. One end of each spring, far from the piston, is fixed on the inner wall of the top of the cylinder. The top of each cylinder is in threaded connection with a water outlet interface, and the bottom of the cylinder is in threaded connection with an air inlet interface. The bottom of the stirring chamber is provided with a connecting pipe. The top of the housing is equipped with a feed inlet. According to the invention, the stirring effect of dye preparation can be enhanced, and the content of dyes which are not completely stirred but deposited at the bottom during stirring can be reduced as much as possible. By the dye stirring apparatus, working efficiency is improved.

Owner:长兴瑞韬纺织科技有限公司

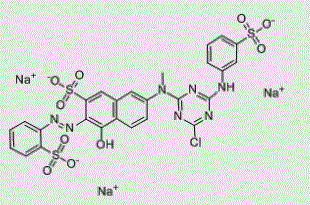

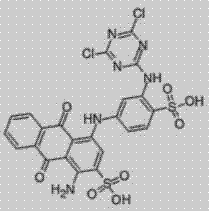

Modification method for reactive dye for leather

InactiveCN104927395AImprove stabilityImprove mechanical propertiesReactive dyesWastewaterCarboxylic acid

The invention belongs to the technical field of light industries, and particularly relates to a modification method for a reactive dye for leather. The modification method for the reactive dye for leather is characterized in that a product applied to the dyeing of leather and products thereof is obtained by reacting the reactive dye with one or more of hydroxycarboxylic acid or salts thereof, amino acid or salts thereof and oligopeptides and introducing carboxyl groups into reactive dye molecules. According to the method, the application fields of the reactive dye are extended, the performance of leather, such as dyeing fastness, washing durability and sweat resistance, can be effectively improved, the utilization rate of the dye can be increased, and the dye content of wastewater can be reduced.

Owner:QILU UNIV OF TECH

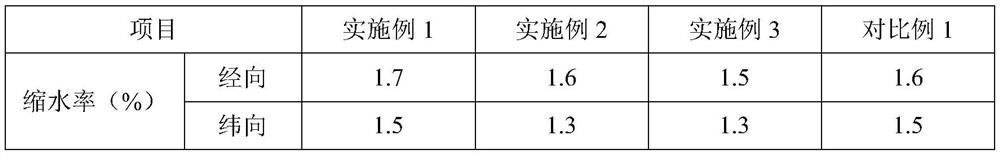

Preparation method of dancing rainbow yarn fiber Raschel blanket

ActiveCN112030341ABright colorVariety of colorsWarp knittingHeating/cooling textile fabricsPolyesterColour fastness

The invention discloses a preparation method of a dancing rainbow yarn fiber Raschel blanket. The preparation method comprises the following steps of (1) weaving: performing weaving on a high-speed warp knitting machine by adopting dancing rainbow yarn fibers as plush yarns and polyester fully-drawn yarns as bottom yarns in a full-penetration same-direction yarn laying manner to obtain a gray fabric; (2) pre-finishing: carrying out wool smoothing pre-shaping, wool reversing pre-lustring, wool smoothing high carding, and wool reversing and wool smoothing alternating lustring on the gray fabricto obtain a pre-finished gray fabric; (3) dyeing and finishing: carrying out wool reversing dyeing on the grey cloth subjected to pre-finishing, washing with water, performing softening and dehydrating to obtain dyed and finished grey fabric; and (4) after-finishing: enabling the dyed and finished gray fabric to be subjected to drying and shaping, wool smoothing and wool reversing, wool reversingfluffing, front face lustring, front face ironing and shearing, reverse face lustring, reverse face ironing and shearing and then to be tailored and sewn, and obtaining the dancing rainbow yarn fiberRaschel blanket. The dancing rainbow yarn fiber with good dyeability is adopted as the raw material, the Raschel blanket with diversified colors and high color fastness can be prepared, and the marketrequirements are fully met.

