Dopamine-assisted dyeing high performance fiber, yarn or fabric and preparation method thereof

A high-performance fiber and auxiliary dyeing technology, applied in the field of textile fiber dyeing, can solve the problems of difficulty in dyeing and single color of high-performance fibers, and achieve the effect of strong universality, high color fastness and improved dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

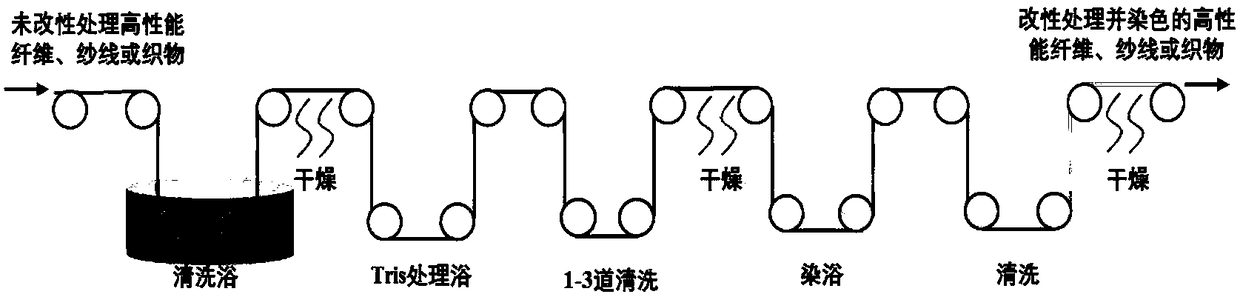

Method used

Image

Examples

Embodiment 1

[0028] A dopamine-assisted dyed glass fiber yarn is obtained by dyeing the glass fiber yarn through a dopamine Tris solution treatment bath for modification.

[0029] The preparation method of described glass fiber yarn, concrete steps are as follows:

[0030] The glass fiber yarn was washed three times through an acetone pretreatment bath to remove surface impurities, and then dried at room temperature (25°C) for 1 h; a Tris-HCl (Tris-HCl) buffer solution with a concentration of 10 mM was prepared, Adjust the pH value to 8.5, add dopamine hydrochloride, stir to dissolve, and prepare a Tris solution treatment bath of 1.2g / L dopamine; treat the glass fiber yarn with a solid-to-liquid ratio of 1:2 and place it in a Tris solution of dopamine at 30°C bath, treated for 30 minutes, washed in 3 water baths, and dried at 60°C for 20 minutes; prepared a rhodamine B fluorescent dye dyeing bath with a concentration of 1% (owf), and a color-fixing agent Na 2 CO 3 The total dosage is 15g...

Embodiment 2

[0033] A dopamine-aided para-aramid fiber fabric is obtained by dyeing the para-aramid fiber fabric through a dopamine Tris solution treatment bath for modification.

[0034] The preparation method of the para-aramid fiber fabric assisted by dopamine dyeing, the specific steps are as follows:

[0035] The para-aramid fiber fabric was pre-cleaned with an acetone bath, washed twice to remove surface impurities, and then dried at room temperature (25°C) for 30 minutes; the concentration was prepared as 7mM Tris-HCl buffer solution, adjust the pH value to 10, add dopamine hydrochloride, stir and dissolve, and prepare a Tris solution treatment bath of 0.8g / L dopamine; In the Tris solution treatment bath, it was treated for 8 minutes, washed with water three times, and dried at 70°C for 15 minutes; the reactive brilliant red X-3B reactive dye dyeing bath with a concentration of 1% (owf) was prepared, and the one-bath two-step method was used for dipping. Para-aramid fiber fabric, t...

Embodiment 3

[0038] The invention relates to an ultra-high molecular weight polyethylene (UHMWPE) multifilament assisted by dopamine dyeing, which is obtained by modifying the surface of the UHMWPE multifilament with polydopamine and then dyeing it.

[0039] The preparation method of the UHMWPE multifilament assisted dyeing of dopamine is characterized in that, comprises the following steps:

[0040] The UHMWPE multifilament was pre-cleaned in an acetone bath, washed twice, and dried at 50°C for 10 minutes; a buffer solution with a concentration of 15mM Tris-HCl was prepared, the pH value was adjusted to 9, and dopamine hydrochloride was added , stir and dissolve, and prepare a Tris solution treatment bath of 1.8g / L dopamine; put the UHMWPE multifilament in the Tris solution treatment bath of dopamine at 40°C with a solid-to-liquid ratio of 1:5, treat for 60min, wash with water three times, and Dry at 60°C for 15 minutes; prepare a reactive dyeing bath of reactive brilliant red X-3B reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com