Owner:ZHEJIANG TRUELOVE GROUP

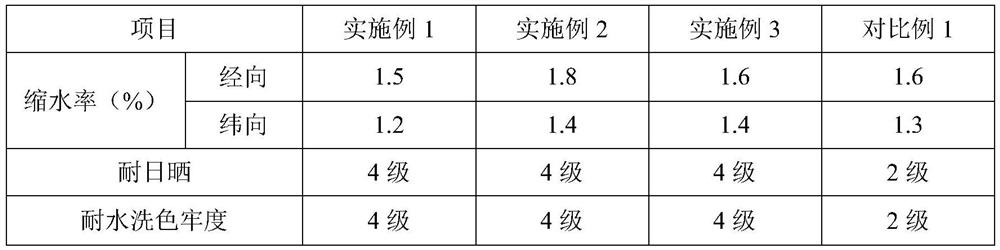

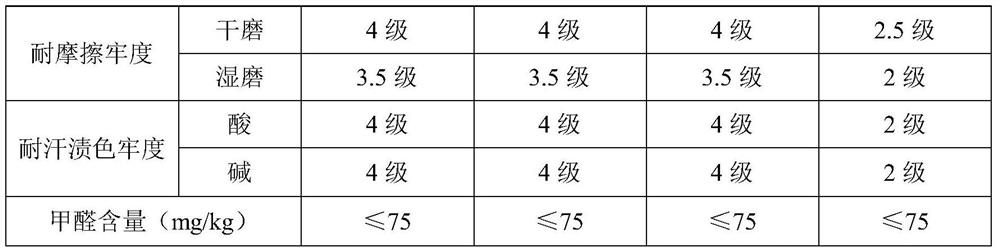

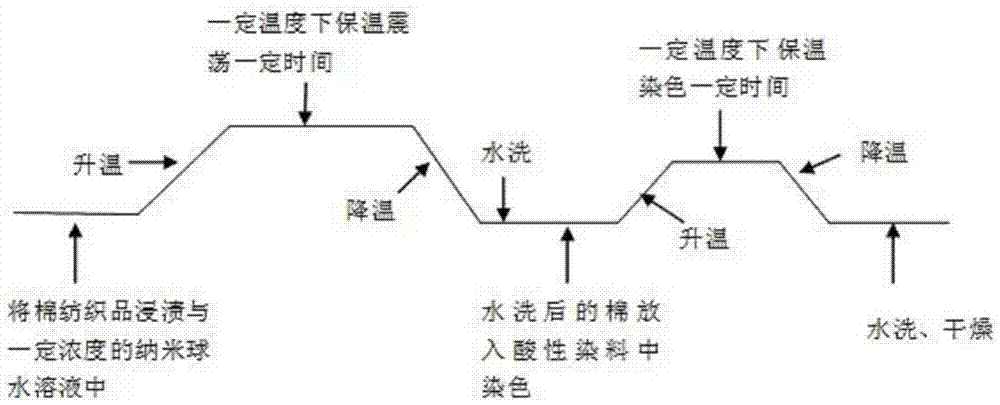

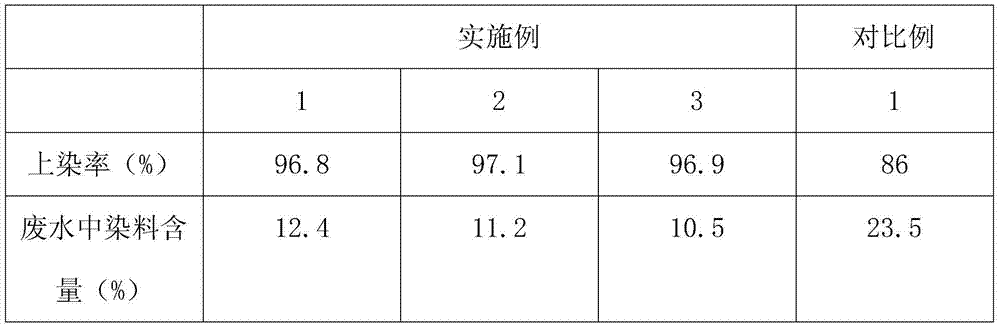

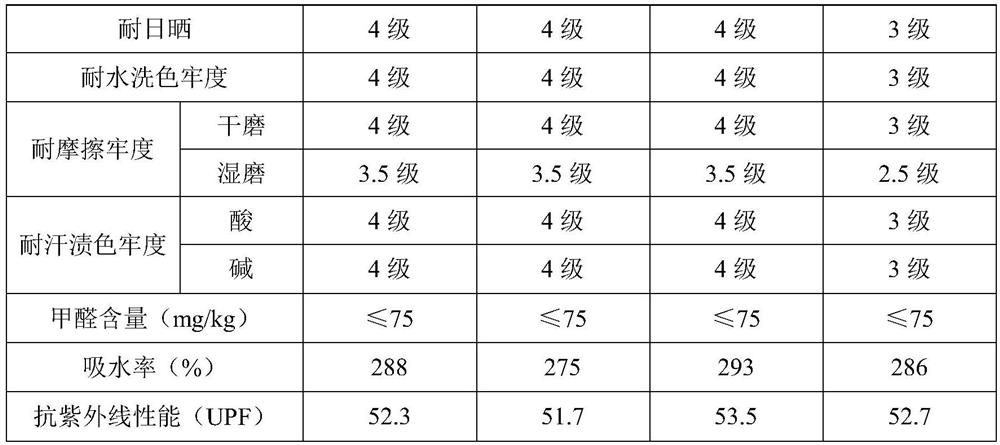

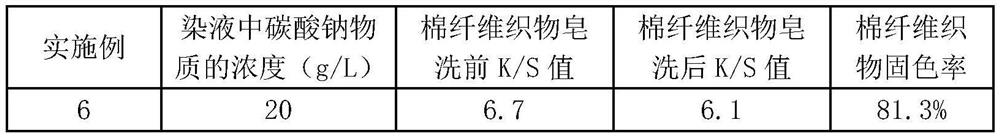

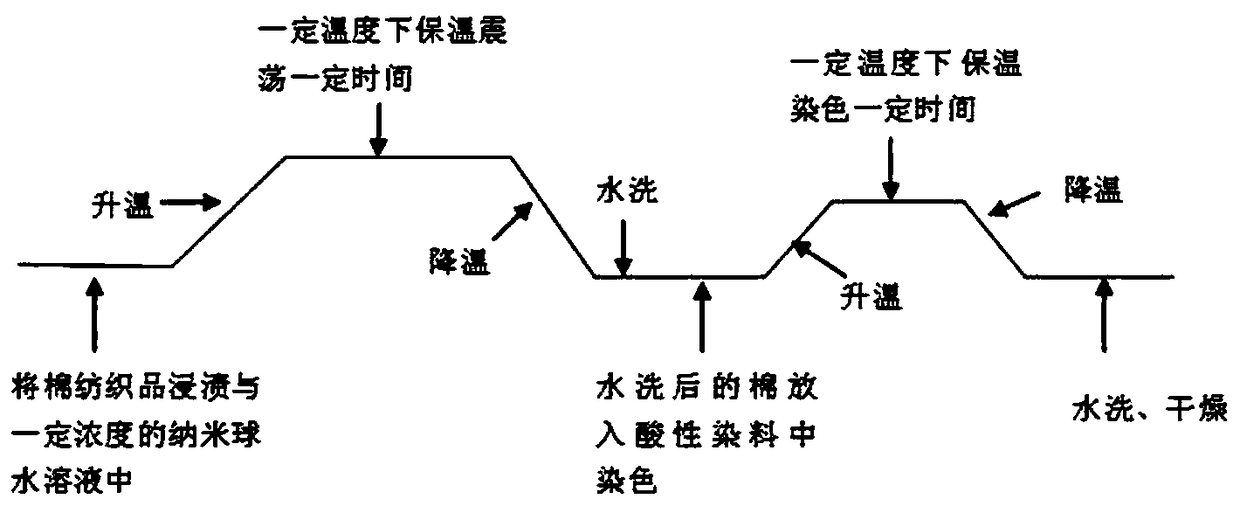

Acidic dye dyeing method of cotton textiles

The invention relates to an acidic dye dyeing method of cotton textiles. The acidic dye dyeing method comprises the following steps: treating the cotton textiles with a carboxylated carbon cationic polymer nano-ball solution; and after adding an acidic dye for dyeing, carrying out fixation treatment. A preparation method of carboxylated carbon nano-balls comprises the following steps: after mixing carbon nano-balls and an acidic solution, carrying out ultrasonic treatment; after standing and immersing, heating, condensing and reflowing; and repeatedly washing with water and separating until the pH is neutral. The carboxylated carbon cationic polymer nano-ball solution is used for modifying the acidic dye so that the cotton textiles are treated by using the cationic polymer nano-balls, and furthermore, the acidic dye dyeing is realized and the problems that the water resistance, sunlight resistance and wear resistance of the dye are poor, the content of the dye in dye wastewater is relatively high and the like are overcome.

Owner:嘉兴市金宇达染整有限公司

A kind of frost dye on grass and preparation method thereof

The invention discloses a snow top dye and a preparation method thereof. The preparation method of the snow top dye comprises the following steps: adding a dispersing agent NNO, a dispersing agent SN, a penetrating agent T and anhydrous sodium sulphate into a disperse dye in parts by weight, mixing, and dull polishing, drying and crushing the mixture to obtain the dry crushed disperse dye; and adding an acid dye, a nonionic surfactant, a fluorescent brightener, white dextrin and anhydrous sodium sulphate into the crushed disperse dye, and sufficiently mixing and stirring the ingredients at first preset time to obtain the powder snow top dye. The snow top dye prepared by using the preparation method disclosed by the invention is good in dyeing performance and environment protection performance.

Owner:BEIJING FANBO CHEM

A kind of frost dye on grass and preparation method thereof

ActiveCN104448931BImprove dye uptakeImprove dyeing effectOrganic dyesEnvironmental resistanceSulfonate

The invention provides a fur-with-frost dye and a preparation method thereof. The fur-with-frost dye is prepared from the following raw materials in parts by mass: 20-50 parts of acid dye, 10-20 parts of ammonium sulfate, 2-10 parts of fluorescent whitening agent, 2-5 parts of penetrant, 2-5 parts of sodium xylene sulfonate, 10-20 parts of white dextrin and 20-35 parts of anhydrous sodium sulfate; the preparation method of the fur-with-frost dye comprises the following steps: (A) weighing the raw materials and mixing for 1-3 hours to obtain a first powdery mixture; (B) pouring the first mixture into a pelletizer for pelleting to obtain the granular fur-with-frost dye. The dye-uptake of the prepared fur-with-frost dye is increased in the dyeing process, the content of the dye in the waste liquid is effectively reduced and the harm to the environment and the human body is reduced. The dye is prepared into the granular form, and therefore, the dust is greatly reduced and the harm to the using environment and the operating workers is reduced; the prepared fur-with-frost dye has excellent dyeing property and environmental protection performance.

Owner:BEIJING FANBO CHEM

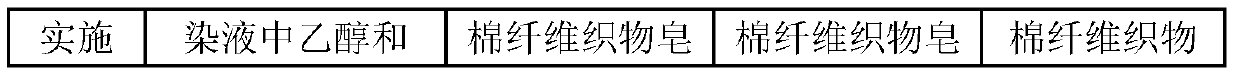

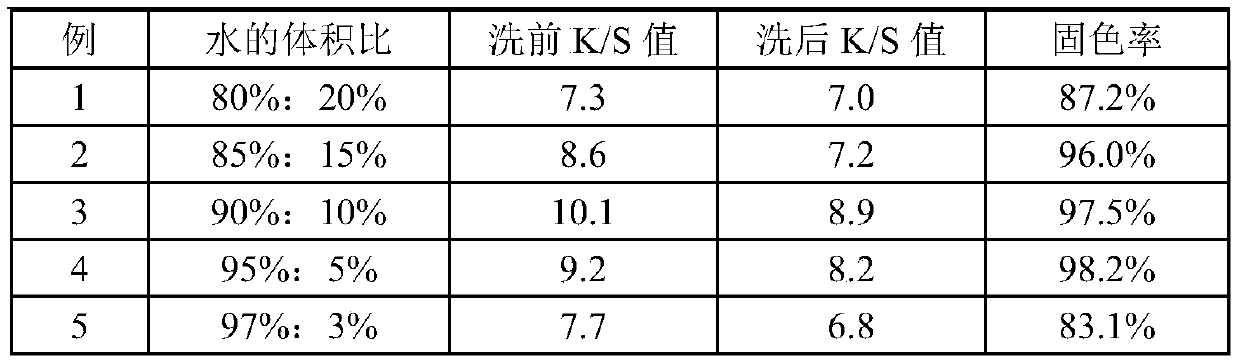

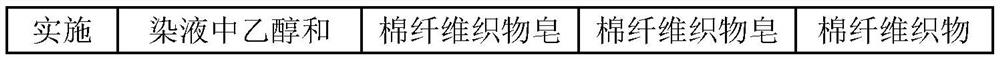

Salt-free cold pad batch dyeing method for uncooked and unbleached cotton fibers

The invention provides a salt-free cold pad batch dyeing method for uncooked and unbleached cotton fibers, and belongs to the field of cotton fiber printing and dyeing. The salt-free cold pad batch dyeing method includes putting reactive dye and alkaline substances in a mixed solution of an alcoholic organic solvent-water system to obtain dyeing liquid; putting the uncooked and unbleached cotton fibers in the prepared dyeing liquid, and performing padding by a double-dip-double-nip method; rolling the dyed uncooked and unbleached cotton fibers on a rolling machine, wrapping the rolled uncookedand unbleached cotton fibers with a plastic film, and performing rotating and stacking; after stacking, performing soaping, hot water washing, cold water washing and drying. The method has the advantages that the characteristics of high dyeing speed and high dyeing rate of the dye in an ethanol-water system are combined, the uncooked and unbleached cotton fibers can be quickly dyed by the reactive dye under the action of high permeability of ethanol according to a padding method, the dyed cotton fibers can be covalently bonded with hydroxyl groups on cellulose slowly under the condition of normal-temperature stacking to carry out dyeing, and the color fixation rate of the reactive dye in the alcoholic organic solvent-water system is increased under normal temperature conditions.

Owner:WUHAN TEXTILE UNIV

Nylon cheese and dyeing method thereof

The invention relates to the technical field of dyeing and finishing, in particular to a nylon cheese and a dyeing method thereof, the nylon cheese is dyed by a first dye, the dye utilization rate of the first dye is not less than 95%, and the leveling property is 4-5 grade. According to the scheme, when the non-aqueous medium is used for dyeing the nylon cheese, the utilization rate of the dye can be increased (up to 95% or above); the level dyeing property of dyeing is improved; no extra salt is added during dyeing, so that the alkalinity is reduced; and dyeing wastewater is reduced, so that the dyeing wastewater is simple to treat, and the recycling rate of the dyeing wastewater is increased.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

A kind of synthetic method of water-based aliphatic hyperbranched polyester polymer dye

InactiveCN105085882BGood light fastnessLightfastness does not affectOrganic dyesDyeing processPropanoic acidSynthesis methods

The invention discloses a synthesis method for waterborne aliphatic hyperbranched polyester type polymer dye and belongs to the technical field of fine chemical industry. The waterborne aliphatic hyperbranched polyester type polymer dye is obtained through the following steps: enabling 2,2-dimethylol propionic acid and a small molecule polyhydroxy compound to react under the action of a catalyst according to a certain mole ratio so as to obtain hydroxyl-terminated hyperbranched polyester; modifying hydroxyl-terminated hyperbranched polyester through acid anhydride; enabling hyperbranched polyester modified by acid anhydride to react with reactive dye so as to obtain the waterborne aliphatic hyperbranched polyester type polymer dye. By adopting the waterborne aliphatic hyperbranched polyester type polymer dye prepared through the synthesis method disclosed by the invention, the problems that dye is poor in binding fastness and residual dye in waste liquid is high in concentration in the conventional leather manufacturing and fur industry are solved, colour fasteness, washing resistance and the like of leather products are effectively improved, the utilization ratio of dye is increased and the content of dye in dyeing waste liquid is reduced.

Owner:山东巨业精细化工有限公司

A kind of preparation method of Yidalun fiber raschel blanket

ActiveCN112030342BRich patternsFeel smooth and comfortableWarp knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a preparation method of Yidalun fiber Raschel blanket. The steps are as follows: (1) Weaving: using Yidalun fiber as plush yarn, polyester full-drawn yarn as bottom yarn, and using full-wearing same-direction (2) Pre-finishing: Pre-finish the gray cloth after pre-shaping along the wool, pre-ironing against the wool, high combing along the wool, and alternating ironing against the wool to obtain the pre-finishing (3) Printing and softening: the gray cloth after pre-finishing is printed, steamed, washed and softened, and then dehydrated to obtain the printed gray cloth; (4) Finishing: the gray cloth after dyeing and finishing is dried Shaping, combing along the wool, fluffing against the wool, ironing on the front, ironing on the front, ironing on the back, ironing on the back, cutting and sewing the Yidalun fiber raschel blanket. The invention uses Yidalun fiber as a raw material to realize water-less / water-less printing and washing processes, has a high utilization rate of dyestuffs, and finally produces a raschel blanket with rich patterns and fully meets market demands.

Owner:ZHEJIANG TRUELOVE GROUP

A kind of preparation method of dyeing-free superfine fiber synthetic leather base with high color fastness

The invention relates to a making method of a high-color fastness dye-free ultrafine fiber synthetic leather base. The making method comprises the following steps: base cloth decrement, impregnation in colored aqueous polyurethane, polyurethane solidification and post-treatment. The ultrafine fiber synthetic leather base made in the invention has the advantages of full color, high color fastness and no dyeing. The making method of the ultrafine fiber synthetic leather base has the advantages of small dye use amount in the making process, high dye utilization rate, and no use of toluene, dimethyl formamide or other organic solvents, and is environmentally friendly.

Owner:山东济清科技服务有限公司

A kind of preparation method of Raschel blanket of Fidelon absorbing and discharging silk fiber

ActiveCN112030343BStrong moisture absorption and quick drying performanceComfortable to useWarp knittingHeating/cooling textile fabricsPolyesterYarn

The invention discloses a preparation method of a Raschel blanket made of fidelon suction and discharge silk fiber. Weaving with three-needle and four-needle weft-inserted yarn in the same direction to obtain the gray cloth; (2) Pre-finishing: the gray cloth is first ironed and then pre-shaped to obtain the gray cloth after the pre-finishing; (3) The printed soft : Printing, steaming, color fixing, washing, softening, and dehydration of the gray cloth after pre-finishing to obtain the printed gray cloth; Fluffing, front ironing, front ironing, back ironing, back ironing, cutting and sewing to obtain Fudalun absorbent silk fiber raschel blanket. The invention adopts Fidelon absorbing and discharging filament fiber as raw material, and the prepared raschel blanket has good hygroscopicity, perspiration and remarkable anti-ultraviolet performance, good use comfort and rich patterns.

Owner:ZHEJIANG TRUELOVE GROUP

Printing and dyeing sewage filter material containing mesoporous material and preparation method of printing and dyeing sewage filter material

InactiveCN108609685ASimple processLow cost of preparationWater/sewage treatment by irradiationWater contaminantsIonMolecular sieve

The invention discloses a printing and dyeing sewage filter material containing a mesoporous material and a preparation method of the printing and dyeing sewage filter material. The filter material ischaracterized by comprising binchotan fibers, bamboo carbon fibers and a basalt base material part, and through loading the three filter components with a mesoporous molecular sieve, the specific surface area of a filter tip and a micro pore channel are increased. The filter material prepared by the preparation method disclosed by the invention is used for wastewater treatment of a textile printing and dyeing enterprise and has the advantages of being high in decolorizing rate, high in dye and metal ion adsorbability, free from environmental secondary pollution, green, environmentally-friendly and the like; and the preparation method is simple in process and has a good application prospect.

Owner:IANGSU COLLEGE OF ENG & TECH

A kind of salt-free cold pad-batch dyeing method of unboiled bleached cotton fiber

ActiveCN110219184BAchieving salt-free dyeingSolve the problem of unsatisfactory color fixing rateDyeing processCelluloseOrganosolv

The invention provides a salt-free cold pad-batch dyeing method of unboiled and bleached cotton fibers, which belongs to the field of cotton fiber printing and dyeing. The method is prepared by placing reactive dyes and alkaline substances in a mixed solution of an alcohol organic solvent-water system Dye liquor; put the unboiled and bleached cotton fiber in the prepared dye liquor, and pad the dye liquor by two dipping and two padding methods; roll the dyed unboiled and bleached cotton fiber on a coiling machine, and the coiled cotton fiber Unboiled bleached cotton fibers are wrapped in plastic film and then stacked; after stacking, they are soaped, washed with hot water, washed with cold water and dried; this method combines the characteristics of fast dyeing rate and high dyeing rate in the ethanol-water system Under the high permeability of ethanol, reactive dyes can be used to quickly dye uncooked bleached cotton fibers by padding, and at the same time, under the condition of stacking at room temperature, the dyed cotton fibers can slowly co-exist with hydroxyl groups on cellulose. The valence bond is combined for dyeing, and the color fixation rate of the reactive dye in the alcohol organic solvent-water system is improved under normal temperature conditions.

Owner:WUHAN TEXTILE UNIV

Regenerated cellulose fiber cheese and reactive dye dyeing method thereof

The invention relates to the technical field of dyeing and finishing, in particular to regenerated cellulose fiber cheese and a reactive dye dyeing method thereof. The regenerated cellulose fiber cheese is dyed by reactive dye, the soaping fastness of dyeing of the regenerated cellulose fiber cheese under the national standard GB / T 3921-2008 is grade 4-5, the dry rubbing fastness under the national standard GB / T 3920-2008 is grade 4-5, the wet rubbing fastness is grade 3-4, and the color depth under the national standard GB / T 4841.7-2006 can reach 2 / 1 standard depth.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

A kind of acid dye dyeing method of cotton textile

The invention relates to an acid dye dyeing method for cotton textiles. Cotton textiles are first treated with an acidified carbocation polymer nanosphere solution, and then dyed with an acid dye for color fixation. The preparation method of the acidified carbon nanospheres is as follows: the carbon nanospheres are mixed with an acidic solution, and then subjected to ultrasonic treatment, then standing and soaking, then heating, condensing and refluxing, and repeated washing and separation until the pH is neutral. Acidic dyes are modified with an acidified carbocationic polymer nanosphere solution, so that the cationic polymer nanospheres are used to treat cotton textiles to achieve dyeing with acid dyes, and overcome the poor water resistance, light fastness and abrasion resistance of dyes and dye wastewater Problems such as high dye content in the medium.

Owner:嘉兴市金宇达染整有限公司

Hemp cheese and reactive dye dyeing method thereof

The invention relates to the technical field of dyeing and finishing, in particular to linen cheese and a reactive dye dyeing method thereof. The linen cheese is dyed by reactive dye, the soaping fastness of dyeing of the linen cheese under the national standard GB / T 3921-2008 is grade 4-5, the dry rubbing fastness of dyeing of the linen cheese under the national standard GB / T 3920-2008 is grade 4-5, the wet rubbing fastness of dyeing of the linen cheese under the national standard GB / T 4841.7-2006 is grade 3-4, and the color depth of dyeing of the linen cheese under the national standard GB / T 4841.7-2006 can reach 2 / 1 standard depth.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Silk fiber cheese and dyeing method thereof

The invention relates to the technical field of dyeing and finishing, in particular to a silk fiber cheese and a dyeing method thereof. The silk fiber cheese is dyed by a first dye, the soaping fastness of the dyeing of the silk fiber cheese under the national standard GB / T 3921-2008 is grade 4-5, the dry rubbing fastness under the national standard GB / T 3920-2008 is grade 4-5, the wet rubbing fastness is grade 3-4, and the color depth under the national standard GB / T 4841.7-2006 can reach 2 / 1 standard depth.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

A kind of reactive dye and preparation method thereof

ActiveCN104448930BIncrease profitHigh color fastnessOrganic dyesDyeing processCarboxylic saltDicarboxylic acid

The invention discloses a reactive dye and a preparation method thereof. In order to achieve the above purpose, the reactive dye is prepared from a reactive dye and hydroxy amide carboxylate in a molar ratio N of 0.1: 1 to 2: 1, wherein the hydroxy amide carboxylate is prepared by neutralizing the pH value of a reaction product of hydramine and dicarboxylic anhydride in an equal molar ratio in a solvent to 8-10 by an alkaline solution. The method for preparing the reactive dye comprises the following steps: (1) taking the hydramine and the dicarboxylic anhydride in equal molar ratio to carry out amidation, neutralizing by using the alkaline solution until pH value is 8-10, and removing the solvent to obtain the hydroxy amide carboxylate; (2) reacting the hydroxy amide carboxylate with the reactive dye, and drying and grinding the product to obtain the reactive dye. The reactive dye and the preparation method of the reactive dye can be used for solving the problem that the existing reactive dye is hard to be applied in the leather dye; meanwhile, the color fastness of the leather is improved; the concentration of the residual dye of the dye waste solution is improved.

Owner:广州狮岭皮革皮具产业研究中心有限公司

A kind of preparation method of polymer dye based on hyperbranched polyamine-ester

The invention relates to the technical field of special polymeric dyes for leather, fur and leather and fur products, in particular to a preparation method for a polymeric dye based on hyperbranched polyamine-ester. The preparation method comprises the following steps: by taking alcohol amine and acrylate as raw materials, reacting the alcohol amine and the acrylate, and removing a solvent after the reaction is ended to obtain an AB2 type monomer; reacting the AB2 type monomer, a catalyst and a micromolecular polyhydroxy compound to obtain hydroxyl-terminated hyperbranched polyamine-ester, and performing modification by using acid anhydride; reacting acid anhydride modified hyperbranched polyamine-ester with an active dye to obtain the polymeric dye. Compared with the prior art, the obtained polymeric dye can effectively improve the dyeing fastness, washing resistance, sweat resistance and other performance of the leather, the fur and the leather and fur products, the dye utilization rate is increased, and the content of dyes in waste liquor is reduced.

Owner:QILU UNIV OF TECH

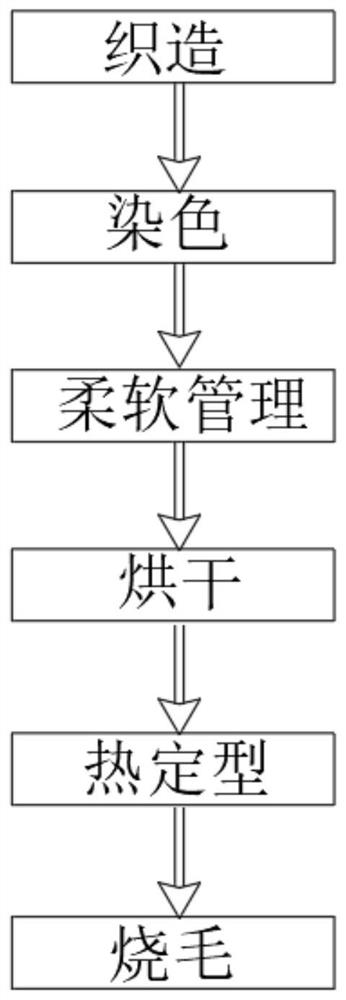

Rib heating fiber fabric

PendingCN112899852AGood heat retentionGood hygroscopicityHeating/cooling textile fabricsDyeing processYarnPolymer science

The invention relates to the technical field of rib fabrics, and discloses a rib heating fiber fabric. A preparation method of the rib heating fiber fabric comprises the following steps of S1, performing weaving: selecting proper yarns to weave a fabric; S2, performing dyeing: putting the woven fabric into a dyehouse for dyeing; S3, performing softening finishing: softening the fabric by adopting a one-dipping and one-rolling process; S4, performing drying: firstly primarily wringing out moisture in the fabric, and then putting the fabric into a drying cylinder for drying; S5, performing heat setting: after the fabric is subjected to heat treatment for a period of time, rapidly cooling the fabric to enable the fabric to be formed; and S6, performing singeing. According to the invention, kapok fibers and soft silk protein fibers are used in cooperation, so that the fabric has good heating and heat retention properties and comfort; meanwhile, through a low-temperature dyeing accelerant, the dye-uptake rate of dye to the fibers is improved and the dyeing preparation time of the fabric is shortened; and the fabric can be smoother and brighter through the softening treatment step.

Owner:无锡兴之盛针织有限公司

Cotton cheese and reactive dye dyeing method thereof

The invention relates to the technical field of dyeing and finishing, in particular to a cotton cheese and a reactive dye dyeing method thereof. The cotton cheese is dyed by a reactive dye, the soaping fastness of the dyeing of the cotton cheese under the national standard GB / T 3921-2008 is grade 4-5, the dry rubbing fastness under the national standard GB / T 3920-2008 is grade 4-5, the wet rubbing fastness is grade 3-4, and the color depth under the national standard GB / T 4841.7-2006 can reach 2 / 1 standard depth.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD +1

A kind of preparation method of Wuhong yarn fiber Raschel blanket

ActiveCN112030341BBright colorVariety of colorsWarp knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a preparation method of a Raschel blanket made of Wuhong yarn fiber. The steps are as follows: (1) Weaving: using Wuhong yarn fiber as plush yarn, polyester full-drawn yarn as bottom yarn, and using full-wearing same-direction (2) Pre-finishing: Pre-finish the gray cloth after pre-shaping along the wool, pre-ironing against the wool, high combing along the wool, and alternating ironing against the wool to obtain the pre-finishing (3) Dyeing and finishing: the gray cloth after pre-finishing is dyed in reverse wool, washed and softened, and then dehydrated to obtain the dyed and finished gray cloth; (4) Finishing: The gray cloth after dyeing and finishing is dried and shaped, smoothed Wool combing, reverse wool fluffing, front ironing, front ironing, back ironing, back ironing, cutting and sewing to obtain the Wuhong yarn fiber raschel blanket. The invention adopts the rainbow yarn fiber with good dyeability as a raw material, and can prepare a raschel blanket with various colors and high color fastness, which fully meets the market demand.

Owner:ZHEJIANG TRUELOVE GROUP

A kind of textile dye and its preparation method and water-free dyeing method

Owner:KUNSHAN KAIZHOU ENVIRONMENTAL PROTECTION MACHINERY CO LTD

A kind of leather retanning and dyeing process

ActiveCN103603216BReduce usageReduce color registration processDyeing processDyeing wastewaterEnergy consumption

The invention relates to the field of leather processing and provides a leather retanning and dyeing process through which the dyeing accuracy and color fullness can be obviously improved, the manual labor is effectively saved, the energy consumption and material cost are reduced, the environmental pollution is reduced and the dyeing wastewater treatment difficulty is reduced. The leather retanning and dyeing process sequentially comprises the process steps: bleaching, retanning, neutralizing, filling, stuffing and dyeing, wherein the pH in the dyeing process is controlled to be 3.5-4.5, and the dye amount is 1.5-2.5 percent.

Owner:XINGYE LEATHER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com